Manitowoc Flockeneisbereiter RF 0399 A - Kälte Berlin

Manitowoc Flockeneisbereiter RF 0399 A - Kälte Berlin

Manitowoc Flockeneisbereiter RF 0399 A - Kälte Berlin

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

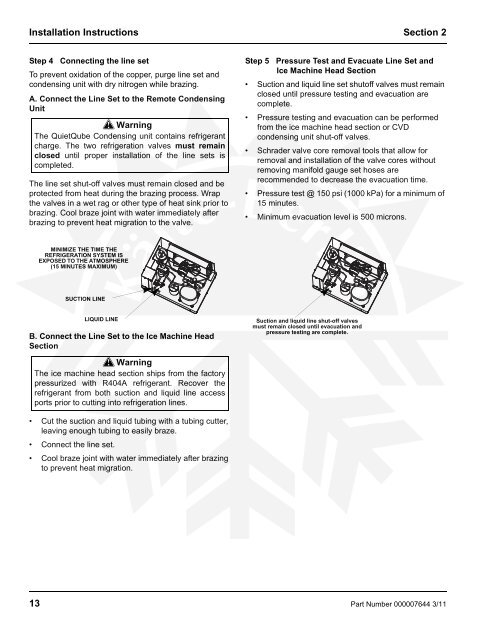

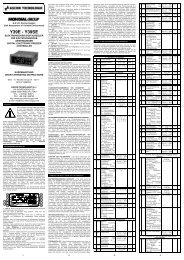

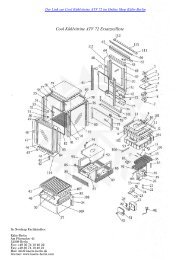

Installation Instructions Section 2<br />

Step 4 Connecting the line set<br />

To prevent oxidation of the copper, purge line set and<br />

condensing unit with dry nitrogen while brazing.<br />

A. Connect the Line Set to the Remote Condensing<br />

Unit<br />

! Warning<br />

The QuietQube Condensing unit contains refrigerant<br />

charge. The two refrigeration valves must remain<br />

closed until proper installation of the line sets is<br />

completed.<br />

The line set shut-off valves must remain closed and be<br />

protected from heat during the brazing process. Wrap<br />

the valves in a wet rag or other type of heat sink prior to<br />

brazing. Cool braze joint with water immediately after<br />

brazing to prevent heat migration to the valve.<br />

Step 5 Pressure Test and Evacuate Line Set and<br />

Ice Machine Head Section<br />

• Suction and liquid line set shutoff valves must remain<br />

closed until pressure testing and evacuation are<br />

complete.<br />

• Pressure testing and evacuation can be performed<br />

from the ice machine head section or CVD<br />

condensing unit shut-off valves.<br />

• Schrader valve core removal tools that allow for<br />

removal and installation of the valve cores without<br />

removing manifold gauge set hoses are<br />

recommended to decrease the evacuation time.<br />

• Pressure test @ 150 psi (1000 kPa) for a minimum of<br />

15 minutes.<br />

• Minimum evacuation level is 500 microns.<br />

MINIMIZE THE TIME THE<br />

REFRIGERATION SYSTEM IS<br />

EXPOSED TO THE ATMOSPHERE<br />

(15 MINUTES MAXIMUM)<br />

SUCTION LINE<br />

LIQUID LINE<br />

B. Connect the Line Set to the Ice Machine Head<br />

Section<br />

Suction and liquid line shut-off valves<br />

must remain closed until evacuation and<br />

pressure testing are complete.<br />

! Warning<br />

The ice machine head section ships from the factory<br />

pressurized with R404A refrigerant. Recover the<br />

refrigerant from both suction and liquid line access<br />

ports prior to cutting into refrigeration lines.<br />

• Cut the suction and liquid tubing with a tubing cutter,<br />

leaving enough tubing to easily braze.<br />

• Connect the line set.<br />

• Cool braze joint with water immediately after brazing<br />

to prevent heat migration.<br />

13 Part Number 000007644 3/11