You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

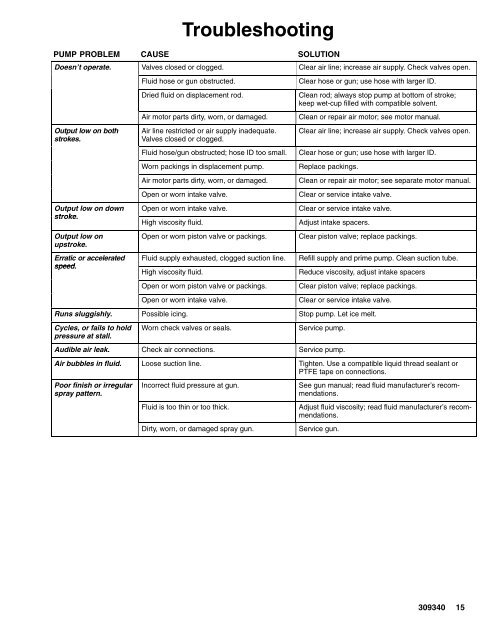

Troubleshooting<br />

PUMP PROBLEM CAUSE SOLUTION<br />

Doesn’t operate. Valves closed or clogged. Clear air line; increase air supply. Check valves open.<br />

Output low on both<br />

strokes.<br />

Output low on down<br />

stroke.<br />

Output low on<br />

upstroke.<br />

Erratic or accelerated<br />

speed.<br />

Fluid hose or gun obstructed.<br />

Dried fluid on displacement rod.<br />

Air motor parts dirty, worn, or damaged.<br />

Air line restricted or air supply inadequate.<br />

Valves closed or clogged.<br />

Fluid hose/gun obstructed; hose ID too small.<br />

Worn packings in displacement pump.<br />

Air motor parts dirty, worn, or damaged.<br />

Open or worn intake valve.<br />

Open or worn intake valve.<br />

High viscosity fluid.<br />

Open or worn piston valve or packings.<br />

Fluid supply exhausted, clogged suction line.<br />

High viscosity fluid.<br />

Open or worn piston valve or packings.<br />

Open or worn intake valve.<br />

Clear hose or gun; use hose with larger ID.<br />

Clean rod; always stop pump at bottom of stroke;<br />

keep wet-cup filled with compatible solvent.<br />

Clean or repair air motor; see motor manual.<br />

Clear air line; increase air supply. Check valves open.<br />

Clear hose or gun; use hose with larger ID.<br />

Replace packings.<br />

Clean or repair air motor; see separate motor manual.<br />

Clear or service intake valve.<br />

Clear or service intake valve.<br />

Adjust intake spacers.<br />

Clear piston valve; replace packings.<br />

Refill supply and prime pump. Clean suction tube.<br />

Reduce viscosity, adjust intake spacers<br />

Clear piston valve; replace packings.<br />

Clear or service intake valve.<br />

Runs sluggishly. Possible icing. Stop pump. Let ice melt.<br />

Cycles, or fails to hold<br />

pressure at stall.<br />

Worn check valves or seals.<br />

Service pump.<br />

Audible air leak. Check air connections. Service pump.<br />

Air bubbles in fluid. Loose suction line. Tighten. Use a compatible liquid thread sealant or<br />

PTFE tape on connections.<br />

Poor finish or irregular<br />

spray pattern.<br />

<strong>Inc</strong>orrect fluid pressure at gun.<br />

Fluid is too thin or too thick.<br />

Dirty, worn, or damaged spray gun.<br />

See gun manual; read fluid manufacturer’s recommendations.<br />

Adjust fluid viscosity; read fluid manufacturer’s recommendations.<br />

Service gun.<br />

309340 15