TEST SWITCHES TEST SWITCHES - Brooks Utility

TEST SWITCHES TEST SWITCHES - Brooks Utility

TEST SWITCHES TEST SWITCHES - Brooks Utility

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

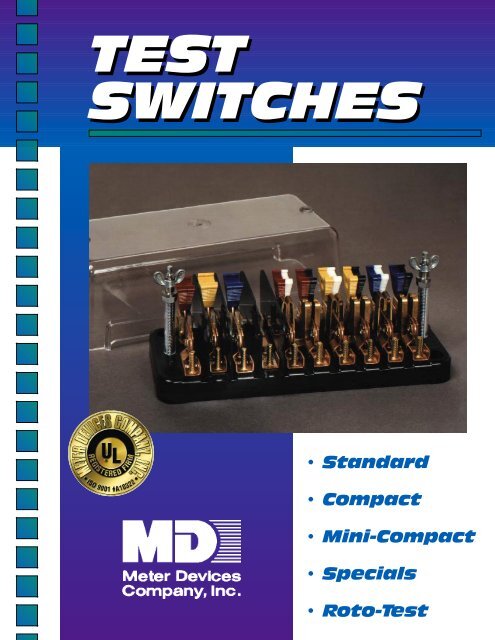

<strong>TEST</strong><br />

<strong>SWITCHES</strong><br />

• Standard<br />

• Compact<br />

• Mini-Compact<br />

• Specials<br />

• Roto-Test

<strong>TEST</strong><br />

<strong>SWITCHES</strong><br />

Contents<br />

Design & Construction Features .................................2<br />

Connection Suggestions for Test Switches...................4<br />

Single-Phase..........................................................4<br />

Network or Three-Phase ........................................4<br />

Three-Phase, Four Wire .........................................5<br />

Special Switches ........................................................6<br />

Back-Connected Switches ..........................................8<br />

Flush-Mounted Switches ............................................8<br />

Test Switch Covers......................................................9<br />

Instructions For Ordering Special Switches...............10<br />

Standard Switch Assemblies .....................................11<br />

2, 3, 4 and 6 Poles ..............................................12<br />

7, 8 and 9 Poles ..................................................13<br />

10 and 11 Poles ..................................................14<br />

Compact and Mini-Compact Test Switches...............15<br />

Compact Design & Construction Features ...........16<br />

Standard Compact Switch Assemblies .................17<br />

Semi-Flush Mounted Type ................................18<br />

Front-Connected Type .....................................20<br />

Mini-Compact Design & Construction Features ...22<br />

Standard Mini-Compact Switch Assemblies.........23<br />

Semi-Flush Mounted Type ................................24<br />

Front-Connected Type .....................................26<br />

Roto-Test Switch.......................................................28<br />

Roto-Test Switch Design and Construction ...............29<br />

Roto-Test Switch Catalog Numbers...........................32<br />

METER DEVICES COMPANY<br />

A Subsidiary of the E. J. BROOKS Company<br />

3359 Bruening Avenue S.W.<br />

P.O. Box 6382, Station B<br />

Canton, Ohio 44706<br />

Phone: (330) 455-0301<br />

Fax: (330) 455-1461<br />

Toll Free - 1 888 FOR-METER<br />

www.meter-devices.com<br />

MD-TS99-20M<br />

© 1999 Meter Devices Company<br />

Printed in U.S.A

Meter Devices Test Switches<br />

Meter Devices Company, founded in<br />

1918, has been a member of the E.J.<br />

<strong>Brooks</strong> family of companies since<br />

1981. The company has earned an<br />

enviable reputation among the<br />

world’s electric utilities as the<br />

premier supplier of knife type test<br />

switches.<br />

Meter Devices Company designs and<br />

manufacturers the finest quality and<br />

most complete line of test switches in<br />

the industry. Applications include<br />

meter, relay, instrument transducer<br />

and control system calibration,<br />

disconnecting, troubleshooting and<br />

testing.<br />

Meter Devices test switches<br />

incorporate many features for safety,<br />

durability, reliability and<br />

dependability. Test switches are rated<br />

at 30 amperes, 600 volts, A.C. and<br />

meet all applicable l.E.E.E., E.E.I.,<br />

A.N.S.I. C12.9, and Underwriters<br />

Laboratories standards.<br />

All test switches are completely nonferrous,<br />

manufactured from high-conductivity<br />

copper and phosphor<br />

bronze. Test switches are furnished<br />

unplated as standard; however, tin or<br />

nickel plating for corrosion protection<br />

are available upon request.<br />

1

Meter Devices Test Switches<br />

Design & Construction Features<br />

Meter Devices exclusive<br />

double spring, phosphor<br />

bronze contact jaw<br />

assures positive contact<br />

and long life<br />

A serrated or<br />

corrugated test ear<br />

designed to positively<br />

prevent test clips from<br />

coming off<br />

Molded black<br />

Plaslok ® or specialsized<br />

black<br />

Resiten ® bases<br />

provide excellent<br />

insulating, tracking<br />

and dielectric<br />

properties<br />

Molded plastic handles<br />

available in 12 solid<br />

colors, or 2-piece colored,<br />

have provision for wire<br />

i.d. Iabel<br />

Hinge jaw assembly<br />

has brass rivet in<br />

combination with a<br />

compression Belleville<br />

spring washer which<br />

maintains correctly<br />

adjusted jaw tension<br />

Wire saddle traps the wire or<br />

crimp connector to insure<br />

positive location; the terminal<br />

stud is long enough to accept<br />

multiple connections<br />

Bases<br />

Insulating bases are molded from<br />

tough, time-tested materials with<br />

excellent insulating, tracking and<br />

dielectric properties. Select from<br />

four sizes of molded-base test<br />

switches – 4-1/2 “, 7-1/2 “, 9-1/2 “<br />

and 11-1/2” for either frontconnect,<br />

semi-flush, or flush<br />

mounting. Special Resiten ® base<br />

test switches complement and<br />

satisfy still other special<br />

requirements which cannot be met<br />

with molded-base switches.<br />

Handles<br />

Test switches are supplied as<br />

standard with red potential and<br />

black current handles. Other<br />

colors available: blue, brown,<br />

green, orange, white, yellow, red<br />

w/white tracer, green w/white<br />

tracer black w/white tracer, white<br />

w/black tracer. Handles include<br />

provisions for a wire i.d. Iabel.<br />

Optional Handles<br />

Two-Piece Colored Handles -<br />

Meter Devices offers ultrasonically<br />

welded two-piece handles as an<br />

option for customers who desire<br />

full-color mulitcolor handles on<br />

their switches.<br />

The Hinge Jaw<br />

Assembly assures a constant,<br />

uniform smooth pressure against<br />

the switch blade by use of a brass<br />

rivet that can’t come off, in<br />

combination with a compression<br />

Belleville spring washer which<br />

maintains correctly adjusted jaw<br />

tension.<br />

Double-Spring<br />

Reinforced Contacts<br />

Designed and developed by Meter<br />

Devices exclusively for Meter<br />

Devices products and considered,<br />

by far, the best contacts yet<br />

designed; contact jaws made of<br />

high conductivity phosphor bronze<br />

and reinforced with high<br />

conductivity bronze clips. The jaw<br />

is a spring in itself and will not<br />

spread, assuring perfect-contact,<br />

low resistance, no overheating and<br />

easy operation at all times. Added<br />

reinforcement of the phosphor<br />

bronze clips is positive assurance<br />

of long life and perfect action.<br />

2

Meter Devices Test Switches<br />

The Short Circuit Clip<br />

Developed by Meter Devices, the<br />

short circuit clip eliminates the<br />

weakest, most troublesome part of<br />

most present<br />

day test<br />

switches.<br />

It is a make<br />

before-break<br />

type, made<br />

from one piece of<br />

phosphor bronze. It cannot get out<br />

of alignment; projections on the<br />

knife blade prevent raising the<br />

blade to a point where it is out of<br />

contact with the clip. A return<br />

strap completes the circuit to the<br />

spring jack.<br />

Test Jack<br />

Eliminates the possibility of<br />

accidentally opening CT<br />

secondaries and permits safe, easy<br />

measurements to be made in<br />

current circuits without disturbing<br />

permanent wiring. A dual-circuit<br />

test plug, such as Meter<br />

Devices Cat. #903-1116, is<br />

inserted into the test jack,<br />

putting the measuring<br />

instrument in<br />

series with the<br />

current circuit.<br />

Barriers<br />

Barriers of flame-resistant nylon<br />

are normally supplied between<br />

potential elements of all switches<br />

where center-to center spacing is<br />

less than one inch. Meter Devices’<br />

barriers are higher than<br />

competitive brands to provide an<br />

extra measure of safety.<br />

Optional Channel Barriers<br />

Meter Devices<br />

can now supply<br />

channel barriers<br />

as an option<br />

replacing the<br />

standard snap-in<br />

barriers. The<br />

channel barriers<br />

are made of the<br />

same flame-resistant material as<br />

the standard snap-in barriers. The<br />

channel barriers also provide<br />

the mechanical and electrical<br />

advantages as the standard<br />

snap-in barriers.<br />

Wire Saddle & Terminal<br />

Studs<br />

Provided as standard for wiring test<br />

switches, wire saddle traps the<br />

wire or crimp connector to insure<br />

positive location and protect<br />

against rotation. The terminal stud<br />

is long enough to accept multiple<br />

connections at one point. For ease<br />

of wiring, solderless terminals are<br />

an option (in place of the wire<br />

terminal stud).<br />

Hexagon Nuts<br />

Of 3/8 “ heavy brass for fastening<br />

wire.<br />

Test Ears - Provided<br />

A serrated or corrugated test ear of<br />

ample size is designed to positively<br />

prevent test clips from coming off<br />

unless the spring tension is<br />

released.<br />

3

Meter Devices Test Switches<br />

Connection Suggestions for Test Switches<br />

Single-Phase Connections<br />

1Ø3W with 1 C.T.<br />

Single Stator (2W1ø) - Form 3S Meter<br />

Cat. No. 104-5401<br />

1Ø2W with 1 P.T. & 1 C.T.<br />

Single Stator (2W1Ø) - Form 3S Meter<br />

Cat. No. 104-5401<br />

1Ø3W with 2 C.T.’s<br />

Single Stator (3W1Ø) - Form 4S Meter<br />

Cat. No. 106-2434<br />

Network or Three-Phase Connections<br />

4<br />

1Ø3W or 3W Network with 2 C.T.’s<br />

2 Stator Meter - Form 5S<br />

Cat. No. 107-1266<br />

3Ø3W “ ∆ “ with 2 P.T.’s & 2 C.T.’s<br />

2 Stator Meter - Form 5S<br />

Cat. No. 107-1266<br />

3Ø3W “ ∆ “ with 2 C.T.’s<br />

2 Stator Meter - Form 5S<br />

Cat. No. 107-1266

Meter Devices Test Switches<br />

Three-Phase,<br />

Four-Wire Connections<br />

3Ø4W “Y” with 3 C.T.’s<br />

2-1/2 Stator Meter - Form 6S<br />

Cat. No. 109-4456<br />

3Ø4W “Y” with 2 P.T.’s & 3 C.T.’s<br />

2-1/2 Stator Meter - Form 6S<br />

Cat. No. 109-4456<br />

WIDE CT<br />

LINE<br />

WIDE CT<br />

WIDE CT<br />

LOAD<br />

3Ø4W “Y” or “ ∆ “ with 3 C.T.’s<br />

“Y” 3 Stator Meter - Form 9S<br />

“ ∆ “ 2 Stator Meter - Form 8S<br />

Cat. No. 110-54583<br />

3Ø4W “Y” with 3 P.T.’s & 3 C.T.’s<br />

3 Stator Meter - Form 9S<br />

Cat. No. 110-54583<br />

3Ø4W “Y” with 3 C.T.’s<br />

3 Stator Meter - Form (ALT) IOS<br />

Cat. No. 110-54583<br />

5

Meter Devices Test Switches<br />

Special Switches<br />

Plated Meter<br />

Test Switches<br />

Meter Test Switches –<br />

Colored Handles<br />

Meter Test Switches<br />

Screw Terminals<br />

Meter Devices Company test<br />

switches are completely nonferrous<br />

being manufactured of<br />

copper and phosphor bronze. As<br />

such, they are furnished as<br />

standard unplated. If plating is<br />

required, tin or nickel, are<br />

available. To order, please suffix<br />

catalog number: TP - tin, NP -<br />

nickel, i.e., #110-54580-TP.<br />

Plating is a slight additional cost.<br />

High Voltage Test Switch<br />

Meter Devices test switches are<br />

furnished as standard with red<br />

potentials and black current<br />

handles. Other colors available<br />

are: blue, brown, green, orange,<br />

white, yellow, purple, red w/white<br />

tracer, green w/white tracer, black<br />

w/white tracer, and white w/black<br />

tracer. Two-piece color handles<br />

optional. Please specify handle<br />

colors from left to right when<br />

ordering. Red and Black are<br />

standard. Other color handles are<br />

a slight additional cost.<br />

Screw type terminals with a<br />

captive pressure pad are available<br />

on all front connected switches.<br />

No looping of wires is necessary,<br />

no loose parts to become<br />

misplaced. Simply insert the<br />

stripped wire beneath the pressure<br />

pad and tighten the terminal screw<br />

with a screwdriver. To order this<br />

type of terminal add suffix “ST” to<br />

the switch catalog number, i.e.<br />

#110-54521-ST. Price is slightly<br />

higher than standard terminal stud<br />

and nut.<br />

Reversed Potential<br />

Switches<br />

Meter Devices type HV High Voltage<br />

test switch provides a maximum<br />

amount of safety on services where<br />

2 5/8”<br />

277/480 volts are used. The test<br />

switch is made on a Resiten ® base<br />

material which has excellent<br />

4 1/4”<br />

insulating properties. Potentials are<br />

spaced further apart and are<br />

protected by barriers that are higher and thicker for added safety. Other<br />

usual utility safety procedures should continue to be followed.<br />

Reversed potentials are available<br />

on any of our standard test<br />

switches. They are popular with<br />

utilities that are seeking an added<br />

margin of safety for their personnel.<br />

Potential switch handles are<br />

mounted in reverse so that when<br />

the switch is open, the potential<br />

blades are not energized as would<br />

be the case if mounted in the conventional<br />

way.<br />

6

Meter Devices Test Switches<br />

Small Base Test Switches<br />

Reactive Volt-Ampere Metering<br />

Switches<br />

Small base test switches are made on Resiten ® bases.<br />

They are available in any combination of currents or<br />

potentials, front or back connected, with handle<br />

ganging for single throw capability as an option.<br />

Switch elements are the same as on large base test<br />

switches. These switches are used where physical<br />

space is at a premium.<br />

Single or Double Throw<br />

Test Switches<br />

Reactive volt-ampere metering switches are a doublethrow<br />

type that permits testing reactive meters as<br />

KWH meters by shifting the potential. Commonly<br />

known as “heel-and-toe switches”, they are available<br />

in two types: “make-after-break” in which the switch<br />

blade has a neutral position and leaves the first jaw<br />

before it enters the second jaw; and “make-before<br />

break” in which the blade enters the second jaw<br />

before it leaves the first jaw. All Meter Devices heel<br />

and toe switches are furnished “make-after-break”<br />

unless specified otherwise.<br />

Single or double throw switches of<br />

any number of poles are available<br />

in front or back-connected styles.<br />

Fusing provisions for a 30 or 60<br />

ampere fuse is also available.<br />

Fused Potential<br />

Switches<br />

Potential switches are available in<br />

single or multiple pole arrangements<br />

with provisions for<br />

mounting a 30 or 60 ampere fuse.<br />

Test switches are available in a<br />

front or back connected style, as<br />

shown above.<br />

Fuse Blocks<br />

Some utilities specify that where<br />

potential coils, telemetering<br />

circuits, or communication circuits<br />

are connected directly to a service<br />

without potential transformers,<br />

fuses must be used in the leads.<br />

Equipment protection and the<br />

presence of relaying devices may<br />

make the use of fuses advisable.<br />

The Catalog No. 101-1375 single<br />

pole Fuseholder Block here<br />

illustrated is for mounting on the<br />

primary bar of 600 volt current<br />

transformers.<br />

Unmounted Test<br />

Switches<br />

Meter Devices Unmounted<br />

Potential Test Switches can be<br />

supplied to meet your special<br />

requirements. These switches are<br />

available in single pole or ganged<br />

as two up to six poles, single<br />

throw, or double throw, front or<br />

back-connected. Illustrations are<br />

back connected.<br />

7

Meter Devices Test Switches<br />

Back-Connected Switches<br />

Any Meter Devices test switch can<br />

be supplied in a back-connected<br />

version whereby the switch is<br />

mounted on one side of a panel<br />

and the wiring connections are<br />

made on the opposite side. Backconnected<br />

switches are designated<br />

by the catalog number prefix and<br />

the suffix "B", i.e., #130-54580B.<br />

Back-connected switches are<br />

furnished as standard with<br />

insulated bushings for steel panel<br />

mounting. Switches may also be<br />

supplied without bushings for<br />

panels that are insulated. Please<br />

specify without bushings when<br />

required.<br />

Flush-Mounted Switches<br />

Meter Devices Switches can be<br />

supplied mounted in our Flush<br />

Mounting Cases with cover. These<br />

cases are especially suitable for<br />

steel panel mounting so as to<br />

conform to other flush mounted instruments<br />

such as meter relays, etc.<br />

The assembly consists of an<br />

insulated case and a semi-flush<br />

sealable cover of cast metal and<br />

Lexan ® insert. Covers are finished<br />

in dull-lustre black to match the<br />

switch board panel.<br />

SIMPLE INSTALLATION<br />

For installing Flush Mounting<br />

Cases and Covers, all one needs to<br />

do is cut a hole in the panel<br />

[dimensions as shown here]. Insert<br />

the case from the front of panel<br />

and attach with four screws. The<br />

cover fits over the opening and is<br />

then secured by means of two<br />

sealable cover studs.<br />

8<br />

DRILLING DIMENSIONS FOR<br />

FLUSH MOUNTING <strong>TEST</strong><br />

SWITCH CASES<br />

Flush-Mounted Switches<br />

3/8” DIA. HOLE - C’SK. 3/16” DEEP<br />

2 REQD.<br />

4-13/16”<br />

Cat. # Width of Base A B<br />

115-204FM 4-1/2 5-1/16 5-5/8<br />

115-207FM 7-1/2 8-3/16 8-3/4<br />

115-209FM 9-1/2 10-1/2 11-1/16<br />

115-211FM 11-1/2 13-9/16 14-1/8<br />

B<br />

A<br />

3/16” DIA<br />

HOLE<br />

4 REQD.<br />

1-1/2”<br />

1-1/2”

Meter Devices Test Switches<br />

Test Switch Covers<br />

All Meter Devices test switches can be supplied with either a clear or black<br />

opaque plastic cover. Plastic covers are injection molded of Lexan ® which<br />

is a flame-resistant, unbreakable UL-listed material. Slotted covers for front<br />

connect or solid covers for back connect test switches are available. To<br />

prevent loss of registration, Meter Devices covers are made so that all<br />

switch blades must be in a closed position before covers can be sealed.<br />

Optional Cover - Captive Hardware<br />

All test switch covers are available with<br />

the optional feature of captive hardware.<br />

This hardware prevents the loss of the<br />

cover stud nuts during testing and saves<br />

the time and expense of looking<br />

for lost cover nuts or the expense of<br />

replacement nuts.<br />

Slotted Covers for Front Connected Test Switches<br />

CLEAR w/ Optional Captive BLACK w/ Optional Captive Dimensions<br />

Cat. # Hardware Cat. # Hardware A B C<br />

115-204LF 115-204LFCH 115-204PF 115-204PFCH 4-5/8 3-1/2 3-1/4<br />

115-207LF 115-207LFCH 115-207PF 115-207PFCH 7-5/8 6-1/2 6-1/4<br />

115-209LF 115-209LFCH 115-209PF 115-209PFCH 9-5/8 8-1/2 8-1/4<br />

115-211LF 115-211LFCH 115-211PF 115-211PFCH 11-5/8 10-1/2 10-1/4<br />

1/4” HOLE<br />

1/2”<br />

4 1/4”<br />

A<br />

B<br />

3 1/16”<br />

Solid Covers for Back Connected Test Switches<br />

C<br />

CLEAR w/ Optional Captive BLACK w/ Optional Captive Dimensions<br />

Cat. # Hardware Cat. # Hardware A B<br />

115-204LB 115-204LBCH 115-204PB 115-204PBCH 4-5/8 3-1/2 -------<br />

115-207LB 115-207LBCH 115-207PB 115-207PBCH 7-5/8 6-1/2 -------<br />

115-209LB 115-209LBCH 115-209PB 115-209PBCH 9-5/8 8-1/2 -------<br />

115-211LB 115-211LBCH 115-211PB 115-211PBCH 11-5/8 10-1/2 -------<br />

9

Meter Devices Test Switches<br />

Instructions For Ordering Special Switches<br />

Assembly #1 Assembly #26 Assembly #27<br />

Assembly Number<br />

EXAMPLE<br />

Test switch No. 107-54502 is made up of<br />

assemblies 1-1-1-26-27, these assemblies,<br />

found on following page, may be ordered<br />

to fit your requirements.<br />

METER DEVICES can supply test<br />

switches to meet practically any<br />

meter or relay testing requirement.<br />

Those standard switches which<br />

meet the majority of requirements<br />

are listed in the catalog. But if you<br />

need a special test switch you may<br />

design one to meet your own<br />

particular use by application of the<br />

information outlined below:<br />

1. STANDARD ASSEMBLIES: You<br />

may design a switch made up of<br />

any number, or combinations,<br />

of potential or current elements<br />

by selecting any of the<br />

combinations possible from the<br />

standard assemblies illustrated<br />

on page 11. These assembly<br />

numbers are not the catalog<br />

numbers but are for convenience<br />

of switch layout.<br />

2. DIMENSIONS: The minimum<br />

center-to-center horizontal<br />

dimensions between studs of<br />

adjoining elements is 13/16”. A<br />

minimum of 2-1/4” is required<br />

in addition to the sum of the<br />

dimensions between elements<br />

selected, as it requires 1-1/8” at<br />

each end of the base from<br />

center line to end elements, for<br />

mounting holes and cover<br />

sealing stud clearance. Barriers,<br />

Assembly No. 19, are provided<br />

on all switches where center-tocenter<br />

distances between<br />

potential and other assemblies<br />

are less than one inch. Barriers<br />

require no additional spacing.<br />

3. SWITCH BASES: All standard<br />

bases are 3-1/2” in height .<br />

Standard base widths are 4-1/2”,<br />

7-1/2”, 9-1/2” and 11-1/2”<br />

inches. The available working<br />

space is the base width less<br />

2-1/4”.<br />

Base Working Maximum No.<br />

Length Space of Poles<br />

4-5/8” 2-7/16” 4<br />

7-1/2” 5-5/16” 7<br />

9-1/2” 7-5/16” 10<br />

11-1/2” 9-5/16” 12<br />

4. SPECIAL RESITEN ® BASES: Are<br />

available for special spacing of<br />

elements or switches with more<br />

than twelve poles.<br />

10

STANDARD Test Switches<br />

Standard Switch Assemblies<br />

Assembly #1<br />

Single pole potential<br />

Assembly #4<br />

Solid thru bar<br />

Assembly #12<br />

Single pole current<br />

element right<br />

Assembly #13<br />

Single pole current<br />

element left<br />

Assembly #14<br />

Double pole<br />

current element<br />

Assembly #16<br />

Double pole potential<br />

Assembly #17<br />

Three pole potential<br />

Assembly #18<br />

Three pole current elemtent<br />

Assembly #19<br />

Barrier<br />

Assembly #20<br />

Single pole double throw<br />

break before make<br />

Assembly #21<br />

#20 & 21 are double throw switches that break before<br />

make. Can be supplied with make before break<br />

Assembly #26<br />

Load test jack double pole<br />

current element right hand<br />

Assembly #27<br />

Load test jack double pole<br />

current element left hand<br />

Assembly #28<br />

Load test jack single<br />

pole current element<br />

Assembly #29<br />

Load test jack single pole<br />

current element right<br />

Assembly #30<br />

Load test jack single pole<br />

current element left<br />

Assembly #31<br />

30 Amp fuse clip<br />

Assembly #32<br />

60 Amp fuse clip<br />

Assembly #40<br />

Channel Barrier<br />

11

STANDARD Test Switches<br />

Standard Switch Assemblies - 2, 3, 4 and 6 poles<br />

Cat. No. 102-687<br />

Cat. No. 103-54539<br />

Cat. No. 104-5401<br />

Cat. No. 104-5402<br />

Cat. No. 104-5403<br />

Cat. No. 104-54504<br />

Cat. No. 104-54505<br />

Cat. No. 106-5405<br />

Cat. No. 104-525<br />

Cat. No. 106-1345<br />

Cat. No. 106-54518<br />

Cat. No. 106-527<br />

12<br />

2,3,4 and 6 poles -All heights 3 1/2”<br />

Catalog No. Number of Poles Base Width (Inches) Arrangement of Assemblies<br />

102-687 2 4-1/2 16 (with #19 center barrier)<br />

103-54539 3 4-1/2 28-28-28<br />

104-5401 4 4-1/2 1-19-1-19-26<br />

104-5402 4 4-1/2 1-19-26-19-1<br />

104-5403 4 4-1/2 1-19-1-19-27<br />

104-54504 4 4-1/2 1-19-27-19-1<br />

104-54505 4 7-1/2 1-1-27<br />

104-525 4 7-1/2 21-21 all handles ganged<br />

106-5405 6 7-1/2 1-1-12-12-29-28<br />

106--1345 6 7-1/2 27-27-27<br />

106-54518 6 7-1/2 28-13-30-13-30-13<br />

106-527 6 9 -1/2 21-21-21 all ganged handles

STANDARD Test Switches<br />

Standard Switch Assemblies - 7, 8 and 9 poles<br />

Cat. No. 107-54915<br />

Cat. No. 107-54900<br />

Cat. No. 107-54515<br />

Cat. No. 107-54502<br />

Cat. No. 107-54547<br />

Cat. No. 107-54942<br />

Cat. No. 107-620<br />

Cat. No. 107-1280<br />

Cat. No. 108-54931<br />

Cat. No. 108-1278<br />

Cat. No. 109-54516<br />

Cat. No. 109-54517<br />

7, 8 and 9 poles<br />

Catalog No. Number of Poles Base Width (Inches) Arrangement of Assemblies<br />

107-54915 7 7-1/2 1-19-26-19-1-19-27-19-1<br />

107-54900 7 9-1/2 1-19-26-19-1-19-26-19-1<br />

107-54515 7 9-1/2 1-26-1-27-1<br />

107-54502 7 9 1/2 1-1-1-26-27<br />

107-54547 7 7-1/2 1-19-1-19-1-19-26-27<br />

107-54942 7 9-1/2 1-19-1-19-1-26-26<br />

107-620 7 9-1/2 1-14-1-14-1<br />

107-1280 7 9-1/2 19-1-19-1-19-1-26-26 (reversed potential handles)<br />

108-54931 8 9-1/2 1-1-1-26-27<br />

108-1278 8 9-1/2 1-19-12-19-1-19-12-29-19-1-19-28-19-1<br />

109-54516 9 9-1/2 1-19-26-19-1-19-26-19-1-19-26<br />

109-54517 9 9-1/2 1-19-1-19-1-19-27-27-27<br />

13

STANDARD Test Switches<br />

Standard Switch Assemblies - 10 and 11 poles<br />

Cat. No. 110-54580<br />

Cat. No. 110-54583<br />

Cat. No. 110-54522<br />

Cat. No. 110-54943<br />

Cat. No. 110-54941<br />

Cat. No. 110-54895<br />

Cat. No. 110-54523<br />

Cat. No. 110-54924<br />

Cat. No. 110-1268<br />

Cat. No. 110-1385<br />

Cat. No. 110-671<br />

Cat. No. 111-54541<br />

14<br />

10 and 11 poles<br />

Catalog No. Number of Poles Base Width (Inches) Arrangement of Assemblies<br />

110-54580 10 9-1/2 1-19-26-19-1-19-26-19-1-19-26-19-1<br />

110-54583 10 9-1/2 1-19-1-19-1-19-1-19-26-26-26<br />

110-54522 10 9-1/2 1-19-1-19-1-19-4-19-27-30-13-30-13<br />

110-54943 10 9-1/2 1-19-1-19-1-19-4-26-26-26<br />

110-54941 10 9-1/2 1-19-1-19-1-19-1-19-27-30-13-30-13<br />

110-54895 10 9-1/2 12-19-1-19-12-19-1-19-12-19-1-19-1-19-29-29-28<br />

110-54523 10 9-1/2 1-19-26-19-1-19-26-19-1-19-26-19-4<br />

110-54924 10 9-1/2 1-19-1-19-1-19-1-27-27-27<br />

110-1268 10 9-1/2 1-19-1-19-1-19-4-26-26-26<br />

(reversed potential handles)<br />

110-1385 10 11-1/2 1-14-1-14-1-14-1<br />

110-671 10 9-1/2 1-19-1-19-1-19-4-19-14-14-14<br />

111-54541 11 11-1/2 1-1-1-26-27-26-27

COMPACT & MINI-COMPACT Test Switches<br />

Compact and Mini-Compact Test Switches<br />

• Compact and Versatile<br />

• Front and Semi-Flush<br />

Connected Styles<br />

• Safe, Durable, Rugged<br />

and Reliable<br />

• Class 1E Qualified per<br />

IEEE Standard 3213-1974<br />

Compact Test<br />

Switch<br />

Mini-Compact<br />

Test Switch<br />

Meter Devices compact and minicompact<br />

test switches provide<br />

quick and easy multicircuit testing<br />

of switchboard relays, meters and<br />

instruments by any conventional<br />

system. Meter Devices compact<br />

and mini-compact switches are<br />

designed for both front and back<br />

connected configurations.<br />

The rugged construction, huskiness<br />

and capacity of the Meter Devices<br />

"standard" larger size has been<br />

retained. Without sacrificing these<br />

features, the compact and minicompact<br />

switch is appreciably<br />

shorter in length to conserve and<br />

utilize panel space on switchboard<br />

installations. The mini-compact<br />

switch is also narrower.<br />

The compact test switch and the<br />

mini compact test switch are<br />

extremely flexible to the extent<br />

that one can be furnished to fit the<br />

exact need. If only a two pole<br />

switch is needed, then a two pole<br />

switch can be furnished in a two<br />

pole case. This same two pole<br />

switch can be furnished in a larger<br />

case, if desired. If a 24 pole switch<br />

is needed, it can be furnished in a<br />

24 pole case, or any combination<br />

in between.<br />

Any arrangement of switch<br />

elements can be made available.<br />

Standard handle color is black.<br />

Color coding of the handles can be<br />

provided as an option. Individual<br />

switches can be operated<br />

independently, replaced or<br />

rearranged in the field. Ganging of<br />

the test switch handles is also<br />

available.<br />

15

COMPACT Test Switches<br />

Compact Semi-Flush Mounted Test Switches<br />

Switch Handle<br />

Short Circuit Clip<br />

Switch Blade<br />

Inner Spring<br />

Contact Jaw<br />

Outer Spring<br />

Clip Contact Jaw<br />

Test Jack<br />

Phenolic Barrier<br />

Brass Rivet<br />

Molded<br />

Plastic Base<br />

Test Ear<br />

One Piece Hinge Jaw<br />

Screw Type Terminal<br />

Base<br />

Molded plastic which has<br />

excellent insulating qualities and<br />

non-tracking characteristics.<br />

Switch Blade<br />

Standard size special tempered<br />

copper.<br />

Switch Handle<br />

Standard color unless specified is<br />

black. Other colors available are:<br />

red, yellow, orange, brown, green,<br />

blue, white, red with white tracer,<br />

green with white tracer, black with<br />

white tracer and white with black<br />

tracer.<br />

The design of all handles will<br />

permit multiple ganging if desired<br />

and will hold identification cards.<br />

The handle has deep serrations for<br />

utmost safety and convenience,<br />

offering a secure grip when<br />

operating the blade.<br />

16<br />

Contact Jaw<br />

Double spring reinforced contacts<br />

designed and developed by Meter<br />

Devices Company are considered<br />

by far the best contacts available.<br />

Contact jaws are made of high<br />

conductivity spring bronze and are<br />

reinforced with high conductivity<br />

spring bronze clips. The jaw is a<br />

spring in itself and will not spread,<br />

thus assuring perfect contact, low<br />

resistance, no over-heating and<br />

easy operation at all times. The<br />

added reinforcement of the clip is<br />

positive assurance at long life and<br />

perfect action.<br />

Hinge Jaw<br />

Constant and uniform smooth<br />

pressure against the switch blade is<br />

assured by the use of a spring<br />

washer under the head of the<br />

hinge rivet, which maintains the<br />

correctly adjusted jaw tension.<br />

Short Circuit Clip<br />

This clip developed by Meter<br />

Devices Company eliminates the<br />

weakest and most troublesome<br />

part of present day test switches. It<br />

is a ‘make-before-break’ type,<br />

made from one piece of high<br />

conductivity spring bronze. It<br />

cannot get out of alignment, while<br />

projections on the knife-blade<br />

prevent raising the blade to a point<br />

where it is out of contact with the<br />

clip. A return strap completes the<br />

circuit to the spring test jack.<br />

Test Jack<br />

A pair of high conductivity bronze<br />

springs are built into the return<br />

circuit of a pair of current elements<br />

of a Meter Devices’ test switch.<br />

The test jack keeps the secondary<br />

circuit of the transformer closed.<br />

When it is desired to isolate the<br />

current coil, Cat. #903-1116 test<br />

plug is used. The plug also<br />

provides a quick and easy method<br />

of connecting indicating or graphic<br />

meters into the circuit. A switch<br />

blade is also included in the<br />

assembly.

COMPACT Test Switches<br />

Test Ear<br />

Allows testing from front of<br />

switchboard by use of clips and<br />

test plugs. Designed to positively<br />

prevent clips coming off unless<br />

spring tension is released.<br />

Stud<br />

Screw type terminal for back<br />

connection with screw and cup<br />

washer furnished for each stud<br />

connection. In front connected<br />

applications, terminal connections<br />

are made with screw stud and hex<br />

nut. These parts are furnished with<br />

each switch.<br />

Case and Cover<br />

Semi-Flush case is insulated for<br />

use with steel panel switchboards<br />

and is fastened by means of four<br />

screws furnished with the case. The<br />

screws are hidden by the cover<br />

and walls. Lucite cover is held in<br />

place with knurled cover stud nuts.<br />

Cover studs have wire sealing<br />

holes. Covers for front connected<br />

switches are optional and are<br />

made of Lucite.<br />

Barrier<br />

Phenolic barriers are provided<br />

between all poles.<br />

Meter Devices can supply test<br />

switches to meet practically any<br />

meter or relay testing requirement.<br />

Those standard switches are listed on<br />

pages 18 and 20. But if you need a<br />

special test switch you may design<br />

one to meet you own special use by<br />

application of the information<br />

outlined below. These assembly<br />

numbers are not the catalog numbers<br />

but are for convenience of switch<br />

layout.<br />

Standard Compact Switch Assemblies –<br />

for ordering test switches not cataloged<br />

For those desiring to<br />

use an oversize case<br />

with the test switch<br />

Assembly #1c<br />

Single pole potential<br />

Assembly #4c<br />

Solid thru bar<br />

Assembly #12c<br />

Single pole current<br />

element - right<br />

Assembly #13c<br />

Single pole current<br />

element - left<br />

Assembly #14c<br />

Double pole<br />

current element<br />

Assembly #15c<br />

Spacing Base<br />

Supplied between<br />

all poles<br />

Assembly #16c<br />

Double pole potential<br />

Assembly #17c<br />

Three pole potential<br />

Assembly #19c<br />

Barrier<br />

Assembly #26c<br />

Load test jack double<br />

pole current element<br />

right hand<br />

Assembly #27c<br />

Load test jack double<br />

pole current element<br />

left hand<br />

Assembly #28c<br />

Load test jack<br />

Single pole potential<br />

current element<br />

17

COMPACT Test Switches<br />

Semi-Flush Mounted Type Compact Test Switches<br />

202-1512C 203-1513C 204-1514C 205-1515C 206-1516C<br />

207-1517C 208-1518C 209-1519C 210-1520C 202-1521C<br />

203-1522C 204-1523C 205-1524C 205-1525C 206-1526C<br />

207-1527C 207-1528C 207-1529C 208-1530C 209-1531C<br />

208-1532C 204-1533C 205-1534C 206-1535C 208-1536C<br />

208-1537C 208-1538C 210-1539C 210-1540C 210-1541C<br />

207-1542C 208-1543C 210-1544C 206-1545C 208-1546C<br />

208-1547C 209-1548C 210-1549C 210-1550C 208-1551C<br />

210-1552C 210-1553C 209-2403C 204-1748C 207-1575C<br />

18<br />

Symbol Identification<br />

#1 – Potential Element<br />

#26 – Double pole current element (Short Circuit & Jack)<br />

#12 – Current Element (Short Circuit)<br />

#28 – Current Element (Load Test Jack)<br />

Notes:<br />

1. All arrangements are front view.<br />

2. Standard handle color is black.<br />

3. Special handle color coding can be furnished.<br />

Customer should specify colors, left to right,<br />

following switch part number.<br />

4. Handle ties can be provided. Customer should<br />

specify poles that are to be tied together. Pole<br />

numbering left to right.

COMPACT Test Switches<br />

1 15/16”<br />

“B”<br />

C L – C L<br />

COVER STUDS<br />

1/8”<br />

PANEL<br />

4 1/8”<br />

1 3/8”<br />

3/8”<br />

“C”<br />

2 1/4”<br />

4 1/4”<br />

1 27/32”<br />

1 27/32”<br />

Notes:<br />

5/32”<br />

REF<br />

1 1/8”<br />

1 1/8”<br />

“B”<br />

C L – C L<br />

“A” CUTOUT<br />

CUTOUT<br />

1/4”<br />

6–REQ’D<br />

1. Switch furnished complete with case and cover<br />

2. Case is fastened in place on the panel with four (4)<br />

screws that are furnished.<br />

5/32”<br />

REF<br />

3 11/16”<br />

CUTOUT<br />

Semi-Flush Mounted Type<br />

Compact Test Switch<br />

Poles Dim “A” Dim “B” Dim “C”<br />

2 1-5/16 1-5/8 2-1/16<br />

3 1-15/16 2-1/4 2-11/16<br />

4 2-17/32 2-27/32 3-9/32<br />

5 3-5/32 3-15/32 3-29/32<br />

6 3-3/4 4-1/16 4-1/2<br />

7 4-3/8 4-11/16 5-1/8<br />

8 4-31/32 5-9/32 5-23/32<br />

9 5-19/32 5-29/32 6-11/32<br />

10 6-3/16 6-1/2 6-15/16<br />

11 6-13/16 7-1/8 7-9/16<br />

12 7-13/32 7-23/32 8-5/32<br />

13 8-1/32 8-11/32 8-25/32<br />

14 8-5/8 8-15/16 9-3/8<br />

15 9-1/4 9-9/16 10<br />

16 9-27/32 10-5/32 10-19/32<br />

17 10-15/32 10-25/32 11-7/32<br />

18 11-1/16 11-3/8 11-13/16<br />

19

COMPACT Test Switches<br />

Front-Connected Type Compact Test Switches<br />

222-452 223-1453 224-1454 225-1455 226-1456<br />

227-1457 228-1458 229-1459 230-1460 222-1554<br />

222-1555 223-1556 223-1557 224-1558 224-1559<br />

224-1560 224-1561 224-1562 225-1563 225-1564<br />

226-1565 226-1566 227-1567 227-1568 227-1569<br />

228-1570 229-1571 230-1572 230-1573 230-1574<br />

232-2206<br />

Symbol Identification<br />

#1 – Potential Element<br />

#26 – Double pole current element (Short Circuit & Jack)<br />

#14 – Ganged pair (Short Circuit Elements)<br />

Notes:<br />

1. All arrangements are front view.<br />

2. Standard handle color is black.<br />

3. Special handle color coding can be furnished.<br />

Customer should specify colors, left to right,<br />

following switch part number.<br />

4. Handle ties can be provided. Customer should<br />

specify poles that are to be tied together. Pole<br />

numbering left to right.<br />

20

COMPACT Test Switches<br />

D L C L C COVER STUDS<br />

Front Connected Switch<br />

(with optional cover)<br />

4-1/8”<br />

1-5/16”<br />

1-5/16”<br />

C<br />

OVERALL WITH COVER<br />

3-3/8”<br />

1/4 DIA”<br />

3/8” C’ BORE<br />

MTG HOLES<br />

MTG HOLES<br />

B<br />

OVERALL NO COVER<br />

A<br />

3-1/2”<br />

Front Connected Switch<br />

(w/o cover)<br />

2-3/4”<br />

Front-Connected Type<br />

Compact Test Switches<br />

Poles Dim “A” Dim “B” Dim “C” Dim “D”<br />

2 1-1/2 -5/8 1-7/8 1-5/16<br />

3 2-3/32 1-7/32 2-15/32 1-7/8<br />

4 2-23/32 1-27/32 3-3/32 2-27/32<br />

5 3-5/16 2-7/16 3-11/16 3-1/8<br />

6 3-15/16 3-1/16 4-5/16 3-3/4<br />

7 4-17/32 3-21/32 4-29/32 4-11/32<br />

8 5-5/32 4-9/32 5-17/32 4-31/32<br />

9 5-3/4 4-7/8 6-1/8 5-9/16<br />

10 6-3/8 5-1/2 6-3/4 6-3/16<br />

11 6-31/32 6-3/32 7-11/32 6-25/32<br />

12 7-19/32 6-21/32 7-31/32 7-13/32<br />

13 8-3/16 7-5/16 8-9/16 7-31/32<br />

14 8-13/16 7-15/16 9-3/16 8-17/32<br />

Notes:<br />

1. Covers are optional on front-connected compact<br />

switches. Switch with cover designated by “C” suffix<br />

following the catalog No. of the switch.<br />

2. Bagged test ears and trim nuts are furnished with each<br />

test switch.<br />

3. If switch arrangement calls for current elements in<br />

either of the end positions, add one pole to base for<br />

mounting hole on that end.<br />

4. If switch arrangement calls for current elements in<br />

both ends, add two poles to the base size for mounting<br />

holes.<br />

5. Switches without covers use overall dimension ”A”.<br />

6. Switches with covers use overall dimension “C”.<br />

21

MINI-COMPACT Test Switches<br />

Mini-Compact Test Switches<br />

Switch Handle<br />

Inner Spring<br />

Contact Jaw<br />

Short Circuit Clip<br />

Switch Blade<br />

Outer Spring<br />

Clip Contact Jaw<br />

Test Jack<br />

Phenolic Barrier<br />

Molded<br />

Plastic Base<br />

Brass Rivet<br />

One Piece Hinge Jaw<br />

Test Ear<br />

Screw Type Terminal<br />

Base<br />

Molded plastic which has<br />

excellent insulating qualities and<br />

non-tracking characteristics.<br />

Switch Blade<br />

Standard size special tempered<br />

copper.<br />

Switch Handle<br />

Standard color unless specified is<br />

black. Other colors available are:<br />

red, yellow, orange, brown, green,<br />

blue, white, red with white tracer,<br />

green with white tracer, black with<br />

white tracer and white with black<br />

tracer. The design of all handles<br />

will permit multiple ganging if<br />

desired and will hold identification<br />

cards. The handle has deep<br />

serrations for utmost safety and<br />

convenience, offering a secure grip<br />

when operating the blade. Blank<br />

identification stickers are available<br />

from stock.<br />

Contact Jaw<br />

Double spring reinforced contacts<br />

designed and developed by Meter<br />

Devices Company are considered<br />

by far the best contacts available.<br />

Contact jaws are made of high<br />

conductivity spring bronze and are<br />

reinforced with high conductivity<br />

spring bronze clips. The jaw is a<br />

spring in itself and will not spread,<br />

thus assuring perfect contact, low<br />

resistance, no overheating and<br />

easy operation at all times. The<br />

added reinforcement of the clip is<br />

positive assurance of long life and<br />

perfect action.<br />

Hinge Jaw<br />

Constant and uniform smooth<br />

pressure against the switch blade is<br />

assured by the use of a spring<br />

washer under the head of the<br />

hinge rivet, which maintains the<br />

correctly adjusted jaw tension.<br />

Barrier<br />

Phenolic barriers are provided<br />

between all poles of a switch.<br />

Short Circuit Clip<br />

This clip developed by Meter<br />

Devices Company eliminates the<br />

weakest and most troublesome<br />

part of present day test switches. It<br />

is a 'make-before-break' type,<br />

made from one piece of high<br />

conductivity spring bronze. It<br />

cannot get out of alignment, while<br />

projections on the knife-blade<br />

prevent raising the blade to a point<br />

where it is out of contact with the<br />

clip. A return strap completes the<br />

circuit to the spring test jack.<br />

22

MINI-COMPACT Test Switches<br />

Test Jack<br />

A pair of high conductivity bronze<br />

springs are built into the return<br />

circuit of a pair of current elements<br />

of a Meter Devices test switch. The<br />

test jack keeps the secondary<br />

circuit of the transformer closed.<br />

When it is desired to isolate the<br />

current coil, Cat. #903-1116 test<br />

plug is used. The plug also<br />

provides a quick and easy method<br />

of connecting indicating or graphic<br />

meters into the circuit. A switch<br />

blade is also included in the<br />

assembly.<br />

Test Ear<br />

Allows testing from front of<br />

switchboard by use of clips and<br />

test plugs. Designed to positively<br />

prevent clips coming off unless<br />

spring tension is released.<br />

STUD<br />

Screw type terminal for back<br />

connection with screw and lock<br />

washer furnished for each stud<br />

connection.<br />

Solderless Type<br />

Terminals<br />

Will accept #14 - #10 wire. Test<br />

clip connections are made on the<br />

head of the screw. Used on Front<br />

Connected switches Only.<br />

Case and Cover<br />

Semi-flush case is insulated for use<br />

with steel panel switchboards and<br />

is fastened by means of four screws<br />

furnished with the case. The screws<br />

are hidden by the cover end walls.<br />

Lucite cover is held in place with<br />

rubber friction tabs. Covers for<br />

front connected switches are also<br />

Lucite.<br />

Standard Mini-Compact Switch Assemblies –<br />

for ordering test switches not cataloged<br />

For those desiring to<br />

use an oversize case<br />

with the test switch<br />

Assembly #1m<br />

Single pole potential<br />

Assembly #4m<br />

Solid thru bar<br />

Assembly #12m<br />

Single pole current<br />

element - right<br />

Assembly #13m<br />

Single pole current<br />

element - left<br />

Assembly #14m<br />

Double pole<br />

current element<br />

Assembly #15m<br />

Spacing Base<br />

Supplied between<br />

all poles<br />

Assembly #16m<br />

Double pole potential<br />

Assembly #17m<br />

Three pole potential<br />

Assembly #19m<br />

Barrier<br />

Notes:<br />

1. All arrangements are front view.<br />

2. Standard handle color is black.<br />

3. Special handle color coding can be furnished. Customer should<br />

specify colors, left to right, following switch part number.<br />

4. Handle ties can be provided. Customer should specify poles that are<br />

to be tied together. Pole numbering left to right.<br />

Assembly #26m<br />

Load test jack double<br />

pole current element<br />

right hand<br />

Assembly #27m<br />

Load test jack double<br />

pole current element<br />

left hand<br />

Assembly #28m<br />

Load test jack<br />

Single pole potential<br />

current element<br />

23

MINI-COMPACT Test Switches<br />

Semi-Flush Mounted Mini-Compact Test Switches<br />

302-2070C 302-2071C 302-2072C 302-2073C 303-2074C<br />

303-2075C 303-2076C 304-2077C 304-2078C 304-2079C<br />

304-2080C 304-2081C 304-2082C 305-2083C 305-2084C<br />

305-2085C 305-2086C 305-2087C 306-2088C 306-2089C<br />

306-2090C 306-2091C 306-2092C 306-2093C 307-2094C<br />

307-2095C 307-2096C 307-2097C 307-2098C 307-2099C<br />

307-2100C 307-2101C 308-2102C 308-2103C 308-2104C<br />

308-2105C 308-2106C 308-2107C 308-2108C 308-2109C<br />

308-2110C 308-2111C 308-2112C 308-2113C 308-2114C<br />

309-2115C 309-2116C 309-2117C 309-2118C 309-2119C<br />

24<br />

Note:<br />

For symbol<br />

identification,<br />

ordering information,<br />

special notes etc.,<br />

refer to page 26.<br />

309-2120C 309-2121C 310-2122C 310-2123C

MINI-COMPACT Test Switches<br />

“B” CL<br />

PANEL<br />

SHIELD<br />

(EACH SIDE)<br />

PANEL<br />

3 7/16”<br />

OVERALL<br />

PANEL<br />

SHEILD<br />

COVER<br />

3”<br />

1 3/8”<br />

3/8”<br />

1 5/16”<br />

2 1/4”<br />

C<br />

1/8” PANEL<br />

1/4”<br />

DIA<br />

6 REQ’D<br />

1 5/16”<br />

1 1/8”<br />

2 5/8”<br />

CUTOUT<br />

1 1/8”<br />

1 5/16”<br />

Notes:<br />

5/32”<br />

REF<br />

“A” CUTOUT<br />

CUTOUT<br />

PANEL DRILLING PLAN<br />

1. Switch furnished complete with case and cover.<br />

2. Case is fastened in place on back of panel with four (4)<br />

screws that are furnished.<br />

3. Cover is friction fit.<br />

“B” C L<br />

3 11/16”<br />

5/32”<br />

REF<br />

Semi-Flush Mounted<br />

Mini-Compact Test Switches<br />

Poles Dim “A” Dim “B” Dim “C”<br />

2 1-7/32 1-17/32 1-31/32<br />

3 1-25/32 2-3/32 2-17/32<br />

4 2-11/32 2-21/32 3-3/32<br />

5 2-29/32 3-7/32 3-21/32<br />

6 3-15/32 3-25/32 4-7/32<br />

7 4-1/32 4-11/32 4-25/32<br />

8 4-5/8 4-15/16 5-3/8<br />

9 5-3/16 5-1/2 5-15/16<br />

10 5-3/4 6-1/16 6-1/2<br />

11 6-5/16 6-5/8 7-1/16<br />

12 6-7/8 7-3/16 7-5/8<br />

310-2124C 310-2125C 310-2126C 310-2127C 310-2128C<br />

310-2129C 310-2130C 310-2131C 310-2132C 310-2133C<br />

310-2134C 310-2135C 310-2136C 310-2137C 311-2138C<br />

312-2139C 312-2140C 312-2147C 312-2148C<br />

Note:<br />

For symbol<br />

identification,<br />

ordering information,<br />

special notes etc.,<br />

refer to page 26.<br />

25

MINI-COMPACT Test Switches<br />

Front-Connected Type Mini-Compact Test Switches<br />

322-2159 323-2160 324-2161 325-2162 326-2163<br />

327-2164 328-2165 329-2166 330-2167 322-2168<br />

322-2169 323-2170 323-2171 324-2172 324-2173<br />

324-2174 324-2175 324-2176 325-2177 325-2178<br />

326-2179 326-2180 327-2181 327-2182 327-2183<br />

328-2184 329-2185 330-2186 330-2187 330-2188<br />

331-2189 331-2190 332-2191<br />

Symbol Identification<br />

#1m – Potential Element<br />

#12m – Current Element (Short circuit)<br />

#14m – Double pole current element (Pair short circuits, handles tied)<br />

#26m – Double pole current element (Short circuit & jack pair)<br />

Notes:<br />

1. All arrangements are front view.<br />

2. Standard handle color is black.<br />

3. Special handle color coding can be furnished.<br />

Customer should specify colors, left to right,<br />

following switch part number.<br />

4. Handle ties can be provided. Customer should<br />

specify poles that are to be tied together. Pole<br />

numbering left to right.<br />

#27m– Double pole current element (Jack & short circuit pair)<br />

#28m – Current element (Load test jack)<br />

26

MINI-COMPACT Test Switches<br />

FRONT CONNECTED SWITCH<br />

(with optional cover)<br />

3”<br />

“B”<br />

MTG<br />

HOLES<br />

C<br />

OVERALL WITH COVER<br />

1 11/32” 1 19/32”<br />

2 5/8”<br />

1/4” DIA<br />

3/8” C’T<br />

BORE<br />

MTG<br />

HOLES<br />

2 3/4”<br />

FRONT CONNECTED SWITCH<br />

WITH NO COVER<br />

OVERALL<br />

NO COVER<br />

“A” 2 3/4”<br />

Notes:<br />

1. Covers are optional on front-connected mini-compact<br />

switches. Switch “WITH COVER” designated by “C”<br />

suffix following the part no. of the switch.<br />

2. If terminal connectors are solderless screw-type, wire<br />

range 14-10.<br />

3. If switch arrangement calls for current elements in<br />

either of the end positions, add one pole to base size<br />

for mounting hole that end.<br />

4. If switch arrangement calls for current elements in<br />

both of the end positions, add two poles to the base<br />

size for mounting holes.<br />

5. Switches without covers use overall dimensions “A”.<br />

6. Switches with covers use overall dimensions “C”.<br />

Front-Connected Type<br />

Mini-Compact Test Switches<br />

Poles Dim “A” Dim “B” Dim “C”<br />

2 1-13/32 -9/16 1-31/32<br />

3 1-31/32 1-1/8 2-9/16<br />

4 2-17/32 1-11/16 3-1/8<br />

5 3-1/8 2-1/4 3-11/16<br />

6 3-11/16 2-27/32 4-1/4<br />

7 4-1/4 3-13/32 4-13/16<br />

8 4-13/16 3-31/32 5-3/8<br />

9 5-3/8 4-17/32 5-15/16<br />

10 5-15/16 5-3/32 6-1/2<br />

11 6-1/2 5-21/32 7-3/32<br />

12 7-1/16 6-7/32 7-21/32<br />

27

ROTO-<strong>TEST</strong> Switches<br />

Roto-Test Switches<br />

The Roto-Test Switch is the result<br />

of years of experience and<br />

research in the manufacture of<br />

testing devices for instruments,<br />

relays and meters, and it achieves<br />

a mechanical and electrical<br />

perfection never before attained in<br />

a device for this purpose.<br />

It combines safety and efficiency,<br />

saves time and space and<br />

embodies all the desired features<br />

for safe, speedy and dependable<br />

relay and meter testing.<br />

With the Roto-Test Switch, relays<br />

and meters may be tested at the<br />

turn of a key without<br />

disconnecting for service. Overcurrent<br />

relays may be tested in any<br />

one phase without disturbing the<br />

others, thereby providing partial<br />

protection during the testing<br />

period. The switch can be used for<br />

transfer of relays and meter<br />

circuits for quick testing without<br />

removing any wiring.<br />

28<br />

RATING-30 AMPERES 600 VOLTS<br />

MULTIPLE<br />

COMBINATIONS<br />

These switches are available in<br />

four, six, ten, twelve, fourteen,<br />

sixteen, eighteen and twenty pole<br />

combinations. Switches mount on<br />

the rear of the switchboard and the<br />

face plate appears on the front of<br />

the board. This highly efficient and<br />

effective installation, not only<br />

conserves space on the<br />

switchboard and matches other<br />

instruments and installations.<br />

DIVERSIFIED<br />

APPLICATIONS<br />

The Roto-Test switch can be<br />

applied to any type of switchboard<br />

and used with all standard makes<br />

of instruments, relays and meters.<br />

ABSOLUTELY SAFE<br />

The Roto-Test switch is the safest<br />

device of its kind on the market.<br />

Its mechanical construction is such<br />

that it is practically impossible for<br />

any parts to loosen up in operation<br />

and cause trouble. Perfect contact<br />

is maintained between blades<br />

and clips.<br />

No live parts are exposed–only the<br />

face plate appears on the front of<br />

the board.<br />

Heavy Textolite (Bakelite) case and<br />

Rotor provide positive insulation.<br />

Test of relays and meters is made<br />

from front of board on test studs<br />

without any connection or<br />

disconnection and without<br />

interruption of service.<br />

It is impossible to trip the circuit<br />

breakers when testing. However,<br />

any relay may be cut out by the<br />

operator should emergency<br />

demand it.

ROTO-<strong>TEST</strong> Switches<br />

Roto-Test Switch – Design and Construction<br />

Heavy brass terminals with<br />

wire holders.<br />

Drawn copper<br />

contact blades and<br />

blade assembly.<br />

Die cast rotor flange<br />

and bearing.<br />

One piece Textolite<br />

(Bakelite) case with<br />

removable top and<br />

bottom covers.<br />

Specially designed<br />

phosphor bronze<br />

contact clips. Potential<br />

jaws are shorter than<br />

current jaws so<br />

potential contact is<br />

broken before current<br />

contact is made.<br />

Textolite rotor mounted<br />

on square steel shaft.<br />

Extra strong mounting<br />

inserts molded in case.<br />

Design & Construction Features<br />

SIMPLE AND<br />

EFFICIENT<br />

Meter Devices Roto-Test Switch is<br />

extremely simple and efficient in<br />

design and compact in<br />

construction. Mechanically and<br />

electrically, its construction is as<br />

close to perfect as humanly<br />

possible.<br />

SAVES SPACE<br />

With numerous instruments now<br />

used on a single panel, space is at<br />

a premium. The Roto-Test Switch<br />

saves space, requiring only a 4"x4"<br />

area on the board. The Roto-Test<br />

Switch can be applied to any type<br />

of switchboard for use with any<br />

standard make of instruments,<br />

meters, relays, etc.<br />

SAVES TIME IN<br />

<strong>TEST</strong>ING<br />

The Roto-Test Switch reduces<br />

testing time to a minimum. A turn<br />

of the key throws the switch into<br />

the testing position without<br />

disconnecting the instruments or<br />

meters from service. Testing is<br />

completed in as little as 60<br />

seconds. Compared to other<br />

methods, Meter Devices Roto-Test<br />

Switch operates in a fraction of the<br />

time.<br />

Operators can test many more<br />

applications per day. The number<br />

of testers required is materially<br />

reduced. Substantial savings in<br />

maintenance costs are realized.<br />

CASE<br />

One piece Textolite (Bakelite) case<br />

with removable top and bottom<br />

covers. Extra strong brass inserts<br />

and reinforcing ribs are molded<br />

into the case. Die cast rotor flange<br />

and bearing provide years of<br />

trouble free operation. Heavy brass<br />

terminals and wire holders are<br />

standard.<br />

CONTACT JAWS &<br />

BLADES<br />

The contact jaws are a Meter<br />

Devices exclusive! The doublespring,<br />

phosphor-bronze jaws are<br />

fortified with high conductivity<br />

phosphor bronze reinforcing clips.<br />

The jaw is a spring in itself and will<br />

not spread, assuring perfect<br />

contact, low resistance and no<br />

overheating.<br />

29

Meter Devices Test Switches<br />

Roto-Test Switch<br />

PHOSPHOR BRONZE<br />

CONTACT JAWS<br />

The jaw is press-formed around the<br />

head of the stud, making it rigid,<br />

permanent and impossible to<br />

detach. Spring bronze clip is<br />

inserted over all. The phosphor<br />

bronze jaw is a spring in itself and<br />

will not spread, insuring perfect<br />

contact at all times. An extra heavy<br />

stud bolt is used. The design of the<br />

contact jaws is exclusive to Meter<br />

Devices.<br />

BLADE ASSEMBLY<br />

The hinge jaw is formed around<br />

the heavy stud bolt, locking it<br />

permanently in place. The blade<br />

pivots in the jaw on a brass rivet. A<br />

Belleville spring washer secures<br />

the blade. This method of assembly<br />

provides a free turning, nonbinding<br />

joint between blade and<br />

jaws. Contact blades are made of<br />

hard-drawn copper. Contact edges<br />

are chamfered, assuring perfect<br />

contact.<br />

ROTOR AND SHAFT<br />

Rotor is unusually tough and<br />

durable, made of Textolite<br />

(Bakelite). It is mounted on a<br />

square shaft to prevent any<br />

possibility of misalignment.<br />

Contains no pins to shear off and<br />

allow rotor to turn on the shaft.<br />

Rotor is mounted meshing<br />

perfectly with the teeth of the<br />

contact blade, preventing any<br />

possibility of working out of<br />

alignment. Shaft does not extend<br />

through rear of case, since the<br />

rear hub is cast in the case.<br />

BAKELITE OVAL<br />

HANDLE<br />

BAKELITE PISTOL-<br />

GRIP HANDLE<br />

STEEL <strong>TEST</strong> KEY<br />

with interlocking pin<br />

Catalog No. Description Type of Handle<br />

30<br />

400-400 Steel, Cadmium Plated Removable<br />

400-401 Bakelite, Pistol Grip Removable<br />

400-402 Bakelite, Oval Non-removable<br />

400-405 Bakelite, Pistol Grip Non-removable<br />

400-406 Bakelite, Oval Removable

Meter Devices Test Switches<br />

ESCUTCHEON PLATE<br />

The Escutcheon Plate is of standard<br />

switchboard design and readily<br />

aligns with instrument plates of<br />

leading instrument manufacturers.<br />

Constructed of heavy pressed<br />

metal with counter-sunk holes to<br />

mount screws in a neat<br />

appearance. A slot in the plate<br />

interlocks and secures the key. It is<br />

impossible to remove the key until<br />

the switch has been restored to the<br />

operating position.<br />

5 5/8”<br />

4”<br />

END<br />

3 3/4”<br />

9/32” DIA<br />

4 HOLES<br />

1 7/8”<br />

CASE<br />

2 3/8”<br />

1 3/16”<br />

DRILLING TEMPLATE<br />

4 1/4” 6 1/4”<br />

Case is molded in one piece using<br />

Textolite (Bakelite). All-brass inserts<br />

are molded in place for optimum<br />

strength, both electrically and<br />

mechanically. Removable top and<br />

bottom dust-proof covers are<br />

interchangeable. Four-point<br />

suspension is provided for<br />

mounting with heavy brass inserts<br />

molded in position. No nuts are<br />

necessary in the switch case.<br />

4”<br />

2”<br />

2 3/8”<br />

1 3/16”<br />

7/8”<br />

MOUNTING & <strong>TEST</strong>ING<br />

The Roto-Test Switch is<br />

permanently mounted on the rear<br />

of the board by means of heavy<br />

brass inserts molded into the case.<br />

Only five holes are required.<br />

All operations and tests are made<br />

in front of the board; there is no<br />

need for the tester to go to the rear<br />

of the board.<br />

Testing is made by interlocking<br />

key. When the switch is in the<br />

"Test" position, the key cannot be<br />

removed.<br />

Thus there is no possible danger<br />

to operator or equipment since<br />

there are:<br />

No live parts exposed<br />

No wrong connections<br />

No current transformers open<br />

No trip circuits open<br />

No loose connections<br />

All hazards to which an operator<br />

or tester is exposed when testing<br />

instruments or relays at the rear of<br />

the board are entirely eliminated.<br />

3 3/4”<br />

4 AND 6 POLE 8 AND 10 POLE<br />

115º<br />

90º<br />

25º<br />

OPERATING POSITION<br />

IN.<br />

.307 +0 .003 DIA OF SHAFT<br />

31

Meter Devices Test Switches<br />

Roto-Test Switch<br />

32<br />

POTENTIAL CURRENT Approx.<br />

Meter Devices No. of Poles CONTACTS CONTACTS Shipping<br />

Catalog No.* each S.P.D.T. (Break before (Make before Weight<br />

make)<br />

break)<br />

401-404 4 0 4 5lbs.<br />

401-422 4 2 2<br />

401-440 4 4 0<br />

402-606 6 0 6 5 lbs.<br />

402-624 6 2 4<br />

402-633 6 3 3<br />

402-642 6 4 2<br />

402-660 6 6 0<br />

403-808 8 0 8 6 lbs.<br />

403-826 8 2 6<br />

403-844 8 4 4<br />

403-862 8 6 2<br />

403-880 8 8 0<br />

404-10010 10 0 10 7 lbs.<br />

404-1028 10 2 8<br />

404-1046 10 4 6<br />

404-1064 10 6 4<br />

404-1082 10 8 2<br />

404-10100 10 10 0<br />

405-12012 12 0 12 7 lbs.<br />

405-12210 12 2 10<br />

405-1248 12 4 8<br />

405-1266 12 6 6<br />

405-1284 12 8 4<br />

405-12102 12 10 2<br />

405-12120 12 12 0<br />

405-14014 14 0 14 8 lbs.<br />

405-14212 14 2 12<br />

405-14410 14 4 10<br />

405-1468 14 6 8<br />

405-1486 14 8 6<br />

405-14104 14 10 4<br />

405-14122 14 12 2<br />

405-14140 14 14 0<br />

405-16016 16 0 16 10lbs.<br />

405-16214 16 2 14<br />

405-16412 16 4 12<br />

405-16610 16 6 10<br />

405-1688 16 8 8<br />

405-16106 16 10 6<br />

405-16124 16 12 4<br />

405-16142 16 14 2<br />

405-16160 16 16 0<br />

405-18018 18 0 18 13 lbs.<br />

405-18216 18 2 16<br />

405-18414 18 4 14<br />

405-18612 18 6 12<br />

405-18810 18 8 10<br />

405-18108 18 10 8<br />

405-18126 18 12 6<br />

405-18144 18 14 4<br />

405-18162 18 16 2<br />

405-18180 18 18 0<br />

405-20020 20 0 20 15 lbs.<br />

405-20218 20 2 18<br />

405-20416 20 4 16<br />

405-20614 20 6 14<br />

405-20812 20 8 12<br />

405-201010 20 10 10<br />

405-20128 20 12 8<br />

405-20146 20 14 6<br />

405-20164 20 16 4<br />

405-20182 20 18 2<br />

405-20200 20 20 0

Meter Devices Test Switches<br />

BROOKS UTILITY PRODUCTS GROUP<br />

METER DEVICES COMPANY<br />

A Subsidiary of E.J. BROOKS Company<br />

P.O. Box 6382, Station B<br />

Canton, Ohio 44706<br />

Phone: (330) 455-0301<br />

Fax: (330) 455-1461<br />

Toll Free – 1 888 FOR-METER<br />

www.meter-devices.com<br />

E.J. BROOKS COMPANY<br />

8 Microlab Road<br />

Livingston N.J. 07039<br />

Phone: (973) 597-2900<br />

Fax: (973) 597-2919<br />

Toll Free: 1 800 458-SEAL<br />

www.ejbrooks.com<br />

EKSTROM INDUSTRIES, INC.<br />

A Subsidiary of E.J. BROOKS Company<br />

23847 Industrial Park Drive<br />

Farmington Hills, MI 48335<br />

Phone: (248) 477-0250<br />

Fax: (248) 477-2583<br />

Toll Free: 1 800 532-IDEA<br />

www.ekstrom-metering.com<br />

e-mail: marketing@ekstrom-metering.com<br />

OTHER BROOKS OPERATING UNITS<br />

In 1998, the E. J. <strong>Brooks</strong> Company celebrated its 125th<br />

anniversary. Originally staffed by a small handful of<br />

employees, our company now employs over 600<br />

people. E. J. <strong>Brooks</strong> has grown into a manufacturing<br />

enterprise with 12 operating units worldwide serving<br />

customers in more than 60 countries.<br />

E.J. BROOKS<br />

INDUSTRIES, LTD.<br />

412 High Street, East<br />

Strathroy, Ontario N7G 1H5<br />

Canada<br />

Phone: (519) 245-5369<br />

Fax: (519) 245-5352<br />

E.J. BROOKS (EUROPE)<br />

LIMITED<br />

6, The Metro Centre,<br />

Bridge Road<br />

Orpington, Kent BR5 2BE,<br />

England<br />

Phone: (0) 1689 83 63 31<br />

Fax: (0) 1689 83 62 94<br />

BROOKS SELOS DE<br />

SEGURANCA DO BRASIL<br />

LTDA.<br />

Rua Timoteo, 80 - Bairro:<br />

Santa Ines<br />

CEP: 31080-040, Belo<br />

Horizonte<br />

Minas Gerais, Brasil<br />

Phone: 31-463-1839<br />

Fax: 31-463-4724<br />

BROOKS/TODO Seguridad<br />

En Espana S.A.<br />

C/VIC No. 26-28,<br />

08120 La Llagosta<br />

Barcelona, Spain<br />

Phone: 3-560-5500<br />

Fax: 3-560-5701<br />

R A N S<br />

U A R D<br />

TRANS-GUARD<br />

INDUSTRIES, INC.<br />

903 S. Wayne<br />

P.O. Box 367<br />

Angola, Indiana 46703<br />

Phone: (219) 665-9402<br />

Fax: (219) 665-5814<br />

ZAPPA PLASTICS. INC.<br />

165 Howard Street<br />

Phillipsburg, N.J. 08865<br />

Phone: (908) 454-4500<br />

Fax: (908) 454-4507<br />

WALING TOOL & DIE<br />

COMPANY<br />

23850 Freeway Park Drive<br />

Farmington Hills, MI 48335<br />

Phone: (248) 476-6680<br />

Fax: (248) 476-7964<br />

ACROMARK INDUSTRIES<br />

60 Locust Avenue<br />

P.O. Box 236<br />

Berkeley Heights, N.J. 07922<br />

Phone: (908) 464-6474<br />

Fax: (908) 464-0673

METER DEVICES COMPANY<br />

A Subsidiary of the E. J. BROOKS Company<br />

3359 Bruening Avenue S.W.<br />

P.O. Box 6382, Station B<br />

Canton, Ohio 44706<br />

Phone: (330) 455-0301<br />

Fax: (330) 455-1461<br />

Toll Free - 1 888 FOR-METER<br />

www.meter-devices.com