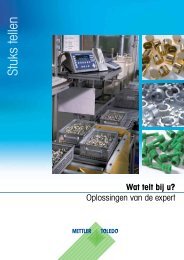

Bakkerij, snacks & snoep - METTLER TOLEDO

Bakkerij, snacks & snoep - METTLER TOLEDO

Bakkerij, snacks & snoep - METTLER TOLEDO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Bezoek onze internetsite<br />

Gebruik www.mt.com<br />

als hulpmiddel voor meer efficiency<br />

Profiteer van onze informatiegidsen en white papers<br />

Onze nieuwe gidsen helpen bij het maken van weloverwogen beslissingen<br />

en versnellen de productie. Bestel gratis de complete<br />

informatiegids of download een white paper over een van de volgende<br />

onderwerpen:<br />

• Traceerbaarheid / receptuur<br />

• Quality Data Management<br />

• Vision inspectie<br />

• Detectie van productvreemde deeltjes<br />

• Hygiënisch ontworpen apparatuur<br />

• Goedgekeurde metrologie<br />

• En nog 7 andere onderwerpen<br />

www.mt.com/ind-food-guides-bak15<br />

Bekijk ons op YouTube<br />

Bekijk onze video en ontdek onze oplossingen voor het volgende:<br />

• Handmatig controlewegen<br />

• X-ray inspectie<br />

• Vision inspectie<br />

• En nog veel meer<br />

www.youtube.com/mtindustrial<br />

Nederland<br />

Mettler-Toledo B.V.<br />

Franklinstraat 5<br />

4004 JK Tiel<br />

Tel. + 31 344 63 83 63<br />

Fax + 31 344 63 83 90<br />

contact.nl@mt.com<br />

Nederland<br />

Mettler-Toledo PI B.V.<br />

Het Sterrenbeeld 48<br />

5215 ML’s-Hertogenbosch<br />

Tel. + 31 735 48 11 88<br />

Fax + 31 735 48 11 90<br />

info.nl@mt.com<br />

Formulation<br />

Improved Production Yield through<br />

Computer Based Formulation / Recipe Weighing<br />

Vehicle Weighing<br />

Gratis<br />

X-ray Inspection<br />

Foreign Body Detection<br />

X-ray Inspection<br />

Food manufacturing companies are under increased pressure to improve plant productivity,<br />

X-ray inspection technology is increasingly used in food, pharmaceutical and related<br />

product quality and consumer safety. For all three, ingredient traceability and process track-<br />

industries, to ensure product safety and quality. Brand reputation is easily damaged<br />

ing play central roles.<br />

by customer complaints and product recalls. Manufacturers use x-ray inspection systems<br />

to detect foreign bodies and perform in-line quality checks to protect consumers<br />

and safeguard their brands.<br />

Reliable Vehicle Weighing<br />

International standards designed to ensure product<br />

X-ray inspection technology not only offers exceptional<br />

safety (EC 178/2002, US Bioterrorism Act, FDA, GMP,<br />

ferrous, non-ferrous and stainless steel detection, it is<br />

BRC, IFS, ISO 22000) are cropping up. A prerequisite<br />

Helps Protect Profits - White Paper<br />

also extremely good at detecting other foreign bodies<br />

to the traceability required is documentation of all rele-<br />

such as glass, stone, bone, high density plastics, and<br />

vant formulation and weighing process activities.<br />

rubber compounds. In addition, x-ray systems can be<br />

used to perform a wide range of in-line quality checks<br />

A computer-guided and networked, rather than paper-<br />

including:<br />

based, production system provides easily accessible<br />

• Measuring mass<br />

Moving bulk goods or raw materials into or out of a processing facility effectively is critical<br />

production data. The resulting documentation and<br />

• Components<br />

analysis can improve quality, reduce waste and protect<br />

to plant productivity. As a result, unplanned truck scale downtime can seriously impact • Identifying the missing or broken products<br />

both consumers and brand reputation, providing signif-<br />

total product output of a processing plant and threaten profit margins.<br />

• Monitoring fill levels<br />

icant bottom-line improvement.<br />

• Inspecting seal integrity<br />

• Checking for damaged product and packaging<br />

This paper will address the benefits of investing in such<br />

a system as well as considerations that help ensure the<br />

Food manufacturers are under pressure to adopt the<br />

system enhances manufacturing processes.<br />

Primary causes of unplanned downtime in traditional<br />

standards of the Global Food Safety Initiative (GFSI).<br />

Contents<br />

Contents<br />

truck-scale systems include:<br />

Other directives and standards such as HACCP (Haz-<br />

1 Increasing regulatory pressure<br />

• Harsh<br />

requires<br />

conditions, including water ingress, damage<br />

ard Analysis Critical Control Points) and GMP (Good<br />

1 The case for x-ray inspection<br />

traceability<br />

to load cells, junction boxes, and scale terminals,<br />

Manufacturing Practice) require food and pharmaceuti-<br />

2 How x-ray Inspection Systems work<br />

and lightning-generated surges<br />

cal manufacturers to make their processes as safe and<br />

2 Traceable weighing / formulation • Heavy is loads and high traffic volume, which con-<br />

transparent as possible.<br />

3 X-ray Inspection System Design<br />

computer-based tribute to issues such as scale drift, and cause de-<br />

4 Summary<br />

3 System components / configuration creased accuracy over time<br />

This chapter explores why x-ray inspection could be<br />

• Rodent and debris damage which can affect the in-<br />

5 Additional resources<br />

the solution, how x-ray inspection technology works<br />

4 Real-world tracking / tracing<br />

tegrity of cables and wiring<br />

and looks at effective x-ray inspection system design.<br />

5 Summary<br />

Many companies believe unplanned downtime to<br />

6 Additional resources<br />

maintain or repair truck scales is unavoidable. However,<br />

unplanned scale downtime does not have to be<br />

an accepted variable in the productivity equation.<br />

Newer scale technologies, such as microprocessorequipped<br />

load cells and systems that eliminate junc-<br />

Contents<br />

tion boxes, have many advantages over older<br />

1 The importance of reliable vehicle weighing<br />

technology.<br />

2 Enhancing accuracy: microprocessors within<br />

load cells<br />

This paper addresses technology and design<br />

advances that help eliminate unplanned downtime<br />

3 Reducing physical threats: innovative product<br />

such as self-monitoring load cell networks, which<br />

design<br />

keep scales operating and help ensure in-plant pro-<br />

4 Considering ROI<br />

ductivity gains are not made in vain.<br />

5 Summary<br />

6 Additional resources<br />

www.mt.com/ind-bakery-<strong>snacks</strong>-sweets-bak15<br />

België<br />

N.V. Mettler-Toledo S.A.<br />

Leuvensesteenweg 384<br />

1932 Zaventem<br />

Tel. + 32 2 334 02 11<br />

Fax + 32 2 334 03 34<br />

contact.be@mt.com<br />

Meer informatie: