Energy Materials Testing Laboratory EVALUATION FROM

Energy Materials Testing Laboratory EVALUATION FROM

Energy Materials Testing Laboratory EVALUATION FROM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CeramiC Bulletin<br />

AMERICAN soCIEty<br />

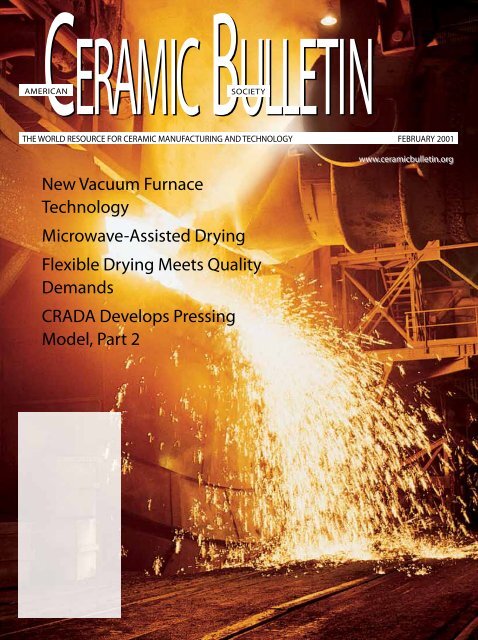

tHe WOrlD reSOurCe FOr CeramiC manuFaCturinG anD teCHnOlOGY FeBruarY 2001<br />

New Vacuum Furnace<br />

technology<br />

Microwave-Assisted Drying<br />

Flexible Drying Meets Quality<br />

Demands<br />

CRADA Develops Pressing<br />

Model, Part 2<br />

www.ceramicbulletin.org

For component metallizations,<br />

Heraeus stands behind you...<br />

and<br />

ahead of<br />

the curve.<br />

For as long as you’ve been building passive components, Heraeus has<br />

supplied metallization products and technology to advance your products<br />

and processes. We provide support at every step: new concepts, technical<br />

expertise, on-site service, and worldwide leadership. And we continue to<br />

stand behind the passive component industry because, frankly, we value<br />

your business.<br />

At the same time, we’re out in front of the market, with a focused effort to<br />

support the shift from precious metals to base metals technology (BME). After a<br />

century of experience in precious metals, we’re applying our wealth of<br />

knowledge to create new products and processes that will propel your<br />

company into the forefront of your marketplace.<br />

Looking further ahead, Heraeus is working on the connectivity between end<br />

termination and solder paste technology, with an emphasis on lead-free<br />

assembly. As the only supplier of products to both the component and<br />

assembly industries—and as a leader in the development of the most promising<br />

lead-free alloy—Heraeus offers expertise and synergy.<br />

So whatever your metallization needs may be —from immediate support to<br />

future developments —only one source supplies it all: Heraeus.<br />

Expect more from Heraeus.<br />

24 Union Hill Road West Conshohocken PA 19428<br />

Tel.: 610-825-6050 • Fax: 610-825-7061 Visit us on the Web at: www.4smt.com<br />

Consistently better SMT<br />

CIRCUIT MATERIALS DIVISION

he<br />

merican<br />

eramic<br />

ociety<br />

Volume 80<br />

Number 2<br />

February 2001<br />

Product Focus . . . . . . . . . . . . . . . . .<br />

62<br />

Corporate<br />

Members<br />

SuStaining<br />

• Aluminum Co. of<br />

America<br />

• Ferro Corp.<br />

• Saint-Gobain Ceramics<br />

& Plastics Inc.<br />

NEW<br />

www.ceramicbulletin.org<br />

Upcoming Events<br />

Meetings & Exposition Calendar . . . . . . . . . . . . 9<br />

u u u u<br />

National Engineers Week . . . . . . . . . . . . . . . . . . . 10<br />

2001 Annual Meeting & Exposition<br />

Preliminary Program . . . . . . . . . . . . . . . . . . . . . . . 81<br />

Registration Form . . . . . . . . . . . . . . . . . . . . . . . . . . 103<br />

Hotel Reservation Form . . . . . . . . . . . . . . . . . . . . 105<br />

News & Views<br />

President’s Letter . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Brick Business . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Environmental Update . . . . . . . . . . . . . . . . . . . . . 14<br />

Refractory Hot Line . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Technology Briefs . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Society/Industry News . . . . . . . . . . . . . . . . . . . . . 17<br />

Business Stats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

ACerS Section Notes . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Legislative & Public Affairs . . . . . . . . . . . . . . . . . . 22<br />

NICE News . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24<br />

Ceramics Online . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

Society Business . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Obituaries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Members Network . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

Names in the News . . . . . . . . . . . . . . . . . . . . . . . . . 33<br />

Products & Processes . . . . . . . . . . . . . . . . . . . . . . . 76<br />

Ceramics Websites . . . . . . . . . . . . . . . . . . . . . . . . . 79<br />

Business Opportunities . . . . . . . . . . . . . . . . . . . . . 106<br />

Career Opportunities & Classifieds . . . . . . . . . . 117<br />

The Last Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120<br />

Advertisers Index . . . . . . . . . . . . . . . . . . . . . . . . . 119<br />

Society/Industry News . . . . . . . . . .<br />

17<br />

TRI Celebrates 50 . . . . . . . . . . . . .<br />

65<br />

www.ceramicbulletin.org • February 2001 3

Products & Processes . . . . . . . .<br />

76<br />

As steelmakers seek improved<br />

life for their ladles and BOF<br />

linings, refractory manufacturers<br />

meet the challenge through the<br />

development of longer-life<br />

products. Cover photo courtesy<br />

of RHI Refractories America,<br />

Pittsburgh.<br />

Manufacturing/<br />

Engineering Features<br />

Special Section:<br />

TRI Celebrates 50 Years of Service<br />

Kathy Woodard . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65<br />

Revolutionary Vacuum<br />

Furnace Technology<br />

R.D. Webb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35<br />

Microwave-Assisted Drying . . . . . . . . . . . . . . . . . 38<br />

Manufacturing Briefs: Flexible Drying Meets<br />

Quality Standards . . . . . . . . . . . . . . . . . . . . . . . . 40<br />

CRADA Develops Model for Powder<br />

Pressing and Die Design: Part Two<br />

K.G. Ewsuk, J.G. Arguello, D.H. Zeuch,<br />

B. Farber, L. Carinci, J. Kaniuk,<br />

J. Keller, C. Cloutier, B. Gold,<br />

R.B. Cass, J.D. French, B. Dinger<br />

and W. Blumenthal . . . . . . . . . . . . . . . . . . . . . . . 41<br />

Deflocculation of Al 2 O 3 -SiC Suspensions<br />

I.R. Oliveira, P. Sepulveda and<br />

V.C. Pandolfelli . . . . . . . . . . . . . . . . . . . . . . . . . . . 47<br />

Precollege Education Program<br />

K. Martin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54<br />

Preparation of KTN Films on<br />

Single Crystal Quartz Substrates<br />

D. Zhang, X. Wang, P. Hen,<br />

M. Huang, Z. Li, M. Zhang,<br />

D. Xu and Y. Wang . . . . . . . . . . . . . . . . . . . . . . . . 57<br />

Product Focus: Thermal Analysis . . . . . . . . . . . . 62<br />

Society Business<br />

Publications/Editorial Staff . . . . . . . . . . . . . . . . . . 6<br />

ACerS Values–Section Membership . . . . . . . . . 6<br />

Advertising Sales Staff . . . . . . . . . . . . . . . . . . . . . . 8<br />

New Book Releases . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

ACerS Membership Recruitment . . . . . . . . . . . . 28<br />

Membership Application . . . . . . . . . . . . . . . . . . . 31<br />

Moving/Changing Position? . . . . . . . . . . . . . . . . 32<br />

Ceramics Correspondence Institute . . . . . . . . . 56<br />

ceramicSOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64<br />

Ceramic Bulletin Subscription . . . . . . . . . . . . . . 64<br />

Microwave-Assisted Drying . . . . . .<br />

38<br />

The American Ceramic Society Bulletin<br />

covers news and activities of the Society<br />

and its members, includes items of<br />

interest to the ceramic community, and<br />

provides the most current information<br />

concerning all aspects of ceramic<br />

technology, including research and<br />

d e v e l o p m e n t , m a n u f a c t u r i n g ,<br />

engineering and marketing.<br />

American Ceramic Society Bulletin (ISSN<br />

0002-7812).<br />

©2001 Published monthly, 12 times a year.<br />

Printed in the United States of America.<br />

Editorial and Subscription Offices: P.O. Box<br />

6 1 3 6 , We s ter v i l l e, O H 4 3 0 8 6 - 6 1 3 6 .<br />

Subscription included with American<br />

Ceramic Society membership. Nonmember<br />

subscriber rates: North America, 1 year $50, 2<br />

years $95; international (air mail only), 1 year<br />

$100, 2 years $195. Back issues: North<br />

America, $6 per issue plus $3 shipping and<br />

handling for the first issue, $2 each<br />

additional; international, $6 per issue plus $6<br />

shipping and handling for the first issue, $4<br />

each additional.<br />

POSTMASTER: Please send address changes<br />

to American Ceramic Society Bulletin, P.O.<br />

Box 6136, Westerville, OH 43086-6136.<br />

Periodical postage paid at Westerville, Ohio,<br />

and additional mailing offices. Allow six<br />

weeks for address changes.<br />

ACSBA7, Vol. 80, No. 2, pp 1–120<br />

4 The American Ceramic Society Bulletin, Vol. 80, No. 2

A C e r S<br />

VA L U E S<br />

ACerS Books Program<br />

The American Ceramic Society’s books<br />

program is dedicated to serving the<br />

informational needs of the ceramics<br />

community by publishing the highest<br />

quality books about ceramics. With more<br />

than 200 titles available, ACerS continues to<br />

seek new authors, ideas and innovative<br />

ways to expand its books program and to<br />

introduce these titles into classrooms and<br />

libraries widely. For a complete list of ACerS<br />

titles, visit our web site at www.ceramics.<br />

org. Members receive a reduced rate on all<br />

books published by ACerS.<br />

Ann Baldwin,<br />

Director Student Services,<br />

NYS College of Ceramics<br />

at Alfred University<br />

“ T h e A m e r i c a n C e r a m i c<br />

Society’s books program has<br />

helped us in our efforts for<br />

recruiting and spreading the<br />

word about ceramic engineering. We have<br />

distributed The Magic of Ceramics to high school<br />

chemistry and physics teachers where we’ve made a<br />

presentation to the classes as well as to those who<br />

have invited us to speak at targeted group meetings.<br />

The book has been well received. Teachers<br />

particularly like the flow of the text and the<br />

combination of pictures and text instead of a text<br />

heavy book. In addition, we have asked teachers to<br />

attempt to develop labs based on some of the<br />

material in the book.”<br />

To find out more about books published by ACerS,<br />

contact our customer service at 614/794-5890,<br />

e-mail at customersrvc@acers.org or visit ACerS web<br />

site at www.ceramics.org.<br />

The American Ceramic Society<br />

P.O. Box 6136<br />

Westerville, OH 43086-6136<br />

614/890-4700 (phone)<br />

614/899-6109 (fax)<br />

www.ceramics.org<br />

01AV02<br />

CeramiC Bulletin<br />

AMERICAN SOCIETY<br />

THE MAGAZINE FOR TECHNOLOGY • ENGINEERING • MANUFACTURING<br />

W. Paul Holbrook<br />

Executive Director and Publisher<br />

Mark J. Mecklenborg<br />

Senior Director, Publications<br />

Patricia A. Janeway<br />

Editor<br />

Jon W. Hines<br />

Senior Editor, Departments<br />

Karla B. Vierthaler<br />

Associate Editor<br />

Cleopatra G. Eddie<br />

Circulation Supervisor<br />

EXECUTIVE STAFF<br />

EDITORIAL AND PRODUCTION<br />

The American Ceramic Society<br />

(735 Ceramic Place)<br />

P.O. Box 6136<br />

Westerville, OH 43086-6136<br />

Tel. 614-890-4700<br />

Fax 614-899-6109<br />

Internet www.ceramics.org<br />

John Wilson<br />

Publication Production Manager<br />

Carl M. Turner<br />

Graphics Production Coordinator<br />

Clark Watson<br />

Prepress Production Specialist<br />

Greg Geiger, B.S. Cer. Eng.<br />

Technical Editor<br />

CERAMIC BULLETIN ADVISORY BOARD<br />

Denis A. Brosnan<br />

Rutgers University<br />

The National Brick Research Center<br />

Clemson University<br />

Charles G. Marvin<br />

Consultant<br />

Rosario Gerhardt<br />

Georgia Institute of Technology<br />

Victor C. Pandolfelli<br />

Universidade Federal de São Carlos<br />

Richard Haber<br />

PUBLICATIONS COMMITTEE<br />

John E. Blendell, chair, NIST; James C. Marra, Westinghouse Savannah River Co.;<br />

John J. Petrovic, Los Alamos National Lab; Richard E. Riman, Rutgers University;<br />

J. Richard Schorr, Orton Ceramic Foundation (ex officio); John R. Hellmann Jr.,<br />

The Pennsylvania State University (ex officio); W. Paul Holbrook, The American<br />

Ceramic Society (ex officio); and Mark J. Mecklenborg, The American Ceramic<br />

Society (ex officio).<br />

NICE PUBLICATIONS COMMITTEE<br />

Thomas D. McGee, chair, Iowa State University; Gary S. Fischman, University of<br />

Chicago; and Diane C. Folz, Virginia Polytechnic Institute & State University<br />

© Copyright 2001 by The American Ceramic Society.<br />

American Ceramic Society Bulletin is covered in Current Contents.<br />

The American Ceramic Society assumes no responsibility for the statements and<br />

opinions advanced by the contributors to its publications or by the speakers at<br />

its programs. Registered names and trademarks, etc., used in this publication,<br />

even without specific indication thereof, are not to be considered unprotected<br />

by the law.<br />

No part of this publication may be reproduced, stored in a retrieval system or<br />

transmitted in any form by any means, electronic, mechanical, photocopying,<br />

recording or otherwise, without the written permission of the publisher.<br />

Permission is not, however, required to copy abstracts of papers or articles on<br />

the condition that a full reference to the source is given.<br />

Authorization to photocopy items for internal or personal use beyond the limits<br />

of Sections 107 and 108 of the U.S. Copyright Law is granted by The<br />

American Ceramic Society, ISSN No. 0002-7812, provided that the appropriate<br />

fee is paid directly to Copyright Clearance Center Inc., 222 Rosewood Drive,<br />

Danvers, MA 01923 USA; tel. 978-750-8400; Internet www.copyright.com. This<br />

consent does not extend to copying items for general distribution or for<br />

advertising or promotional purposes or to republishing items in whole or in<br />

part in any work in any format. Prior to photocopying items for educational<br />

classroom use, please contact Copyright Clearance Center Inc.<br />

Please direct republication or special copying permission requests to<br />

Copyright Clearance Center, Inc., 222 Rosewood Drive, Danvers, MA 01923<br />

USA; tel. 978-750-8400; Internet www.copyright.com.<br />

Orders for copies of articles published in this or other ceramic-related publications<br />

may be placed through The American Ceramic Society’s Ceramic<br />

Information Center, tel. 614-794-5810, fax 614-794-5812.<br />

Custom reprints, in quantities of 100 or more, may be purchased through<br />

Ceramic Bulletin’s editorial department. Requests for reprint quotes should be<br />

directed to Cleo Eddie, tel. 614-794-5827 or fax 614-794-5842.<br />

Instructions for the preparation of articles to be submitted for possible publication in<br />

this periodical are available from the Editor; tel. 614-794-5826, fax 614-794-5822,<br />

E-mail pjaneway@acers.org, Internet www.ceramicbulletin.org.<br />

6 The American Ceramic Society Bulletin, Vol. 80, No. 2

President’s Letter<br />

Officers<br />

PRESIDENT<br />

roBert t. oxnard, maryland refraCtories Co.<br />

PRESIDENT-ELECT<br />

James e. Houseman, Harrop industries inC.<br />

TREASURER<br />

J. riCHard sCHorr, orton CeramiC foundation<br />

DIRECTORS<br />

stepHen J. Bennison (2003), e.i. du pont de nemours & Co. inC.<br />

amar s. BHalla (2002), tHe pennsylvania state university<br />

margaret l. Carney (2001), alfred university<br />

david e. Clark (2001), virginia polyteCHniC institute & state<br />

university<br />

don e. denison (2002), denison engineering Co.<br />

roger H. frenCH (2002), e.i. du pont de nemours & Co. inC.<br />

dale a. fronk (2001), orton CeramiC foundation<br />

riCHard l. leHman (2001), rutgers university<br />

katHryn v. logan (2003), u.s. army researCH offiCe<br />

Carlo g. pantano (2001), tHe pennsylvania state university<br />

david W. riCHerson (2003), riCHerson & assoCiates<br />

david r. rossington (2001), alfred university<br />

leslie J. struBle (2002), university of illinois, urBana<br />

louis J. trostel (2002), prinCeton, mass.<br />

SECRETARY<br />

W. paul HolBrook, tHe ameriCan CeramiC soCiety<br />

ART DIVISION<br />

CHair—derek r. gordon, ColumBus Clay Co.<br />

BASIC SCIENCE DIVISION<br />

CHair—James H. adair, tHe pennsylvania state university<br />

CEMENTS DIVISION<br />

CHair—CHiara f. ferraris, nist<br />

ELECTRONICS DIVISION<br />

CHair—rosario a. gerHardt, georgia institute of teCHnology<br />

ENGINEERING CERAMICS DIVISION<br />

CHair—ersan ustundag, California institute of teCHnology<br />

GLASS & OPTICAL MATERIALS DIVISION<br />

CHair—denise m. krol, university of California, davis-livermore<br />

NUCLEAR & ENVIRONMENTAL TECHNOLOGY DIVISION<br />

CHair—James C. marra, WestingHouse savannaH river Co.<br />

REFRACTORY CERAMICS DIVISION<br />

CHair—nanCy e. Bunt, lafarge aluminates inC.<br />

STRUCTURAL CLAY PRODUCTS DIVISION<br />

CHair—edWard C. milliken, BoWerston sHale Co.<br />

WHITEWARES & MATERIALS DIVISION<br />

CHair—William m. Carty, alfred university<br />

CERAMIC EDUCATIONAL COUNCIL<br />

president—Jennifer a. leWis, university of illinois, urBana<br />

CERAMIC MANUFACTURING COUNCIL<br />

president—riCHard HaBer, rutgers university<br />

NATIONAL INSTITUTE OF CERAMIC ENGINEERS<br />

president—Harrie J. stevens, Corning inC.<br />

The American Ceramic Society serves its members<br />

and the worldwide ceramics community by<br />

promoting the development and use of ceramics<br />

through forums for knowledge exchange. The chief<br />

means by which the Society fulfills this mission are<br />

the publication of periodical journals and books and<br />

the sponsorship of meetings. The Society also<br />

provides a number of other technical and support<br />

services for members and the worldwide ceramics<br />

community.<br />

February 2001<br />

The Prez Sez ...<br />

Who’s on First?<br />

Abbott & Costello’s comedy skit about who<br />

played which position on a baseball team sometimes<br />

reminds me of the leaders of your Society.<br />

It can be hard to keep everybody straight.<br />

You recently elected division and class officers,<br />

as well as three new directors with terms expiring<br />

in 2004. They join an outstanding and talented<br />

group of volunteers who work with your headquarters<br />

staff to provide the myriad services and<br />

benefits you expect from your professional<br />

Society. My association with your Board of<br />

Directors is truly the highlight of my professional<br />

career.<br />

Fan Them and Feed Them Grapes…<br />

Please join me in thanking the board members who complete their terms at this<br />

year’s Annual Meeting. Their genuine concern and desire to provide a bright<br />

future for your Society deserve more than mere words of thanks. If you could<br />

envision me fanning them and feeding them grapes, you would know the<br />

appreciation I feel.<br />

Knowing them, however, I’m sure it will be hard enough to get them to stand<br />

still long enough for a handshake and “thanks, job well done.”<br />

Margaret Carney, Alfred University, is the personification of the Art Division.<br />

She champions the museum and promotional activities of the Society with a je<br />

ne sais quoi that commands respect from all who know her.<br />

David E. Clark, Virginia Tech via the University of Florida, brought his NICE<br />

experience to the board. His background and dedication belay an “E.F. Huttonlike”<br />

respect—when David talks, people listen.<br />

Dale Fronk, Orton Foundation, represents the manufacturing community with<br />

a fervor and frankness that will be impossible to replace. I didn’t know Mother<br />

Theresa personally, but I’m going to remind St. Peter that I was a friend of Dale’s.<br />

Rick Lehman, Rutgers University, representing the Whitewares & <strong>Materials</strong><br />

Division, brings class to any group. He has a wonderful ability to think “big picture,”<br />

often helping us reach consensus.<br />

Carlo Pantano, Penn State, will be remembered as the Glass & Optical <strong>Materials</strong><br />

Division’s most ardent supporter. His leadership on the board has been so subtle<br />

and unassuming that I often thought it was my own ideas we were supporting.<br />

David Rossington, Alfred University, offers a studious, thoughtful approach to<br />

problem solving that pays homage to his Ceramic Educational Council perspective.<br />

I hope to have Dave’s sage diplomacy someday.<br />

Paul Becher, past president, goes off the board this year as well. The “sheriff”<br />

from Oak Ridge continues to serve admirably in every capacity after filling<br />

nearly every office in the Society. He’s a darned good “doer” and a tough act to<br />

follow.<br />

See You in Indianapolis?<br />

Why not join us at the Annual Meeting? Mark April 22–25 on your calendar now.<br />

This is a great benefit of your membership and one of the best ways to stay<br />

informed. You’ll visit old friends and colleagues, keep abreast of ceramic trends,<br />

and join your fellow movers and shakers. Our meetings committee has done an<br />

exceptional job on the program and symposia. I hope to see you there.<br />

Bob Oxnard, President<br />

The American Ceramic Society<br />

Tel. 330-532-9845 (Ohio) or 941-482-8017 (Florida)<br />

Fax 330-532-3224 (Ohio) or 941-482-8274 (Florida)<br />

www.ceramicbulletin.org • February 2001 7

CeramiC Bulletin<br />

AMERICAN SOCIETY<br />

THE MAGAZINE FOR TECHNOLOGY • ENGINEERING • MANUFACTURING<br />

Internet<br />

www.ceramicbulletin.org<br />

Advertising Sales Manager<br />

peter sCott<br />

tel. 614-794-5844<br />

fax 614-794-5842<br />

e-mail psCott@aCers.org<br />

Advertising Production Coordinator<br />

Wendy WHitesCarver<br />

tel. 614-794-5841<br />

fax 614-794-5842<br />

e-mail WWHitesCarver@aCers.org<br />

Western & Southern U.S., Canada<br />

annette delagrange<br />

3830 lakevieW drive<br />

galena, oH 43021<br />

tel. 740-965-1753<br />

fax 740-965-6712<br />

e-mail adelagrange@eartHlink.net<br />

New England, Mid-Atlantic & Midwestern U.S.<br />

Bonnie d. Hunt<br />

2953 ColumBia drive<br />

Bensalem, pa 19020<br />

tel. 215-750-7692, 800-598-7947 fax<br />

215-750-9557<br />

e-mail Bonnie@Hunt4ads.Com<br />

Europe<br />

Celine Beilvert/Crispin fordHam<br />

alain CHarles House,<br />

27 Wilfred street<br />

london sW1e 6pr england<br />

tel. 44-(0)-20-7834-7676<br />

fax 44-(0)-20-7973-0076<br />

e-mail media@alain.demon.Co.uk<br />

Italy<br />

federiCa ZuCCHini<br />

ADVERTISING SALES<br />

puBliZeta<br />

via CortiCella 216/6<br />

40128 Bologna, italy<br />

tel. 39-051-325452<br />

fax 39-051-320309<br />

CUSTOMER SERVICES<br />

Customer Service Representatives<br />

tel. 614-794-5890<br />

fax 614-899-6109<br />

e-mail CustomersrvC@aCers.org<br />

Diane Ritchey<br />

Ceramic Information Center<br />

tel. 614-794-5810<br />

fax 614-794-5812<br />

e-mail CiC@aCers.org<br />

Greg Geiger, CeramiC engineer<br />

8 The American Ceramic Society Bulletin, Vol. 80, No. 2

The American Ceramic Society<br />

103rd Annual Meeting & Exposition, Indianapolis, April 22–25 (tel. 614-<br />

794-5880, fax 614-794-5882, E-mail meetings@acers.org, Internet<br />

www.ceramics.org)<br />

104th Annual Meeting & Exposition, St. Louis, April 28–May 1, 2002 (614-<br />

794-5890, fax 614-899-6109, E-mail customersrvc@acers.org, Internet<br />

www.ceramics.org)<br />

Divisions<br />

PAC RIM IV, Int’l Conference on Advanced Ceramics and Glasses in conjunction<br />

with the Basic Science, Electronics and Glass & Optical<br />

<strong>Materials</strong> Divisions fall meetings, and the 53rd Pacific Coast Regional<br />

Meeting, Outrigger Wailea Resort, Maui, Hawaii, Nov. 4–8 (contact<br />

Christine Schnitzer, tel. 614-794-5819, E-mail cschnitzer@acers.org)<br />

Structural Clay Products, Sheraton Four Points, Canton, Ohio, May 19–22<br />

(contac t Howard Sachs, tel. 513-424-3573, E-mail JHS<br />

@meco-wires.com)<br />

Sections<br />

Southeastern, spring meeting, Manor Inn, Pinehurst, N.C., Feb. 27–March<br />

1 (contact Mitch Treadaway at Atofina Chemicals Inc., tel. 336-766-<br />

6685, fax 336-766-7455)<br />

Southwest, spring meeting, Ramada Plaza Hotel, Fort Worth, Texas,<br />

June 6–8; fall meeting, Harrah’s Shreveport Hotel, Shreveport, La.,<br />

Nov. 7–9 (contact Richard Tucker, tel. 903-843-2509, E-mail<br />

richardtucker@excelonline.com)<br />

St. Louis, 37th Annual Refractories Symposium, St. Louis Airport<br />

Marriott, St. Louis, March 23 (tel. 573-341-6265, E-mail psmith @umr.<br />

edu)<br />

Other Organizations<br />

4th Industrial <strong>Energy</strong> Efficiency Symposium and Exposition, Washigton,<br />

Feb. 19–22 (tel. 877-648-7967, Internet www.oitexpo4 .com)<br />

South-Tec Greenville 2001, Advanced Productivity Exposition,<br />

Greenville, S.C., Feb. 20–22 (tel. 800-733-4763, Internet www.sme .org/<br />

greenville)<br />

GlassLat 2001, Int’l Exhibition of the Glass Industry, Monterrey, Mexico,<br />

Feb. 21–23 (tel. 52-8-348-48-48, fax 52-8-348-60-00, E-mail giplaura@<br />

acnet.net)<br />

GMIC Workshop on Glass Melting Technologies of the Future,<br />

Washington, Feb. 22 (contact Michael Greenman, tel. 614-818-9423,<br />

E-mail mgreenman@gmic.org)<br />

Cevisama 2001, 19th Int’l Trade Show for Ceramics, Valencia, Spain, Feb.<br />

27–March 3 (tel. 34-96-386-1100, fax 34-96-363-61-11,<br />

E-mail feriavalencia@feriavalencia.com)<br />

North American Manufacturing Co. Annual Ceramic Seminar, Nashville,<br />

Te n n . , Fe b . 2 8 – M a r c h 2 ( t e l . 6 1 5 - 3 7 1 - 8 4 9 6 , E - m a i l<br />

ceramicseminar@namfg.com)<br />

S PittCon 2001, New Orleans, March 4–9 (tel. 412-825-3220, fax 412-825-<br />

3224, E-mail pittconinfo@pittcon.org, Internet www.pittcon.org)<br />

ICSHM7, 7th Int’l Conference on the Science of Hard <strong>Materials</strong>, Ixtapa,<br />

Mexico, March 5–9 (tel. 58-2-908-6843, fax 58-2-908-6916,<br />

E-mail grigorescuc@pdvsa.com, Internet www.upc.es/cmem/ICSHM7)<br />

Inter-Society Color Council Educational Council, Cleveland, March 19–20<br />

( t e l . 7 0 3 - 3 1 8 - 0 2 6 3 , f a x 7 0 3 - 3 1 8 - 0 5 1 4 , E - m a i l i s c c<br />

@compuserve.com, Internet www.iscc.org)<br />

S CerMA Spring Educational Conference on Drying, Tour of Metropolitan<br />

Ceramics by Ironrock Capital Inc., Holiday Inn-North Canton, Ohio,<br />

M a r c h 2 2 – 2 3 ( t e l . 7 4 0 - 4 5 2 - 4 5 4 1 , f a x 7 4 0 - 4 5 2 - 2 5 5 2 ,<br />

E-mail cerma.info@offinger.com)<br />

S Denotes new entry in this issue.<br />

Meetings & expositions Calendar<br />

S 2001 Ceramic Industry Combustion Seminar, Cleoria, Pa., March 26–27<br />

(contact Paul Palkovic, tel. 717-272-3051)<br />

Workshop on Microwave Ceramics, Adams Mark Hotel, Denver, March<br />

26–27 (E-mail abstracts@imaps.org, Internet www.imaps.org /<br />

abstracts.htm)<br />

Hyalos-Vitrum-Glass: History, Technology and Conservation of<br />

Glass and Vitreous <strong>Materials</strong> of the Hellenic World, Rhodes,<br />

Greece, April 1–4 (tel. 301-650-3301, fax 301-654-7690,<br />

E-mail gkordas@ims.demokritos.gr)<br />

Annual Ceramics Convention, Cirencester, U.K., April 4–5 (E-mail melanie_boyce@materials.org.uk)<br />

Glassman Europe 2001, 15th Int’l Glass Manufacturing Exhibition, Palais<br />

des Congres, Lyon, France, April 4–5 (tel. 44-0-1737-855301,<br />

E-mail tickets@uk.dmgworldmedia.com)<br />

S Seramiktek 2001, 3rd Int’l Trade Fair for Ceramic and Glass<br />

Technologies, Beylikdüzü, Istanbul, April 19–22 (tel. 0212-251-23-28,<br />

fax 0212-252-98-86, E-mail asdf@rdf.com.tr, Internet www.asdf .com.<br />

tr)<br />

S ASTM Advanced Ceramics Committee Meeting, Indianapolis, April<br />

20–22 (contact Gloria Collins, tel. 610-832-9715, E-mail gcollins@astm.<br />

org)<br />

Process Industries Exposition, George R. Brown Convention Center,<br />

Houston, April 24–26 (tel. 203-221-9232, Internet www<br />

.processexpo.com)<br />

PEI Technical Forum, Nashville Airport Marriott, Nashville, Tenn., May<br />

19–22 (tel. 615-385-5357, fax 615-385-5463, E-mail penamel @aol.<br />

com)<br />

Powder and Bulk Solids Conference/Exhibition, Chicago, May 7–10 (tel.<br />

800-354-4003, Internet powdershow.reedexpo.com)<br />

Fractography of Advanced Ceramics Int’l Conference, Stará Lesná, The<br />

High Tatras, Poprad, The Slovak Republic, May 13–16 (tel. 421-95-633-<br />

8115, fax 421-95-633-7108, E-mail fac2001@imrnov.saske.sk, Internet<br />

www.imrnov.saske.sk/CONFER /fac2001.htm)<br />

Ceramics China 2001, 15th China Int’l Ceramics Industry Exhibition,<br />

China Foreign Trade Center, Guangzhou, May 14–17 (tel. 86-10-<br />

68041566-7, fax 86-10-6834698-0, E-mail ccpitbms@public3 .bta.net.<br />

cn)<br />

S i k k i m I n t ’ l N a n o t r i b o l o g y S y m p o s i u m , S i k k i m , I n d i a ,<br />

May 16–25 (tel. 91-80-360-0586, fax 91-80-360-0648, E-mail nanosikkim@mecheng.iisc.ernet.in,<br />

Internet www.mecheng.iisc .ernet.in/<br />

nanosikkim.html)<br />

Coverings 2001, The Int’l Tile and Stone Exhibition, New Orleans, May<br />

21–23 (tel. 561-776-0600, fax 561-776-7466, E-mail info@coverings .<br />

com, Internet www.coverings.com)<br />

SOFC-VII, 7th Int ’l Symposium on Solid Oxide Fuel Cells,<br />

Ts u k u b a I n t ’ l C o n g r e s s C e n t e r, I b a r a k i , J a p a n , J u n e<br />

3–8 (tel. 81-298-61-4542, fax 81-298-61-4540, E-mail sofc7 @nimc.go.<br />

jp, Internet www.nimc.go.jp/sofc7/index-e.html)<br />

Structure and Mechanical Properties of Nanostructured <strong>Materials</strong>, Barga,<br />

Italy, June 3–8 (tel. 212-591-7441, fax 212-591-7441, E-mail engfnd@<br />

aol.com, Internet www.engfnd.org/engfnd/1au)<br />

S CIP’ 2001, 13th Int’l Colloquium on Plasma Processes, Antibes-Juanles-Pins,<br />

French Riviera, June 10–14 (fax 33-01-42-78-63-20, E-mail<br />

sfv@vide.org, Internet www.vide.org/cip2001.htm)<br />

Glass Processing Days, 7th Int’l Conference on Architectural and<br />

Automotive Glass, Tampere, Finland, June 18–21 (tel. 358-3-372-3111,<br />

fax 358-3-372-3190, Internet www.glassprocessingdays.com)<br />

2nd European Cells & <strong>Materials</strong> Meeting, Congress Center, Davos,<br />

Switzerland, June 25–28 (tel. 41-81-4142-397, fax 41-81-4142-288,<br />

E-mail geoff.richards@ao-asif.ch, Internet www.ao-asif.ch/ari /<br />

research/interface/index.shtml)<br />

www.ceramicbulletin.org • February 2001 9

Meetings & expositions Calendar<br />

S 59th Annual Device Research Conference, Notre Dame, Ind., June<br />

25–27 (contact Beate Helsel, tel. 724-776-9000 ext. 259, fax 724-776-<br />

3770, E-mail tmsgeneral@tms.org)<br />

S 2001 Society of Women Enginners National Conference, Denver, June<br />

26–30 (tel. 212-509-9577, Internet www.SWE.org)<br />

EMC, 43rd Electronic <strong>Materials</strong> Conference, University of Notre Dame,<br />

Notre Dame, Ind., June 27–29 (tel. 724-776-9000 ext. 243,<br />

E-mail mtgserv@tms.org, Internet www.tms.org/Meetings/Specialty /<br />

EMC01/ EMC01.html)<br />

Advances in Environmental <strong>Materials</strong>, Int’l Convention and Exhibition<br />

Centre, Singapore, July 1–6 (tel. 65-794-1509, fax 65-792-1291, E-mail<br />

tjwhite@eti.org.sg, Internet www.mrs.org.sg/icmat2001)<br />

ICGXIX, 19th Int’l Conference on Glass, Edinburgh, Scotland, July 2–6<br />

(contact: Karen Boston, tel. 44-114-263-44555, fax 44-114-263-4411,<br />

E-mail Karen@sgt.org)<br />

CSC’4, 4th Int’l Conference on Electric Charges in Nonconductive<br />

<strong>Materials</strong>, Tours, France, July 2–6 (tel. 33-1-53-01-90-30, fax 33-1-42-<br />

78-63-20, E-mail sfv@vide.org, Internet www.vide.org/CSC4.htm)<br />

Fuel Cell 2001, Int’l Conference and Exhibition, Lucerne, Switzerland,<br />

July 2–6 (tel. 41-56-496-7292, fax 41-56-496-4412, E-mail info @efcf.<br />

com, Internet www.efcf.com)<br />

E-MRS 2001, European <strong>Materials</strong> Research Society, Strasbourg, France,<br />

June 5–8 (tel. 33-3-88-10-65-43, fax 33-3-88-10-63-43, E-mail emrs@<br />

phase.c-strasbourg.fr, Internet www.emrs.c-strasbourg.fr)<br />

23rd Mexican Ceramic Convention, Manzanillo Colima, Mexico, July<br />

8–15 (tel. 528-369-6441, fax 528-369-6443, E-mail soceram@prodigy .<br />

net.mx)<br />

Int’l Conference on Calcium Aluminate Cements, Edinburgh, Scotland,<br />

July 16–19 (E-mail Eleanor_Tipton@materials.org.uk)<br />

S CerMA Annual Golf Classic, Eaglesticks Golf Club, Zanesville, Ohio, Aug.<br />

7 (tel. 740-452-4541, fax 740-452-2552, E-mail cerma.info @offinger.<br />

com)<br />

World Ceramic Exhibition 2001 Korea, Ichon, Yoju and<br />

Kwangju, Korea, Aug. 10–Oct. 28 (tel. 82-331-237-8011, fax<br />

82-331-237-4295, E-mail p1@worldceramic.or.kr, Internet www .<br />

worldceramic.or.kr)<br />

EUROCVD13, 13th European Conference on Chemical Vapor<br />

Deposition, Glyfada, Athens, Greece, Aug. 26–31 (tel.<br />

33-562885670, fax 33-562885600, E-mail eurocvd13@imel.demokritos<br />

.gr, Internet www.imel.demokritos.gr/EUROCVD/eurocvd13.<br />

html)<br />

10th Int’l Meeting on Ferroelectricity, Madrid, Spain, Sept. 3–7 (tel.<br />

34-91-871-1800, fax 34-91-870-0550, E-mail imf10@etsit.upm.es,<br />

Internet www.imf10.etsit.upm.es)<br />

S CerMA Fall Educational Conference on Firing and Refractories, Batavia,<br />

N.Y., Sept. 12–13 (tel. 740-452-4541, fax 740-452-2552, E-mail cerma.<br />

info@offinger.com)<br />

29th Annual Conference of the North American Thermal Analysis<br />

Society, Adams Mark Hotel, St. Louis, Sept. 24–26 (phone 916-922-<br />

7032, fax 916-922-7379, Internet www.NATASINFO.org)<br />

S 44th Int’l Colloquium on Refractories 2001, Aachen, Germany, Sept.<br />

26–27 (tel. 49-228-91508-45, fax 49-228-91508-55, E-mail DIFK-<br />

BONN@t-online.de)<br />

Turning Ideas Into Reality for 50 Years<br />

National Engineers Week ®<br />

celebrates golden anniversary<br />

For the last 50 years, National Engineers Week has<br />

inspired students to explore the fields of math and<br />

science and discover how engineering improves their<br />

lives.<br />

And we’re not stopping now!<br />

Help discover the ceramic engineers of the next 50<br />

years by ordering a free planning kit from ACerS<br />

headquarters. Contact Mark Glasper, ACerS director of<br />

communications, by phone at 614/794-5898 or e-mail<br />

at mglasper@acers.org.<br />

National Engineers Week ® is supported by<br />

The American Ceramic Society and the<br />

National Institute of Ceramic Engineers.<br />

10 The American Ceramic Society Bulletin, Vol. 80, No. 2

Meetings & expositions Calendar<br />

SGCD DECO 2001 Show and Technical Seminar, Arlington, Va., Sept. 30–<br />

Oct. 3 (tel. 202-728-4132, fax 202-728-4133, Internet www.sgcd .org)<br />

High Temperature Ceramic Composite Conference, Munich,<br />

Germany, Oct. 1–3 (tel. 49-69-7917-747, fax 49-69-7917-733,<br />

E-mail info@htcmc.org)<br />

47th Int’l Brick Plant Operators Forum, Clemson, S.C., Oct. 1–3 (tel.<br />

864-656-1094 fax 864-656-1095, E-mail brick@clemson.edu,<br />

Internet www.brickandtile.org)<br />

S Int’l Workshop on Flow and Fracture of Advanced Glasses, Rennes,<br />

France, Oct. 21–25 (tel. 33-2-9928-2685, fax 33-2-9928-1600, E-mail<br />

vincent.keryvin@univ-rennes1.fr, Internet www.larmaur.univ<br />

-rennes1.fr/ffag)<br />

6th Int’l Symposium on Self-Propagating High-Temperature Synthesis,<br />

Haifa, Israel, Oct. 14–18 (Internet www.ism.ac.ru/events /shs2001/<br />

shs2001.html)<br />

S Int’l Workshop on Flow and Fracture of Advanced Glasses, Rennes,<br />

France, Oct. 21–25 (tel. 33-2-9928-2685, fax 33-2-9928-1600, E-mail<br />

vincent.keryvin@univ-rennes1.fr, Internet www.larmaur.univ<br />

-rennes1.fr/ffag)<br />

CICC-2, 2nd China Int’l Conference on High-Performance Ceramics,<br />

Kunming, Yunnan Province, China, Nov. 3–6 (Internet www.chimeb.<br />

edu.cn/meeting_e.htm)<br />

UNITECR 2001 Congress, 7th Biennial Worldwide Conference on<br />

Refractories, Fiesta Americana Coral Beach Hotel, Cancun, Mexico,<br />

November 4–8 (contact Gerardo Cortina, tel. 52-5-872-1005, fax 52-<br />

5-872-2541, E-mail gcortina@possehlmex.com, Internet www .<br />

unitecr-alafar2001.com)<br />

59th Electric Furnace Conference, Phoenix, Nov. 11–14 (tel. 724-776-<br />

1535 ext. 1, fax 724-776-0430, E-mail custserv@iss.org, Internet<br />

www.iss.org)<br />

2002<br />

2nd Int’l Colloquium on Modeling of Glass, Forming and Temping,<br />

Valenciennes, France, Jan. 23–25, 2002 (Internet www.univ<br />

-valenciennes.fr)<br />

IREFCON, 5th India Int’l Refractory Congress, Bhubaneswar, India, Feb.<br />

7–8, 2002 (tel. 91-33-240-8357, fax 91-33-240-8357, E-mail irmandia @<br />

hotmail.com, Internet www.irmaindia.org)<br />

S Qualicer 2002, 7th World Congress on Ceramic Tile Quality, Castellón,<br />

Spain, March 3–6, 2002 (tel. 34-964-35-65-00, fax 34-964-35-65-10,<br />

E-mail qualicer@camaracs.es, Internet www.qualicer.org)<br />

Fuel Cell 2002, Int’l Conference and Exhibition, Lucerne, Switzerland,<br />

July 1–5, 2002 (tel. 41-56-496-7292, fax 41-56-496-4412, E-mail info@<br />

efcf.com, Internet www.efcf.com)<br />

ICOM 2002 The Int’l Congress on Membranes and Mem brane<br />

Processes, Toulouse, France, July 7–12, 2002 (Internet www .ems.<br />

cict.fr)<br />

2nd Trade Show and Symposium for the Ceramic Industry, Monterrey,<br />

N.L., Mexico, July 11–12, 2002 (tel. 528-369-6441, fax 528-369-6443,<br />

E-mail soceram@prodigy.net.mx)<br />

S Tecnargilla 2002, Int’l Exhibition of Technology and Supplies for the<br />

Ceramic and Brick Industries, Rimini Expo Center, Rimini, Italy, Oct 1–5,<br />

2002 (tel. 039-0541-711-711, fax 039-0541-786-686, Internet www.tecnargilla.it)<br />

12 The American Ceramic Society Bulletin, Vol. 80, No. 2

Brick Business<br />

General Shale Products LLC (aka<br />

General Shale Brick) maintains one of<br />

the most widely respected laboratories<br />

in the North American brick industry at<br />

Kingsport, Tenn. The impact of the laboratory<br />

is seen in standards for brick<br />

products, research affecting reduction<br />

of production costs and research<br />

related to new products.<br />

General Shale takes a unique corporate<br />

approach to its research and product<br />

development. A corporate research<br />

committee, consisting of the president<br />

and the vice presidents of sales, finance,<br />

and engineering and research, meets<br />

regularly with the director of research<br />

and the ceramic engineer to make key<br />

decisions.<br />

According to Bob O’Quinn, director of<br />

research, the laboratory can cite several<br />

important contributions to the company.<br />

One of the foremost is the development<br />

of user-friendly coal firing,<br />

which involved the selection of coal<br />

preparation systems, the development<br />

of distribution methods and the engineering<br />

of burners to handle solid fuel.<br />

The work resulted in a patent on the<br />

coal feeder and injector system. General<br />

Shale practices coal firing at 12 plants in<br />

a total of 15 tunnel kilns.<br />

Other notable successes have been<br />

the development of coatings, precise<br />

control of colorants and accelerated<br />

quality-control procedures.<br />

One unusual capability in the<br />

Kingsport laboratory is a large-capacity<br />

General Shale’s Kingsport <strong>Laboratory</strong><br />

Denis Brosnan, Contributing Editor<br />

Overview of General Shale’s Research <strong>Laboratory</strong><br />

Year 1954<br />

started<br />

Key Continuing durability testing<br />

activities Plant support<br />

Product (color and texture) development<br />

Analysis of “in-wall” problems<br />

Training<br />

Key Joe Edwards, vice president of engineering and research<br />

technical Bob O’Quinn, director of research<br />

personnel John Brown, manager of process research<br />

Farrell Long, manager of material and product testing<br />

Ron Bacon, manager of electronic technicians<br />

Kevin Ham, ceramic engineer<br />

(13 employees total)<br />

Key All ASTM properties for block and brick<br />

capabilities Raw material evaluations/test firing (shuttle kiln)<br />

Freeze-thaw capability for 108 sample sets<br />

Coal testing<br />

Electrical laboratory<br />

Building 5750 ft 2 (534 m 2)<br />

size<br />

Plants 16 brick plants, four block plants and one lightweight<br />

served aggregate plant<br />

freezer used in durability testing. One<br />

hundred and eight 5-brick specimen<br />

sets can be tested simultaneously in the<br />

freezer.<br />

According to O’Quinn, the Kingsport<br />

facility conducts an annual laboratory<br />

school for newly hired production<br />

supervisors. College students frequently<br />

serve as interns during the<br />

summer months. O’Quinn urges college<br />

students to pay particular attention<br />

to raw material and processing<br />

fundamentals. As he sees increasing<br />

a u t o m a t i o n c o m i n g<br />

into the industry, a good fundamental<br />

Garvey Bright, a 28-year employee, runs a sulfur test in General Shale’s laboratory.<br />

background and long hours may be<br />

required to make the automatic systems<br />

work in a clay plant.<br />

The expansion of the laboratory since<br />

its beginnings is due, in part, to Joe<br />

Edwards, vice president of engineering<br />

and research, and Farrell Long, manager<br />

of material and product testing. Both<br />

joined the company in 1961, and both<br />

have recently been honored for their<br />

contributions to the brick industry. Joe<br />

Edwards received a doctor of laws<br />

degree from Clemson University in<br />

December 2000, for his contributions to<br />

the industry and his work in establishing<br />

the Bishop Ceramic Lab at Clemson<br />

University. (See also p 12 in the August<br />

2000 issue and p 33 in this issue of<br />

Ceramic Bulletin.)<br />

Edwards also is a long-time leader of<br />

ASTM’s task group on durability. His<br />

article, “Relation Between Physical<br />

Properties and Durability of Commercially<br />

Marketed Brick” (see pp 1071–75<br />

in the December 1977 issue), remains<br />

the basis for classifying brick durability,<br />

according to the standards.<br />

Farrell Long is the initial recipient of<br />

ASTM’s Gilbert C. Robinson Memorial<br />

Award. Presented in December 2000, the<br />

award recognizes his long-time contributions<br />

in standards development. (See<br />

p 34 in this issue.)<br />

It is fair to say that General Shale is a<br />

leader in the brick industry, in part,<br />

because of the Kingsport laboratory. n<br />

www.ceramicbulletin.org • February 2001 13

Technology Briefs<br />

New Process for<br />

High-T c Tape<br />

Researchers at the Superconductivity<br />

Technology Center at Los Alamos<br />

National Lab (N.M.) have developed a<br />

new process for producing high-performance<br />

superconducting tape. The<br />

process involves replacing cubic zirconia<br />

with magnesium oxide as the<br />

template material for the high-T c film.<br />

This change increases the template<br />

deposition process by 100 times.<br />

Long lengths of tape were manufactured<br />

at a rate of kilometers per day.<br />

To accelerate commercial development<br />

of these tapes, Los Alamos is<br />

colaborating with American Super -<br />

conductor Corp., 3M Co. and Intermagnetics<br />

G eneral Corp. The<br />

de vel op ment could mean an estimated<br />

$50-billion commercial market<br />

to produce more efficient<br />

electrical power transmission equipment,<br />

saving energy and money, laboratory<br />

officials reported. (Contact:<br />

D. Peterson, E-mail dpeterson@lanl.<br />

gov)<br />

Heat-Resistant<br />

Piezoceramics<br />

When conventional piezoceramics are<br />

heated to temperatures of ≈250°C<br />

(i.e., during the solder reflow process<br />

in filter production) and then cooled<br />

to room temperature, properties, such<br />

as the resonance frequency, often<br />

become degraded. Matsushita Electric<br />

Indus trial Co. (Japan) reports it has<br />

solved this problem by developing a<br />

PZT piezoelectric ceramic composition<br />

with improved thermal stability.<br />

Possible applications of the new<br />

ceramic include filters, oscillators,<br />

transducers and sensors. (Contact:<br />

Matsushita Electric Industrial Co., 1006<br />

Oaza Kadoma, Kadoma City, Osaka<br />

571-8501, Japan, tel. 81-6-6908-1121)<br />

Atom Substitution for<br />

Better Ceramics<br />

At t h e U n i ve r s i t y o f M u n i c h<br />

(Germany), scientists have added various<br />

atoms into the crystal structure<br />

of nitridosilicates, sions (silicon oxynitrides),<br />

and sialons (silicon aluminum<br />

oxynitrides) to create materials with<br />

unusual properties. When atoms of<br />

strontium, barium or europium were<br />

added to nitridosilicates, the material<br />

was found to have excellent nonlinear<br />

optical properties, was stable at<br />

Greg Geiger, Technical Editor<br />

high temperatures and was strongly<br />

resistant to hydrolysis.<br />

When lanthanum, cerium, erbium,<br />

praseodymium and neodymium<br />

atoms were added to sions and<br />

sialons, investigators reported that<br />

some combinations resulted in<br />

exceptionally hard materials. Others<br />

formed regular arrays of microtubules<br />

or clathrate-type (cage) structures.<br />

(Contact: W. Schnick, E-mail wsc@cup.<br />

uni-muenchen.de)<br />

Imaging of<br />

Mesoporous <strong>Materials</strong><br />

A technique for the direct determination<br />

of 3-D mesoporous structures<br />

has been developed in a collaborative<br />

effort by researchers at the<br />

Tohoku University (Sedai, Japan), the<br />

University of California (Santa<br />

Barbara) and others. The method<br />

uses high-resolution elec tron<br />

microscopy to obtain images that<br />

can be mathematically treated to<br />

give a full 3-D structure.<br />

The images provide information<br />

about the size and shape of the pores<br />

at the nanoscale level as well as their<br />

connectivity. The technique also can<br />

be used to characterize the detailed<br />

structure of a wide range of composite<br />

materials. (Contact: O. Terasaki,<br />

E-mail terasaki@msp.phys.tohoku.ac.<br />

jp)<br />

Eco-friendly Process for<br />

Silicon-Based Chemicals<br />

An inexpensive and relatively nontoxic<br />

method for producing a variety<br />

of silicon-based chemicals from sand<br />

or rice hull ash and ethylene glycol<br />

(antifreeze) has been developed at<br />

The University of Michigan (Ann<br />

Arbor). According to investigators,<br />

the new technology could enable<br />

manufacturers to create siliconbased<br />

compounds without expensive,<br />

high-temperature processing<br />

and toxic by-products. Products that<br />

could be made using this process<br />

include common silicon-containing<br />

chemicals, polymers, plastics and<br />

pure silica. The silica could be used,<br />

among other things, as filler for polymers,<br />

in papermaking and in the production<br />

of optical glass. (Contact: R.<br />

Laine, E-mail talsdad@umich.edu)<br />

For further information, contact Greg<br />

Geiger at the Ceramic Information Center,<br />

tel. 614-794-5817, 3E-mail ggeiger @acers.<br />

org.<br />

16 The American Ceramic Society Bulletin, Vol. 80, No. 2

Society/<br />

Industry<br />

NEWS<br />

Ferro Buys EMCA-Remex<br />

Ferro Corp., Cleveland, has acquired<br />

EMCA-Remex from National Starch &<br />

Chemical Co., Bridgewater, N.J. Terms<br />

of the agreement were not disclosed.<br />

EMCA-Remex specializes in the production<br />

of thick-film pastes for<br />

hybrid microelectronics. These materials<br />

are used in applications in the<br />

automotive, telecommunications and<br />

consumer electronics markets. The<br />

business has a technology and distribution<br />

agreement for resistor formulations<br />

that provides exclusive selling<br />

rights in the United States and<br />

Europe.<br />

“We continue to invest in our electronic<br />

materials business to build<br />

greater scale,” said Hector R. Ortino,<br />

chair and CEO of Ferro. “Through a<br />

combination of internal strategic<br />

changes, acquisitions and strong<br />

demand, in a short period of time, we<br />

have built an electronic materials<br />

business that is a much more significant<br />

driver of Ferro’s overall performance.”<br />

Ferro’s existing thick-film paste<br />

product line, produced in a new<br />

state-of-the-art facility at Vista, Calif.,<br />

serves market segments that complement<br />

EMCA-Remex’s product line.<br />

EMCA-Remex’s only U.S. manufacturing<br />

site is at Montgomeryville, Pa. It<br />

also operates a technical service laboratory<br />

and production facility at<br />

Linton, U.K.<br />

Keller Acquisition<br />

Ceric S.A., Paris, officially took over<br />

the remaining operations of Keller<br />

GmbH, Laggenbeck, Germany, Dec.<br />

1, 2000.<br />

More than 100 years old, Keller had<br />

fallen into bankruptcy in early Septem<br />

ber last year. The administrator in<br />

charge of the bankruptcy chose<br />

Ceric from among a few other candidates<br />

to take over Keller, primarily<br />

because the Ceric plan saves 340<br />

jobs out of the ≈500 that existed<br />

prior to the bankruptcy.<br />

The previous management team<br />

has been replaced by a group of<br />

German and French business leaders<br />

who will make sure the Ceric philosophy<br />

centered around customer service<br />

is understood and followed.<br />

Former Keller customers can be<br />

assured of continuity of after-sales<br />

service, especially where spare parts<br />

are concerned.<br />

Following the acquisition earlier<br />

this year of Rieter, also a German<br />

company, the addition of Keller to<br />

the Ceric Group creates the largest<br />

worldwide consortium for the supply<br />

of manufacturing systems for the<br />

clay products industry.<br />

The Keller and Rieter names will be<br />

kept for the foreseeable future.<br />

However, all companies will operate<br />

in a coordinated manner, and for<br />

ease of business, Ceric Inc. (Golden,<br />

Colo.) will be the focus and sole representative<br />

for the Ceric Group of<br />

companies in North America.<br />

MCS Officers Meet at ACerS Headquarters<br />

Three Mexican Ceramic Society (MCS) officers met with staff at ACerS headquarters Dec.<br />

11–12, 2000, to wrap up discussions regarding the First Trade Show & Conference for the<br />

Ceramics Industry 2000, held jointly in November by MCS and ACerS. They also discussed<br />

future joint efforts between the two organizations. Officers attending the meeting<br />

included (l–r) Angél Hernández R., MCS past president; Paul Holbrook, ACerS executive<br />

director; Constantino Gianacópulos R., MCS president; and Aniceto Arroyo Gómez, MCS<br />

vice president.<br />

www.ceramicbulletin.org • February 2001 17

S O C I E T Y / I N D U S T R Y<br />

HOUSING STARTS*<br />

Privately Owned<br />

Units Change<br />

2000 (000) (±6%)<br />

Nov 1,562 1%<br />

Oct 1,528 -2%<br />

Sep † 1,537 1%<br />

Aug † 1,519 -1%<br />

*Seasonally adjusted annual rate<br />

† Revised<br />

MANUFACTURED HOME<br />

SHIPMENTS*<br />

2000 Units (000) Change (±)<br />

Nov 196 -8%<br />

Oct 213 -1%<br />

Sep 231 -7%<br />

Aug 249 -1%<br />

*Seasonally adjusted annual rate<br />

STEEL MILL SHAPES<br />

Short Tons (000)<br />

2000 Shipments* Imports †<br />

Oct 9,006 (NA)<br />

Sep 8,632 2,321<br />

Aug 9,302 2,857<br />

Jul 8,556 2,865<br />

*Source: American Iron & Steel Institute<br />

† Source: Bureau of Census Report IM 145<br />

Business Stats Confrontational Clay<br />

PLUMBING FIXTURES*<br />

Value of Shipments (US$M)<br />

1999 1998 1997 1996 1995<br />

Cast iron<br />

(enameled)<br />

289 274 261 270 239<br />

Vitreous<br />

china<br />

932 884 876 860 892<br />

Fiberglass<br />

1,358 1,288 1,267 1,145 996<br />

Plastics 427 416 372 362 337<br />

* Data is now published on the new North American Industry<br />

Classification System (NAICS) basis and, therefore, is not always<br />

comparable to the old Standard Industrial Classification (SIC)<br />

code<br />

VALUE OF<br />

MANUFACTURERS<br />

SHIPMENTS<br />

Seasonally Adjusted<br />

Monthly (US$M)<br />

2000 Nov* Oct † Sep<br />

Stone, clay,<br />

glass products<br />

8,521 8,677 8,741<br />

Blast furnaces,<br />

steel mills<br />

5,466 5,678 5,715<br />

Iron, steel<br />

foundries<br />

1,415 1,405 1,408<br />

Electrical transmission/<br />

distribution<br />

equipment,<br />

industrial<br />

apparatus<br />

4,162 4,086 4,159<br />

Household<br />

appliances<br />

2,320 2,320 2,396<br />

Household A/V<br />

equipment<br />

1,117 1,125 1,074<br />

Communications<br />

equipment<br />

10,286 10,570 10,733<br />

Electronic<br />

components<br />

17,968 18,027 18,594<br />

Motor<br />

vehicles, parts<br />

30,041 31,444 32,821<br />

Aircraft, missiles,<br />

space vehicles,<br />

parts<br />

11,821 10,529 11,992<br />

Instruments,<br />

related products<br />

*Preliminary<br />

† Revised<br />

15,371 15,459 15,574<br />

GLASS CONTAINER<br />

SHIPMENTS<br />

(000 gross)<br />

2000 1999<br />

Dec 18,085<br />

Nov 20,508<br />

Oct 20,409 20,265<br />

Sep 20,141 21,121<br />

Aug 22,910 22,656<br />

Jul 21,087 22,244<br />

Jun 23,154 24,128<br />

May 23,037 22,476<br />

Apr 20,179 21,806<br />

Mar 21,924 23,617<br />

Feb 19,614 19,453<br />

Jan 19,367 19,260<br />

Total 211,822 255,619<br />

Source of Statistics: U.S. Dept. of Commerce, Bureau<br />

of the Census<br />

For additional information, please<br />

contact the<br />

Ceramic Information Center<br />

614-794-5810<br />

“Mist” by Sergei Isupov, porcelain, 1998.<br />

Social commentaries by ceramic artists are<br />

the topic of the current exhibit at the<br />

American Craft Museum in New York.<br />

“Confrontational Clay: The Artist as Social<br />

Critic” runs through March 16, 2001. For<br />

more information, call 212-956-3535.<br />

(Photo courtesy of The Ferrin Gallery)<br />

Tosoh Realigns Silica Glass<br />

Material Sales<br />

Nippon Silica Glass USA Inc., Bound<br />

Brook, N.J., has been renamed Tosoh<br />

SGM USA Inc. Tosoh SGM continues<br />

as the sales and distribution channel<br />

of silica glass materials, zirconia powders<br />

and advanced ceramic products<br />

and materials for Tosoh Corp. (Tokyo)<br />

in the United States.<br />

This renaming strategically follows<br />

the recent name change of quartz<br />

material producer NSG Yamaguchi<br />

Co. Ltd. to Tosoh SGM Corp., as well as<br />

the transfer of silica glass sales<br />

assignments from Nippon Silica Glass<br />

Co. Ltd. to the Tosoh Quartz Div. All<br />

Tosoh-affiliated quartz fabrication<br />

companies throughout the world<br />

have been unified under the name<br />

Tosoh Quartz.<br />

As part of the quartz group unifica-<br />

18 The American Ceramic Society Bulletin, Vol. 80, No. 2

tion process, Tosoh aims to enhance<br />

further its worldwide silica glass<br />

material line of business by bringing<br />

about a more efficient utilization of<br />

resources through the sharing of<br />

information and technology as well<br />

as R&D and marketing efforts.<br />

CoorsTek Expands<br />

Capability in Korea<br />

CoorsTek Inc., Golden, Colo., is<br />

expanding the capacity of its subsidiary,<br />

CoorsTek Korea, Kyungbook,<br />

South Korea, to include lasered substrates.<br />

These ceramic substrates are<br />

used in the production of electronic<br />

circuits for the telecommunications<br />

and automotive markets.<br />

State-of-the-art laser equipment<br />

using technology developed and<br />

refined by CoorsTek in the United<br />

States and Scotland is being<br />

installed. This expansion enhances<br />

CoorsTek’s position as a leading producer<br />

of thick- and thin-film substrates,<br />

and extends its offering of<br />

lasered substrates to all key global<br />

markets. CoorsTek Korea is expected<br />

to begin production of the lasered<br />

substrates during the first quarter of<br />

2001.<br />

Expansion Complete at<br />

Horizon Photonics<br />

Horizon Photonics Inc., a wholly<br />

owned subsidiary of LightPath<br />

Technologies Inc., has completed the<br />

expansion of its automated manufacturing<br />

facility at Walnut, Calif. The<br />

930-m 2 (10,000-ft 2 ) facility is currently<br />

dedicated to large volume isolator<br />

production and the development of<br />

next-generation optical subassemblies.<br />

Horizon’s component packaging<br />

capabilities are based on its<br />

recently issued U.S. patent covering<br />

its automated fabrication platform<br />

for micro-optics.<br />

Bob Cullen, president of Horizon<br />

Photonics, commented, “We are truly<br />

pleased with our expansion efforts<br />

since merging with LightPath. We<br />

S O C I E T Y /<br />

now have the capacity and automated<br />

packaging experience in place to<br />

execute our ramping orders from<br />

both existing and new OEM customers.”<br />

In addition, LightPath has hired<br />

Joseph E. Sauvageau as Horizon’s<br />

chief technology officer. Sauvageau<br />

has a significant background in optoelectronic<br />

engineering, packaging<br />

and manufacturing, with a number of<br />

related patents and publications to<br />

his credit. He spent a number of years<br />

at NIST and, most recently, was with<br />

Motorola.<br />

Royal Porcelain Seeks New<br />

Asian Markets<br />

Royal Porcelain Plc, Thailand’s largest<br />

exporter of tableware, plans to<br />

increase sales to $40 million in 2001<br />

by pursuing new markets in Asia.<br />

Sales to Russia and the Middle East<br />

have been growing steadily, but Asia<br />

remains an attractive market yet to be<br />

captured.<br />

www.ceramicbulletin.org • February 2001 19

ACerS Section Notes<br />

S O C I E T Y / I N D U S T R Y<br />

• Central Ohio. Da Vinci Ristorante in Columbus was<br />

the venue for President’s Night, Nov. 30, 2000. ACerS<br />

President Bob Oxnard presented “A Pop Quiz about<br />

ACerS.”<br />

The Section also organized a group to attend a<br />

hockey game at Nationwide Arena, Dec. 2. The<br />

Columbus Blue Jackets played the Atlanta Thrashers.<br />

• Rocky Mountain. Together with the <strong>Materials</strong> Dept.<br />

at the Colorado School of Mines, the Section sponsors<br />

the <strong>Materials</strong> Science Lecture Series at the university.<br />

Sheldon M. Wiederhorn of NIST, Gaithersburg, Md.,<br />

was the guest lecturer, Oct. 12, 2000. In his talk, “Hightemperature<br />

Creep Behavior of Particulate Ceramic<br />

Composites,” he discussed the causes of degradation<br />

in mechanical behavior at elevated temperatures and<br />

the mechanisms of deformation in the bonding phase.<br />

Zemir Gavra, a professor at Ben-Gurion University,<br />

Israel, delivered the Dec. 7 lecture. He spoke about<br />

“New Trends in Hydrogen Storage <strong>Materials</strong>.”<br />

• Northwest Indiana. Quentin Robinson (manager of<br />

research, Vesuvius USA) was the dinner speaker when<br />

the Section met Nov. 30, 2000, at the Patio Restaurant<br />

in Merrillville. Approximately 30 members attended.<br />

The topic of his discussion was “Casting Channel<br />

Design (i.e., Tundish Slide Gates) and Its Effect on Steel<br />

Flow and Clogging.” Robinson included slides of the<br />

slide gate water model, showing the flow in a tundish<br />

system.<br />

Various designs and configurations were used to<br />

determine the best flow pattern for a tundish slide<br />

gate. The water model was computer modeled to<br />

check for consistency and reproducibility.<br />

Calculations from the data provided comparable<br />

Quentin Robinson discusses casting channel design at a<br />

meeting of the Northwest Indiana Section.<br />

results between the water and computer models. From<br />

this information, the computer model can be used to<br />

determine the effects of variations on the slide gate<br />

system.<br />

• Southwest. The fall meeting went as planned at the<br />

Arlington Hotel, Hot Springs, Ark., Nov. 15–17, 2000.<br />

More brickmakers attended this meeting than in the<br />

recent past. Perhaps the tour of Acme Brick Co.’s<br />

Ouachita plant had something to do with it.<br />

Some of the highlights are reported below:<br />

Barry T. Hughes, president of Halbert Mill Co.,<br />

Jacksonville, Texas, was honored with the Harry E.<br />

Ebright Service Award. He was cited for his outstanding<br />

service to the Section through contributions to<br />

the ceramic arts and sciences and for the promotion<br />

of the Southwest Section and, thus, The American<br />

Ceramic Society.<br />

The Carl and Barbara Hogue First Lady Award was<br />

presented to Beckie Schlager who has taken charge<br />

of the ladies program several times and served on the<br />

companions program committee even more frequently.<br />

Robert H. Bruns, Gilmer Potteries Inc., reports that<br />

11 golfers braved the cold at the Hot Springs Country<br />

Club Arlington Course. Bruns, together with Carl<br />

Hogue and Dave Kirkendall, finished first with a score<br />

of 71 (one under par). The fact that they were the only<br />

team with three players may have had something to<br />

do with it.<br />

The team of Richard C. Tucker (Gilmer Potteries Inc.)<br />

and Bryan Byrd (American Restoration Tile) came in<br />

second with a score of 81. Steve Bohannon (Acme<br />

Brick Co.) had the longest drive on hole No. 9; Bruns<br />

was closest to the hole on No. 8; and Dusty McGregor<br />

(Acme Brick Co.) was closest to the hole on No. 17<br />

New officers for 2001 were installed during the business<br />

meeting. They are: chair, Richard C. Tucker,<br />

Gilmer Potteries Inc.; chair-elect, Michael E. Shipley,<br />

U.S. Brick Co.; vice chair, Randall Wheeler, Jonesboro,<br />

Ark.; treasurer, Robert H. Bruns, Gilmer Potteries Inc.;<br />

and secretary, Gary Schlager, Process Engineering<br />

Services. Fred C. McMann of North American Mfg. Co.<br />

continues to serve as counselor.<br />

The spring meeting will be held at the Ramada<br />

Plaza Hotel, Fort Worth, Texas, June 6–8, 2001. The fall<br />

2001 meeting is scheduled at Harrah’s Shreveport<br />

Hotel, Shreveport, La., Nov. 7–9. In spring 2002, the<br />

meeting will be at the Holiday Inn Sun Spree Resort,<br />

South Padre Island, Texas, June 26–28. Contact<br />

Richard Tucker, tel. 903-843-2509, E-mail richardtucker<br />

20 The American Ceramic Society Bulletin, Vol. 80, No. 2

Last year, exports earned the company<br />

$30 million, primarily from the<br />

United States and Europe. Both company<br />

brands, Royal Porcelain and<br />

Bone China, were particularly wellknown<br />

in Italy and the United<br />

Kingdom.<br />

The company’s two factories in<br />

Saraburi have a combined production<br />

capacity of 3.5 million pieces per<br />

month, 80% of which is exported.<br />

ICDD Scholarships<br />

The International Centre for Diffraction<br />

Data (ICDD), Newtown<br />

Square, Pa., has selected recipients of<br />

its Ludo Frevel Crystallography<br />

Scholarships for 2001.<br />

James Lettieri, The Pennsylvania<br />

State University, is working on<br />

research involving “Ferroelectric<br />

Anisotropy and Integration of<br />

SrBi 2 Ta 2 O 9 .” Jennifer Stone, Oregon<br />

State University, is investigating<br />

“Structural Studies of High-Power<br />

Optical <strong>Materials</strong>.” Each student<br />

receives a check for $2250 to help<br />

them continue their studies in their<br />

selected fields of crystallographic<br />

research.<br />

Alumina Ceramic Tile<br />

Alumina ceramic offers superior<br />

protection with minimum weight, features<br />

needed when developing vehicle armor. It<br />

meets the demand for modern vehicles to<br />

have high mobility and maneuverability,<br />

without compromising survivability.<br />

(Photo courtesy of Morgan Advanced<br />

Ceramics Inc., Latrobe, Pa.)<br />

S O C I E T Y / I N D U S T R Y<br />

Navitar Coating Labs<br />

Expands Product Line<br />

Navitar Coating Labs Inc. (formerly<br />

GM Vacuum Coating), Rochester, N.Y.,<br />

has expanded its line of solderable<br />

coatings for glass and ceramic substrates<br />

to include coatings as thin as<br />

0.30 µm. These micro-thin coatings<br />

find applications in missiles, fiber<br />

optics, aerospace and passive IR<br />

detectors. They also are suited for the<br />

hermetic sealing of optical systems.<br />

The coating is applied using a special<br />

low-stress sputtering process so<br />

that it is extremely durable. In fact, its<br />

strength exceeds that of the glass<br />

substrate.<br />

PPG Joint Ventures<br />

PPG Industries Inc., Pittsburgh, is the<br />

technical and training advisor for a<br />

$10-million expansion at the Cristal<br />

Laminado o Templado S.A. de C.V.<br />

(CITSA) automotive glass fabricating<br />

plant at Tepeji del Rio, Mexico, 30<br />

miles north of Mexico City. The oper-<br />

www.ceramicbulletin.org • February 2001 21

Legislative & Public Affairs<br />

S O C I E T Y / I N D U S T R Y<br />

John Kaniuk, president of Zircoa<br />

Inc., is a member of the LPAC<br />

Executive Committee<br />

Update on Naturally Occurring<br />

Radioactive <strong>Materials</strong> (NORMs)<br />

Naturally occurring radioactive<br />

materials (NORMs) and technology<br />

enhanced radioactive materials<br />

(TENORMs) continue to be<br />

important topics for the ceramics<br />

industry. Small amounts of uranium<br />

(U) and thorium (Th) are present<br />

in most raw materials mined<br />

from the earth, and various governmental<br />

agencies are deciding<br />

how to regulate these materials<br />

to ensure public safety.<br />

The Nuclear Regulatory Commis<br />

sion (NRC) is responsible for<br />

regulating radioactive materials.<br />

NRC currently grants an unrestricted<br />

license to those who handle<br />

radioactive materials below<br />

500 ppm of U and Th. The states<br />

and EPA, however, want these<br />

materials regulated more closely.<br />

Therefore, NRC is contemplating<br />

a rule that would require persons<br />

who hold NRC specific source<br />

material licenses to notify NRC<br />

before any unimportant quantities<br />

of source material (

ation is a partnership of PPG and the<br />

Villaseñor family.<br />

The expansion includes addition of<br />

tempering equipment that will allow<br />

CITSA to produce side and back automotive<br />

windows, as well as windshield<br />

production equipment using<br />

advanced PPG technology to supply<br />

more complicated original-equipment<br />

parts. This will allow CITSA to<br />

supply full-car sets of windows to the<br />

growing Mexican automotive industry.<br />

PPG also plans to join Nan Ya<br />

Plastics Corp. of Taiwan in building a<br />

plant at Kunshan, China, to make<br />

fiber-glass yarns, primarily for electronics<br />

customers. The project is subject<br />

to Taiwan government approval.<br />

PFG Fiber Glass (Kunshan) Co. Ltd.<br />

will produce electronic yarns in a<br />

Kunshan industrial economic development<br />

zone west of Shanghai. Nan<br />

Ya is building an adjacent complex<br />

that will include weaving, laminating<br />

and circuit board production facilities.<br />

It will be PFG’s principal customer.<br />

Startup is scheduled in early 2003.<br />

Lindberg/BlueM Distributor —<br />

Furnaces, Ovens &<br />

Replacement Parts<br />

• Discount Pricing<br />

• Quick Delivery<br />

• Many Models In Stock<br />

• Custom Furnaces<br />

Illustrated Ceramics<br />

These teapots are included in a onewoman<br />

exhibition showcasing the<br />

illustrated ceramic works of Sayoko Becker.<br />

Gallery Alexander, La Jolla, Calif., hosts the<br />

exhibit March 10–April 15, 2001. For<br />

details, call 858-459-9433.<br />

Glass Industry Funded for<br />

<strong>Energy</strong> Efficiency<br />

The age-old trade of glassmaking will<br />

get a helping hand from 21st century<br />

technology under an $11.8-million<br />

government-industry partnership to<br />

reduce energy use and environmen-<br />

Call Toll-Free: 1-888-264-7856<br />

S O C I E T Y / I N D U S T R Y<br />

tal impacts in the U.S. glass industry.<br />

The private sector cost share will be a<br />

minimum of 50% of each project.<br />

Facing pressure from foreign competition<br />

and alternative materials, the<br />

U.S. glass industry must find ways to<br />

reduce manufacturing costs while<br />

maintaining quality and protecting<br />

the environment. The industry spends<br />

more than $1.3 billion each year just<br />

on energy for manufacturing processes.<br />

It is an important segment of the<br />

U.S. economy. The glass industry<br />

employs more than 150,000 people<br />

and generates more than 21 million<br />

tons of consumer products annually<br />

with an estimated value of $22 billion.<br />

DOE has selected four companies<br />

to participate with Argonne National<br />

Lab in a three-year program of cooperative<br />

technology R&D that will<br />

enhance the economic competitiveness<br />

of the nation’s glass industry.<br />

The projects and lead organizations<br />

are:<br />

• Measurement and control of glass<br />

Furnace Concepts, Inc. Tel. 203-264-7856<br />

P.O. Box 863 Fax 203-262-8714<br />

Southbury, CT 06488 E-mail vangoman@aol.com<br />

Visit Our Website http://www.furnace-concepts.com<br />

www.ceramicbulletin.org • February 2001 23

NICE News<br />

S O C I E T Y / I N D U S T R Y<br />

Recognition<br />

Ethics, integrity, honor—as an organization,<br />

we strongly stress these<br />