You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

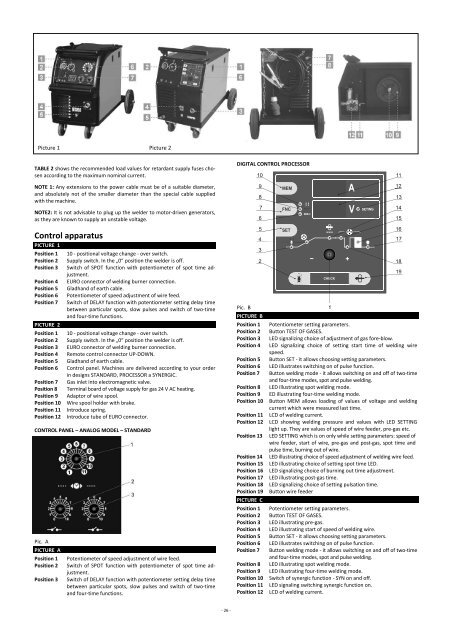

Picture 1 Picture 2<br />

TABLE 2 shows the recommended load values for retardant supply fuses chosen<br />

according to the maximum nominal current.<br />

DIGITAL CONTROL PROCESSOR<br />

NOTE 1: Any extensions to the power cable must be of a suitable diameter,<br />

and absolutely not of the smaller diameter than the special cable supplied<br />

with the machine.<br />

NOTE2: It is not advisable to plug up the welder to motor‐driven generators,<br />

as they are known to supply an unstable voltage.<br />

Control apparatus<br />

PICTURE 1<br />

Position 1<br />

Position 2<br />

Position 3<br />

Position 4<br />

Position 5<br />

Position 6<br />

Position 7<br />

PICTURE 2<br />

Position 1<br />

Position 2<br />

Position 3<br />

Position 4<br />

Position 5<br />

Position 6<br />

Position 7<br />

Position 8<br />

Position 9<br />

Position 10<br />

Position 11<br />

Position 12<br />

10 ‐ positional voltage change ‐ over switch.<br />

Supply switch. In the „0“ position the welder is off.<br />

Switch of SPOT function with potentiometer of spot time adjustment.<br />

EURO connector of welding burner connection.<br />

Gladhand of earth cable.<br />

Potentiometer of speed adjustment of wire feed.<br />

Switch of DELAY function with potentiometer setting delay time<br />

between particular spots, slow pulses and switch of two‐time<br />

and four‐time functions.<br />

10 ‐ positional voltage change ‐ over switch.<br />

Supply switch. In the „0“ position the welder is off.<br />

EURO connector of welding burner connection.<br />

Remote control connector UP‐DOWN.<br />

Gladhand of earth cable.<br />

Control panel. Machines are delivered according to your order<br />

in designs STANDARD, PROCESSOR a SYNERGIC.<br />

Gas inlet into electromagnetic valve.<br />

Terminal board of voltage supply for gas 24 V AC heating.<br />

Adaptor of wire spool.<br />

Wire spool holder with brake.<br />

Introduce spring.<br />

Introduce tube of EURO connector.<br />

CONTROL PANEL – ANALOG MODEL – STANDARD<br />

Pic. A<br />

PICTURE A<br />

Position 1<br />

Position 2<br />

Position 3<br />

Potentiometer of speed adjustment of wire feed.<br />

Switch of SPOT function with potentiometer of spot time adjustment.<br />

Switch of DELAY function with potentiometer setting delay time<br />

between particular spots, slow pulses and switch of two‐time<br />

and four‐time functions.<br />

Pic. B<br />

PICTURE B<br />

Position 1<br />

Position 2<br />

Position 3<br />

Position 4<br />

Position 5<br />

Position 6<br />

Position 7<br />

Position 8<br />

Position 9<br />

Position 10<br />

Position 11<br />

Position 12<br />

Position 13<br />

Position 14<br />

Position 15<br />

Position 16<br />

Position 17<br />

Position 18<br />

Position 19<br />

PICTURE C<br />

Position 1<br />

Position 2<br />

Position 3<br />

Position 4<br />

Position 5<br />

Position 6<br />

Position 7<br />

Position 8<br />

Position 9<br />

Position 10<br />

Position 11<br />

Position 12<br />

Potentiometer setting parameters.<br />

Button TEST OF GASES.<br />

LED signalizing choice of adjustment of gas fore‐blow.<br />

LED signalizing choice of setting start time of welding wire<br />

speed.<br />

Button SET ‐ it allows choosing setting parameters.<br />

LED illustrates switching on of pulse function.<br />

Button welding mode ‐ it allows switching on and off of two‐time<br />

and four‐time modes, spot and pulse welding.<br />

LED illustrating spot welding mode.<br />

ED illustrating four‐time welding mode.<br />

Button MEM allows loading of values of voltage and welding<br />

current which were measured last time.<br />

LCD of welding current.<br />

LCD showing welding pressure and values with LED SETTING<br />

light up. They are values of speed of wire feeder, pre‐gas etc.<br />

LED SETTING which is on only while setting parameters: speed of<br />

wire feeder, start of wire, pre‐gas and post‐gas, spot time and<br />

pulse time, burning out of wire.<br />

LED illustrating choice of speed adjustment of welding wire feed.<br />

LED illustrating choice of setting spot time LED.<br />

LED signalizing choice of burning out time adjustment.<br />

LED illustrating post‐gas time.<br />

LED signalizing choice of setting pulsation time.<br />

Button wire feeder<br />

Potentiometer setting parameters.<br />

Button TEST OF GASES.<br />

LED illustrating pre‐gas.<br />

LED illustrating start of speed of welding wire.<br />

Button SET ‐ it allows choosing setting parameters.<br />

LED illustrates switching on of pulse function.<br />

Button welding mode ‐ it allows switching on and off of two‐time<br />

and four‐time modes, spot and pulse welding.<br />

LED illustrating spot welding mode.<br />

LED illustrating four‐time welding mode.<br />

Switch of synergic function ‐ SYN on and off.<br />

LED signaling switching synergic function on.<br />

LCD of welding current.<br />

‐ 26 ‐