Compression Technology for plastic closures - Sacmi

Compression Technology for plastic closures - Sacmi

Compression Technology for plastic closures - Sacmi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

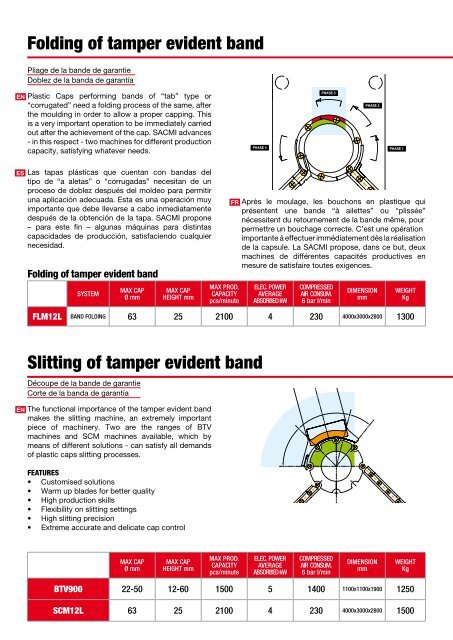

Folding of tamper evident band<br />

Pliage de la bande de garantie<br />

Doblez de la banda de garantía<br />

EN Plastic Caps per<strong>for</strong>ming bands of “tab” type or<br />

“corrugated” need a folding process of the same, after<br />

the moulding in order to allow a proper capping. This<br />

is a very important operation to be immediately carried<br />

out after the achievement of the cap. SACMI advances<br />

- in this respect - two machines <strong>for</strong> different production<br />

capacity, satisfying whatever needs.<br />

PHASE 4<br />

PHASE 3<br />

PHASE 2<br />

PHASE 1<br />

ES Las tapas plásticas que cuentan con bandas del<br />

tipo de “a aletas” o “corrugadas” necesitan de un<br />

proceso de doblez después del moldeo para permitir<br />

una aplicación adecuada. Esta es una operación muy<br />

importante que debe llevarse a cabo inmediatamente<br />

después de la obtención de la tapa. SACMI propone<br />

– para este fin – algunas máquinas para distintas<br />

capacidades de producción, satisfaciendo cualquier<br />

necesidad.<br />

Folding of tamper evident band<br />

SYSTEM<br />

MAX CAP<br />

Ø mm<br />

MAX CAP<br />

HEIGHT mm<br />

MAX PROD.<br />

CAPACITY<br />

pcs/minute<br />

FR Après le moulage, les bouchons en plastique qui<br />

présentent une bande “à ailettes” ou “plissée”<br />

nécessitent du retournement de la bande même, pour<br />

permettre un bouchage correcte. C’est une opération<br />

importante à effectuer immédiatement dès la réalisation<br />

de la capsule. La SACMI propose, dans ce but, deux<br />

machines de différentes capacités productives en<br />

mesure de satisfaire toutes exigences.<br />

ELEC. POWER<br />

AVERAGE<br />

ABSORBED kW<br />

COMPRESSED<br />

AIR CONSUM.<br />

6 bar l/min<br />

DIMENSION<br />

mm<br />

WEIGHT<br />

Kg<br />

FLM12L<br />

BAND FOLDING<br />

63<br />

25<br />

2100<br />

4<br />

230<br />

4000x3000x2800<br />

1300<br />

EN<br />

Slitting of tamper evident band<br />

Découpe de la bande de garantie<br />

Corte de la banda de garantía<br />

The functional importance of the tamper evident band<br />

makes the slitting machine, an extremely important<br />

piece of machinery. Two are the ranges of BTV<br />

machines and SCM machines available, which by<br />

means of different solutions - can satisfy all demands<br />

of <strong>plastic</strong> caps slitting processes.<br />

FEATURES<br />

• Customised solutions<br />

• Warm up blades <strong>for</strong> better quality<br />

• High production skills<br />

• Flexibility on slitting settings<br />

• High slitting precision<br />

• Extreme accurate and delicate cap control<br />

MAX CAP<br />

Ø mm<br />

MAX CAP<br />

HEIGHT mm<br />

MAX PROD.<br />

CAPACITY<br />

pcs/minute<br />

ELEC. POWER<br />

AVERAGE<br />

ABSORBED kW<br />

COMPRESSED<br />

AIR CONSUM.<br />

6 bar l/min<br />

DIMENSION<br />

mm<br />

WEIGHT<br />

Kg<br />

BTV900<br />

22-50<br />

12-60<br />

1500<br />

5<br />

1400<br />

1100x1100x1900<br />

1250<br />

SCM12L<br />

63<br />

25<br />

2100<br />

4<br />

230<br />

4000x3000x2800<br />

1500