Allround - The multitalented system for building sites - Layher

Allround - The multitalented system for building sites - Layher

Allround - The multitalented system for building sites - Layher

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

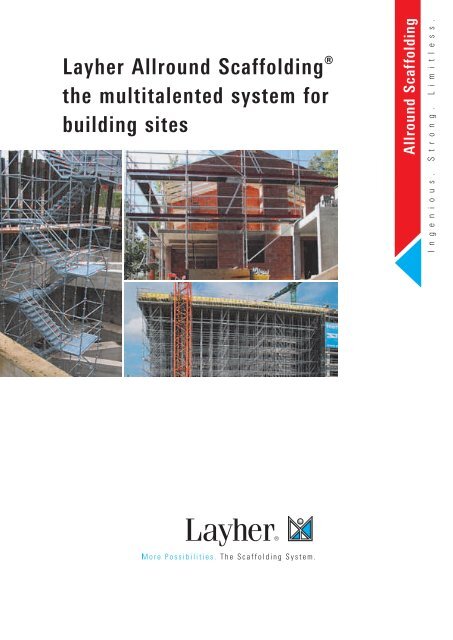

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

the <strong>multitalented</strong> <strong>system</strong> <strong>for</strong><br />

<strong>building</strong> <strong>sites</strong><br />

<strong>Allround</strong> Scaffolding<br />

I n g e n i o u s . S t r o n g . L i m i t l e s s .

2<br />

<strong>Layher</strong><br />

Your dependable partner <strong>for</strong> <strong>building</strong> <strong>sites</strong><br />

<strong>Layher</strong> has been a source of innovation,<br />

top quality and profitability <strong>for</strong> more than<br />

60 years now. <strong>Layher</strong> scaffolding is flexible<br />

to use, quick to assemble and offers<br />

lasting value thanks to the long service<br />

life of all components.<br />

<strong>Layher</strong> scaffolding <strong>system</strong>s are suitable<br />

<strong>for</strong> an unbeatable variety of uses — primarily<br />

on construction <strong>sites</strong> but also in<br />

industry and at events.<br />

<strong>The</strong> wide range of <strong>Layher</strong> products, their<br />

design as modular <strong>system</strong>s and their<br />

cross-<strong>system</strong> compatibility enable you to<br />

cope with every application you can think<br />

of. This consistent focus on the demands<br />

of practical use ensures our products<br />

have a flexible and economical basis.<br />

Company headquarters and production site at Gueglingen-Eibensbach<br />

For more than six decades now the company<br />

has had its sole production and<br />

design facility in Eibensbach. Made by<br />

<strong>Layher</strong> means Made in Germany.<br />

<strong>Layher</strong> quality sets standards. Certified<br />

to DIN ISO 9001:2008, streamlined and<br />

automated production ensures consistent<br />

high quality. Dependable suppliers, selected<br />

materials and strict quality controls at<br />

every phase of production are a matter<br />

of course <strong>for</strong> us, as are the marking and<br />

documenting all <strong>Layher</strong> parts to enable<br />

them to be traced.<br />

Because we maintain high stocks and<br />

operate a flexible production <strong>system</strong>, we<br />

can offer unique delivery capability. With<br />

a very well equipped service and delivery<br />

network of over 30 branches and delivery<br />

warehouses in Germany, a fast delivery<br />

service plus more than 25 sales subsidiaries<br />

and many more trading partners<br />

worldwide, we ensure that you can obtain<br />

our products any time and anywhere.<br />

You too can benefit from our decades of<br />

experience and from the inventive spirit<br />

and skills of our employees. <strong>Layher</strong> scaffolding<br />

guarantees your success. Choosing<br />

<strong>Layher</strong> means choosing partnership,<br />

efficiency and profitability. We will keep<br />

on proving that in scaffolding construction<br />

there are still many “more possibilities”.<br />

Welcome to the world of successful<br />

construction companies.

For further literature: technical brochures, instructions <strong>for</strong><br />

assembly and use, structural strength verifications, user<br />

manual etc. please contact us.<br />

Central warehouse, Gueglingen-Eibensbach<br />

Contents<br />

<strong>Allround</strong> scaffolding <strong>system</strong> 4<br />

<strong>Allround</strong> scaffolding <strong>system</strong> basic components 5<br />

Support scaffolding 6<br />

Economic support scaffolding 8<br />

Scaffolding <strong>for</strong> <strong>for</strong>mworkers and steelfixers 10<br />

Façade scaffolding 14<br />

Birdcage scaffolding 16<br />

Stairway access 18<br />

Mobile work scaffolding 20<br />

Tranches and emergency bridges 22<br />

Further applications 24<br />

Storage and transport 27<br />

3

4<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding® the „Original“<br />

Ingenious technology <strong>for</strong> efficient work<br />

Strong and inexpensive (hot-dip galvanised) steel <strong>Allround</strong> scaffolding<br />

is primarily used <strong>for</strong> elaborate and ambitious scaffolding.<br />

<strong>The</strong> advantage of the aluminium <strong>Allround</strong> scaffolding, which is<br />

identical in design, is its low weight and its suitability <strong>for</strong> applications<br />

where appearance is relevant or where steel is not permitted.<br />

Minimal weight yet<br />

high and ideal transfer<br />

of <strong>for</strong>ce.<br />

<strong>The</strong> wedge head and<br />

standard are matched<br />

to ensure central<br />

loading.<br />

Approvals<br />

<strong>Allround</strong> steel scaffolding<br />

Z-8.22-64 based on EN 12811.<br />

<strong>Allround</strong> aluminium scaffolding<br />

Z-8.22-64.1.<br />

Further international certifications<br />

available<br />

Your benefit<br />

A Save time during assembly and dismantling<br />

thanks to bolt-free connection technology.<br />

A Safe and simple one-man assembly.<br />

A No loose parts.<br />

A Very little material required.<br />

<strong>Allround</strong> scaffolding uses a<br />

simple, unique and bolt-free<br />

connection technology.<br />

Sliding the wedge head<br />

over the rosette and<br />

inserting the wedge into<br />

the opening immediately<br />

secures the component.<br />

<strong>The</strong>re is still sufficient play<br />

to secure the other end of<br />

the ledger.<br />

A hammer blow to the wedge<br />

trans<strong>for</strong>ms the loose connection<br />

into a superbly strong structurally<br />

rigid one. <strong>The</strong> face of the<br />

wedge head is now precisely<br />

positioned against the standard.<br />

<strong>The</strong> result of superior<br />

design:<br />

Up to 8 connections can be<br />

made in the structurally ideal<br />

<strong>Allround</strong> connector on one level<br />

and at various angles. Connections<br />

are provided in standard<br />

dimensions of 50 cm on all<br />

<strong>Allround</strong> standards. <strong>The</strong> flat<br />

rosette prevents clogging with<br />

dirt of whatever type.<br />

Ingenious connection<br />

technology:<br />

<strong>The</strong> four small punched-out<br />

openings in the rosette automatically<br />

centre the ledger at<br />

right angles – the four large<br />

openings allow the angle of<br />

alignment to be selected.<br />

A Maintenance free and always ready<br />

<strong>for</strong> use.<br />

A Low weight of individual parts.<br />

A Tried and proven range of parts.<br />

A Economic and versatile design that convinces.

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Basic components<br />

You have a modular <strong>system</strong> <strong>for</strong> nearly<br />

all conceivable applications, using<br />

just a few basic components. For specific<br />

applications we can supply a large<br />

number of additional efficient <strong>system</strong><br />

solutions.<br />

Vertical<br />

standard<br />

Initial<br />

section<br />

Base plate<br />

Decks <strong>for</strong> mounting<br />

on U-ledgers<br />

U-ledger<br />

Separate lift-off preventer<br />

Diagonal brace<br />

Ledger<br />

Safety is very important at <strong>Layher</strong>. <strong>The</strong><br />

<strong>Layher</strong> advance guardrail (AGR) takes<br />

this into account right from the time<br />

the scaffolding is assembled. <strong>The</strong> AGR<br />

consists of advance guardrail posts and<br />

telescopic guardrails. <strong>The</strong> person erect-<br />

Decks <strong>for</strong> mounting<br />

on O-ledgers<br />

O-ledger<br />

Integrated lift-off<br />

preventer<br />

Scaffolding deck<br />

ing the scaffolding can easily move the<br />

advance guardrail posts up or down using<br />

the blue twist grips.<br />

Tested connection points are provided <strong>for</strong><br />

the rope safety gear.<br />

Advanced guardrail<br />

Diagram illustrating asembly principle<br />

One <strong>system</strong> – Two variants<br />

Choose the variant that is most suitable<br />

<strong>for</strong> your purpose, thus ensuring<br />

that you work as efficiently as possible.<br />

On <strong>Layher</strong> <strong>Allround</strong> scaffolding with<br />

U-ledgers and U-decks the claws of<br />

two decks are both secured by one<br />

lift-off preventer. Lift-off preventers are<br />

incorporated in the base of the decks<br />

on versions with O-ledgers.<br />

5

6<br />

<strong>Layher</strong> <strong>Allround</strong> Shoring TG 60<br />

<strong>The</strong> swift and safe way of flexible shoring<br />

Together with <strong>Layher</strong> <strong>Allround</strong> equipment,<br />

the TG 60 shoring frames create even more<br />

possibilities.<br />

With TG 60, shoring scaffolding can be built<br />

even faster, higher, stronger and safer.<br />

<strong>The</strong> TG 60 shoring frames, available in three<br />

sizes, are made of high-tensile steel, rein<strong>for</strong>ced<br />

with two short struts and provided<br />

with <strong>Allround</strong> rosettes. Each standard of a<br />

TG 60 shoring tower can be subjected to<br />

a load of up to 6 tons.<br />

TG 60 shoring towers can be assembled<br />

at the site either upright or lying on the<br />

ground, <strong>for</strong> subsequent crane movement.<br />

Fully assembled towers or tower combinations<br />

can be moved quickly and easily using<br />

quick-fit castors.<br />

<strong>The</strong> shoring towers can be adapted without<br />

problem to any specific factors of the structure,<br />

terrain or configuration dimension of<br />

the <strong>for</strong>mwork supports. <strong>The</strong> ground plan of<br />

the TG 60 shoring tower results from the<br />

1.09 m wide frames and the <strong>Allround</strong> ledgers<br />

used, from 1.09 m to 3.07 m.<br />

<strong>The</strong> TG 60 shoring frame can be expanded<br />

without problem using <strong>Allround</strong> standard<br />

components. For heavy loads, the shoring<br />

frames can be easily combined using <strong>Layher</strong><br />

twin wedge couplers.<br />

<strong>The</strong> innovative assembly sequence and the<br />

integrated access aid (rungs with 50 cm<br />

spacing) make the assembly of a shoring<br />

tower safer than ever be<strong>for</strong>e.<br />

During upright assembly, you are always<br />

protected by all-round side protection –<br />

without any safety equipment.

Your benefit<br />

A With more than 30 % time saving during assembly in comparison with<br />

structures made from individual parts, economic success will come quickly.<br />

A Easy and rapid assembly thanks to lightweight and symmetrical frames with<br />

proven <strong>Allround</strong> connection technology.<br />

A Optional assembly upright or on the ground. Movement is achieved by<br />

crane or with quick-fit castors.<br />

A Variable bay lengths – simply use ledgers and diagonal braces of<br />

appropriate length to obtain the required bay length.<br />

A Perfect compatible with <strong>Allround</strong> equipment. TG 60 shoring towers can be<br />

expanded or combined with standard <strong>Allround</strong> material whenever required.<br />

A Safe assembly thanks to integrated and all-round advance side protection.<br />

A Integrated access aid thanks to conveniently spaced rungs in the TG 60<br />

shoring tower.<br />

7

8<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Economic support scaffolding<br />

made from <strong>Allround</strong> Scaffolding individual parts<br />

<strong>Layher</strong> <strong>Allround</strong> scaffolding can accommodate<br />

all types of high loads and is the<br />

ideal <strong>system</strong> <strong>for</strong> all kinds of support scaffolding.<br />

Thanks to its versatility, you can<br />

adapt the scaffolding to the conditions on<br />

site.<br />

Variable spacing <strong>for</strong> the standards<br />

ensures that the design of the support<br />

scaffolding can be optimally matched<br />

to the existing load and the falsework<br />

<strong>system</strong> in each case.<br />

Heavy-duty towers made of bundled<br />

standards can carry loads of up to<br />

60 t. Extensive structural strength calculations<br />

and technical user documents are<br />

available.<br />

<strong>Allround</strong> scaffolding has an efficient solution<br />

to deal with all challenges, regardless<br />

of whether they involve ceiling falsework<br />

at a great height, barrel vaults or round<br />

inner scaffolding. Heavy steel beams can<br />

easily be supported with the help of a top<br />

spindle.<br />

Projections, working plat<strong>for</strong>ms and fall<br />

arrest levels can easily be mounted using<br />

existing basic components. Here the<br />

rosette spacing of 50 cm provides the<br />

basis <strong>for</strong> an extremely versatile scaffolding<br />

<strong>system</strong>.<br />

Safety and efficiency will work in your<br />

favour.

Your benefit<br />

A Optimum adaptation to the ground shape.<br />

A You can cope with maximum loads using a minimum of material.<br />

A Thanks to a simple combination of standard components you can<br />

also cope with the greatest challenges in terms of flexibility and<br />

assembly speed.<br />

A Extremely accurate fit thanks to certified high-quality manufacture.<br />

As the outlay required <strong>for</strong> maintenance is minimal, the equipment<br />

is always available and there<strong>for</strong>e allows you to operate more<br />

profitably.<br />

A Tested connection mechanisms provide you with a high degree<br />

of safety.<br />

9

10<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Scaffolding <strong>for</strong> <strong>for</strong>mworkers and steelfixers<br />

Unimpeded access to the wall and beam<br />

rein<strong>for</strong>cement is provided without wall<br />

ties. Stability is achieved through simple<br />

support and, if required, by widening the<br />

base.<br />

Suitable bay lengths ensure that access<br />

is provided to all relevant components.<br />

Inner guardrails and brackets create safe<br />

working conditions where there is a large<br />

gap to the wall. <strong>The</strong> width of the scaffolding<br />

can be adapted to the amount of<br />

space available. <strong>The</strong> fact that the advance<br />

guard rail is fitted to both sides of the<br />

scaffolding provides a high level of safety<br />

even during erection.<br />

Thanks to the use of pull-resistant pins<br />

to connect the standard joints, the scaffolding<br />

can be moved at any time using<br />

a crane.

Your benefit<br />

A You have various <strong>system</strong> solutions available to achieve stability,<br />

even without wall ties.<br />

A You can carry out operations in relation to <strong>for</strong>mwork, rein<strong>for</strong>cing<br />

and concreting using the same scaffolding.<br />

A It is possible to work freely on the <strong>Allround</strong> <strong>system</strong>, without an<br />

inner standard at the top level.<br />

A <strong>The</strong> <strong>system</strong> can be moved by crane, saving time during assembly<br />

and dismantling.<br />

11

12<br />

<strong>Layher</strong> <strong>Allround</strong> STAR<br />

Façade scaffolding – quick and economical<br />

With the <strong>Allround</strong> STAR Frame, the advantages<br />

of SpeedyScaf equipment can be<br />

combined with the flexibility of <strong>Allround</strong><br />

scaffolding. Facade scaffolding can be<br />

built even faster and even more economically.<br />

<strong>The</strong> STAR Frame is available in U and O<br />

design.<br />

<strong>The</strong> innovative guardrailattachment permits<br />

assembly without any tools, where it<br />

is clear even from a distance whether the<br />

guardrail has been secured or not.<br />

<strong>The</strong> lightweight STAR Frame and the also<br />

lightweight guardrails permit fatigue-free<br />

working and hence faster assembly and<br />

dismantling. What’s more, the risk of<br />

overloading the vehicle is reduced and<br />

even larger quantities of material can be<br />

transported.<br />

<strong>The</strong> <strong>Allround</strong> STAR Frame is an open<br />

frame. As a result, decks can be fitted and<br />

removed even when the scaffolding has<br />

been completed. If the scaffolding is not<br />

to be completely decked, the decks can be<br />

moved around as an aid to assembly while<br />

<strong>building</strong> work is in progress.<br />

<strong>The</strong> <strong>Allround</strong> rosettes make the STAR<br />

Frame completely compatible with <strong>Allround</strong><br />

equipment. Strengthening and projecting<br />

structures etc. can be assembled<br />

using standard <strong>Allround</strong> material.

Your benefit<br />

A 24 % time saving during the assembly of facade scaffolding compared<br />

with a facade scaffolding using <strong>Allround</strong> standards and ledgers.<br />

A 38 % weight saving. This permits fatigue-free working and higher<br />

transport volumes.<br />

A Open frame <strong>for</strong> fitting and removal of decks at any time, so they can<br />

<strong>for</strong> example be repositioned to match assembly progress.<br />

A Perfect compatibility with <strong>Allround</strong> equipment thanks to attached<br />

<strong>Allround</strong> rosettes.<br />

A Completely tool-free guardrail assembly.<br />

11 13

14<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Façade scaffolding<br />

made from <strong>Allround</strong> Scaffolding individual parts<br />

With its superlative adaptability <strong>Allround</strong><br />

scaffolding is the obvious choice <strong>for</strong> very<br />

irregular façades. <strong>The</strong> advantages of<br />

<strong>Allround</strong> scaffolding really come to the<br />

<strong>for</strong>e when the <strong>building</strong> has projections,<br />

recesses, cantilevers and niches.<br />

With <strong>Allround</strong> scaffolding all tasks can be<br />

carried out extremely efficiently. <strong>Allround</strong><br />

meets many different requirements at the<br />

same time, acting as a work and protective<br />

scaffolding <strong>for</strong> bricklayers, concrete<br />

workers, carpenters, plumbers, roofers,<br />

plasterers and painters.<br />

<strong>Allround</strong> scaffolding has been granted<br />

<strong>building</strong> authority approval as façade<br />

scaffolding by the Deutsches Institut für<br />

Bautechnik under Z-8.22-64. Where the<br />

configuration requirements differ from the<br />

standard assembly, structural strength<br />

verifications are quickly available, thus<br />

ensuring that erection is not delayed.

Your benefit<br />

A <strong>The</strong> fact that the standard version has been certified and that verifications<br />

of scaffolding stability are available make technical planning easier.<br />

A Depending on requirements, the advance guardrail can be fitted alongside<br />

the scaffolding, on both the outside and the inside, providing maximum<br />

safety at all times.<br />

A All <strong>Layher</strong> <strong>system</strong>s are compatible with one another. A large number of<br />

accessories are there<strong>for</strong>e available <strong>for</strong> different applications.<br />

A Variable adaptation to working height.<br />

A <strong>The</strong> <strong>Allround</strong> <strong>system</strong> allows scaffolding structures to be erected with decks<br />

only at working levels. This saves a considerable amount of material when<br />

compared to frame scaffolding.<br />

11 15

16<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Birdcage scaffolds<br />

Birdcage scaffolding is used <strong>for</strong> applications<br />

that range from small <strong>Allround</strong><br />

scaffolding towers to extensive accesses<br />

under ceilings or bridges. <strong>The</strong>y are used<br />

<strong>for</strong> both stationary and mobile applications.<br />

This means that only a few scaffolding<br />

bays have to be fitted out with<br />

decks. <strong>The</strong>se can be added and removed,<br />

as required, even after the scaffolding has<br />

been completed.<br />

You can accommodate the client’s<br />

requirements and the site situation by<br />

using the appropriate combination of bay<br />

lengths. This will allow you to get around<br />

obstacles.

Your benefit<br />

A Whether rectangular or not, adaptation to the specified contours<br />

of the structure can be achieved at any time thanks to the ingenious<br />

<strong>Allround</strong> rosette.<br />

A After the base has been levelled, the construction is automatically<br />

squared. No further levelling is required.<br />

A Decks only have to be installed where they are required.<br />

A A huge number of <strong>building</strong> tasks can be carried out using only a<br />

few standard parts arranged in a changing sequence of new<br />

configurations. An extensive range of accessories is available <strong>for</strong><br />

special requirements.<br />

A Complicated adjustments and improvising are no longer required.<br />

This makes <strong>for</strong> extremely profitable and effective work.<br />

17

18<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Stairway access<br />

<strong>Layher</strong> has a suitable solution <strong>for</strong> all<br />

your access needs. Access decks with<br />

and without integrated ladders are suitable<br />

<strong>for</strong> internal access. <strong>The</strong> lightweight<br />

alumin ium plat<strong>for</strong>m stair allows ease of<br />

movement between levels and is quickly<br />

assembled.<br />

Stairway towers <strong>for</strong> a broad spectrum of<br />

applications and requirements round off<br />

the range of access solutions.<br />

<strong>The</strong> compact stairtower is designed as a<br />

construction stairway when <strong>building</strong> multi<br />

familiy housing.<br />

Construction stairways and stairway<br />

towers can be used in parallel or dog-leg<br />

configurations.

Your benefit<br />

A Extensive range of access solutions <strong>for</strong> every requirement.<br />

A Optimum adaptation to each storey and exit height.<br />

A Simpler and faster to erect with only a few additional<br />

parts.<br />

A <strong>The</strong> appropriate access solution that complies with regulations<br />

<strong>for</strong> every situation.<br />

A Workers, <strong>building</strong> owners and architects can visit the<br />

construction site safely and with minimum ef<strong>for</strong>t.<br />

11 19

20<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Mobile work scaffolding<br />

Mobile scaffolding provides a crucial<br />

advantage if work has to be per<strong>for</strong>med<br />

section by section. Wheels – ranging from<br />

castors with different load bearing capability<br />

to rail-guided flanged wheels – are<br />

used on mobile scaffolding designs <strong>for</strong><br />

different applications.<br />

<strong>The</strong> appropriate choise of base width and<br />

ballast leads to lightweight structures.

Your benefit<br />

A <strong>Allround</strong> modular scaffolding provides the basis <strong>for</strong> unmatched<br />

economical work to the highest safety standards.<br />

A <strong>The</strong> finished scaffold can be moved to where it is to be used<br />

without technical aids.<br />

A Optimised use of material and fast assembly enhances<br />

effectiveness.<br />

A Repeated assembly and dismantling is no longer required.<br />

A Convenient working, freedom of movement, tools and materials<br />

moved at the same time.<br />

21

22<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Tranches and emergency bridges<br />

Temporary links can be created quickly by<br />

assembling the bridge on one side and<br />

swinging it into position by crane. Access<br />

to the unfinished <strong>building</strong> over excavations<br />

or an emergency bridge over streams<br />

and rivers only requires standard parts<br />

and steel decks. You determine the width<br />

of the span by deciding on the number<br />

and length of bays.<br />

A free projection at the front is possible if<br />

certain prerequi<strong>sites</strong> are fulfilled.<br />

Large widths of up to 30 m can be spanned<br />

using the <strong>Allround</strong> bridge support. This<br />

modular lattice <strong>system</strong> is fully compatible<br />

with <strong>Layher</strong> <strong>Allround</strong> equipment thanks to<br />

the attached wedge heads.

Your benefit<br />

A Highly efficient solutions <strong>for</strong> emergency bridges made<br />

of available standard materials.<br />

A Structural calculations <strong>for</strong> a wide range of standard<br />

applications are available.<br />

A Easy to assemble because the structure is self-bracing.<br />

A System lengths can be combined to produce the required<br />

width and length.<br />

A Can be pre-fabricated and installed by crane.<br />

11 23

24<br />

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Further applications<br />

Cable bridges<br />

Flat roof side protection<br />

<strong>The</strong>re are a large number of tasks on<br />

<strong>building</strong> <strong>sites</strong> that can be carried out very<br />

quickly with <strong>Allround</strong> scaffolding. One<br />

such task, which is now occurring more<br />

frequently, is the erection of cable bridges<br />

over access routes.<br />

When working on flat roofs it is essential<br />

to have effective fall protection fixtures in<br />

place. <strong>Layher</strong>’s flat roof side protection<br />

takes the special design features of flat<br />

roofs into account. You simply have to<br />

adjust it to the fascia and install it around<br />

structures such as chimneys or skylights.<br />

<strong>The</strong> supports can be lifted one by one to<br />

permit work on the roof surface.

Construction and advertising signs<br />

Structures <strong>for</strong> advertising signs to meet<br />

different specifications can be assembled<br />

quickly. It is easy to adapt the sign<br />

to the terrain. <strong>The</strong> structure can be stabilised<br />

using ballast or by installing a base,<br />

depending on site conditions. Either temporary<br />

or permanent fixtures are possible.<br />

System solutions that are well thought<br />

out enhance the appearance of the construction<br />

site or storage area. Speed of<br />

assembly leads to an economic solution<br />

<strong>for</strong> structures used repeatedly.<br />

25

26<br />

Proctection of the environment<br />

Measures to prevent noise pollution and<br />

the spread of dust are required more and<br />

more often, whether at events or at <strong>building</strong><br />

<strong>sites</strong> in urban areas.<br />

<strong>The</strong> <strong>Layher</strong> Protect System is the obvious<br />

choice <strong>for</strong> this task. It blends in with the<br />

neighbouring façades.<br />

<strong>The</strong> Protect System even serves to meet<br />

the high requirements stipulated when<br />

removing asbestos.<br />

<strong>Allround</strong> scaffolding acts as a supporting<br />

structure <strong>for</strong> all these applications.

<strong>Layher</strong> <strong>Allround</strong> Scaffolding®<br />

Storage and transport<br />

<strong>Layher</strong> pallets save on labour and costs<br />

<strong>for</strong> storage, transport, assembly and<br />

inventory control. All pallet types have<br />

been developed on the basis of practical<br />

experience. Loaded pallets can be moved<br />

using a crane or a <strong>for</strong>k-lift truck. <strong>The</strong>y can<br />

be stacked on top of each other and save<br />

storage and transport space.<br />

All <strong>system</strong> components can be transported<br />

using scaffolding pallets. Tube pallets<br />

with box inserts are most suitable <strong>for</strong><br />

small parts. Empty pallets, stored in the<br />

base frame with pallet posts, only require<br />

a very small amount of space.<br />

27

We’re there <strong>for</strong> you. Wherever and whenever you need us.<br />

<strong>Layher</strong> in Germany<br />

Branches and delivery warehouses nationwide.<br />

<strong>Layher</strong> International<br />

Subsidiaries:<br />

Argentina, Australia, Austria, Belgium, Brazil, Bulgaria, Chile,<br />

Colombia, France, Greece, Hungary, India, Italy, Kazakhstan,<br />

Lithuania, Morocco, Netherlands, New Zealand, Norway,<br />

Peru, Poland, Russia, Serbia, Singapore, South Africa, Spain,<br />

Sweden, Switzerland, Turkey, United Kingdom, USA.<br />

Wilhelm <strong>Layher</strong> GmbH & Co. KG<br />

Scaffolding Grandstands Ladders<br />

Ochsenbacher Strasse 56<br />

D-74363 Gueglingen-Eibensbach<br />

Post Box 40<br />

D-74361 Gueglingen-Eibensbach<br />

Telephone +49 (0) 71 35 70-0<br />

Telefax +49 (0) 71 35 70-2 65<br />

E-Mail: export@layher.com<br />

www.layher.com<br />

Representatives:<br />

Croatia, Czech Republic, Denmark, Estonia, Finland, Hong<br />

Kong, Japan, Jordan, Kuwait, Latvija, Lebanon, Libya, Oman,<br />

Philippines, Romania, Saudi-Arabia, Slovakia, Slovenia,<br />

United Arab Emirates<br />

and many other countries.<br />

<strong>The</strong> <strong>Layher</strong> Product Range<br />

Protective<br />

Systems<br />

Event Systems<br />

<strong>Allround</strong> Scaffolding<br />

Rolling Towers<br />

Ladders Accessories<br />

SpeedyScaf<br />

More Possibilities<br />

Ref. No. 8116.208 Edition 15.08.2011