analisis mesin dan komponen kritis sebagai dasar pengembangan ...

analisis mesin dan komponen kritis sebagai dasar pengembangan ...

analisis mesin dan komponen kritis sebagai dasar pengembangan ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ABSTRACT<br />

This study presents a case study to find out the maintenance strategy at the<br />

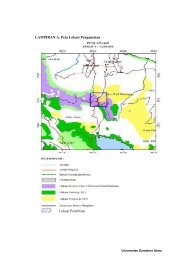

Rambutan Palm Oil Factory of PTP Nusantara 3. The methodology in this research<br />

was by analyzes the failures data of critical machines and it’s components, by<br />

Weibull distribution applications, so it can founded the values of maintenance system<br />

characteristics, i.e: reliability, failure rate, mean time between failure, availability,<br />

failure types, failure cost, preventive cost, and replacement interval time. Based on<br />

analysis of Pareto’s diagram founded that critical machines is Screw Press due<br />

components critical, i.e: Left & Right Handed Worm, Bushing, Press Cylinder,<br />

Rebuild Worm, Bearing SKF 29326, Left Handed Shaft, and Right Handed Shaft<br />

Based on analysis of the failures, the researcher tries to establish the<br />

Maintenance Strategy, so it can be reduce the Screw Press frequency failure, reduce<br />

the loss production, and improve the reliability, availability, and MTBF.<br />

Maintenance strategies are created based on replacement interval time of<br />

subsystems, and then create the optimal maintenance scheduling that has been<br />

modified. Analysis of the new maintenance strategy of different subsystems shows<br />

that the reliability of Screw Press(1) can be improve from 0.4207 to 0,8259, Screw<br />

Press(2) from 0,4024 to 0,8259, Screw Press(3) from 0,4504 to 0,8259, and Screw<br />

Press(4) from 0,4204 to 0,8259 respectively. The availability of Screw Press(1)<br />

improved from 0,8564 to 0,9524, Screw Press(2) from 0,9201, to 0,9524, Screw<br />

Press(3) from 0,8585 to 0,9524, and Screw Press(4) from 0,875 to 0,9524. The<br />

probability of failure frequency of Screw Press(1) is reduced from 37 to 19, Screw<br />

Press(2) from 23 to 19, Screw Press(3) from 25 to 19, and Screw Press(4) from 23 to<br />

19.<br />

This study shows that analyzes of machine failure is very useful for deciding the<br />

policy in the planning of maintenance strategy at a factory..<br />

Keywords: critical machines, reliability, availability, screw press, maintenance<br />

srategy.<br />

ii<br />

Universitas Sumatera Utara