Energy Materials Testing Laboratory EVALUATION FROM

Energy Materials Testing Laboratory EVALUATION FROM

Energy Materials Testing Laboratory EVALUATION FROM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Preparing the Target<br />

With K(OC 2 H 5 ) 5 (95%), Nb(OC 2 H 5 ) 5<br />

(99.8%) and Ta(OC 2 H 5 ) 5 (99.8%) as the<br />

starting materials, we prepared<br />

KTa 0.65 NB 0.35 O 3 powder that included<br />

the excessive K(OC 2 H 5 ) 5 , ≈1%, by the<br />

sol-gel method.<br />

We then pressed the powder into a<br />

30-mm diameter disk. When the temperature<br />

reached 1100°C, we sintered<br />

it for 45 h in the Kali atmosphere.<br />

Details are given in the literature. 8<br />

Preparing the Films<br />

We used Lamda EMG201MSC quasimolecular<br />

laser equipment in the<br />

experiment. The output wavelength<br />

was 308 nm. The repeat frequency<br />

rate was 20 Hz. The single pulsed<br />

laser energy density was 1.6 J/cm 2 ,<br />

2.0 J/cm 2 and 2.4 J/cm 2 , respectively.<br />

The system's automatic scanning of<br />

the beam focuses the laser beam into<br />

a 3 mm 2 flare, after it passes through<br />

a lens. The scanning speed is 20 rpm,<br />

which generates the best proportional<br />

films.<br />

KTN, or K(Ta 1-x Nb x )O 3 , has many<br />

good properties, including electrooptic<br />

characteristics, nonlinear optic<br />

characteristics and pyroelectricity. It<br />

also has a high K. When x = 0.35, it<br />

can be applied in a wide variety of<br />

fields with the highest electro-optic<br />

coefficient.<br />

During deposition and the addition<br />

of oxygen atmosphere, the pressure<br />

was kept between 10 and 15 pa. The<br />

substrate was the simple quartz crystal<br />

(100). The target was the potassium-rich<br />

ceramics. The distance from<br />

the substrate to the target was about<br />

5 cm.<br />

From the experiment, we found<br />

that when the temperature of the<br />

substrate exceeds 350°C, the simple<br />

quartz crystal breaks. The reason was<br />

that the thermal-dilatation coefficient<br />

of quartz differs greatly from<br />

that of the substrate.<br />

The substrate’s temperature must<br />

be controlled at ≈300°C, and the<br />

depositing time at 30 min. At the end<br />

of the experiments, the temperature<br />

of the films must be cooled slowly to<br />

room temperature under a certain<br />

pressure of oxygen.<br />

After analyzing the prepared films<br />

by XRD, we found that the films were<br />

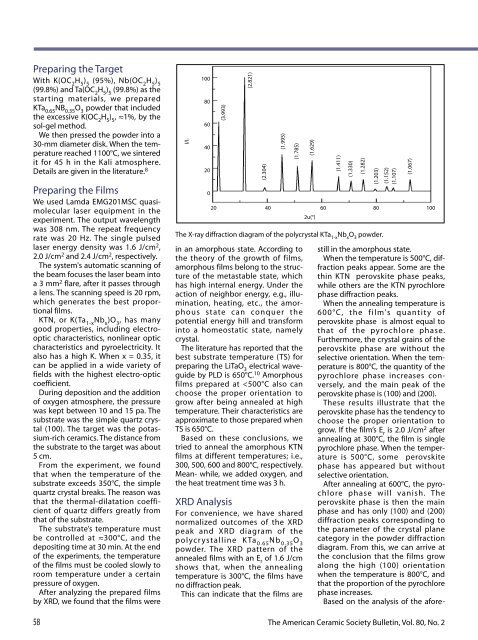

I/I °<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

(3.993)<br />

20 40 60 80 100<br />

The X-ray diffraction diagram of the polycrystal KTa 1-x Nb x O 3 powder.<br />

in an amorphous state. According to<br />

the theory of the growth of films,<br />

amorphous films belong to the structure<br />

of the metastable state, which<br />

has high internal energy. Under the<br />

action of neighbor energy, e.g., illumination,<br />

heating, etc., the amorphous<br />

state can conquer the<br />

potential energy hill and transform<br />

into a homeostatic state, namely<br />

crystal.<br />

The literature has reported that the<br />

best substrate temperature (TS) for<br />

preparing the LiTaO 3 electrical waveguide<br />

by PLD is 650°C. 10 Amorphous<br />

films prepared at