You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

LASER TOOL • English<br />

18<br />

Measuring for Misalignment:<br />

1. Direct beam toward target pulley.<br />

2. If <strong>laser</strong> beam strikes top (center) of second rib (measured from outside of pulley.<br />

farthest fromm engine) pulleys are aligned.<br />

3. If <strong>laser</strong> beam does not strike top (center) of second rib, see table below for accep<br />

table tolerances.<br />

4. If alignment is within tolerance, reverse direction of beam by moving <strong>laser</strong> to target<br />

pulley and check alignment back to original pulley. If beam is now out of tolerance,<br />

pulleys have angular misalignment.<br />

5. If beam is still within tolerance, proceed to testing other pulleys.<br />

6. If beam is out of tolerance when tested in both directions, pulleys have horizontal<br />

misalignment.<br />

Note - Because crankshaff puffer is difficult to adjust, it should be used as reterence<br />

point tor aligning other pulleys.<br />

Testing for Pulley Run-Out or Bent<br />

Accessory Shaft:<br />

1. The <strong>laser</strong> <strong>tool</strong> on base pulley and aim beam at target pulley.<br />

Rotate target pulley and observe movement of beam.<br />

2. If beam moves outside acceptable tolerance range when rotating target pulley,<br />

pulley runout is unacceptable, component shaft is bent or accessory bearings are<br />

faulty.<br />

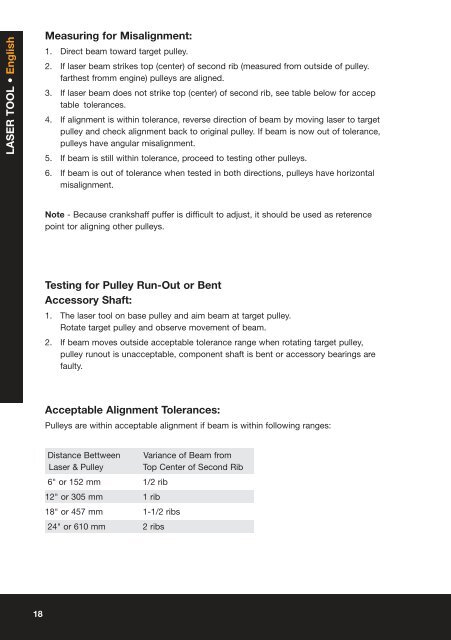

Acceptable Alignment Tolerances:<br />

Pulleys are within acceptable alignment if beam is within following ranges:<br />

Distance Bettween Variance of Beam from<br />

Laser & Pulley Top Center of Second Rib<br />

6" or 152 mm 1/2 rib<br />

12" or 305 mm 1 rib<br />

18" or 457 mm 1-1/2 ribs<br />

24" or 610 mm 2 ribs