ISTRUZIONI Articolo 8069 - Robur

ISTRUZIONI Articolo 8069 - Robur

ISTRUZIONI Articolo 8069 - Robur

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

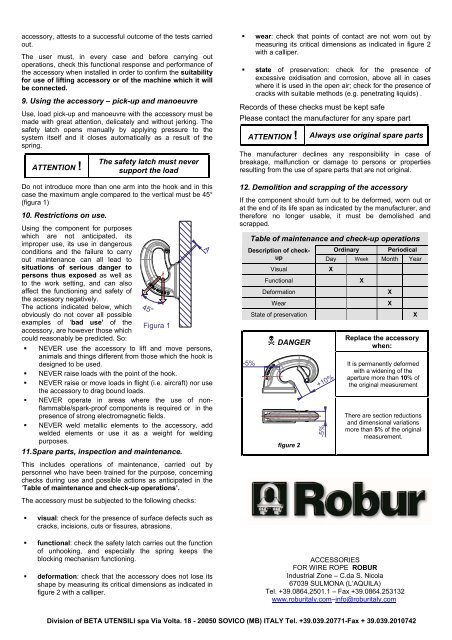

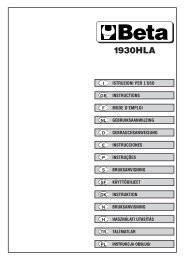

accessory, attests to a successful outcome of the tests carriedout.The user must, in every case and before carrying outoperations, check this functional response and performance ofthe accessory when installed in order to confirm the suitabilityfor use of lifting accessory or of the machine which it willbe connected.9. Using the accessory – pick-up and manoeuvreUse, load pick-up and manoeuvre with the accessory must bemade with great attention, delicately and without jerking. Thesafety latch opens manually by applying pressure to thesystem itself and it closes automatically as a result of thespring.ATTENTION !The safety latch must neversupport the loadDo not introduce more than one arm into the hook and in thiscase the maximum angle compared to the vertical must be 45°(figura 1)10. Restrictions on use.Using the component for purposeswhich are not anticipated, itsimproper use, its use in dangerousconditions and the failure to carryout maintenance can all lead tosituations of serious danger topersons thus exposed as well asto the work setting, and can alsoaffect the functioning and safety ofthe accessory negatively.The actions indicated below, whichobviously do not cover all possibleexamples of ‘bad use’ of theaccessory, are however those whichcould reasonably be predicted. So:45°Figura 1 NEVER use the accessory to lift and move persons,animals and things different from those which the hook isdesigned to be used. NEVER raise loads with the point of the hook. NEVER raise or move loads in flight (i.e. aircraft) nor usethe accessory to drag bound loads. NEVER operate in areas where the use of nonflammable/spark-proofcomponents is required or in thepresence of strong electromagnetic fields. NEVER weld metallic elements to the accessory, addwelded elements or use it as a weight for weldingpurposes.11.Spare parts, inspection and maintenance.This includes operations of maintenance, carried out bypersonnel who have been trained for the purpose, concerningchecks during use and possible actions as anticipated in the‘Table of maintenance and check-up operations’.The accessory must be subjected to the following checks:Awear: check that points of contact are not worn out bymeasuring its critical dimensions as indicated in figure 2with a calliper.state of preservation: check for the presence ofexcessive oxidisation and corrosion, above all in caseswhere it is used in the open air; check for the presence ofcracks with suitable methods (e.g. penetrating liquids) .Records of these checks must be kept safePlease contact the manufacturer for any spare partATTENTION !Always use original spare partsThe manufacturer declines any responsibility in case ofbreakage, malfunction or damage to persons or propertiesresulting from the use of spare parts that are not original.12. Demolition and scrapping of the accessoryIf the component should turn out to be deformed, worn out orat the end of its life span as indicated by the manufacturer, andtherefore no longer usable, it must be demolished andscrapped.Table of maintenance and check-up operationsDescription of checkupDay Week MonthOrdinary PeriodicalYear-5%VisualFunctionalDeformationWearState of preservation DANGERfigure 2X+10%-5%XXXXReplace the accessorywhen:It is permanently deformedwith a widening of theaperture more than 10% ofthe original measurementThere are section reductionsand dimensional variationsmore than 5% of the originalmeasurement.visual: check for the presence of surface defects such ascracks, incisions, cuts or fissures, abrasions.functional: check the safety latch carries out the functionof unhooking, and especially the spring keeps theblocking mechanism functioning.deformation: check that the accessory does not lose itsshape by measuring its critical dimensions as indicated infigure 2 with a calliper.ACCESSORIESFOR WIRE ROPE ROBURIndustrial Zone – C.da S. Nicola67039 SULMONA (L’AQUILA)Tel. +39.0864.2501.1 – Fax +39.0864.253132www.roburitaly.com–info@roburitaly.comDivision of BETA UTENSILI spa Via Volta. 18 - 20050 SOVICO (MB) ITALY Tel. +39.039.20771-Fax + 39.039.2010742