- Page 1 and 2:

HERRAMIENTAS DE CORTE

- Page 3 and 4:

KORLOYHERRAMIENTAS DE CORTE2013

- Page 5 and 6:

C O N T E N I D OGrados/Rompeviruta

- Page 7 and 8:

GUIA DE SEGURIDAD PARA PRODUCTOS DE

- Page 9 and 10:

Como usar el Tool4U (Web quotation

- Page 12 and 13:

AGrados / RompevirutasLos nuevos gr

- Page 14 and 15:

AGradosSist. Clasificación de Grad

- Page 16 and 17:

AA Grados de TorneadoRecubrimiento

- Page 18 and 19:

AA Grados de TorneadoRendimiento de

- Page 20 and 21:

AA Grados de TorneadoRecubrimiento

- Page 22 and 23:

AA Grados de TorneadoGrados de carb

- Page 24 and 25:

AA Grados de TorneadoDesempeño del

- Page 26 and 27:

AGrados para FresadoSelección de g

- Page 28 and 29:

AGrados para FresadoRendimiento de

- Page 30 and 31:

AGrados para FresadoCaracterística

- Page 32 and 33:

AGrados para FresadoGrados Fresados

- Page 34 and 35:

AEndmillsCarburo cementado con gran

- Page 36:

AOtrosGrados con Recubrimiento de D

- Page 39 and 40:

OtrosAcBN para FundiciónCondicione

- Page 41 and 42:

RompevirutasARompevirutas KORLOY pa

- Page 43 and 44:

RompevirutasARompevirutas KORLOY pa

- Page 45 and 46:

Grados /Rompevirutas

- Page 47 and 48:

NEADOBarras para InteriorB122B123B1

- Page 49 and 50:

Rompevirutas TorneadoBRango de Apli

- Page 51 and 52:

Rompevirutas TorneadoBRompeviruta R

- Page 53 and 54:

Rompevirutas TorneadoBRecomendació

- Page 55 and 56:

Rompevirutas TorneadoBRecomendació

- Page 57 and 58:

Rompevirutas TorneadoBRecomendació

- Page 59 and 60:

Rompevirutas TorneadoBRompevirutasR

- Page 61 and 62:

BTorneadoB15

- Page 63 and 64:

Sistema Codicación Insertos para T

- Page 65 and 66:

Insertos para Torneado(Negativo)BCN

- Page 67 and 68:

Insertos para Torneado(Negativo)BCN

- Page 69 and 70:

Insertos para Torneado(Negativo)BDN

- Page 71 and 72:

Insertos para Torneado(Negativo)BDN

- Page 73 and 74:

Insertos para Torneado(Negativo)BKN

- Page 75 and 76:

Insertos para Torneado(Negativo)BSN

- Page 77 and 78:

Insertos para Torneado(Negativo)BSN

- Page 79 and 80:

Insertos para Torneado(Negativo)BSN

- Page 81 and 82:

Insertos para Torneado(Negativo)BTN

- Page 83 and 84:

Insertos para Torneado(Negativo)BTN

- Page 85 and 86:

Insertos para Torneado(Negativo)BTN

- Page 87 and 88:

Insertos para Torneado(Negativo)BTN

- Page 89 and 90:

Insertos para Torneado(Negativo)BVN

- Page 91 and 92:

Insertos para Torneado(Negativo)BWN

- Page 93 and 94:

Insertos para Torneado(Negativo)BWN

- Page 95 and 96:

Insertos para Torneado(Positivo)BCC

- Page 97 and 98:

Insertos para Torneado(Positivo)BCP

- Page 99 and 100:

Insertos para Torneado(Positivo)BDC

- Page 101 and 102:

Insertos para Torneado(Positivo)BSC

- Page 103 and 104:

Insertos para Torneado(Positivo)BSP

- Page 105 and 106:

Insertos para Torneado(Positivo)BTC

- Page 107 and 108:

Insertos para Torneado(Positivo)BTP

- Page 109 and 110:

Insertos para Torneado(Positivo)BVB

- Page 111 and 112:

Insertos para Torneado(Positivo)BVC

- Page 113 and 114:

Insertos para AluminioBInformación

- Page 115 and 116:

Insertos para Aluminio (Positivo)BD

- Page 117 and 118:

Insertos para Aluminio (Positivo)BS

- Page 119 and 120:

Insertos para Aluminio (Positivo)BV

- Page 121 and 122:

Torneado75BBInsertos para cBNInsert

- Page 123 and 124:

Insertos para cBNBCBNPara maquinado

- Page 125 and 126:

Insertos para cBNBCBNUn solo Uso (P

- Page 127 and 128:

Torneado81BBInsertos PCDInsertos PC

- Page 129 and 130:

Sistema Codicación para PortaInser

- Page 131 and 132:

Indice de PortaInsertos ExternosBSi

- Page 133 and 134:

Instrucciones de Ensamblado de Port

- Page 135 and 136:

Sistema de Brida DobleBDCBNR/LCN75

- Page 137 and 138:

Sistema de Brida DobleBDSDNNSN45°C

- Page 139 and 140:

Sistema de Brida DobleBDVVNN72.5°

- Page 141 and 142:

Torneado95BBSistema de PalancaSiste

- Page 143 and 144:

Sistema de PalancaBPRDCNRCMXCodigoH

- Page 145 and 146:

Sistema de PalancaBPSKNR/LCodigo H

- Page 147 and 148:

Sistema de PalancaBPTTNR/LCodigo H

- Page 149 and 150:

Sistema Brida AmpliaBWWLNR/L95°•

- Page 151 and 152:

Sistema de BridaBCSKPR/L75°• Ins

- Page 153 and 154:

Sistema Multi-trabeBMCRNR/L75°•

- Page 155 and 156:

Sistema Multi-trabeBMSKNR/L75°•

- Page 157 and 158:

Sistema Multi-trabeBMTGNR/LCodigo H

- Page 159 and 160:

Sistema con TornilloBSCACR/L90°•

- Page 161 and 162:

Sistema con TornilloBSRGCR/L• Ins

- Page 163 and 164:

Sistema con TornilloBSTGCR/L90°•

- Page 165 and 166:

Sistema con TornilloBSVVBN72.5°(mm

- Page 167 and 168:

Holder CerámicoBCSKNR/L75°• Ins

- Page 169 and 170:

Indice Barras para InteriorBSistema

- Page 171 and 172:

Instrucciones de Ensamblado Barras

- Page 173 and 174:

Sistema de Brida DobleBDTFNR/LØD :

- Page 175 and 176:

Sistema de PalancaBPDUNR/LØD : Dia

- Page 177 and 178:

Sistema de BridaBCKUNR/LØD : Diame

- Page 179 and 180:

Sistema Multi-trabeBMTFNR/LØD : Di

- Page 181 and 182:

Sistema con TornilloBSDQCR/LØD : D

- Page 183 and 184:

Sistema con TornilloBSTFCR/LØD : D

- Page 185 and 186:

Sistema con TornilloBSVUBR/LØD : D

- Page 187 and 188:

Barra Interior C/Zanco de CarburoBS

- Page 189 and 190:

Barra Interior C/Zanco de CarburoBS

- Page 191 and 192:

Barra Interior C/Zanco de CarburoBS

- Page 193 and 194:

Información Ténica del Sistema He

- Page 195 and 196:

Herramienta con Sistema HSKBDCLNR/L

- Page 197 and 198:

Herramienta con Sistema HSKBPRGCR/L

- Page 199 and 200:

Herramienta con Sistema HSKBMCFR/L(

- Page 201 and 202:

Herramienta con Sistema KMBDCLNR/L9

- Page 203 and 204:

Herramienta con Sistema KMBPDJNR/L9

- Page 205 and 206:

Sistema Codicación Cartuchos (ISO)

- Page 207 and 208:

Sistema de BridaBCSKPR/L• Inserto

- Page 209 and 210:

Sistema con TornilloBSSKCR/L• Ins

- Page 211 and 212:

Información Técnica de Herramient

- Page 213 and 214:

Herramientas para Torno Automático

- Page 215 and 216:

Torneado169BB------------1111111111

- Page 217 and 218:

Herramientas para Torno Automático

- Page 219 and 220:

Información Técnica de Micro Bore

- Page 221 and 222:

Micro Boreado de Carburo (MSB)BBore

- Page 223 and 224:

Micro Boreado de Carburo (MSB)BRanu

- Page 226 and 227:

CHERRAMIENTASMULTIFUNCIONALESLas he

- Page 228 and 229:

CEjemplo de AplicaciónPara Maquina

- Page 230 and 231:

CInformación Técnica para Series

- Page 232 and 233:

CInformación Técnica para Series

- Page 234 and 235:

CInformación Técnica para Series

- Page 236 and 237:

CPortainserto MGTMCHR/L(Portainsert

- Page 238 and 239:

12CCHerramientasMultifuncionalesMGT

- Page 240 and 241:

14CCHerramientasMultifuncionalesMGT

- Page 242 and 243:

16CCHerramientasMultifuncionalesMGT

- Page 244 and 245:

18CCHerramientasMultifuncionalesRan

- Page 246 and 247:

CMaquinado en Rines de Aluminio MGT

- Page 248 and 249:

22CCHerramientasMultifuncionalesIns

- Page 250 and 251:

CInsertos Diponibles para MGTApplic

- Page 252 and 253:

CPorta LamaSPB/SPB-S(Lama ó Cuchil

- Page 254 and 255:

CHerramientas para RanuradoIGHPara

- Page 256 and 257:

30CCHerramientasMultifuncionalesHer

- Page 258 and 259:

CHerramientas para TronzadoEHInsert

- Page 260 and 261:

CHerramientas Ranurado y Roscado Fi

- Page 262 and 263:

CInformación Técnica de Herramien

- Page 264 and 265:

38CCMulti functionalToolsTorneado M

- Page 266 and 267:

CSolución en RodamientosCMSN...FTi

- Page 268 and 269:

CSolución en RodamientosSSKP...BTi

- Page 270 and 271:

CSolución en RodamientosCSBN...BST

- Page 272:

CFormato para Orden de Insertos Esp

- Page 275 and 276:

SCADOInserto para RoscadoD24D25D26D

- Page 277 and 278:

Información Ténica de RoscadoDCar

- Page 279 and 280:

Información Ténica de RoscadoDMé

- Page 281 and 282:

Información Ténica de RoscadoDPas

- Page 283 and 284:

Información Técnica para insertos

- Page 285 and 286:

Insertos para RoscadoDPerfl Parcial

- Page 287 and 288:

Insertos para RoscadoDISO Métrico

- Page 289 and 290:

Insertos para RoscadoDISO Métrico

- Page 291 and 292:

Threading17DDInsertos para RoscadoI

- Page 293 and 294:

Insertos para RoscadoDWhitworth (Ro

- Page 295 and 296:

Insertos para RoscadoDWhitworth (Ro

- Page 297 and 298:

Insertos para RoscadoDRoscado de Tu

- Page 299 and 300:

Insertos para RoscadoDStub ACME (ST

- Page 301 and 302:

Threading27DDInsertos para RoscadoI

- Page 303 and 304:

Threading29DDInsertos para RoscadoI

- Page 305 and 306:

Portainserto ExternoDER(L)H(sistema

- Page 307 and 308:

Holder VerticalDVTHInserto Tipo R(m

- Page 309 and 310:

Información Técnica para Roscado

- Page 311 and 312:

Información Técnica para Roscado

- Page 313 and 314:

Información Técnica para Roscado

- Page 315 and 316:

Información Técnica para Roscado

- Page 317 and 318:

Información Técnica para Roscado

- Page 319 and 320:

Insertos para Roscado en FresadoDAm

- Page 321 and 322:

Insertos para Roscado en FresadoDWh

- Page 323 and 324:

Insertos para Roscado en FresadoDTi

- Page 325 and 326:

Enmills Solido para Roscado en Fres

- Page 327 and 328:

Enmills Solido para Roscado en Fres

- Page 329 and 330:

Enmills Solido para Roscado en Fres

- Page 331 and 332:

Enmills Solido para Roscado en Fres

- Page 333 and 334:

Enmills Solido para Roscado en Fres

- Page 335 and 336:

DThreadingD61

- Page 337 and 338:

ESADOCortadores para MoldeoE215E216

- Page 339 and 340:

Sistema Codificación (ISO)E-6 7 8

- Page 341 and 342:

Fresado5EEInsertos para FresadoInse

- Page 343 and 344:

Fresado7EEInsertos para FresadoInse

- Page 345 and 346:

Insertos para FresadoEPieza Trabajo

- Page 347 and 348:

Fresado11EEInsertos para FresadoIns

- Page 349 and 350:

Fresado13EEInsertos para FresadoIns

- Page 351 and 352:

Insertos para FresadoEPieza Trabajo

- Page 353 and 354:

Insertos para FresadoEPieza Trabajo

- Page 355 and 356:

Insertos para FresadoEPieza Trabajo

- Page 357 and 358:

Fresado21EEInsertos para FresadoIns

- Page 359 and 360:

Tabla de CortadoresETipo de Maquina

- Page 361 and 362:

Tabla de CortadoresETipo de Maquina

- Page 363 and 364:

Tabla de CortadoresETipo de Maquina

- Page 365 and 366:

Tabla de ZancosETipo de MaquinadoTi

- Page 367 and 368:

Mill-maxEADN(M)4000AA45• AR : 15

- Page 369 and 370:

Mill-maxEAE(M)4000AA45• AR : 20°

- Page 371 and 372:

Mill-maxEEF(M)4000Fig. 1 Fig. 2 Fig

- Page 373 and 374:

Mill-maxEEPN(M)4000AA75• AR : 7°

- Page 375 and 376:

Mill-maxEPF(M)4000Fig. 1 Fig. 2 Fig

- Page 377 and 378:

Turbo MillEADS4000AA45• AR : 15°

- Page 379 and 380:

Turbo MillEPES2000/3000/40002000/30

- Page 381 and 382:

Double MillEAFO(M)5000Fig. 1 Fig. 2

- Page 383 and 384:

Información Técnica para Power Bu

- Page 385 and 386:

Power busterEPBAC(M)5000Fig. 1 Fig.

- Page 387 and 388:

Información Técnica para Rich Mil

- Page 389 and 390:

Información Técnica para Rich Mil

- Page 391 and 392:

Información Técnica para Rich Mil

- Page 393 and 394:

Información Técnica para Rich Mil

- Page 395 and 396:

Información Técnica para Rich Mil

- Page 397 and 398:

Información Técnica Rich-MillETip

- Page 399 and 400:

Rich MillERMH8AC(M)4000Placa TipoFi

- Page 401 and 402:

Rich MillERMH8AC(M)5000Placa TipoFi

- Page 403 and 404:

Rich MillERMH8EC(M)4000Placa TipoFi

- Page 405 and 406:

Rich MillERMH8EC(M)5000Placa TipoFi

- Page 407 and 408:

Rich MillERMH8QC(M)4000Placa TipoFi

- Page 409 and 410:

Rich MillERM4PC(M)4000Fig. 1 Fig. 2

- Page 411 and 412:

Rich MillERM4PFCB4000(mm)CodigoØD

- Page 413 and 414:

Rich MillERM4PHCB4000(mm)CodigoØD

- Page 415 and 416:

Rich MillERM4PFCP4000(mm)CodigoØD

- Page 417 and 418:

Rich MillERM4PHCP4000(mm)CodigoØD

- Page 419 and 420:

Rich MillERM4PS4000AA90• AR : -6

- Page 421 and 422:

Rich MillERM4ZC(M)3000/4000AA90•

- Page 423 and 424:

Rich MillERM16AC(M)6000Fig. 1 Fig.

- Page 425 and 426:

Rich MillERMT8A(M)4000Fig. 1 Fig. 2

- Page 427 and 428:

Rich MillERMT8E(M)4000Fig. 1 Fig. 2

- Page 429 and 430:

Rich MillERMT8Q(M)Fig. 1 Fig. 2 Fig

- Page 431 and 432:

Información Técnica para Aero Mil

- Page 433 and 434:

Aero MillEAPD(M)-BCuchillaFig. 1 Fi

- Page 435 and 436:

PCD Cortador frontalESistema Codifi

- Page 437 and 438: Información Técnica para Alpha-Mi

- Page 439 and 440: Fresado103EEInformación Técnica p

- Page 441 and 442: Alpha-MillEAMC(M)1500SAA90• AR :

- Page 443 and 444: Alpha-MillEAMC(M)3000SAA90• AR :

- Page 445 and 446: Alpha-MillEAMC(M)4000SAA90• AR :

- Page 447 and 448: Alpha-MillEAMC(M)3000SEAA75• AR :

- Page 449 and 450: Alpha-MillEAMC(M)3000MCodigoAMC(M)

- Page 451 and 452: Fresado115EEAlpha-MillAlpha-MillAMS

- Page 453 and 454: Fresado117EEAlpha-MillAlpha-MillAMS

- Page 455 and 456: Fresado119EEAlpha-MillAlpha-MillAMS

- Page 457 and 458: Fresado121EEAlpha-MillAlpha-MillAMS

- Page 459 and 460: Alpha-MillEAMS1000SE/2000SEAA75•

- Page 461 and 462: Alpha-MillEAMS1000M/1500MAA90• AR

- Page 463 and 464: Alpha-MillEAMS1000MH/1500MH/2000MH/

- Page 465 and 466: Alpha-MillEAMM1500AA90• AR : 7.5

- Page 467 and 468: Información Técnica para Herramen

- Page 469 and 470: Herramentales BT (Filo Simple)EBT40

- Page 471 and 472: Herramentales HSK(Filo Simple)EHSK6

- Page 473 and 474: Herramentales HSK(Filo Simple)EHSK6

- Page 475 and 476: Herramentales BT(Tipo Mazorca)EBT30

- Page 477 and 478: Herramentales BT(Tipo Mazorca)EBT50

- Page 479 and 480: Herramentales HSK (Tipo Mazorca)EHS

- Page 481 and 482: Herramentales HSK (Tipo Mazorca)EHS

- Page 483 and 484: Fresado147EEHerramentales HSK (Modu

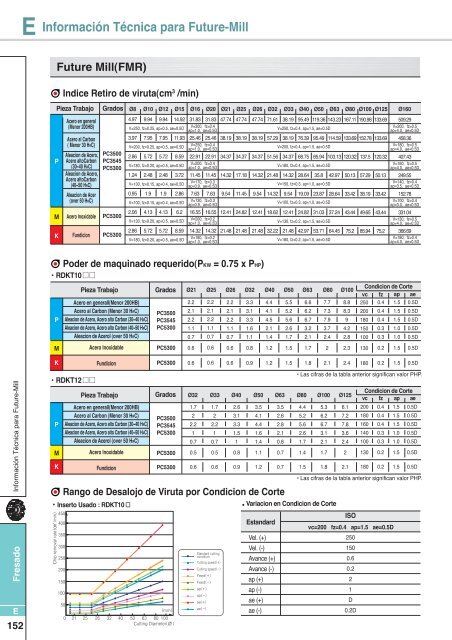

- Page 485 and 486: Información Técnica para Future-M

- Page 487: Información Técnica para Future-M

- Page 491 and 492: Información Técnica para Future-M

- Page 493 and 494: Información Técnica para Future-M

- Page 495 and 496: Future MillEFMAC(M)4000AA45• AR :

- Page 497 and 498: Future MillEFMAC(M)4000-A(Cuerpo Al

- Page 499 and 500: Future MillEFMAS4000AA45• AR : 23

- Page 501 and 502: Future MillEFMPC(M)4000Fig. 1AA90

- Page 503 and 504: Future MillEFMPC(M)4000-A(Cuerpo Al

- Page 505 and 506: Future MillEFMPS4000AA90• AR : 10

- Page 507 and 508: Future MillEFMRC(M)4000• AR : 5

- Page 509 and 510: Future MillEFMRC(M)6000Fig. 1 Fig.

- Page 511 and 512: Future MillEFMRS2000/2500Fig. 1Fig.

- Page 513 and 514: Fresado177EEFuture MillFuture MillF

- Page 515 and 516: Future MillEFMRS6000Fig. 1 Fig. 2

- Page 517 and 518: Future MillEFMRM3000/4000/5000• A

- Page 519 and 520: Información Técnica para HRMDETip

- Page 521: Información Técnica para HRMDEDia

- Page 524 and 525: EHRMDoubleHRMDC(M)13AA14• AR : -7

- Page 526 and 527: Fresado190EEHRMDoubleHRMDouble0616H

- Page 528 and 529: EHRMDoubleHRMDS09AA14• AR : -7°

- Page 530 and 531: EHRMDoubleHRMDS13AA14• AR : -7°

- Page 532 and 533: EHRMDoubleHRMDM09/13AA14• AR : -7

- Page 534 and 535: EHRMHRMS 08/10AA15• AR : 7°• R

- Page 536 and 537: EHRMHRMS 15AA15• AR : 7°• RR :

- Page 538 and 539:

ETank MillTHEAA90• AR : 5°, 10°

- Page 540 and 541:

EInformación Técnica para Láser

- Page 542 and 543:

EInformación Técnica para Láser

- Page 544 and 545:

EInformación Técnica para Láser

- Page 546 and 547:

ELáser MillHoldersDisponiblesInser

- Page 548 and 549:

ELáser MillEsférico Tipo R, Zanco

- Page 550 and 551:

ELáser MillEsquina Tipo R, Zanco A

- Page 552 and 553:

Fresado216EE11111122222233GBE 160-S

- Page 554 and 555:

EBREBREFig. 1Fig. 2Fig. 3Fig. 4•

- Page 556 and 557:

Fresado224EEORCEn Almacen(mm)Partes

- Page 558 and 559:

EInformación Técnica de Herramien

- Page 560 and 561:

EHerramienta para ChaánCE (Frontal

- Page 562 and 563:

EHerramienta para ChaánCE(Multi-Fu

- Page 564 and 565:

Fresado232EEHerramienta para Chaán

- Page 566 and 567:

EInformación Técnica para Pro-A M

- Page 568 and 569:

EInformación Técnica para Pro-X M

- Page 570 and 571:

EPro-A MillPAC(M)4000AA90• AR : 0

- Page 572 and 573:

EPro-A MillPAM2000AA90• AR : 7°~

- Page 574 and 575:

EPAXC(M)6000AA90• AR : 8°~17.5°

- Page 576 and 577:

EPAXS6000AA90• AR : 5°~10°• R

- Page 578 and 579:

EPro-X Mill (sistema de Herramienta

- Page 580 and 581:

EModular AdaptorMAT-C(Zanco de Carb

- Page 582 and 583:

EInformación Técnica para Cortado

- Page 584 and 585:

ECortador LateralTipo Tangencial (C

- Page 586 and 587:

ETipo Radial (Cortador Medio)• RA

- Page 588 and 589:

ECortador LateralHC(Medio Cortador)

- Page 590 and 591:

ECortador LateralSPB(M)• AR : -10

- Page 592 and 593:

EInformación Técnica para Cortado

- Page 594 and 595:

EInformacion Tecnica para Storm Mil

- Page 596 and 597:

EInformación Técnica para Cube-Mi

- Page 598 and 599:

ETechnical Information for Couple M

- Page 600 and 601:

ECortador de Alto AvanceANH5000Fig.

- Page 602 and 603:

ECortador de Alto AvanceCDH5000Fig.

- Page 604 and 605:

ECortador de Alto AvanceDPH5000Fig.

- Page 606 and 607:

ECortador de Alto AvancePPH4000Fig.

- Page 608 and 609:

EShave Mill UltraSVUM6000-BFig. 1 F

- Page 610 and 611:

EInformación Técnica de Cortadore

- Page 612 and 613:

EHerramientas para EngranesAplicaci

- Page 614 and 615:

EHerramienta para EngranesCortador

- Page 616 and 617:

EHerramienta para EngranesCortador

- Page 618 and 619:

EHerramienta para EngranesCortador

- Page 620 and 621:

EHerramienta para EngranesCortador

- Page 622 and 623:

EHerramienta para EngranesEspeciflc

- Page 624 and 625:

FENDMILLSEndmills Korloy, nueva tec

- Page 626 and 627:

FSistema Codicación EndmillsI B E

- Page 628 and 629:

FÍndice de EndmillsTipoFormaCodigo

- Page 630 and 631:

FÍndice de EndmillsTipoFormaCodigo

- Page 632 and 633:

FInformación Técnica para H-MaxCo

- Page 634 and 635:

FH-MaxHPBE2000 (Esférico) / 2000L

- Page 636 and 637:

FInformación Técnica para I-MaxI-

- Page 638 and 639:

FInformación Técnica para I-MaxCo

- Page 640 and 641:

FInformación Técnica para I-MaxCo

- Page 642 and 643:

FI-MaxIFE4000(Plano)EstándarØD1.0

- Page 644 and 645:

FI-MaxIFE2000-T(Cónico Plano)ØD1.

- Page 646 and 647:

FI-MaxIBE2000 / 4000(Esférico) Est

- Page 648 and 649:

FI-MaxIBE2000-T(Esférico cónico)

- Page 650 and 651:

FI-MaxIRE4000(Radio)ØD1.0 ~ 8.00.5

- Page 652 and 653:

FI-MaxFE4000(Plano)EstándarØD1.0

- Page 654 and 655:

FI-MaxFE2000-T(Plano Conico)ØD1.0

- Page 656 and 657:

FI-MaxBE2000 / 4000(Esférico)ØD T

- Page 658 and 659:

F I-MaxBE2000-T(Esférico cónico)

- Page 660 and 661:

FMicro EndmillsMSE2000 (Plano)ØDTo

- Page 662 and 663:

FInformación Técnica para Rib End

- Page 664 and 665:

FInformación Técnica para Rib End

- Page 666 and 667:

FInformación Técnica para Rib End

- Page 668 and 669:

FInformación Técnica para Rib End

- Page 670 and 671:

FRib EndmillsRB(Rib Esférico)R0- 0

- Page 672 and 673:

FRib EndmillsRNR(Rib Endmill Radio)

- Page 674 and 675:

FInformación Técnica de Endmills

- Page 676 and 677:

FEndmills para Materiales Difícile

- Page 678 and 679:

FEndmills para maquinado en Alumini

- Page 680 and 681:

FInformación Técnica para C-Max(C

- Page 682 and 683:

FC-Max(Cobre)CBE2000(Esférico)ØD

- Page 684 and 685:

FInformación Técnica para D-MaxTe

- Page 686 and 687:

Endmills62FFD-MaxD-Max(mm)(mm)(mm)D

- Page 688 and 689:

FInformación Técnica para Endmill

- Page 690 and 691:

Endmills66FFEndmills cBNEndmills cB

- Page 692 and 693:

FEndmills PCDPDE1000/2000 (Plano)(m

- Page 694 and 695:

FEndmills CementadosZSE200 / 300 (P

- Page 696 and 697:

Endmills72FFEndmills CementadosEndm

- Page 698 and 699:

FEndmills CementadosZSBE200 (Esfér

- Page 700 and 701:

GBrocasLas Brocas Korloy ofrecen so

- Page 702 and 703:

GBrocas IndexablesTipo Código Form

- Page 704 and 705:

Brocas4GGInsertos para BarrenadoIns

- Page 706 and 707:

GInformación Técnica para KING DR

- Page 708 and 709:

GInformación Técnica para KING DR

- Page 710 and 711:

Brocas10GG12.012.513.013.514.014.51

- Page 712 and 713:

Brocas12GGBrocas IndexablesKING DRI

- Page 714 and 715:

Brocas14GGBrocas IndexablesKING DRI

- Page 716 and 717:

Brocas16GGBrocas IndexablesKING DRI

- Page 718 and 719:

GInformación Técnica para TPDBTPD

- Page 720 and 721:

GInformación Técnica para TPDBInf

- Page 722 and 723:

GTPDBTPDB-3D(mm)CódigoØD Ød1 Ød

- Page 724 and 725:

GTPDBTPDB-8D(mm)CódigoØD Ød1 Ød

- Page 726 and 727:

GInsertos Disponibles para WPDCComo

- Page 728 and 729:

GBrocas para Centro (Broca Central)

- Page 730 and 731:

GWPDCWPDC-5D/6.5D/8D(Cartucho C / 1

- Page 732 and 733:

GInformación Técnica para Mach Dr

- Page 734 and 735:

GInformación Técnica para Mach Dr

- Page 736 and 737:

GMatch DrillsMSD-P/M/K/NTerminologi

- Page 738 and 739:

GMatch DrillsMSD-P/M/K/NTerminologi

- Page 740 and 741:

GMatch DrillsMSDH-P/M/K/NTerminolog

- Page 742 and 743:

GMatch DrillsMSDH-P/M/K/NTerminolog

- Page 744 and 745:

GInformación Técnica para Mach Lo

- Page 746 and 747:

GFormato de orden brocas con chaanS

- Page 748 and 749:

GVulcan DrillVulcan Drill(VZD)-MA,

- Page 750 and 751:

GInformación Técnica para Brocas

- Page 752 and 753:

GBrocas de CarburoBrocas de Carburo

- Page 754 and 755:

GBroca SolidaBroca SolidaCondición

- Page 756 and 757:

GInformación Técnica para Gun Dri

- Page 758 and 759:

GInformación Técnica para Gun Dri

- Page 760 and 761:

GGun DrilGun Dril-KGDSDe Labio Simp

- Page 762 and 763:

GInformación Técnica para Rimas I

- Page 764 and 765:

GInformación Técnica para Rimas I

- Page 766 and 767:

GRimas IndexablesIndexable Rimas-IR

- Page 768 and 769:

GRimas para conosRimas para ConoCon

- Page 770 and 771:

Brocas70GGRimasRimas para conos7.08

- Page 772 and 773:

G Brocas G72

- Page 774 and 775:

HInformación Tecnica para Herramie

- Page 776 and 777:

HPlaca cuadradaRBToleranciaal pande

- Page 778 and 779:

HBarra Redonda, AnillosSRBarra Redo

- Page 780 and 781:

HerramientasCementadas8HHSquare Bit

- Page 782 and 783:

HerramientasCementadas10HHCuchillas

- Page 784 and 785:

HCortadores CementadosCortadores Ce

- Page 786 and 787:

HFormato Orden EspecialCortador dov

- Page 788 and 789:

ISerie DBT2 Face Constrained BT typ

- Page 790 and 791:

IHerramientas con Sistema HSKHSK Ti

- Page 792 and 793:

IInformación Tecnica para Chuck de

- Page 794 and 795:

IChucks de Expansión Hidráulica S

- Page 796 and 797:

IChuck para Fresado de Poder NPMDBT

- Page 798 and 799:

IInformación Técnica para HPMSist

- Page 800 and 801:

IColletCollet Recto C(mm)Código Ø

- Page 802 and 803:

IInformación Técnica para DSCCara

- Page 804 and 805:

IDSCBT-DSCMAS403-BTCódigo ØD L Ø

- Page 806 and 807:

ISerie Collet ChuckCaracterísticas

- Page 808 and 809:

ISeries Collet ChuckBT-SDCMAS403-BT

- Page 810 and 811:

ISerie Collet ChuckMT-SDC(mm)Códig

- Page 812 and 813:

ISerie Collet ChuckBT-SDC/SMAS403-B

- Page 814 and 815:

ISerie Collet ChuckHPSBalanced G6.3

- Page 816 and 817:

ISerie Collet ChuckHSK-HDCBalancead

- Page 818 and 819:

ISerie Chuck Collet (Pinzas)GER Col

- Page 820 and 821:

ICollet Chuck de Alta VerlocidadCol

- Page 822 and 823:

ICollet Chuck Delgado para Alta Vel

- Page 824 and 825:

ICono MorseBT-MTAMAS403-BTFig. 1 Fi

- Page 826 and 827:

IConos con Sujeción LateralHSK-SLA

- Page 828 and 829:

I Cono con Sujeción LateralHSK-SLW

- Page 830 and 831:

ICono con Sujeción LateralSK-SLW (

- Page 832 and 833:

IHerramienta para MachuelosBT-DTNMA

- Page 834 and 835:

IChucks Synchro-TapHSK-SDTDIN69893-

- Page 836 and 837:

IChucks Synchro-TapBoquilla KT para

- Page 838 and 839:

ICono para FresadoBT-FMAMAS403-BTFi

- Page 840 and 841:

I Cono para FresadoDBT-FMCMAS403-BT

- Page 842 and 843:

ICono para FresadoBT-FMCMAS403-BTFi

- Page 844 and 845:

ICono para Cortadores LateralesPart

- Page 846 and 847:

I Herramienta BalanceadaBT-DBC(Cono

- Page 848 and 849:

IPara mandrinado en desbaste TBC/ P

- Page 850 and 851:

ISerie Micro BoreadoCaracterística

- Page 852 and 853:

ISerie Micro BoreadoBT-SMB Micro Ba

- Page 854 and 855:

ISerie Micro BoreadoBBTipo Barra Bo

- Page 856 and 857:

IMicro Barra para/Boreado FBHBT-FBH

- Page 858 and 859:

ICartucho para/Boreador FBHFBB Cart

- Page 860 and 861:

IMicro Barra para/Boreado FBHS-FBH

- Page 862 and 863:

ICuerpo y Juego para/BoreadorBT-FMD

- Page 864 and 865:

ICono para/Boquilla con Refrigeraci

- Page 866 and 867:

ICabeza Angular Suspende la ventaCa

- Page 868 and 869:

ICabezas Angulares Suspende la vent

- Page 870 and 871:

ISistema ModularDPT, HSK, BT-MD EXT

- Page 872 and 873:

I Sistema ModularHSK-MDDIN 69893-1,

- Page 874 and 875:

I Sistema ModularBT-MD(mm)Código

- Page 876 and 877:

I Sistema ModularRDC(mm)Código Ød

- Page 878 and 879:

I Sistema ModularMD-NPU(mm)CódigoD

- Page 880 and 881:

ISistema ModularMD-SMH• Longitud

- Page 882 and 883:

I ProductosBlank Tool (BLK)(mm)Cód

- Page 884 and 885:

Sistema deHerramientas98IIProductos

- Page 886 and 887:

IProductosKCP(mm)CódigoConoDiam.Co

- Page 888 and 889:

IComparativo de Sistema de Herramie

- Page 890 and 891:

JEj. Maquinado IndustrialMaquinado

- Page 892 and 893:

JEj. Maquinado IndustrialIndustria

- Page 894 and 895:

JEj. Maquinado IndustrialInd. Marit

- Page 896 and 897:

JEj. Maquinado IndustrialIndustria

- Page 898 and 899:

JEj. Maquinado IndustrialTuberiasMa

- Page 900 and 901:

JEj. Maquinado IndustrialRodamiento

- Page 902 and 903:

JEj. Maquinado IndustrialIndustria

- Page 904 and 905:

JEj. Maquinado IndustrialIndustria

- Page 906 and 907:

JEj. Maquinado IndustrialCuchillasA

- Page 908 and 909:

JEj. Maquinado industria Automotriz

- Page 910 and 911:

JEj. Maquinado industria Automotriz

- Page 912 and 913:

JEj. Maquinado industria Automotriz

- Page 914 and 915:

JEj. Maquinado industria Automotriz

- Page 916 and 917:

JEj. Maquinado industria Automotriz

- Page 918 and 919:

JEj. Maquinado industria Automotriz

- Page 920 and 921:

Partes Partes2KK PartesPlacaaangulo

- Page 922 and 923:

Partes Partes4KK PartesCBA063-3IN/M

- Page 924 and 925:

K PartesTornilloGeometriaCodigoFTNB

- Page 926 and 927:

K PartesPartes PartesK8

- Page 928 and 929:

InformaciónGeneral2LLInformación

- Page 930 and 931:

InformaciónGeneral4LInformación g

- Page 932 and 933:

LInformación general Simbología d

- Page 934 and 935:

LInformación general Tabla de Dure

- Page 936 and 937:

LInformación general Información

- Page 938 and 939:

LTorneadoForma del Inserto & termin

- Page 940 and 941:

LTorneadoCondición de Corte El tra

- Page 942 and 943:

LTorneadoÁngulo de Corte FinalAfec

- Page 944 and 945:

L TorneadoLocalización de AveriasF

- Page 946 and 947:

LFresadoForma y Codigo del Cortador

- Page 948 and 949:

LFresadoAceroFundicionPieza detraba

- Page 950 and 951:

L Tapers Cono Morse (tipo espiga)MT

- Page 952 and 953:

LTapers DIN 69871Zanco # D1 D2 D3 D

- Page 954 and 955:

LEndmillsVentajas de la Longitud de

- Page 956 and 957:

LBarrenadoForma y nombre de las Bro

- Page 958 and 959:

LBarrenadoFallas y SolucionesSoluci

- Page 960 and 961:

LBarrenadoPrecauciones Selección d

- Page 962 and 963:

LInformación General Comparación

- Page 964 and 965:

LInformación General Tabla Grados

- Page 966 and 967:

LInformación General Tabla Compara

- Page 968 and 969:

LInformación General IInformación

- Page 970 and 971:

MInformación de ProductosGradosCod

- Page 972 and 973:

MInformación de ProductosCen-millN

- Page 974 and 975:

Indice2NN IndiceAD(M)4000/5000M03AD

- Page 976 and 977:

N IndiceDE FF G HH IDSC I 17~18FMAC

- Page 978 and 979:

Indice6NN IndicePMTFNR/LB110MTGNR/L

- Page 980 and 981:

Indice8NN IndiceSEKR-SME15SEKR-X35E

- Page 982 and 983:

Indice10NN IndiceTPGT-HFPB61TPGWB82