- Page 1 and 2: 2018 Writing Instruments • Sticky

- Page 3 and 4: At BIC ® we firmly believe that gl

- Page 5 and 6: BIC ® LIGHTERS & CASES LIGHTERS -

- Page 7 and 8: C Y M K BIC ® BRAND Your name will

- Page 9 and 10: We offer simple, inventive and reli

- Page 11 and 12: BIC ® is always nearby. Classic Ad

- Page 13 and 14: BIC ® owns and maintains 24 princi

- Page 15 and 16: We believe in making a difference A

- Page 17: MILLION PENS COLLECTED SINCE 2011 I

- Page 21 and 22: SCREEN PRINTING PAD PRINTING DIGITA

- Page 23 and 24: BIC Graphic catalogue on the go The

- Page 25 and 26: T’nB ® - our exclusive technolog

- Page 27 and 28: www.bicgraphic.eu 25

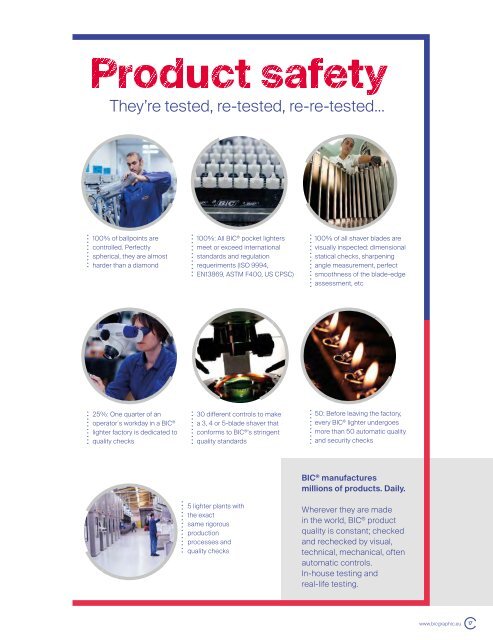

- Page 29 and 30: EN > Worldwide recognised BIC ® ca

- Page 31 and 32: BALLPENS BIC ® WRITING INSTRUMENTS

- Page 33 and 34: Iconic BIC ® Boy is embossed 100%

- Page 35 and 36: BALLPENS BIC ® WRITING INSTRUMENTS

- Page 37 and 38: By the expert in. . . Writing Instr

- Page 39 and 40: EN > Hundreds of colour combination

- Page 41 and 42: BALLPENS BIC ® WRITING INSTRUMENTS

- Page 43 and 44: By the expert in. . . Writing Instr

- Page 45 and 46: EN > The promotional writing instru

- Page 47 and 48: EN > Reliable plunger action mechan

- Page 49 and 50: MIX & MATCH EN > Reliable plunger a

- Page 51 and 52: EN > Luxurious and affordable. Excl

- Page 53 and 54: BALLPENS BIC ® WRITING INSTRUMENTS

- Page 55 and 56: By the expert in. . . Writing Instr

- Page 57 and 58: EN > The Softfeel ® rubberised bar

- Page 59 and 60: EN > MIX & MATCH Modern, flexible,

- Page 61 and 62: EN > 360º full-colour imprint on a

- Page 63 and 64: BALLPENS BIC ® WRITING INSTRUMENTS

- Page 65 and 66: BALLPENS BIC ® WRITING INSTRUMENTS

- Page 67 and 68: MIDA CATÀLEG GENERAL 2016 EN > Mak

- Page 69 and 70:

MIDA CATÀLEG GENERAL 2016 EN / The

- Page 71 and 72:

MIDA CATÀLEG GENERAL 2016 MIDA CAT

- Page 73 and 74:

MIDA CATÀLEG GENERAL 2016 MIX & MA

- Page 75 and 76:

BALLPENS BIC ® WRITING INSTRUMENTS

- Page 77 and 78:

EN > The right size for showing the

- Page 79 and 80:

MIX & MATCH EN > The right size for

- Page 81 and 82:

MIX & MATCH EN > Wide profile and t

- Page 83 and 84:

EN > Compact version ideal to fit a

- Page 85 and 86:

EN > Comfortable design with soft r

- Page 87 and 88:

EN > A versatile design that can ma

- Page 89 and 90:

BALLPENS BIC ® WRITING INSTRUMENTS

- Page 91 and 92:

EN > Four different ink colours in

- Page 93 and 94:

EN > 4 fashion colours in one pen,

- Page 95 and 96:

EN > Colourful fine line version. I

- Page 97 and 98:

EN > 3 standard ink colours, blue,

- Page 99 and 100:

EN > 3 ballpens and 1 mechanical pe

- Page 101 and 102:

METALLIC PENS BIC ® WRITING INSTRU

- Page 103 and 104:

EN > Curved clip design. Metallic f

- Page 105 and 106:

EN > Polished finish with chrome-co

- Page 107 and 108:

EN > Wide-profile, all metal constr

- Page 109 and 110:

EN > Satin chrome and nickel-plated

- Page 111 and 112:

EN > Atlantis ® family welcomes th

- Page 113 and 114:

EN > Stylish ultra-smooth gel pen a

- Page 115 and 116:

EN > Enjoy a smooth writing experie

- Page 117 and 118:

MIDA CATÀLEG GENERAL 2016 EN > Sup

- Page 119 and 120:

HIGHLIGHTERS & MARKERS BIC ® WRITI

- Page 121 and 122:

EN > Ideal for use on dry erase boa

- Page 123 and 124:

EN > Writes on most surfaces. Quick

- Page 125 and 126:

EN > Chisel tip for broad highlight

- Page 127 and 128:

PENCILS BIC ® WRITING INSTRUMENTS

- Page 129 and 130:

A EN > Stay sharp with this first-c

- Page 131 and 132:

EN > Comfortable soft touch rubber

- Page 133 and 134:

MIX & MATCH EN > 360º photo qualit

- Page 135 and 136:

EN > The ideal promotional item sup

- Page 137 and 138:

Add the Möbius loop to your artwor

- Page 139 and 140:

EN > Colouring set of 6 premium pen

- Page 141 and 142:

EN > Set includes: 6 Conté ® colo

- Page 143 and 144:

MIDA CATÀLEG GENERAL 2016 EN > The

- Page 145 and 146:

EN > Retractable ballpen available

- Page 147 and 148:

EN > Retractable ballpen with popul

- Page 149 and 150:

EN > Retractable ballpen with popul

- Page 151 and 152:

EN > Multi-function slim profile ba

- Page 153 and 154:

EN > Multi-function slim-profile ba

- Page 155 and 156:

EN > The pencil comes in a cardboar

- Page 157 and 158:

www.bicgraphic.eu 155

- Page 159 and 160:

EN > Ideal pocket size for mailing

- Page 161 and 162:

EN > Large imprint area in a small

- Page 163 and 164:

EN > Indispensable in any office! M

- Page 165 and 166:

EN > Stand out from the crowd with

- Page 167 and 168:

EN > All BIC ® Sticky Notes Ecolut

- Page 169 and 170:

EN > The most desired office item!

- Page 171 and 172:

EN > Double the impact of your mess

- Page 173 and 174:

EN > This great office set includes

- Page 175 and 176:

EN > Photographic image all around!

- Page 177 and 178:

EN > Make your notes stand out usin

- Page 179 and 180:

QUALITY & SAFETY APPROVED EN > Indi

- Page 181 and 182:

www.bicgraphic.eu 179

- Page 183 and 184:

MIX & MATCH EN > Stand out from the

- Page 185 and 186:

EN > Maximize the impact of your pr

- Page 187 and 188:

EN > Choose a black or white cover

- Page 189 and 190:

QUALITY & SAFETY APPROVED EN > This

- Page 191 and 192:

QUALITY & SAFETY APPROVED EN > Cera

- Page 193 and 194:

www.bicgraphic.eu 191

- Page 195 and 196:

ES > Las 10 principales razones por

- Page 197 and 198:

STABLE FLAME Thanks to pure isobuta

- Page 199 and 200:

EFFECT IN DAYLIGHT EFFECT IN THE DA

- Page 201 and 202:

Our best-seller. Pocket-sized flint

- Page 203 and 204:

MIDA CATÀLEG GENERAL 2016 By the e

- Page 205 and 206:

By the pioneer in. . . EN > Choose

- Page 207 and 208:

By the pioneer in. . . EN > Choose

- Page 209 and 210:

By the pioneer in. . . EN > Choose

- Page 211 and 212:

Our bestselling electronic lighter.

- Page 213 and 214:

By the pioneer in. . . EN > Choose

- Page 215 and 216:

By the pioneer in. . . EN > Choose

- Page 217 and 218:

MIDA CATÀLEG GENERAL 2016 EN > Cur

- Page 219 and 220:

Maximize your brand visibility than

- Page 221 and 222:

MIDA CATÀLEG GENERAL 2016 EN > Pre

- Page 223 and 224:

MIDA CATÀLEG GENERAL 2016 EN > Tre

- Page 225 and 226:

MIDA CATÀLEG GENERAL 2016 EN > Tre

- Page 227 and 228:

EN > Keep the environment cleaner w

- Page 229 and 230:

www.bicgraphic.eu 227

- Page 231 and 232:

2 blades Large lubricating strip wi

- Page 233 and 234:

Large guard bar Pivoting head Lubri

- Page 235 and 236:

2 blades Large lubricating strip wi

- Page 237 and 238:

Pivoting head Lubricating strip wit

- Page 239 and 240:

www.bicgraphic.eu 237

- Page 241 and 242:

EN > Modern design and lightweight

- Page 243 and 244:

EN > The useful accessories pouch w

- Page 245 and 246:

T'nB® www.bicgraphic.eu 243

- Page 247 and 248:

EN > Sport earphones with microphon

- Page 249 and 250:

EN > A vintage atmosphere for this

- Page 251 and 252:

EN > Foldable and adjustable headph

- Page 253 and 254:

4 in 1: Bluetooth ® wireless, wire

- Page 255 and 256:

EN > Enhance the sound of the compu

- Page 257 and 258:

EN > Shockproof 3 watts Bluetooth

- Page 259 and 260:

EN > This 1000 dpi colorful mouse f

- Page 261 and 262:

EN > Compact size wireless optical

- Page 263 and 264:

MIDA CATÀLEG GENERAL 2016 Feels li

- Page 265 and 266:

MIDA CATÀLEG GENERAL 2016 EN > Ult

- Page 267 and 268:

EN > Real 4K video resolution, 16 m

- Page 269 and 270:

EN > No matter where you are travel

- Page 271 and 272:

EN > An easy, reliable connection t

- Page 273 and 274:

EN > This innovative 2-pole adapter

- Page 275 and 276:

www.bicgraphic.eu 273

- Page 277 and 278:

70% 16,4 cm 20 x 50 mm A 70% 15,8 c

- Page 279 and 280:

70% A 16,5 cm 20 x 100 mm A 7,5 cm

- Page 281 and 282:

45% A B 45% 60 x 170 mm 30 x 120 mm

- Page 283 and 284:

8,1 cm 00037 Standard Packaging for

- Page 285 and 286:

TECHNICAL PARAMETERS FOR EACH TYPE

- Page 287 and 288:

FR > Informations BIC ® Sticky Not

- Page 289 and 290:

ALOE MIDA CATÀLEG GENERAL 2016 PRI

- Page 291 and 292:

Nuancier de couleurs / Gama de colo