Mini-X-Purge Size 1 Manual ML 442 - Expo Technologies

Mini-X-Purge Size 1 Manual ML 442 - Expo Technologies

Mini-X-Purge Size 1 Manual ML 442 - Expo Technologies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.2 Relief Valve (RLV)<br />

The Relief Valve unit is fitted to the PE to provide a means of limiting the<br />

maximum pressure experienced by the PE during operation. The RLV<br />

model number has a suffix giving the diameter of the valve aperture in<br />

millimetres e.g. RLV25 (= 25mm bore). The RLV also incorporates a<br />

Spark Arrestor to prevent sparks being ejected from the PE into the<br />

classified area.<br />

In Leakage Compensation systems, the RLV is combined with the flow<br />

measurement mechanism.<br />

Figure 1. LC Relief Valve<br />

3.3 Calibrated Outlet Orifice/Spark Arrestor (SAU)<br />

Continuous Flow systems incorporate the SAU25. This unit has<br />

a range of interchangeable calibrated orifice plates, which are<br />

used to measure the flow through the PE.<br />

3.4 The Methods of Pressurizing<br />

Figure 2 Spark Arrestor Type SAU25<br />

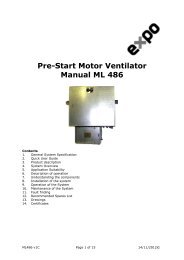

a) CF - Continuous Flow<br />

A Continuous Flow (CF) of protective gas is passed through the PE. Initially this flow is verified<br />

and performs the purging phase of the operation. When the purging phase is completed – i.e.<br />

the purge time has elapsed- the same flow of protective gas maintains the pressurization of the<br />

enclosure. This flow may be required to dilute an internal source of hazardous gas release.<br />

Figure 3 Continuous Flow Circuit Diagram<br />

<strong>ML</strong> <strong>442</strong> Issue 5C SP5115 09/11/12 ©<br />

Page 4 of 22