PROPERTIES AND APPLICATIONS OF HIGH ... - Vacuumschmelze

PROPERTIES AND APPLICATIONS OF HIGH ... - Vacuumschmelze

PROPERTIES AND APPLICATIONS OF HIGH ... - Vacuumschmelze

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

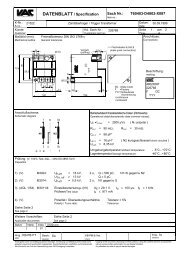

permanent magnets increases proportional to the Curie temperature of the magnet materials, see<br />

Fig. 1.<br />

max. operating temperature in °C<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

Hard Ferrites<br />

(Nd,Dy) 2Fe 14B<br />

Sm 2(Co, Cu,Fe,Zr) 17<br />

SmCo 5<br />

AlNiCo<br />

0 200 400 600 800 1000<br />

Curie temperature in °C<br />

Figure 1: Maximum operating temperatures of permanent magnets in dependence on their Curie temperatures. The shaded<br />

lines give the lowest or the highest operating temperatures for different permanent magnet materials, respectively.<br />

Most of the RE magnets are produced by powder metallurgy in many different grades and shapes.<br />

The alloys are melted from RE metals, Fe and Fe-B master-alloys in vacuum-induction furnaces. The<br />

polycrystalline microstructure of the ingots implies, that the magnetic moments are distributed randomly.<br />

In order to achieve a well defined texture, powder metallurgy is applied. The alloys are crushed<br />

and milled to a fine alloy powder, that must consist of single crystals. In general alloy powders<br />

with an average particle size in the range 3 to 5 µm meet this requirement very well. Such alloy<br />

powders can be aligned by a magnetic field, compacted by cold isostatic pressing (CIP) to blocks, by<br />

axial (AP) or transverse (TP) field die-pressing to net-shape parts and sintered to compact anisotropic<br />

magnet materials [1 - 3].<br />

For many applications the maximum energy density is decisive. At room temperature Nd-Fe-B as<br />

well as Nd-Dy-Fe-TM-B magnets with strong coercivities HcJ >24 kA/cm, TM: transition metals,<br />

have got higher maximum energy densities than SmCo5 or Sm2(Co,Cu,Fe,Zr)17 magnets, see Fig. 2.<br />

But at temperatures of approximately 120 °C sintered Sm2(Co,Cu,Fe,Zr)17 magnets are superior.