- Page 1 and 2:

2015

- Page 3 and 4:

simply reliable Une nouvelle impres

- Page 5 and 6:

Table de Contenu 004 - 007 Index 00

- Page 7 and 8:

TABLE DE CONTENU - TARAUDS Pointe S

- Page 9 and 10:

TABLE DE CONTENU - ALÉSOIRS Carbur

- Page 11 and 12:

Indices Visuel- Forets Head Style:

- Page 13 and 14:

Indices Visuel- Forets Tool Materia

- Page 15 and 16:

Indices Visuel- Forets R10A R15A R1

- Page 17 and 18:

Indices Visuel- Forets A125 QC0860P

- Page 19 and 20:

Indices Visuel- Forets SPR-120 SPRG

- Page 21 and 22:

FORETS HYDRA Tête de foret Hydra R

- Page 23 and 24:

FORETS HYDRA d 1 Øh 7 Inch d 1 Øh

- Page 25 and 26:

FORETS HYDRA d 1 Øh 7 Inch d 1 Øh

- Page 27 and 28:

FORETS HYDRA Corps Hydra 3xD H853 Q

- Page 29 and 30:

Hydra Head d 1 Ø Hydra Head R950 E

- Page 31 and 32:

Hydra Head d 1 Ø Hydra Head R950 E

- Page 33 and 34:

FORETS HYDRA Corps Hydra 8xD H858 Q

- Page 35 and 36:

Hydra Head d 1 Ø Hydra Head R950 E

- Page 37 and 38:

R520 CDX FORET EN CARBURE MONOBLOC

- Page 39 and 40:

R458 MPX FORET EN CARBURE MONOBLOC

- Page 41 and 42:

MPX FORET EN CARBURE MONOBLOC d 1

- Page 43 and 44:

R510 CDX FORET EN CARBURE MONOBLOC

- Page 45 and 46:

MPX FORET EN CARBURE MONOBLOC Multi

- Page 47 and 48:

MPX FORET EN CARBURE MONOBLOC d 1

- Page 49 and 50:

MPX FORET EN CARBURE MONOBLOC d 1

- Page 51 and 52:

Multi-application, série courte A5

- Page 53 and 54:

ADX FORET SÉRIE COURTE d 1 Øh 8 I

- Page 55 and 56:

PFX FORET SÉRIE COURTE d 1 Øh 8 I

- Page 57 and 58:

PFX FORET SÉRIE COURTE d 1 Øh 8 I

- Page 59 and 60:

ADX FORET SÉRIE STANDARD d 1 Øh 8

- Page 61 and 62:

ADX FORET LONGUEUR LONGUE Multi-app

- Page 63 and 64:

PFX FORET SÉRIE STANDARD Série st

- Page 65 and 66:

d 1 Øh 8 PFX FORET SÉRIE STANDARD

- Page 67 and 68:

PFX FORET SÉRIE LONGUE d 1 Øh 8 I

- Page 69 and 70:

PFX FORET SÉRIE EXTRA LONGUE Séri

- Page 71 and 72:

PFX FORET SÉRIE EXTRA LONGUE d 1

- Page 73 and 74:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 75 and 76:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 77 and 78:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 79 and 80:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 81 and 82:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 83 and 84:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 85 and 86:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 87 and 88:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 89 and 90:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 91 and 92:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 93 and 94:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 95 and 96:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 97 and 98:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 99 and 100:

Série standard à hélice rapide F

- Page 101 and 102:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 103 and 104:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø mm d

- Page 105 and 106:

d 1 Ø “/Nr./letter d 1 decimal I

- Page 107 and 108:

FORET SÉRIE STANDARD JOBBER DRILL

- Page 109 and 110:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 111 and 112:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 113 and 114:

R88CO - Fractionnelles R89CO - Num

- Page 115 and 116:

Série courte à usage général FO

- Page 117 and 118:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 119 and 120:

d 1 Øh 8 Inch d 1 Øh 8 mm FORET S

- Page 121 and 122:

FORET SÉRIE COURTE SCREW MACHINE D

- Page 123 and 124:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 125 and 126:

d 1 Ø mm d 1 decimal Inch FORET S

- Page 127 and 128:

d 1 Ø “/Nr. d 1 decimal Inch FOR

- Page 129 and 130:

FORET SÉRIE COURTE AU COBALT COBAL

- Page 131 and 132:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 133 and 134:

Série longue à usage général FO

- Page 135 and 136:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 137 and 138:

Série longue à usage général, m

- Page 139 and 140:

Série longue à hélice serrée FO

- Page 141 and 142:

d 1 Ø “/Nr. d 1 decimal Inch FOR

- Page 143 and 144:

Série longue à usage intensif FOR

- Page 145 and 146:

Série extra longue à usage géné

- Page 147 and 148:

FORET SÉRIE EXTRA LONGUE EXTRA LEN

- Page 149 and 150:

d 1 Ø Inch d 1 decimal Inch d 1 Ø

- Page 151 and 152:

d 1 Ø Inch d 1 decimal Inch d 1 Ø

- Page 153 and 154:

d 1 Ø Inch d 1 decimal Inch FORET

- Page 155 and 156:

FORET AÉRONAUTIQUE RALLONGÉ AIRCR

- Page 157 and 158:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 159 and 160:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 161 and 162:

d 1 Ø Inch d 1 d 1 decimal Inch FO

- Page 163 and 164:

d 1 Ø Inch d 1 decimal Inch FORET

- Page 165 and 166:

Queue conique à usage général, m

- Page 167 and 168:

d 1 Øh 8 mm d 1 decimal Inch l 2 F

- Page 169 and 170:

d 1 Øh 8 Inch d 1 Øh 8 mm d 1 dec

- Page 171 and 172:

d 1 Øh 8 mm d 1 decimal Inch l 2 l

- Page 173 and 174:

d 1 Ø Inch d 1 decimal Inch FORET

- Page 175 and 176:

d 1 Øh 8 Inch d 1 Øh 8 mm d 1 dec

- Page 177 and 178:

d 1 Ø Inch d 1 decimal Inch FORET

- Page 179 and 180:

d 1 Ø Inch d 1 decimal Inch FORET

- Page 181 and 182:

FORET À QUEUE RÉDUITE REDUCED SHA

- Page 183 and 184:

d 1 Ø “/Nr./letter d 1 decimal I

- Page 185 and 186:

FORET EN CARBURE MONOBLOC SOLID CAR

- Page 187 and 188:

d 1 Ø Inch d 1 Ø Nr. d 1 Ø lette

- Page 189 and 190:

FORET EN CARBURE MONOBLOC SOLID CAR

- Page 191 and 192:

FORET SPÉCIALISÉ SPECIAL PURPOSE

- Page 193 and 194:

FORET EN CARBURE MONOBLOC SOLID CAR

- Page 195 and 196:

FORET SPÉCIALISÉ SPECIAL PURPOSE

- Page 197 and 198:

Forets à queue hexagonale filetée

- Page 199 and 200:

JEU DE FORETS SÉRIE STANDARD JOBBE

- Page 201 and 202:

JEU DE FORETS SÉRIE STANDARD JOBBE

- Page 203 and 204:

JEU DE FORETS SÉRIE STANDARD JOBBE

- Page 205 and 206:

A095 JEU DE FORETS SÉRIE STANDARD

- Page 207 and 208:

High Helix Jobber Length Set JEU DE

- Page 209 and 210:

JEU DE FORETS SÉRIE STANDARD JOBBE

- Page 211 and 212:

JEU DE FORETS SÉRIE COURTE SCREW M

- Page 213 and 214:

JEUX DE FORETS SÉRIE COURTE SCREW

- Page 215 and 216:

JEU DE FORETS SÉRIE LONGUE TAPER L

- Page 217 and 218:

215

- Page 219 and 220:

Indices Visuel-Taraud Thread Form:

- Page 221 and 222:

Indices Visuel-Taraud Coolant Throu

- Page 223 and 224:

Indices Visuel-Taraud Coolant Throu

- Page 225 and 226:

Indices Visuel-Taraud 1595 (UNC) 15

- Page 227 and 228:

Indices Visuel-Taraud 1534NE 1534NE

- Page 229 and 230:

Indices Visuel-Taraud 1548 (NPT) 1/

- Page 231 and 232:

Index des numéros de liste - Tarau

- Page 233 and 234:

Multi-Application, Entrée Intermé

- Page 235 and 236:

Multi-Application, Entrée Intermé

- Page 237 and 238:

MPX TARAUD POINTE SPIRALE SPIRAL PO

- Page 239 and 240:

Multi-Application, Entrée Intermé

- Page 241 and 242:

TARAUD POINTE SPIRALE SPIRAL POINT

- Page 243 and 244:

TARAUD POINTE SPIRALE SPIRAL POINT

- Page 245 and 246:

Pour la fonte, Entrée Intermédiai

- Page 247 and 248:

1676AP 1678 APPLIX TARAUD HÉLICOÏ

- Page 249 and 250:

EX20 EX30 TARAUD HÉLICOÏDAL (45°

- Page 251 and 252:

1677AP TARAUD HÉLICOÏDAL (48°-52

- Page 253 and 254:

EX006H TARAUD HÉLICOÏDAL (45°) S

- Page 255 and 256:

Multi-Application, Entrée Semi-Fin

- Page 257 and 258:

TARAUD HÉLICOÏDAL (16°-19°) SPI

- Page 259 and 260:

TARAUD PAR DÉFORMATION THREAD FORM

- Page 261 and 262:

TARAUD PAR DÉFORMATION THREAD FORM

- Page 263 and 264:

TARAUD POUR TUYAUTERIE, Flute DROIT

- Page 265 and 266:

EX40 TARAUD POUR TUYAUTERIE, Flute

- Page 267 and 268:

TARAUD À MAIN HAND TAP Usage gén

- Page 269 and 270:

l 1 l 2 TARAUD À MAIN HAND TAP d 2

- Page 271 and 272:

TARAUD À MAIN HAND TAP Usage gén

- Page 273 and 274:

TARAUD À MAIN HAND TAP Nominal l 1

- Page 275 and 276:

Nominal l 1 l 2 d 2 Ø mm TARAUD À

- Page 277 and 278:

Usage général E061 E071 Les tarau

- Page 279 and 280:

Usage général 1700(M) TARAUD À M

- Page 281 and 282:

Usage général, surdimensionné 15

- Page 283 and 284:

Pour la fonte TARAUD À MAIN HAND T

- Page 285 and 286:

Pour la fonte, Semi-Bottoming E504

- Page 287 and 288:

Type réduit, fractionnelles 1585 1

- Page 289 and 290:

TARAUD POINTE SPIRALE SPIRAL POINT

- Page 291 and 292:

Type non réduit, pour vis mécaniq

- Page 293 and 294:

Type non réduit, fractionnelles TA

- Page 295 and 296:

TARAUD POINTE SPIRALE SPIRAL POINT

- Page 297 and 298:

Hélice normale de 30º 1582 1586 -

- Page 299 and 300:

Hélice de 40°, usage intensif 159

- Page 301 and 302:

TARAUD PAR DÉFORMATION THREAD FORM

- Page 303 and 304:

Rol-Form / rainures de lubrificatio

- Page 305 and 306:

TARAUD PAR DÉFORMATION THREAD FORM

- Page 307 and 308:

E710 E721 TARAUD POUR TUYAUTERIE PI

- Page 309 and 310:

1544 TARAUD POUR TUYAUTERIE PIPE TA

- Page 311 and 312:

TARAUD POUR TUYAUTERIE PIPE TAP Flu

- Page 313 and 314:

Filets interrompus, NPT E711 TARAUD

- Page 315 and 316:

Flute hélicoïdale, Dryseal, NPTF

- Page 317 and 318:

E712 TARAUD POUR TUYAUTERIE PIPE TA

- Page 319 and 320:

TARAUD POUR TUYAUTERIE PIPE TAP Tar

- Page 321 and 322:

Insert de filetage, STI 1572 1578 -

- Page 323 and 324:

Type à écrou (Nut Tap) TARAUD SP

- Page 325 and 326:

Foret taraudeur 1994 TARAUD SPÉCIA

- Page 327 and 328:

TARAUD SPÉCIALISÉ SPECIAL PURPOSE

- Page 329 and 330:

DIVERS MISCELLANEOUS Tourne-à-gauc

- Page 331 and 332:

DIVERS MISCELLANEOUS Jeu de foret e

- Page 333 and 334:

Indices Visuel- Filière 2010(UNS)

- Page 335 and 336:

Index des numéros de liste - Fili

- Page 337 and 338:

FILIÈRE d 2 Ø Inch h 1 Pack Qty 2

- Page 339 and 340:

FILIÈRE d 2 Ø Inch h 1 Pack Qty 2

- Page 341 and 342:

FILIÈRE d 1 nom mm d 2 Ø Inch UNC

- Page 343 and 344:

FILIÈRE Rond, ajustable et fendu F

- Page 345 and 346:

FILIÈRE Filière hexagonne pour re

- Page 347 and 348:

FILIÈRE Filière hexagonne pour re

- Page 349 and 350:

Porte-filière, poignée droite 130

- Page 351 and 352:

Indices Visuel- Forets 349

- Page 353 and 354:

Indices Visual Visuel- Index - Fore

- Page 355 and 356:

Indices Visual Visuel- Index - Fore

- Page 357 and 358:

Index des numéros de liste - Frais

- Page 359 and 360:

Fraise de finition en carbure monob

- Page 361 and 362:

Fraise de finition en carbure monob

- Page 363 and 364:

Fraise de finition Multi-Flutes en

- Page 365 and 366:

Fraise de finition en carbure monob

- Page 367 and 368:

Fraise de finition en carbure monob

- Page 369 and 370:

E3302M Fraise de finition en carbur

- Page 371 and 372:

Fraise de finition en carbure monob

- Page 373 and 374:

Fraise de finition en carbure monob

- Page 375 and 376:

EB6302 EB6302V Fraise de finition e

- Page 377 and 378:

E4304 Fraise de finition en carbure

- Page 379 and 380:

Fraise de finition en carbure monob

- Page 381 and 382:

E6304 Fraise de finition en carbure

- Page 383 and 384:

EB3304M EB3304MV Fraise de finition

- Page 385 and 386:

EB6304 Fraise de finition en carbur

- Page 387 and 388:

d 1 Ø Inch d 1 Ø mm d 2 Øh 6 mm

- Page 389 and 390:

Fraise de finition à 2 flute HSS H

- Page 391 and 392:

963 Fraise de finition à 2 flute a

- Page 393 and 394:

Fraise de finition à 2 flute HSS-P

- Page 395 and 396:

Fraise de finition à 2 flute HSS H

- Page 397 and 398:

930 Fraise de finition à 3 flute H

- Page 399 and 400:

9002 TC9002 Fraise d’ébauchage

- Page 401 and 402:

Fraise d’ébauchage à 4 flute au

- Page 403 and 404:

Fraise de finition à 4 flute HSS H

- Page 405 and 406:

C247 Fraise de finition à 4 flute

- Page 407 and 408:

Longueur longue, bout plat, queue W

- Page 409 and 410:

Fraise de finition à 4 flute HSS H

- Page 411 and 412:

960 Fraise de finition multi-flute

- Page 413 and 414:

Indices Visuel- Alésoirs Tool Mate

- Page 415 and 416:

Index des numéros de liste - Alés

- Page 417 and 418:

ALÉSOIR EN CARBURE APPLICATION APP

- Page 419 and 420:

ALÉSOIR EN CARBURE APPLICATION APP

- Page 421 and 422:

ALÉSOIR EN CARBURE APPLICATION APP

- Page 423 and 424:

d 1 Ø mm l 1 ALÉSOIR AU COBALT AP

- Page 425 and 426:

ALÉSOIR HSS HSS CHUCKING REAMER Al

- Page 427 and 428:

d 1 Ø “/Nr./letter d 1 decimal I

- Page 429 and 430:

ALÉSOIR HSS HSS EXPANSION REAMER A

- Page 431 and 432:

Alésoir machine, queue droite ALÉ

- Page 433 and 434:

B122 ALÉSOIR HSS HSS CAR REAMER Al

- Page 435 and 436:

ALÉSOIR HSS HSS TAPER SHANK CHUCKI

- Page 437 and 438:

ALÉSOIR COBALT COBALT TAPER SHANK

- Page 439 and 440:

Alésoir de structure, queue coniqu

- Page 441 and 442:

Queue conique, - 4 flutes T400 FORE

- Page 443 and 444:

ALÉSOIR HSS HSS ADJUSTABLE HAND RE

- Page 445 and 446:

ALÉSOIR HSS HSS TAPER PIN HAND REA

- Page 447 and 448:

ALÉSOIR HSS HSS HAND TAPER PIPE RE

- Page 449 and 450:

ALÉSOIR HSS HSS HAND REAMER d 1 Ø

- Page 451 and 452:

Indices Visuel - Fraises Fraises à

- Page 453 and 454:

Indices Visuel - Fraises Fraises à

- Page 455 and 456:

Index des numéros de liste Fraises

- Page 457 and 458:

Fraise, queue droite, 1 flute 4603

- Page 459 and 460:

Fraise, queue droite, 4 flutes 4602

- Page 461 and 462:

Queue droite, 3 flutes FRAISE HSS H

- Page 463 and 464:

Queue droite, 3 flutes G136 FRAISE

- Page 465 and 466:

Queue droite, 3 flute G570 FRAISE A

- Page 467 and 468:

FRAISE HSS HSS COUNTERSINK Queue dr

- Page 469 and 470:

Queue conique, 3 flutes FRAISE HSS

- Page 471 and 472:

FRAISE HSS HSS COUNTERSINK Queue dr

- Page 473 and 474:

FRAISE À CHANFREINER HSS HSS COUNT

- Page 475 and 476:

FRAISE À CHANFREINER HSS HSS TAPER

- Page 477 and 478:

pilot Ø Inch d 1 Ø Inch FRAISE À

- Page 479 and 480:

ARRACHE-VIS 1800 1815 1816 DIVERS M

- Page 481 and 482:

DIVERS MISCELLANEOUS MANCHONS ET CH

- Page 483 and 484:

Technical Section - Icon Descriptio

- Page 485 and 486:

Technical Section - Icon Descriptio

- Page 487 and 488: Technical Section - Icon Descriptio

- Page 489 and 490: Technical Section - Icon Descriptio

- Page 491 and 492: Technical Section - General Tool Ma

- Page 493 and 494: Technical Section - General Surface

- Page 495 and 496: Technical Section - General Decimal

- Page 497 and 498: Technical Section - General Industr

- Page 499 and 500: Technical Section - Drilling (CONTI

- Page 501 and 502: Technical Section - Drilling Hole S

- Page 503 and 504: Technical Section - Drilling - Hydr

- Page 505 and 506: Technical Section - Threading Tap G

- Page 507 and 508: Technical Section - Threading Cutti

- Page 509 and 510: Tapping Technical Data Technical Se

- Page 511 and 512: Technical Section - Threading The l

- Page 513 and 514: Technical Section - Threading SELF-

- Page 515 and 516: Technical Section - Threading TAP D

- Page 517 and 518: Technical Section - Threading Note:

- Page 519 and 520: Technical Section - Threading Tap S

- Page 521 and 522: Technical Section - Threading TAPPI

- Page 523 and 524: Technical Section - Threading Probl

- Page 525 and 526: Technical Section - Threading Troub

- Page 527 and 528: Technical Section - Reaming Reamer

- Page 529 and 530: Technical Section - Reaming Applica

- Page 531 and 532: Technical Section - Reaming Applica

- Page 533 and 534: Technical Section - Counterboring a

- Page 535 and 536: Technical Section - Milling Nomencl

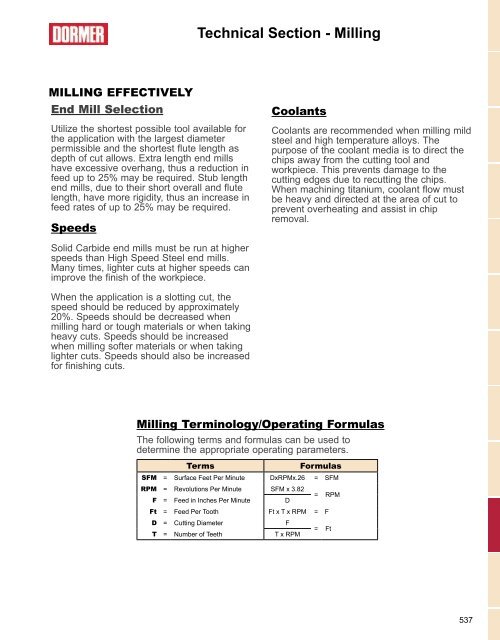

- Page 537: Technical Section - Milling FEATURE

- Page 541 and 542: Technical Section - Milling CUTTING

- Page 543 and 544: Technical Section - Milling S406HA

- Page 545 and 546: Technical Section - Milling MILLING

- Page 547 and 548: Technical Section - General APPLICA

- Page 549 and 550: GROUPE D’APPLICATION POUR MATÉRI

- Page 551 and 552: GROUPE D’APPLICATION POUR MATÉRI

- Page 553 and 554: GROUPE D’APPLICATION POUR MATÉRI

- Page 555 and 556: GROUPE D’APPLICATION POUR MATÉRI

- Page 557 and 558: GROUPE D’APPLICATION POUR MATÉRI

- Page 559 and 560: GROUPE D’APPLICATION POUR MATÉRI

- Page 561 and 562: GROUPE D’APPLICATION POUR MATÉRI

- Page 563 and 564: GROUPE D’APPLICATION POUR MATÉRI

- Page 565 and 566: GROUPE D’APPLICATION POUR MATÉRI

- Page 567 and 568: EDP# E-Code Page # EDP# E-Code Page

- Page 569 and 570: EDP# E-Code Page # EDP# E-Code Page

- Page 571 and 572: EDP# E-Code Page # EDP# E-Code Page

- Page 573 and 574: EDP# E-Code Page # EDP# E-Code Page

- Page 575 and 576: EDP# E-Code Page # EDP# E-Code Page

- Page 577 and 578: EDP# E-Code Page # EDP# E-Code Page

- Page 579 and 580: EDP# E-Code Page # EDP# E-Code Page

- Page 581 and 582: EDP# E-Code Page # EDP# E-Code Page

- Page 583 and 584: EDP# E-Code Page # EDP# E-Code Page

- Page 585 and 586: EDP# E-Code Page # EDP# E-Code Page

- Page 587 and 588: EDP# E-Code Page # EDP# E-Code Page

- Page 589 and 590:

EDP# E-Code Page # EDP# E-Code Page

- Page 591 and 592:

EDP# E-Code Page # EDP# E-Code Page

- Page 593 and 594:

EDP# E-Code Page # EDP# E-Code Page

- Page 595 and 596:

EDP# E-Code Page # EDP# E-Code Page

- Page 597 and 598:

EDP# E-Code Page # EDP# E-Code Page

- Page 599 and 600:

EDP# E-Code Page # EDP# E-Code Page

- Page 601 and 602:

EDP NUMBER INDEX - 0635506 - 101035

- Page 603 and 604:

EDP# E-Code Page # EDP# E-Code Page

- Page 605 and 606:

EDP# E-Code Page # EDP# E-Code Page

- Page 607 and 608:

EDP# E-Code Page # EDP# E-Code Page

- Page 609:

EDP# E-Code Page # EDP# E-Code Page

- Page 612:

. T: 54 (11) 6777-6777 F: 54 (11)