Drilling, Cutting & Grinding Perçage, découpage ... - NAPA Auto Parts

Drilling, Cutting & Grinding Perçage, découpage ... - NAPA Auto Parts

Drilling, Cutting & Grinding Perçage, découpage ... - NAPA Auto Parts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DRILLING, CUTTING & GRINDING<br />

Abrasive Discs<br />

Brush Safety<br />

CAUTION<br />

Abrasive users and others in<br />

area must wear goggles or face<br />

shields over safety glasses.<br />

DRILLING, CUTTING & GRINDING<br />

Brush Usage Recommendations<br />

Inspection and Storage: Upon receipt, inspect brushes for damage, rust<br />

and deterioration. Store in original containers in a clean, dry location. Do<br />

not allow distortion of brush filaments/components or foreign matter to<br />

become lodged in brush face.<br />

Dust and Fumes: Wear respiratory protection against this hazard (see<br />

ANSI Z88.2).<br />

Pressure: Avoid excessive pressure when using a wire-filled power<br />

brush. Excessive pressure causes over-bending of the filaments and heat<br />

build-up resulting in filament breakage, rapid dulling and reduced brush<br />

life. Instead of greater pressure on a brush, it is suggested that you try:<br />

1) A brush with a more aggressive cutting action (increased wire size,<br />

decreased filament length, change to a different brush type, i.e. knot type<br />

instead of crimped wire type), or 2) Higher speed (increased R.P.M.,<br />

increased brush diameter).<br />

Safety Information: Many brush manufacturers mark some safety<br />

warning, recommendations and usage restrictions directly on the product.<br />

It is not always practical to include even the most limited safety<br />

information on the brush itself. Therefore, before operating the brush,<br />

the operator must read and follow all instructions supplied in or on the<br />

product container, as well as those marked on the product itself.<br />

Application Information - Type or Wire<br />

Straight: Twisted tough, provides maximum impact action for severe<br />

applications.<br />

Crimped: Provides a continuous brushing action and a relatively<br />

finefinish.<br />

Steel: Used in most brushes and made with an extremely high degree of<br />

fatigue resistance for longer life.<br />

Stainless Steel: Type 302 stainless for non-contamination on brushing<br />

stainless and other non-ferrous metals.<br />

Wire Size: For maximum brush life, always select the smallest wire size<br />

that will perform your operation.<br />

Important Note: Never exceed the Manufacturer’s recommended<br />

MAXIMUM SAFE FREE SPEED R.P.M. (MSFS) rating of the brush.<br />

Operation Adjustments Chart<br />

Brush works too<br />

slowly<br />

Increase surface speed by increasing brush<br />

diameter or RPM<br />

234<br />

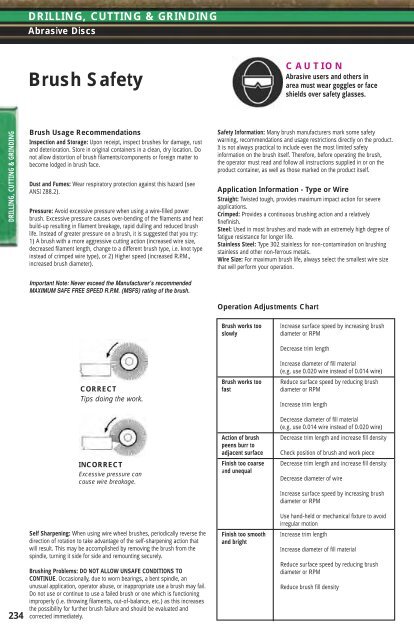

CORRECT<br />

Tips doing the work.<br />

INCORRECT<br />

Excessive pressure can<br />

cause wire breakage.<br />

Self Sharpening: When using wire wheel brushes, periodically reverse the<br />

direction of rotation to take advantage of the self-sharpening action that<br />

will result. This may be accomplished by removing the brush from the<br />

spindle, turning it side for side and remounting securely.<br />

Brushing Problems: DO NOT ALLOW UNSAFE CONDITIONS TO<br />

CONTINUE. Occasionally, due to worn bearings, a bent spindle, an<br />

unusual application, operator abuse, or inappropriate use a brush may fail.<br />

Do not use or continue to use a failed brush or one which is functioning<br />

improperly (i.e. throwing filaments, out-of-balance, etc.) as this increases<br />

the possibility for further brush failure and should be evaluated and<br />

corrected immediately.<br />

Brush works too<br />

fast<br />

Action of brush<br />

peens burr to<br />

adjacent surface<br />

Finish too coarse<br />

and unequal<br />

Finish too smooth<br />

and bright<br />

Decrease trim length<br />

Increase diameter of fill material<br />

(e.g. use 0.020 wire instead of 0.014 wire)<br />

Reduce surface speed by reducing brush<br />

diameter or RPM<br />

Increase trim length<br />

Decrease diameter of fill material<br />

(e.g. use 0.014 wire instead of 0.020 wire)<br />

Decrease trim length and increase fill density<br />

Check position of brush and work piece<br />

Decrease trim length and increase fill density<br />

Decrease diameter of wire<br />

Increase surface speed by increasing brush<br />

diameter or RPM<br />

Use hand-held or mechanical fixture to avoid<br />

irregular motion<br />

Increase trim length<br />

Increase diameter of fill material<br />

Reduce surface speed by reducing brush<br />

diameter or RPM<br />

Reduce brush fill density