The world of hot dip galvanizing around us - hdgasa

The world of hot dip galvanizing around us - hdgasa

The world of hot dip galvanizing around us - hdgasa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>The</strong> <strong>world</strong> <strong>of</strong> <strong>hot</strong> <strong>dip</strong> <strong>galvanizing</strong> <strong>around</strong> <strong>us</strong><br />

Use <strong>of</strong> duplex systems in Chile<br />

Cement grinding Mill, Melon S.A. Ventanas, Chile<br />

General<br />

Melon Cement Project located in the<br />

commune <strong>of</strong> Puchuncavi, sector Ventanas<br />

coastline in central Chile.<br />

Environmental characteristics<br />

<strong>The</strong> exposure conditions are unique in<br />

combining the effects <strong>of</strong> marine and<br />

ind<strong>us</strong>trial environment, given the<br />

influence <strong>of</strong> the activity in the area, which<br />

highlights the presence <strong>of</strong> a smelting and<br />

refining <strong>of</strong> copper concentrates and<br />

thermoelectric power generation plants.<br />

This combination <strong>of</strong> high concentration <strong>of</strong><br />

sulphur dioxide in a marine environment<br />

in the upper range <strong>of</strong> C5 environments<br />

according to ISO 12944-2.<br />

<strong>The</strong> requirements imposed by the client<br />

for the corrosion protection coating<br />

require time for its first maintenance work<br />

over 15 years.<br />

Project<br />

<strong>The</strong> project consists <strong>of</strong> the corrosion<br />

protection <strong>of</strong> 800 tons <strong>of</strong> structural steel,<br />

grills and railings, equivalent to 30 000m 2 .<br />

<strong>The</strong> specified duplex protection system<br />

was:<br />

◆ Hot <strong>dip</strong> <strong>galvanizing</strong> conforms to ASTM<br />

A123<br />

◆ Abrasive br<strong>us</strong>h <strong>of</strong>f cleaning, SSPC SP7<br />

◆ Epoxy primer, 50µm DTF<br />

◆ Aliphatic polyuretane, 60µm DTF<br />

After assembly <strong>of</strong> the structure is carried<br />

out an inspection to determine possible<br />

alterations and damage to the coating to<br />

ensure durability <strong>of</strong> the protection system.<br />

Life cycle costing analysis<br />

<strong>The</strong> analysis <strong>of</strong> life cycle cost is carried out<br />

with the methodology published by NACE<br />

international in the paper number 08279<br />

to compare different alternatives for<br />

corrosion protection considering the<br />

maintenance <strong>of</strong> the protection system<br />

through the years <strong>of</strong> service. <strong>The</strong> results<br />

are delivered in a current cost curve vers<strong>us</strong><br />

time graph, figure 5.<br />

8 Hot Dip Galvanizing Today Volume 8 Issue 4 2011<br />

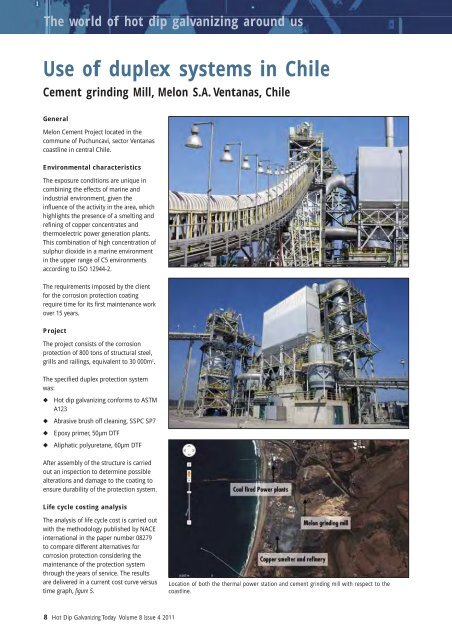

Location <strong>of</strong> both the thermal power station and cement grinding mill with respect to the<br />

coastline.