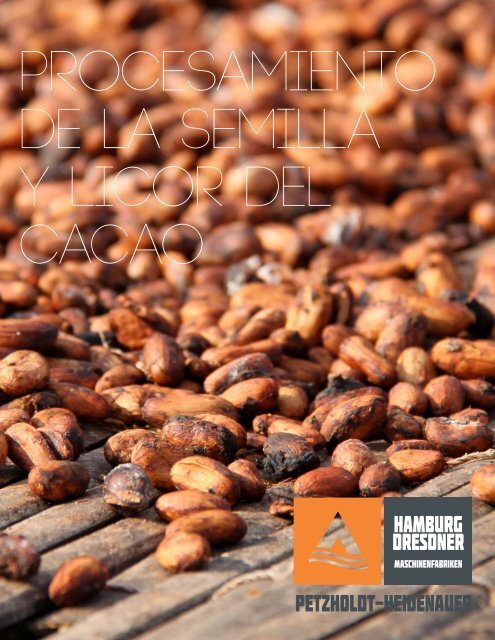

proc cacao.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

COCOA PROCESSING<br />

H-D-M.COM<br />

CONTINUOUS<br />

ROASTING<br />

PLANT<br />

HKR<br />

150/1<br />

CONTINUOUS WORKING SHAFT ROASTER FOR<br />

ROASTING OF COCOA BEANS, NIBS OR SIMILAR<br />

GOODS WITH CAPACITIES UP TO 1600 KG/H

H-D-M.COM<br />

CONTINUOUS ROASTING PLANT<br />

HKR 150/1<br />

Application<br />

For continuous roasting or kiln-drying of cocoa<br />

beans, nuts and similar goods as well as pretreated<br />

and untreated nibs.<br />

Construction Features<br />

• Roasting shaft consisting of 3 roasting zones<br />

• Roasting zones with heat-insulating body made<br />

of stainless steel<br />

• Roasting in circulating air stream generated<br />

by axial fans and heated in steam-heated heat<br />

exchangers<br />

1 Product Feeding<br />

2 Roasting Air Exhaust<br />

3 Rubble Discharge<br />

4 Dust Discharge<br />

5 Discharge Screw<br />

6 Product Discharge<br />

7 Fresh Air<br />

8 Air-Return System<br />

9 Filter<br />

10 Heat Exchanger<br />

11 Axial Fsn<br />

12 Roasting Shaft<br />

13 Dust Extractor<br />

• Cleaning of circulating air over filters respectively<br />

cyclone<br />

• Differential pressure survey to keep the fixed<br />

cleaning intervals<br />

Technological Scheme HKR 150/1<br />

• Bean inlet with automatic level control for the<br />

roasting shaft<br />

• Rubble discharge over cyclone and separate in<br />

each roasting zone<br />

• Throughput pre-adjustable<br />

• Automatic control of the roasting temperature<br />

ensures a constant roasting or kiln-drying<br />

quality<br />

5955<br />

4280<br />

6020<br />

4915<br />

• Security flap for fast product discharge in emergency<br />

cases<br />

1570<br />

690<br />

1120<br />

900<br />

725<br />

• Operation platform for easy maintenance and<br />

cleaning of the HKR 150/1<br />

6500<br />

External Dimensions HKR 150/1<br />

5200<br />

• Electrical control cabinet with touch panel and<br />

CPU Siemens step 7 for displaying of all <strong>proc</strong>ess<br />

values and managing of <strong>proc</strong>ess data<br />

• Grecon fire extinguisher with spark indicator for<br />

each roasting zone separate<br />

• CE conformance (meets EU machinery guideline),<br />

if required UL or CSA guide lines possible)<br />

Technical Data<br />

Capacity in kg/h<br />

for bean roasting<br />

for nib roasting<br />

Connected load in kW<br />

up to 1600<br />

up to 1000<br />

22 kW<br />

Steam consumption in kg/h at 12 bar approx. 300<br />

Weight in kg<br />

net<br />

gross<br />

approx. 7500<br />

approx. 8200<br />

Subject to technical alternations!<br />

Petzholdt-Heidenauer Maschinen- und Anlagenbau International GmbH<br />

Niedersedlitzer Straße 41 | 01239 Dresden | DE<br />

+49 351 2861-200 +49 351 2861-282<br />

info petzholdt-heidenauer.de | www.h-d-m.com

COCOA PROCESSING<br />

H-D-M.COM<br />

DIFFEREN-<br />

TIAL<br />

MILL<br />

310H<br />

CONTINUOUS WORKING MILL FOR GRINDING OF ROASTED<br />

BROKEN COCOA NIBS, PREGROUND COCOA MASS, SESAME<br />

AND NUTS WITH CAPACITIES UP TO 1500 KG/H

H-D-M.COM<br />

DIFFERENTIAL MILL<br />

310H<br />

Application<br />

For grinding of roasted broken cocoa nibs, preground<br />

cocoa mass, sesame seed, roasted hazel<br />

nuts, peanuts and cashew nuts.<br />

~250<br />

Construction Features<br />

• Low thermal load and high throughput by<br />

grinding between two carborundum disks which<br />

rotate with different speed in the same direction<br />

• Accurate hydraulic grinding pressure adjustment<br />

of the friction disks with pressure indication<br />

1925<br />

2400<br />

• Grinding pressure of the friction disks remains<br />

stable during the whole pre-grinding <strong>proc</strong>ess<br />

and guarantees a constant grinding quality<br />

• Protection of the adjusted contact pressure<br />

against unauthorised changing<br />

• Quick automatic opening of the friction gap<br />

during malfunctioning and at the end of the<br />

grinding <strong>proc</strong>ess in order to prevent dry running<br />

590<br />

1250<br />

1800<br />

External Dimentsions of Differential Mill 310H<br />

720<br />

1075<br />

• Programmable Logic Controller ensures a high<br />

degree of automation, operation reliability and<br />

customizability<br />

• Automatic machine operation with registration<br />

and evaluation of operating states and failures<br />

• Easy change of the friction disks with mounting<br />

device<br />

• Dresser for the friction disks can be delivered<br />

additionally<br />

• Can be combined with Beater Mill SMM and<br />

Spindle Mill HKM<br />

Technical Data<br />

Capacity in kg/h<br />

depending on the technological constitution<br />

of the grinding material and the requested<br />

degree of fineness<br />

Cooling water consumption in m³/h<br />

(at + 15 ºC inlet temperature)<br />

up to 1500<br />

approx. 0.8<br />

Connected load in kW 59<br />

Weight net in kg<br />

machine<br />

control cabinet<br />

approx. 1600<br />

approx. 245<br />

External dimensions (length x width x height)<br />

Machine<br />

Control cabinet<br />

1800 x 1075 x 2515<br />

800 x 1500 x 1800<br />

Required freight space in mm 1900 x 2700<br />

Subject to technical alternations!<br />

Cross section of Differential Mill 310H<br />

Petzholdt-Heidenauer Maschinen- und Anlagenbau International GmbH<br />

Niedersedlitzer Straße 41 | 01239 Dresden | DE<br />

+49 351 2861-200 +49 351 2861-282<br />

info petzholdt-heidenauer.de | www.h-d-m.com

CHOCOLATE MAKING<br />

H-D-M.COM<br />

CONTINUOUS<br />

KNEADING<br />

PLANT<br />

HKK<br />

200<br />

CONTINUOUS KNEADING PLANT FOR INTEGRATION<br />

WITHIN AUTOMATIC PRODUCTION LINES USING<br />

PRE-REFINER TECHNOLOGY

H-D-M.COM<br />

CONTINUOUS KNEADING<br />

PLANT HK 200<br />

Application<br />

For continuous prodution of refineable milk, dark, filling or<br />

coating masses with up to 5 solid and 5 liquid components<br />

and an intensive mixing effect. Preferable used in automatic<br />

<strong>proc</strong>essing lines based on pre-refining technology.<br />

Construction Features<br />

• The plant works computeraided and thus offers such<br />

advantages as video-controlled operation, recipe storing,<br />

recording of the consumption and fully automatic mode of<br />

operation<br />

• Double walled kneading pot with special kneader and<br />

discharge device<br />

• 1 weighing tank each for liquid and solid ingredient<br />

• Up to 5 dosing devices for solid ingredients with coarse<br />

and fine stream dosing and level switch to control the<br />

relevant transport devices<br />

• Up to 5 dosing devices for liquid ingredients with coarse<br />

and fine stream dosing<br />

• Control system for the pressureless temperature equalisation<br />

of kneading pot<br />

Technical Data<br />

Capacity using refined sugar crystals<br />

Connected load<br />

depends on the configuration of the plant<br />

standard configuration<br />

Compressed air<br />

max. 2,000 kg/h<br />

15 kW<br />

at least 6 bar<br />

Weight (without control box)<br />

net<br />

gross<br />

approx. 2.4 t<br />

approx. 3.5 t<br />

Required freight space approx. 17 m²<br />

Subject to technical alternations!<br />

1 Kneader | 2 dosing apparatus, solid ingredients<br />

3 dosing apparatus, liquid ingredients | 4 solid ingredient<br />

5 liquid ingredient | 6 refinable chocolate mass<br />

7 temperature equalising medium<br />

Petzholdt-Heidenauer Maschinen- und Anlagenbau International GmbH<br />

Niedersedlitzer Straße 41 | 01239 Dresden | DE<br />

+49 351 2861-200 +49 351 2861-282<br />

info petzholdt-heidenauer.de | www.h-d-m.com

CHOCOLATE MAKING<br />

H-D-M.COM<br />

PRE-REFINER<br />

HVS<br />

100<br />

100E<br />

140<br />

140E<br />

SEMI- AND FULL AUTOMATED PRE-REFINERS WITH 100<br />

AND 140 CM WORKING WIDTH AND CAPACITIES<br />

UP TO 6000 KG/H

H-D-M.COM<br />

PRE-REFINERS<br />

HVS 100 | HVS 100E | HVS 140 | HVS 140E<br />

Application<br />

For pre-grinding of high capacities of milk or dark chocolates,<br />

crumb, filling and coating paste in automatic <strong>proc</strong>essing lines<br />

based on pre-refining technology.<br />

A<br />

Construction Features<br />

• 2 special ground rollers made of centrifugal casting provides<br />

optimal surface properties and high roller lifetimes<br />

• Hydraulic contact pressure system to guarantee a constant<br />

working pressure<br />

1000 (1400)<br />

1060 (1260) 1120 (1320)<br />

1510 (1710) 1760 (1960)<br />

3450 (3850)<br />

• Fixed gap device for constant and accurate pre-grinding independent<br />

of mass consistence or recipe<br />

• Integrated roller cooling system to guarantee defined roller<br />

temperatures and a constant heat distribution<br />

• Extendable storage tank with automatic dosing flap and level<br />

control ensures a constant feeding of the rollers adapted to the<br />

mass consistence and filling level of the grinding gap<br />

A<br />

650<br />

• Customizable solutions for discharging and conveying of the<br />

pre-grinded chocolate paste<br />

• Programmable Logic Controller<br />

• Automatic operation of the machine with logging and evaluation<br />

of operating states and failures<br />

• On-site terminal for interactive operation at the machine<br />

• Stable machine frame made of solid cast iron<br />

• Safety devices to prevent machine overload<br />

• CE-conformance (according EU machinery guideline)<br />

2465 (2775)<br />

Technical Data<br />

550<br />

185<br />

750<br />

1150<br />

Dimensions of HVS 140<br />

Version HVS 100 HVS 140<br />

Capacity up to 4000 kg/h up to 6000 kg/h<br />

305 2900<br />

ca. 3720<br />

Upgrade of former HVS versions available!<br />

New PLC control provides electronic recipe management<br />

and automatic gap adjustment during operation.<br />

Roller measurement<br />

working width in mm<br />

diameter in mm<br />

Connected load in kW<br />

including screw conveyor<br />

1000<br />

400<br />

1400<br />

400<br />

46 59<br />

Automatic “E” version available available<br />

Dimensions in mm<br />

(length x width x height)<br />

3470x2300x3700<br />

3870x2300x3700<br />

Weight net in kg approx. 4800 approx. 5800<br />

Subject to technical alternations!<br />

Petzholdt-Heidenauer Maschinen- und Anlagenbau International GmbH<br />

Niedersedlitzer Straße 41 | 01239 Dresden | DE<br />

+49 351 2861-200 +49 351 2861-282<br />

info petzholdt-heidenauer.de | www.h-d-m.com

COCOA PROCESSING<br />

H-D-M.COM<br />

SPINDLE<br />

MILL<br />

HKM<br />

80 &<br />

200<br />

CONTINUOUS WORKING MILL FOR FINE AND<br />

SUPER FINE GRINDING OF COCOA LIQUOR, TAHINA<br />

OR NUT PASTE WITH CAPACITIES UP TO 2000 KG/H

H-D-M.COM<br />

SPINDLE MILL<br />

HKM 80 | HKM 200<br />

Application<br />

For gentle fine and super fine grinding of preground cocoa<br />

liquor, tahina, nut paste and similar goods.<br />

Construction Features<br />

• Continuous grinding with flexible throughput<br />

• Balls grind the product by using pressure-, friction-, shear<br />

forces<br />

• Agitator shaft with wear resistant disks for intensive grinding<br />

1 driving motor<br />

2 temperature sensor<br />

3 rotating screen<br />

4 grinding pot<br />

5 agitator shaft<br />

6 grinding bodies<br />

7 three-way cock<br />

8 pressure sensor<br />

9 rotary piston pump<br />

10 product inlet<br />

11 product outlet<br />

12 water inlet<br />

13 water outlet<br />

1<br />

11<br />

2<br />

3<br />

4<br />

5<br />

6<br />

• Rotating screen separates the ground product from the balls<br />

10<br />

13<br />

p<br />

12<br />

• Product infeed by continuously variable and heatable rotary<br />

piston pump<br />

9 8<br />

7<br />

• Wear resistant stainless steel grinding pot with tempering<br />

Technological Scheme HKM 80<br />

• Reversible grinding pot for longer lifetime<br />

• Valveless product inlet<br />

• Automatic product temperature control<br />

• Automatic preheating of machine (stand by mode available)<br />

355<br />

115<br />

• Machine terminal for automatic operation, indication and<br />

display of operating states as well as failure indication<br />

2440<br />

• Machine PLC controlled with separate switch cabinet<br />

1700<br />

• Combinable with Beater Mill SMM and Differential Mill 310H<br />

• CE conformance (meets EU machinery guideline resp. UL or<br />

CSA guideline possible)<br />

Technical Data<br />

1650<br />

External DImensions HKM 80<br />

230<br />

780<br />

HKM 80 HKM 200<br />

Throughput in kg/h, controllable up to 1250 up to 2000<br />

Grinding pot fi lling content in l 80 200<br />

Connected load in kW 47 92<br />

Cooling water consumption in m³/h<br />

(at + 15 ºC inlet temperature)<br />

Warm water consumption in m³/h<br />

(at + 60 ºC inlet temperature)<br />

approx. 0.7 approx. 1.8<br />

approx. 0.1 approx. 0.2<br />

External Dimensions in mm 1650 x 780 x 2440 1700 x 1200 x 3100<br />

Weight net in kg 2100 4000<br />

Subject to technical alternations!<br />

Petzholdt-Heidenauer Maschinen- und Anlagenbau International GmbH<br />

Niedersedlitzer Straße 41 | 01239 Dresden | DE<br />

+49 351 2861-200 +49 351 2861-282<br />

info petzholdt-heidenauer.de | www.h-d-m.com

CHOCOLATE MAKING<br />

H-D-M.COM<br />

CONTINUOUS<br />

CONCHE<br />

HCC<br />

75<br />

TO<br />

500<br />

FULLY-AUTOMATED CONTINUOUS WORKING CONCHING<br />

PLANT WITH CAPACITIES UP TO 6500 KG/H AND UNIFORM<br />

CONCHING RESULTS FROM RECIPE TO RECIPE

H-D-M.COM<br />

CONTINUOUS CONCHE<br />

HCC 75 | HCC 125 | HCC 250 | HCC 375 | HCC 500<br />

Application<br />

For continuous dry conching and liquefying of chocolate and<br />

compound masses with insensive matter exchange, short<br />

<strong>proc</strong>essing times and low energy consumption.<br />

Advantages<br />

• Unique efficiency of employed energy to effect structural<br />

changes during conching <strong>proc</strong>ess<br />

• High specific surface of <strong>proc</strong>essed chocolate masses<br />

Technical Features<br />

• Fully-automated continuous working principle ensures<br />

reproducible conching results from recipe to recipe<br />

• Exceptionally short conching times by using the high<br />

specific energy density of the HCC<br />

• Low energy consumption and space requirements<br />

• Automatic throughput adaption to the refiner’s capacity<br />

• Integrated tempering system to satisfy the defined<br />

<strong>proc</strong>ess temperature range<br />

• Permanent speration and intensive movement of the<br />

particles for improving the external and internal matter<br />

exchange <strong>proc</strong>esses in the mass<br />

• Uniform treatment of every particle in the mass<br />

• Fast and easy recipe changes and minimal residual<br />

amounts due to the automatic cleaning programm<br />

• Compact and hygienically safe closed machine system<br />

• Modular design, with possibility of flexible setup and<br />

„step-by-step“ future extensions<br />

• Computer controlled fully-automated operation with<br />

Erection • Final plan composition of the recipe in the weighing station recipe management, storing of machinery / <strong>proc</strong>ess data<br />

including start, emptying, stopping and service programm<br />

• Intensive homogenizing of final product<br />

Technological Scheme<br />

pasting station weighing station homogenizing station<br />

with vibrating screen<br />

16<br />

5<br />

13<br />

17<br />

2,69 m<br />

6<br />

pasting station<br />

weighing and homogenizing<br />

station with vibrating screen<br />

10<br />

1<br />

2<br />

4<br />

7<br />

14<br />

8<br />

9<br />

2,23 m<br />

11 12<br />

3<br />

15<br />

18<br />

6,12 m<br />

Technical Data<br />

basic switch cabinet<br />

5,40 m<br />

Setup HCC 125<br />

switch cabinet for one pasting<br />

station with variable speed<br />

1 feeding hopper<br />

2 paster<br />

3 blower with air filter and air heater<br />

4 mass pump<br />

5 intermediate tank<br />

6 weighing tank<br />

7 collecting tank<br />

8 dynamic flow mixer<br />

9 vibrating screen<br />

10 refined chocolate mass<br />

11 cocaobutter (optional)<br />

12 lecithin (optional)<br />

Technological Scheme HCC<br />

13 lecithin<br />

14 temperature regulating medium<br />

15 conditioned air<br />

16 outgoing air<br />

17 liquid components for completion of recipe<br />

18 final chocolate<br />

Subject to technical alternations!<br />

Version HCC 75 HCC 125 HCC 250 HCC 375 HCC 500<br />

Capacity in kg/h up to 1000 up to 2000 up to 4000 up to 5000 up to 6500<br />

Weight net in kg<br />

(without switch cabinet)<br />

7000 8600 15100 21700 28200<br />

Connected load in kW 90 148 282 416 550<br />

External Dimensions in mm<br />

(without switch cabinet)<br />

- 6120x2230x2690 10260x2230x2690 14300x2230x2690 18000x2230x2690<br />

Petzholdt-Heidenauer Maschinen- und Anlagenbau International GmbH<br />

Niedersedlitzer Straße 41 | 01239 Dresden | DE<br />

+49 351 2861-200 +49 351 2861-282<br />

info petzholdt-heidenauer.de | www.h-d-m.com

CHOCOLATE MAKING<br />

H-D-M.COM<br />

BATCH<br />

CONCHES<br />

HBC<br />

3 TO 12<br />

DOUBLE SHAFT BATCH CONCHES WITH BATCH CONTENTS<br />

FROM 3 TO 12 TONS FOR ABSOLUTE DRY CHONCHING<br />

AND LIQUEFYING

H-D-M.COM<br />

BATCH CONCHES<br />

HBC 3 | HBC 6 | HBC 9 | HBC 12<br />

Application<br />

For absolute dry conching and liquefying of chocolate and<br />

compound masses.<br />

Construction Features<br />

• 2 conching shafts equipped with rugged and efficient<br />

conching tools<br />

• 2 geared driving motors, frequency controlled for optimal<br />

speed adjustment within the different phases of conching<br />

• 1 shut-able mass inlet<br />

• 1 pneumatic operated louver for optimal exchange of<br />

matter<br />

• Conche bowl with double jacket and integrated tempering<br />

system to observe the adjusted <strong>proc</strong>ess temperatures<br />

• 2 pneumatic operated outlet ball valves with connection to<br />

the discharge pump<br />

• Constructed from mild steel<br />

• 1 switch cabinet for conching <strong>proc</strong>ess and recipe management<br />

Optional Equipment<br />

• Control of dosing equipment for final addition of cocoa<br />

butter, vegetable fat, lecithin, admul etc.<br />

• Discharge Pumps with capacities up to 20000 kg/h<br />

• Blower with heater for increasing exchange of matter<br />

H<br />

C<br />

D<br />

Technical Data<br />

E<br />

A<br />

Subject to technical alternations!<br />

HBC 3 HBC 6 HBC 9 HBC 12<br />

F<br />

B<br />

G<br />

Batch content in kg 3000 6000 9000 12000<br />

Connected load in kW 74 90 150 150<br />

Weight net in kg 14500 22500 24500 28000<br />

A in mm 4270 4640 4670 4825<br />

B in mm 3070 3840 4770 5140<br />

C in mm 2870 3570 3760 4060<br />

D in mm 2650 3350 3640 3940<br />

E in mm 2870 4190 3653 3835<br />

F in mm 2040 2690 3050 3335<br />

Shaft with conching tools<br />

G in mm 720 720 1000 1000<br />

H in mm 2660 3560 4500 5140<br />

Petzholdt-Heidenauer Maschinen- und Anlagenbau International GmbH<br />

Niedersedlitzer Straße 41 | 01239 Dresden | DE<br />

+49 351 2861-200 +49 351 2861-282<br />

info petzholdt-heidenauer.de | www.h-d-m.com

COCOA PROCESSING<br />

H-D-M.COM<br />

Beater<br />

Blade<br />

Mill<br />

Series

H-D-M.COM<br />

Beater Blade Mill<br />

The Bauermeister Beater Blade Mill SMM is used for the<br />

grinding of products with a high fat content e.g. Cocoa nibs<br />

and Hazelnuts.<br />

The product is fed into the grinding chamber at a controlled<br />

rate, by means of a dosing screw. High speed rotating blades<br />

break the product down to the required particle size and the<br />

high fat content ensures conversion into a pumpable mass<br />

with optimal flow properties. The fineness of the finished<br />

product is determined by the mesh size of an integral, annular<br />

sieve, through which the mass flows on its way to the<br />

exit of the mill.<br />

The shell and base of the grinding chamber are of jacketed<br />

design, to facilitate the <strong>proc</strong>essing of product under controlled<br />

conditions of operation; hot or cold water is circulated,<br />

as appropriate, to maintain a constant temperature.<br />

The moisture content is also reduced during the grinding<br />

<strong>proc</strong>ess.<br />

Advantages<br />

• Continuous grinding. Non or un-sufficiently ground particles<br />

remain inside the grinding chamber. The subsequent<br />

plant components such as roll refiners will be wear<br />

protected.<br />

• High capacity at a constant fineness.<br />

• Determination of the requested fineness by choosing the<br />

mesh width of the sieves (0,15 – 0,5 mm).<br />

• The achieved particle size spectrum favors the subsequent<br />

fine grinding by means of ball mills and roll refiners.<br />

• Controlled product temperature.<br />

• Fast exchange of blades and sieves due to swiveling<br />

• Fast exchange of blades and sieves due to swiveling cover.<br />

• Short maintenance breaks, since the sense of rotation<br />

can be changed.<br />

• The mill is equipped with automatically operated grease<br />

lubrication.<br />

• Cleaning of the sieves can be done without its removal.<br />

Technical Data<br />

SMM 801 801.1 SMM 1100 SMM 1100.1<br />

Diameter of Grinding Chamber 802 802 1140 1140<br />

Height of Grinding Chamber 333 333 460 460<br />

Connected load 45 55 90 110<br />

Number of Beater Blades 8 8 8 8<br />

Bauermeister Zerkleinerungstechnik GmbH<br />

Oststraße 40 | 22844 Norderstedt | DE<br />

+49 40 526 08-0 +49 40 526 08-199<br />

info.bauermeister@h-d-m.com | www.h-d-m.com

HDM – Main Machinery Cocoa Bean Processing<br />

From Cleaning up to Powdering - HDM completely designs and engineers, as<br />

well as provides installation supervision and commissioning on request

Cocoa Bean Processing Line – Nib Roasting<br />

Bean Intake & Cleaning<br />

Batch Roasting & Sterilizing/Alkalizing<br />

Bean Treatment<br />

Bean Intake & Cleaning<br />

Winnowing<br />

|<br />

Bean Treatment<br />

|<br />

Winnowing<br />

|<br />

Batch Roasting & Sterilizing/Alkalizing<br />

|<br />

Powdering<br />

Pressing<br />

Pre-Grinding<br />

Pre-Grinding<br />

Mass Sterilizing/Alkalizing (optional)<br />

|<br />

Fine Grinding<br />

|<br />

Pressing<br />

Cocoa Butter<br />

Cocoa Cake<br />

Powder Bagging<br />

Butter Filtration<br />

Sterilizing & Alkalizing<br />

| |<br />

Butter Filtration<br />

Powdering<br />

|<br />

Powder Bagging<br />

Fine-Grinding

Cocoa Bean Processing Line – Bean Roasting<br />

Bean Intake & Cleaning<br />

Powdering<br />

Powder Bagging<br />

Winnowing<br />

Bean Roasting<br />

Pressing<br />

Butter Deodorizing<br />

Butter Filtration<br />

Pre-Grinding<br />

Sterilizing<br />

Alkalizing<br />

Fine-Grinding<br />

Butter / Mass Blocking<br />

Bean Intake & Cleaning<br />

|<br />

Bean Roasting<br />

|<br />

Winnowing<br />

|<br />

Pre-Grinding<br />

|<br />

Mass Sterilizing/Alkalizing<br />

|<br />

Fine Grinding Cocoa Mass<br />

| |<br />

Pressing<br />

Mass Blocking<br />

Cocoa Butter Cocoa Cake<br />

| |<br />

Butter Powdering<br />

Filtration<br />

| |<br />

Butter<br />

Deodorizing<br />

|<br />

Butter Blocking<br />

Powder<br />

Bagging

Bean; Drop-Off / Cleaning / Storage<br />

Bean Intake Hopper with Wind Sifter, Metal Separator, Rotary Sieve and Destoner<br />

Dumping Stations<br />

Bean Silos<br />

Pendulum Bucket Conveyor<br />

Rotary Sieve<br />

Drum Magnet<br />

Tube Chain Conveyor

Bean; Drop-Off / Cleaning / Storage<br />

Truck unloading Area<br />

Destoner with elevator<br />

and silo connection

Nib & Bean Treatment / Roasting<br />

Bean Roasting<br />

ShellCon FSC 2000<br />

Nib Roasting and Cooling<br />

Exhaust Treatment

Winnowers<br />

FBR 81 – up to 4000 kg/h<br />

FBR 63 – up to 2.400 kg/h<br />

Excellent separating result:<br />

Nib loss 0,15 – 0,25%; Shell in Nibs

Alkalizer / Sterilizer for Beans, Nibs or Cocoa Liquor<br />

Bean Treatment<br />

Cocoa Liquor &<br />

Cake Treatment<br />

Superheated steam<br />

for short reaction time<br />

Reduction rate<br />

in continuous operation<br />

less 500/g<br />

Nib Treatment

Vacuum Mixers - 500 to 6000 kg Batch Content<br />

in use as:<br />

- Cocoa Liquor Sterilizer / Alkalizer<br />

- Cocoa Cake Sterilizer / Alkalizer<br />

Version Batch Time Capacity<br />

Sterilizing (+Akalizing)<br />

HBM 500V 130 min. 230 (180) kg/h<br />

HBM1000V 130 min. 460 (360) kg/h<br />

HBM2000V 130 min. 925 (700) kg/h<br />

HBM3000V 130 min. 1400 (925) kg/h<br />

HBM4000V 130 min. 1800 (1400) kg/h<br />

HBM5000V 130 min. 2300 (1800) kg/h<br />

HBM6000V 140 min. 2500 (2100) kg/h<br />

Sample for HBM5000V<br />

Cocoa Liquor<br />

Sterilization / Alkalization<br />

Product Goal:<br />

water content max. 1,50%<br />

by shell content max. 1,75%<br />

total plate count per gram;<br />

sterilized ≤ 1500<br />

alkalized ≤ 3000<br />

PH value up to 9

Vacuum Mixers “HBM-V” - Results in Field of Application<br />

1 - Sterilisation<br />

Before Treatment<br />

After Treatment<br />

Cocoa Mass pH Value moisture TPC pH Value moisture TPC<br />

West Africa (Mix) 5,55 2,50% >120.000 5,63 0,82% 14.600 5,46 0,78% 12.800 5,69 0,74% 38.000 5,84 0,92%

Pre- & Fine Grinding

Nib & Fine Grinders<br />

HKM 200<br />

Throughput up to 2000 kg/h<br />

HKM 80<br />

Throughput up to 1000 kg/h<br />

SMM 801<br />

Throughput up to 1000 kg/h<br />

SMM 1100<br />

Throughput up to 2000 kg/h

Cocoa Presses – Version HHP<br />

Throughput for: HHP 6 HHP 12 HHP 14<br />

at 22/24 % up to 750 kg/h up to 1875 kg/h up to 2700 kg/h<br />

at 10/12 % up to 350 kg/h up to 735 kg/h up to 1080 kg/h<br />

at 8/10 % up to 190 kg/h up to 500 kg/h up to 740 kg/h<br />

Cycle Time for HHP 6 HHP 12 HHP 14<br />

at 22/24 % about 7,2 min about 5,8 min about 5,8 min<br />

at 10/12 % about 15,4 min about 14,7 min about 14,4 min<br />

at 8/10 % about 28,4 min about 21,6 min about 21,4 min<br />

Technical Data HHP 6 HHP 12 HHP 14<br />

max. pressure 550 bar 550 bar 550 bar<br />

pressure on mass 850 bar 850 bar 795 bar<br />

main ram feed 103 mm/min 195 mm/min 300 mm/min<br />

number of pots 6 12 14<br />

pot diameter 450 mm 450 mm 500 mm<br />

pot height 90 mm 90 mm 90 mm<br />

pot filling content 15 kg 15 kg 18,5 kg<br />

total filling content 90 kg 180 kg 260 kg

Cocoa Presses<br />

HHP 14 – ready for dispatch<br />

HHP 14 – in field of Application

Cocoa Press Details<br />

Pots & Counter Pots

Cocoa Press Arrangements

Cocoa Hydraulic Press Pump Unit – HHP Vario<br />

Maximum Flow Rate (low pressure pump at 170 bars) l/min 48<br />

Flow Rate continuously variable<br />

Minimum Flow Rate (high pressure pump at 550 bars) l/min 1,6<br />

Flow Rate continuously variable<br />

Main Ram Feed (cocoa press HHP12 + 1450) mm/min 195<br />

Possible Cycle Time<br />

for 22/24% min. 8,65<br />

for 22/24% min. 12,9<br />

for 22/24% min. 18,0<br />

Connected Load kW 19,5<br />

Oil Tank Capacity litre 400<br />

Cooling Water Consumption (at +20°C) m³/h 0,8<br />

External Dimensions (mm) 1110 x 690 x 1465<br />

Weight (net) kg 560

Hydraulic Pump Unit – HHP Vario Maxi<br />

Maximum Flow Rate (low pressure pump at 170 bars) l/min 85<br />

Maximum Flow Rate (medium pressure pump at 450 bars) l/min 31,8<br />

Minimum Flow Rate (high pressure pump at 550 bars) l/min 1,7<br />

Flow Rate continuously variable<br />

Main Ram Feed (cocoa press HHP12 + 1450) mm/min 300<br />

Possible Cycle Time<br />

for 22/24% min. 7<br />

for 22/24% min. 15<br />

for 22/24% min. 25<br />

Connected Load kW 23<br />

Oil Tank Capacity litre 600<br />

Cooling Water Consumption (at +20°C) m³/h 0,8<br />

External Dimensions (mm) 1515 x 735 x 950<br />

Weight (net) kg 650

Cocoa Butter Deodorising Plant – version HCBD<br />

Cocoa Butter Cricket Filter<br />

Cocoa Butter Deodorising Plant<br />

Stainless Steel Storage Tank<br />

Helical Rotor Pumps

HDM Deodorising Units<br />

Version HCBD 250 HCDB 600 HBCD 1000 HBCD 2000<br />

Capacity by FFA of max. 5% 200 kg/h 500 kg/h 850 kg/h 1600 kg/h<br />

Capacity by FFA of max. 3% 325 kg/h 800 kg/h 1300 kg/h 2400 kg/h<br />

Capacity by FFA of max. 2,2% 400 kg/h 960 kg/h 1600 kg/h 2800 kg/h<br />

FFA Content after Deodorising < 1,6 % < 1,6 % < 1,6 % < 1,6 %<br />

Aroma Index deodorised Butter (0 to 9) < 6 < 6 < 6 < 6

Additional Equipment - Cocoa Bean Processing Lines<br />

Cocoa Butter / Cocoa Mass<br />

Tempering Equipment<br />

Cocoa Butter / Cocoa Mass Blocking Station

Powder Plants – “under construction”<br />

Available after Interpack<br />

Version up to 1000 kg/h<br />

Version up to 2000 kg/h