You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Types of Pulley Misalignment:<br />

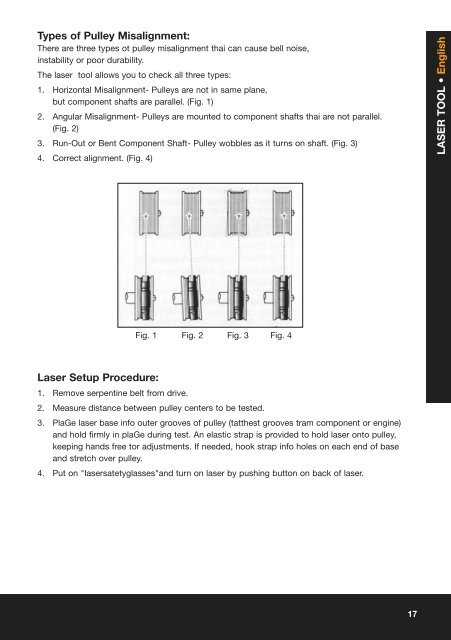

There are three types ot pulley misalignment thai can cause bell noise,<br />

instability or poor durability.<br />

The <strong>laser</strong> <strong>tool</strong> allows you to check all three types:<br />

1. Horizontal Misalignment- Pulleys are not in same plane,<br />

but component shafts are parallel. (Fig. 1)<br />

2. Angular Misalignment- Pulleys are mounted to component shafts thai are not parallel.<br />

(Fig. 2)<br />

3. Run-Out or Bent Component Shaft- Pulley wobbles as it turns on shaft. (Fig. 3)<br />

4. Correct alignment. (Fig. 4)<br />

Fig. 1 Fig. 2 Fig. 3 Fig. 4<br />

Laser Setup Procedure:<br />

1. Remove serpentine belt from drive.<br />

2. Measure distance between pulley centers to be tested.<br />

3. PlaGe <strong>laser</strong> base info outer grooves of pulley (tatthest grooves tram component or engine)<br />

and hold firmly in plaGe during test. An elastic strap is provided to hold <strong>laser</strong> onto pulley,<br />

keeping hands free tor adjustments. If needed, hook strap info holes on each end of base<br />

and stretch over pulley.<br />

4. Put on "Iasersatetyglasses"and turn on <strong>laser</strong> by pushing button on back of <strong>laser</strong>.<br />

17 17<br />

LASER TOOL • English