paraglas soundstop - Armtec

paraglas soundstop - Armtec

paraglas soundstop - Armtec

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

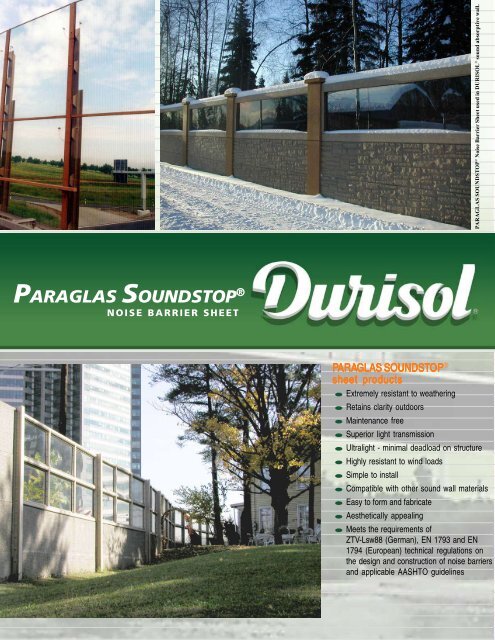

PARAGLAS SOUNDSTOP ®<br />

NOISE BARRIER SHEET<br />

PARA ARA ARA ARAGLAS ARA GLAS SOUNDST SOUNDSTOP<br />

SOUNDST OP<br />

sheet sheet products<br />

Extremely resistant to weathering<br />

Retains clarity outdoors<br />

Maintenance free<br />

Superior light transmission<br />

Ultralight - minimal deadload on structure<br />

Highly resistant to wind loads<br />

Simple to install<br />

Compatible with other sound wall materials<br />

Easy to form and fabricate<br />

Aesthetically appealing<br />

OP ®<br />

PARAGLAS SOUNDSTOP ® Noise Barrier Sheet used in DURISOL ® sound absorptive wall.<br />

Meets the requirements of<br />

ZTV-Lsw88 (German), EN 1793 and EN<br />

1794 (European) technical regulations on<br />

the design and construction of noise barriers<br />

and applicable AASHTO guidelines

TRANSPARENT NOISE BARRIERS<br />

PARAGLAS SOUNDSTOP ® Noise Barrier Sheet<br />

products have been successfully used in<br />

transparent noise barriers along roads and<br />

railroads around the world for almost 30 years.<br />

Easy to form and fabricate, PARAGLAS<br />

SOUNDSTOP sheet is extremely resistant to<br />

weathering from UV exposure and retains clarity<br />

and strength for many years.<br />

Colors<br />

All PARAGLAS SOUNDSTOP sheet grades are available<br />

in the following standard colors. The color impression remains<br />

the same in different thicknesses. Other colors can be<br />

manufactured on request.<br />

Transparent - Colorless and Colors:<br />

Shades of blue - Midnight Blue, Steel Blue, Sky Blue<br />

Shades of green - Forest Green, Sea Green, Spring Green<br />

Shades of brown - Smoky Brown<br />

Translucent - Colorless<br />

Product Overview<br />

Available in two grades:<br />

PARAGLAS SOUNDSTOP ® Noise Barrier Sheet<br />

is a standard, lightweight noise barrier.<br />

PARAGLAS SOUNDSTOP ® GS CC Noise Barrier Sheet<br />

incorporates polyamide filaments and is typically used on bridges<br />

and overpasses. In the event of impact by a car or truck, the<br />

imbedded filaments will hold the broken sheet, preventing<br />

fragments from falling below. Because the GS CC grade is<br />

self-containing safety netting is not necessary.<br />

Gaskets<br />

We offer EPDM gaskets compatible with our material<br />

for installing PARAGLAS SOUNDSTOP sheet.<br />

Service<br />

Cut-to-size sheets<br />

Surface-treated sheets (e.g., with matte stripes)<br />

Sheets that can be line-bent and/or thermoformed<br />

Hands-on technical support<br />

Grade Thickness (mm) Sheet Size (mm) Other Remarks<br />

PARAGLAS SOUNDSTOP sheet 15, 20, 25 2000 mm wide<br />

up to 6000 mm<br />

PARAGLAS SOUNDSTOP GS CC sheet 15, 20, 25 2500 X 2000<br />

3000 X 2000<br />

4200 X 2000<br />

5000 X 2000<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

www.durisol.com<br />

Larger sheet sizes<br />

available on request.<br />

Incorporated fragment-retaining,<br />

polyamide filaments run vertically<br />

or horizontally.<br />

Black or clear threads available on request.<br />

Non-standard sizes available on request.<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a wholly-owned<br />

subsidiary of Degussa.<br />

PARAGLAS Soundstop® is a registered<br />

trademark of CYRO Industries.

T E C H N I C A L D A T A<br />

PARAGLAS SOUNDSTOP ®<br />

NOISE BARRIER SHEET<br />

PARAGLAS SOUNDSTOP ® Noise Barrier Sheet is used as transparent noise<br />

barrier material along roads and railroads. Easy to install, form and fabricate, PARAGLAS SOUNDSTOP sheet<br />

is extremely resistant to weathering from UV exposure and retains a high transparency for many years providing<br />

architecturally appealing structures.<br />

The product is available in two grades:<br />

PARAGLAS SOUNDSTOP sheet is a standard clear transparent sheet.<br />

PARAGLAS SOUNDSTOP GS CC sheet incorporates polyamide filaments and is typically used on bridges and<br />

overpasses. In the event of impact by a car or truck,<br />

the imbedded filaments will hold the broken sheet, preventing pieces from falling below.<br />

Physical Properties PARAGLAS PARAGLAS<br />

Test SOUNDSTOP SOUNDSTOP GS CC<br />

Property Method sheet (a) sheet (b)<br />

Mechanical<br />

Specific Gravity ASTM D-792 1.19 1.19<br />

Tensile Strength ASTM D-638 10,000 psi (69 MPa) 10,000 psi (69 MPa)<br />

Elongation at Break (%) 4.5 4.8<br />

Modulus of Elasticity 400,000 psi (2800 MPa) 400,000 psi (2800 MPa)<br />

Flexural Strength ASTM D-790 17,000 psi (117 MPa) 16,500 psi (114 MPa)<br />

Modulus of Elasticity 480,000 psi (3300 MPa) 475,000 psi (3300 MPa)<br />

Compressive Strength (Yield) ASTM D-695 17,000 psi (117 MPa) 18,000 psi (124 MPa)<br />

Resistance Against Stone Projectiles (15 mm thickness) EN 1794-1 Pass Pass<br />

Unnotched Charpy Impact ASTM D-4812 6.5 ft-lbs/in 2 6.5 ft-lbs/in 2<br />

Weathered 5 years AZ 6.5 ft-lbs/in 2 6.5 ft-lbs/in 2<br />

-5°F 6.5 ft-lbs/in 2 6.5 ft-lbs/in 2<br />

Optical (Colorless)<br />

Refractive Index ASTM D-542 1.49 1.49<br />

Light Transmission, Total ASTM D-1003 92% 92%<br />

Weathered 5 years AZ 92% 92%<br />

Haze ASTM D-1003 1% 1%<br />

Weathered 5 years AZ 1.5% 1.5%<br />

Yellowness Index ASTM E-313 < 1 < 1<br />

Weathered 5 years AZ 1.5 1.5<br />

Thermal Properties<br />

Resistance to Brushfire (15 mm thickness) EN 1794-2 Class 2 Class 2<br />

Deflection Temperature under load, 264 psi ASTM D-648 195 °F (91°C) 210 °F (99 °C)<br />

Co-efficient of Linear Expansion ASTM D-696 0.000040 in/in/ °F 0.000040 in/in/ °F<br />

(0.072 mm/m °C) (0.072 mm/m °C)<br />

Vicat Softening Temperature ASTM D-1525 220 °F (105 °C) 239 °F (115 °C)<br />

Flammability, Burning Rate (15 mm thickness) ASTM D-635 0.6 in/min (14 mm/min) 0.8 in/min (20 mm/min)<br />

Self Ignition Temperature ASTM D-1929 850°F (455°C) 910°F (490°C)<br />

Smoke Density Rating (15 mm thickness) ASTM D- 2843 20% 20%<br />

Service Temperature >160 °F (71 °C) >180 °F (82 °C)<br />

Sound Transmission Loss ASTM E-90 15 mm 32 dB 15 mm 32 dB<br />

20 mm 34 dB 20 mm 34 dB<br />

25 mm 36 dB 25 mm 36 dB<br />

Weight per Square Foot 15 mm Thickness 3.66 lb/ft 2 (17.9 Kg/m 2 ) 3.66 lb/ft 2 (17.9 Kg/m 2 )<br />

20 mm Thickness 4.86 lb/ft 2 (23.8 Kg/m 2 ) 4.86 lb/ft 2 (23.8 Kg/m 2 )<br />

25 mm Thickness 6.1 lb/ft 2 (29.8 Kg/m 2 ) 6.1 lb/ft 2 (29.8 Kg/m 2 )<br />

(a) Typical values: should not be used for specification purposes.<br />

(b) Values shown are for 0.250" (6 mm) thickness unless noted otherwise.<br />

Some values will change with thickness.

Chemical Resistance of PARAGLAS SOUNDSTOP ® Noise Barrier Sheet<br />

The table below gives an indication of the chemical<br />

resistance of PARAGLAS SOUNDSTOP sheet and<br />

PARAGLAS SOUNDSTOP GS CC sheet. Plastic<br />

materials can be attacked by chemicals in several<br />

ways. The methods of fabrication and/or conditions of<br />

exposure of PARAGLAS SOUNDSTOP sheet, as well<br />

as the manner in which the chemicals are applied, can<br />

influence the final results even for “R” coded chemicals.<br />

Some of these factors include:<br />

Fabrication - stress generated while sawing, sanding,<br />

machining, drilling, and/or forming.<br />

Exposure - length of exposure, stresses induced<br />

during the life of the product due to various loads,<br />

changes in temperatures, etc.<br />

Application of Chemicals - by contact, rubbing,<br />

wiping, spraying, etc.<br />

Chemicals Code<br />

Acetone N<br />

Ammonium Chloride R<br />

Ammonium Hydroxide (Conc.) R<br />

Aromatic Based Graffiti Removers N<br />

Battery Acid R<br />

Benzene N<br />

Butyl Acetate N<br />

Calcium Chloride (100%) R<br />

Calcium Hypochlorite R<br />

Calcium / Magnesium Acetate R<br />

Citric acid (20%) R<br />

CMAK (Potassium Acetate/Calcium Magnesium acetate) R<br />

Diesel Oil R<br />

Ethyl Alcohol (30%) LR<br />

Ethyl Alcohol (95%) N<br />

Ethylene Glycol R<br />

Gasoline LR<br />

Heptane R<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

The table should be used as only a general guide<br />

and, in case of doubt, it should be supplemented<br />

by tests made under actual working conditions.<br />

The codes used to describe chemical resistance are<br />

as follow:<br />

R = Resistant PARAGLAS SOUNDSTOP sheet<br />

withstands this substance for long periods and at<br />

temperatures up to 120°F (49°C).<br />

LR = Limited Resistance PARAGLAS SOUNDSTOP<br />

sheet only resists the action of this substances for<br />

short periods at room temperatures. The resistance for<br />

a particular application must be determined.<br />

N = Not Resistant PARAGLAS SOUNDSTOP sheet<br />

is not resistant to this substance. It is either swelled,<br />

attacked, dissolved or damaged in some manner.<br />

Chemicals Code<br />

Hexane R<br />

Hydrochloric Acid R<br />

Ice Ban® Ultra TM M R<br />

Isopropyl Alcohol LR<br />

Kerosene R<br />

Lacquer Thinner N<br />

Magnesium Chloride R<br />

Methyl Alcohol (30%) LR<br />

Methyl Alcohol (100%) N<br />

Methyl Ethyl Ketone (MEK) N<br />

Methylene Chloride N<br />

Potassium Acetate R<br />

Sodium Acetate R<br />

Sulphuric Acid (3%) R<br />

Sulphuric Acid (30%) R<br />

Sulphuric Acid (Conc.) N<br />

Toluene N<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary<br />

of Degussa.<br />

PARAGLAS Soundstop®<br />

is a registered trademark<br />

of CYRO Industries.

PARAGLAS SOUNDSTOP ®<br />

NOISE BARRIER SHEET<br />

Handling & Maintenance<br />

This brief gives advice for:<br />

� Storage<br />

� Removing Masking<br />

� Cleaning<br />

� Removing Scratches<br />

� Graffiti Removal<br />

� Equipment and Materials Suppliers<br />

� Additional Technical Information and<br />

Assistance<br />

Storage<br />

PARAGLAS SOUNDSTOP ® Noise Barrier Sheet<br />

is shipped on pallets packaged in polyethylene film<br />

overwrap that protects the sheet from dirt and moisture.<br />

The overwrap should be left intact during storage to<br />

protect the sheet. Pallets can be stacked to maximize<br />

storage space. If various sizes are stacked horizontally,<br />

the larger sheets should be at the bottom to avoid<br />

unsupported overhang.<br />

PARAGLAS SOUNDSTOP sheet is supplied with a<br />

protective polyethylene masking on both surfaces. The<br />

masked sheet must NOT be stored in direct sunlight for<br />

prolonged periods of time. Prolonged exposure to direct<br />

sunlight may make the masking brittle which can cause<br />

the masking to tear upon removal.<br />

PARAGLAS SOUNDSTOP sheet should not be stored<br />

near radiators or steam pipes or other heat sources,<br />

as excessive heat tends to soften and deform acrylic<br />

sheet. Do not store sheets near or expose them to<br />

solvent vapors that may penetrate the masking and<br />

damage the sheet surface.<br />

T E C H B R I E F<br />

—— 1 of 4 ——<br />

Removing Masking<br />

The sheet masking should be left in place during most<br />

cutting operations and installation to protect the sheet<br />

surface. During installation roll back masking from the<br />

sheet edge to avoid engagement in glazing channels.<br />

Do not use gasoline or sharp-edged objects such<br />

as razor blades to remove masking that is stuck to<br />

the sheet too firmly.<br />

Cleaning<br />

As a result of the production process, acrylic has a<br />

smooth, non-porous surface that is retained even after<br />

long-term outdoor exposure. Dirt will not readily adhere<br />

to this polished surface, as a result, rain or the dew that<br />

frequently forms at night, will rinse the sheet clean.<br />

In most cases, PARAGLAS SOUNDSTOP sheet needs<br />

no additional cleaning. Should special circumstances<br />

make it desirable to clean the sheet, cleaning is best<br />

accomplished with water using a high-pressure washer.<br />

Grease, oil or tar may be removed with a good grade<br />

of hexane, aliphatic naphtha, or kerosene. These<br />

solvents may be obtained at a paint or hardware store<br />

and should be used in accordance with manufacturer’s<br />

recommendations.<br />

WARNING<br />

DO NOT USE: window cleaning sprays, kitchen<br />

scouring compounds or solvents such as acetone,<br />

gasoline, benzene, alcohol, carbon tetrachloride,<br />

or lacquer thinner. These can permanently damage<br />

the sheet’s surface and/or weaken the sheet<br />

causing small surface cracks called, “crazing”.

Removing Scratches<br />

Fine scratches can be removed by hand polishing. Apply<br />

a plastic scratch remover to a soft flannel pad and<br />

rub. When the scratches have disappeared, remove<br />

all residue and polish. For deeper scratches, first wet<br />

sand lightly with 400 grit “wet or dry” sandpaper, using<br />

plenty of water and rinsing the sandpaper frequently.<br />

Follow by buffing with a clean muslin wheel and a good<br />

polishing compound. For the highest gloss, use a<br />

clean-up wheel made of soft cotton or flannel sections<br />

on which no compound is used. An electric drill with a<br />

buffing wheel is ideal.<br />

Graffiti Removal<br />

Graffiti can be removed from PARAGLAS SOUND-<br />

STOP sheet using a graffiti remover designed for use<br />

on plastics. It is important to use a recommended graffiti<br />

remover as many traditional graffiti removers contain<br />

aromatic solvents that may damage PARAGLAS<br />

SOUNDSTOP sheet. When using any graffiti remover it<br />

is important to follow the manufacturer’s recommendations<br />

and rinse thoroughly with clean water.<br />

1. Start of Test 2. 10 Minutes after Remover is Applied<br />

—— 2 of 4 ——<br />

To remove the graffiti, spray the remover on the<br />

surface to be cleaned. Allow the remover to soak for<br />

2 to 30 minutes, depending on the manufacturer’s<br />

recommendation, and rinse off with water. Highpressure<br />

water is recommended for the rinse and will<br />

speed the process. In some cases, such as when the<br />

temperature is below 55°F, a second application or<br />

agitation of the graffiti with a clean soft cloth may be<br />

required to remove all of the graffiti.<br />

Below are pictures of PARAGLAS SOUNDSTOP sheet<br />

that were defaced or “tagged” with a solvent- based<br />

acrylic modified resin spray paint and then cleaned with<br />

Disappear TM graffiti remover. For this test, the remover<br />

was sprayed on the graffiti and allowed to soak for 15<br />

minutes. Then it was removed with a 2300-psi pressure<br />

wash. The paint was allowed to dry for 25 days prior to<br />

removal under this procedure.

3. Close-up of Graffiti<br />

Equipment and Materials Suppliers<br />

The suppliers listed below offer materials and equipment suitable for use with PARAGLAS SOUNDSTOP sheet.<br />

Graffiti Removers<br />

Disappear TM Graffiti / Adhesive Remover<br />

ND Expressions Graffiti Remover<br />

New Dimensions Solutions, LLC<br />

2151 Irving Street, Suite 202<br />

San Francisco, CA 94122<br />

www.ndclean.com<br />

Anti-Static Cleaners and Polishes<br />

210 Plastic Cleaner & Polish and 210 Plus Cleaner<br />

Sumner Laboratories<br />

186 Lincoln Street<br />

Boston, MA 02111<br />

617-542-8656<br />

Fax: 617-482-9001<br />

20/20 Plastic-Cleaner<br />

Craftics, Inc.<br />

2701 N. Pulaski<br />

Chicago, IL 60639<br />

773-235-3307<br />

Fax: 773-235-7204<br />

Crystalclean<br />

Discovery Plastics<br />

3700 Western Way, NE<br />

Millersburg, OR 97231<br />

541-926-2900<br />

Fax: 541-967-8441<br />

www.discoveryplastics.com<br />

—— 3 of 4 ——<br />

4. After Water Rinse with 2300-psi Pressure-Wash<br />

GRAFFI-GO II TM<br />

J&R Industries, Inc.<br />

800 E. Anaheim Street<br />

Wilmington, CA 90744<br />

www.jandrindustries.com<br />

Plexus Plastic Center<br />

Plexus<br />

638 Lindero Canyon Rd. #371<br />

Agoura, CA 91301<br />

800-405-6495<br />

Fax: 818-879-0697<br />

Scotch-Brite High Performance Cloth<br />

3M Stationery & Office Supplies Div.<br />

3M Center<br />

St. Paul, MN 55144-1000<br />

877-362-5684<br />

Fax: 651-733-0382<br />

www.mmm.com

Fire Precautions<br />

PARAGLAS SOUNDSTOP sheet is a combustible thermoplastic. Precautions should<br />

be taken to protect this material from flames and high heat sources. PARAGLAS<br />

SOUNDSTOP sheet usually burns rapidly to completion if not extinguished. The<br />

products of combustion, if sufficient air is present are carbon dioxide and water.<br />

However, in many fires sufficient air will not be available and toxic carbon monoxide<br />

will be formed, as it will when other common combustible materials are burned. We<br />

urge good judgement in the use of this versatile material and recommend that building<br />

codes be followed carefully to assure it is used properly.<br />

Compatibility<br />

Like other plastic materials, PARAGLAS SOUNDSTOP sheet is subject to crazing,<br />

cracking or discoloration if brought into contact with incompatible materials. These<br />

materials may include cleaners, polishes, adhesives, sealants, gasketing or<br />

packaging materials, cutting emulsions, etc.<br />

Important Notice:<br />

The information and statements herein are believed to be reliable but are not to be<br />

construed as a warranty or representation for which we assume legal responsibility.<br />

Users should undertake sufficient verification and testing to determine the suitability<br />

for their own particular purpose of any information or products referred to herein.<br />

NO WARRANTY OF FITNESS FOR PARTICULAR PURPOSE IS MADE. Nothing<br />

herein is to be taken as permission, inducement or recommendation to practice any<br />

patented invention without a license.<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

—— 4 of 4 ——<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary<br />

of Degussa.<br />

PARAGLAS Soundstop®<br />

is a registered trademark<br />

of CYRO Industries.

PARAGLAS SOUNDSTOP ®<br />

NOISE BARRIER SHEET<br />

Flammability<br />

This Technical Bulletin contains a description and results of a test method used for evaluating<br />

the resistance of PARAGLAS SOUNDSTOP ® Noise Barrier Sheet to a fire arising from dry<br />

vegetation or other material in close proximity to a sound wall. This test was designed to<br />

simulate small brush fire exposure1 . It is equivalent to the fire test used in the European<br />

Standard EN 1794-2, Resistance Against Fire in the Case of Low Fire Load which has been<br />

in use for many years to evaluate the suitability of materials as road side noise barriers.<br />

Fire Test<br />

Two PARAGLAS SOUNDSTOP sheet panels 1.5<br />

meters by 2 meters by 15 mm thick were exposed to a<br />

localized fire at their base, both at the front and back of<br />

the sheet. The fire sources consisted of wire baskets<br />

that each contained 600 grams of spruce shavings, 0.2<br />

mm thick by 2 mm wide and approximately 50 mm long.<br />

The test was conducted with the panels in the vertical<br />

position.<br />

1. Test Setup<br />

Both of the fire sources were lit simultaneously<br />

and allowed to burn to completion.<br />

T E C H B R I E F<br />

—— 1 of 2 ——<br />

2. Burning of Spruce Shavings<br />

After the fires burned to completion, brown discoloration<br />

and minor blistering can be seen on the PARAG-<br />

LAS SOUNDSTOP sheet panels. However, the static<br />

and acoustic functionality of the test barrier was not<br />

affected by the exposure to fire. No holes or cracks<br />

developed during the test.<br />

One hour after the burning down of the first two baskets,<br />

two more baskets of wood shavings were placed<br />

on the opposite side of the panels and ignited. Again,<br />

only minor discoloration of the panels was noted at the<br />

completion of the test.

—— 2 of 2 ——<br />

3. PARAGLAS SOUNDSTOP<br />

Sheet after Completion of Fire Test<br />

Based on the results of this test, PARAGLAS<br />

SOUNDSTOP sheet is not expected to assist<br />

the spread of fire from modest amounts<br />

of dry vegetation or other brush material in<br />

close proximity to the sound wall.<br />

1. This test is a simulated fire exposure intended to demonstrate the behavior of PARAGLAS SOUNDSTOP sheet in a<br />

specific situation. Actual results may vary due to circumstances outside the conditions of this test.<br />

Fire Precautions<br />

PARAGLAS SOUNDSTOP sheet is a combustible thermoplastic. Precautions should be taken to protect<br />

this material from flames and high heat sources. PARAGLAS SOUNDSTOP sheet usually burns rapidly to completion<br />

if not extinguished. The products of combustion, if sufficient air is present are carbon dioxide and water. However,<br />

in many fires sufficient air will not be available and toxic carbon monoxide will be formed,<br />

as it will when other common combustible materials are burned. We urge good judgement in the use of this versatile<br />

material and recommend that building codes be followed carefully to assure it is used properly.<br />

Compatibility<br />

Like other plastic materials, PARAGLAS SOUNDSTOP sheet is subject to crazing, cracking or discoloration if<br />

brought into contact with incompatible materials. These materials may include cleaners, polishes, adhesives,<br />

sealants, gasketing or packaging materials, cutting emulsions, etc.<br />

Important Notice:<br />

The information and statements herein are believed to be reliable but are not to be construed as a warranty or<br />

representation for which we assume legal responsibility. Users should undertake sufficient verification and testing<br />

to determine the suitability for their own particular purpose of any information or products referred to herein. NO<br />

WARRANTY OF FITNESS FOR PARTICULAR PURPOSE IS MADE. Nothing herein is to be taken as permission,<br />

inducement or recommendation to practice any patented invention without a license.<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary<br />

of Degussa.<br />

PARAGLAS Soundstop®<br />

is a registered trademark<br />

of CYRO Industries.

PARAGLAS SOUNDSTOP ®<br />

NOISE BARRIER SHEET<br />

Impact Resistance<br />

Sound barriers are often subjected to impacts caused by stones or other debris thrown up by vehicle<br />

tires. Therefore, it is important to construct a noise barrier from materials able to withstand these impact<br />

forces. The following test method is used to evaluate the resistance of PARAGLAS SOUNDSTOP ® Noise<br />

Barrier Sheet to impacts and is technically equivalent to the European standard EN 1794-1, Appendix C,<br />

Resistance against Damage by Stone Projectiles.<br />

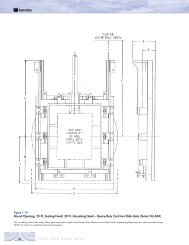

Test Method<br />

Testing with a mechanical hammer is used to<br />

simulate the stone impacts. Three hammer<br />

strikes at 30 Nm ± 1 Nm (22 ft-lbs) are performed<br />

which are roughly equivalent to a 77<br />

gram (0.17 lb) object traveling at 100 km/hr (60<br />

mph). One of the test strikes must be near one<br />

corner of the test panel within a test area bounded<br />

by a margin of 125 mm (5”) from the edge of<br />

the panel, one must be near the center of the<br />

test panel and the third is chosen at random.<br />

The exact position of the point to be tested must<br />

be chosen to be representative of the panel as a<br />

whole and avoid places of local strength.<br />

Test Results<br />

Three points of impact were marked on the panel<br />

of PARAGLAS SOUNDSTOP sheet. Point 1,<br />

is a corner point with a distance of 125 mm (5”)<br />

from the upper edge and 125 mm (5”) from the<br />

side edge. Point 2, is at the center of the sheet<br />

and point 3 was chosen at random.<br />

T E C H B R I E F<br />

—— 1 of 2 ——<br />

1. Edge Impact with Concrete Testing Hammer

—— 2 of 2 ——<br />

2. Center Impact with<br />

Concrete Testing Hammer<br />

At the conclusion of the test there was<br />

no evidence of penetration, destruction,<br />

formation of cracks or chipping on<br />

the PARAGLAS SOUNDSTOP Sheet<br />

panels.<br />

PARAGLAS SOUNDSTOP sheet<br />

meets the requirements of EN 1794-1,<br />

Appendix C, Resistance Against<br />

Damage by Stone Projectiles.<br />

Fire Precautions<br />

PARAGLAS SOUNDSTOP sheet is a combustible thermoplastic. Precautions should be taken to protect<br />

this material from flames and high heat sources. PARAGLAS SOUNDSTOP sheet usually burns rapidly to completion<br />

if not extinguished. The products of combustion, if sufficient air is present are carbon dioxide and water. However,<br />

in many fires sufficient air will not be available and toxic carbon monoxide will be formed,<br />

as it will when other common combustible materials are burned. We urge good judgement in the use of this versatile<br />

material and recommend that building codes be followed carefully to assure it is used properly.<br />

Compatibility<br />

Like other plastic materials, PARAGLAS SOUNDSTOP sheet is subject to crazing, cracking or discoloration if<br />

brought into contact with incompatible materials. These materials may include cleaners, polishes, adhesives,<br />

sealants, gasketing or packaging materials, cutting emulsions, etc.<br />

Important Notice:<br />

The information and statements herein are believed to be reliable but are not to be construed as a warranty or<br />

representation for which we assume legal responsibility. Users should undertake sufficient verification and testing to<br />

determine the suitability for their own particular purpose of any information or products referred to herein. NO WAR-<br />

RANTY OF FITNESS FOR PARTICULAR PURPOSE IS MADE. Nothing herein is to be taken as permission, inducement<br />

or recommendation to practice any patented invention without a license.<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary<br />

of Degussa.<br />

PARAGLAS Soundstop®<br />

is a registered trademark<br />

of CYRO Industries.

PARAGLAS SOUNDSTOP ®<br />

NOISE BARRIER SHEET<br />

T E C H B R I E F<br />

Roadway Glare & Reflection<br />

Technical Brief Overview<br />

The purpose of this Technical Brief is to discuss reflective glare relative<br />

to PARAGLAS SOUNDSTOP ® noise barrier sheet panels and offer explanation<br />

as to why it has not been a significant deterrent for the driving public.<br />

The Technical Brief will expand on three characteristic facts:<br />

1. Most reflections are above the line of sight.<br />

2. Intensity of light diminishes sharply as distance increases.<br />

3. PARAGLAS SOUNDSTOP sheet reflects only a portion of the light<br />

that is projected against its surface.<br />

PARAGLAS SOUNDSTOP sheet is a lightweight sound insulating panel that features outstanding<br />

optical clarity, long-term weatherability, and excellent impact resistance. A common misconception<br />

associated with transparent PARAGLAS SOUNDSTOP sound walls is the potential for glare due<br />

to the headlights of oncoming vehicular traffic. For many years, transparent PARAGLAS SOUND-<br />

STOP sound walls have been installed along highways in Europe, Asia and other parts of the world.<br />

To our knowledge, reflected glare from a noise barrier has not created issues with traffic in any of<br />

these installations. A close examination of the geometry and optics involved suggests why.<br />

The Reflections are Typically Above the Line-of-Sight<br />

In many sound wall installations, the PARAGLAS SOUNDSTOP sheet only makes up a portion of<br />

the sound wall panel material. It is very common for walls to have a concrete, wood or metal base,<br />

with the transparent panels mounted above. When the bottom of the transparent sound wall panel is<br />

above the sight line of the driver, then all reflections will be above the driver.<br />

The Intensity of Light is Significantly Reduced as Distance Increases.<br />

In general, the intensity of the light decreases proportionally to the square of the distance traveled.<br />

Hence, the intensity of the light reflected from a sound wall is greatly diminished due to the distance<br />

it travels from the headlamp to the PARAGLAS SOUNDSTOP wall and from the PARAGLAS<br />

SOUNDSTOP wall to the driver.<br />

Illuminance is the measurement of how bright a point source of light appears to the eye. Figure<br />

1 shows the decrease in illuminance over distance for a typical automotive high beam headlamp<br />

directed into a 45° cone. It illustrates how significantly light will diminish in intensity over distance<br />

traveled. For example at a distance of 20 meters, a standard headlamp high beam brightness is<br />

measured at 50 vertical lux. At 110 meters distance, that same light source measures 5 vertical lux.<br />

Simply stated, the brightness of a light source will diminish over greater distance in the same manner<br />

that objects appear smaller as distance increases.<br />

—— 1 of 5 ——

Figure 1. Iso-illuminance diagram (vertical lux) at the road surface from a pair of lamps<br />

having the median luminous intensities for the sales-weighted sample representing the high<br />

beam headlamps on current passenger vehicles in the U.S. 1<br />

Figure 1<br />

Longitidunal Distance fron Headlamps ( m )<br />

Source: The University of Michigan Transportation Research Institute, Report UMTRI-2001-19<br />

When light is projected against a PARAGLAS SOUNDSTOP panel, only a portion of that light<br />

is reflected. The remainder passes through the panel.<br />

Since PARAGLAS SOUNDSTOP has a very smooth “high gloss” surface it is assumed that it also<br />

has a very high reflectance but this is not necessarily true. When light is projected at a PARA-<br />

GLAS SOUNDSTOP panel, a portion of the light passes through the sheet and the remainder is<br />

reflected. The percentages of light that are transmitted and reflected will vary according to the<br />

angle of projection. At very low angles (see Figure 2) PARAGLAS SOUNDSTOP sheet reflects a<br />

majority of the incident light. As angles or reflection increase, the amount of light reflected diminishes<br />

sharply. For light projected at angles below 10° the light typically travels a very long distance<br />

and this has the effect of reducing the brightness of the light as seen by the oncoming driver.<br />

Figure 2<br />

Reflection of PARAGLAS SOUNDSTOP Sheet<br />

1. The University of Michigan Transportation Research Institute, Report No. UMTRI-2001-19, May 2001.<br />

—— 2 of 5 ——

Figure 3<br />

The effects of both distance and angle of reflection combine together<br />

to greatly reduce the intensity of reflected light.<br />

The intensity of the light is greatly diminished due to the distance the light has traveled from<br />

the headlamp to the PARAGLAS SOUNDSTOP sound wall, it is then reduced in intensity<br />

further according to the angle at which it is reflected and then further reduced in intensity due<br />

to the distance the reflected light travels from the PARAGLAS SOUNDSTOP sound wall to the<br />

driver.<br />

In most circumstances, the light projected directly from the headlights of an oncoming vehicle<br />

is significantly more intense than the reflected light.<br />

How much glare is too much?<br />

Disability glare is created by a light so bright that its intensity results in a measurable reduction<br />

in a driver’s ability to perform visual tasks. This reduction in performance is a direct result<br />

of the effects of stray light within the eye, which in turn are dependent on the age of the<br />

driver. At night, vehicle headlights produce direct glare by shining into the eyes of drivers in<br />

approaching cars and indirect glare such as reflections from rearview mirrors. Typically, the<br />

effects of glare on drivers is much greater at night than during the day, because at night drivers<br />

are adapted to lower light levels. For example, lights that are barely noticeable by day can be<br />

uncomfortably glaring at night.<br />

The following are two examples to help illustrate the differences between direct glare from<br />

an oncoming vehicle’s headlamp and indirect glare from a sound wall constructed from<br />

PARAGLAS SOUNDSTOP sheet.<br />

Example 1. First, consider the glare from an oncoming vehicle with the following assumptions:<br />

One lane of traffic in each direction<br />

Each lane is 10-ft wide<br />

The driver is 50 years old and looking straight ahead along the middle of the lane<br />

The cars are separated by a distance of 225-ft<br />

A background luminance of 0.026-cd/ft2 (an unlighted roadway at night)<br />

A headlamp luminous intensity of 42,500-cd and 25,431-cd at 2.5° left of center.<br />

In this example, the luminance of the glare reaching the drivers eyes is caculated to be 0.50fc.<br />

Thus, an object in the roadway will have to have its luminance compared to the background<br />

luminance increased over 40-fold to be detected. In other words an object in the roadway<br />

will have to be about 40 times brighter to be seen when there is glare from an oncoming high<br />

beam headlight at 225 feet away.<br />

Example 1<br />

—— 3 of 5 ——

Now lets look at the case of glare from light reflected from<br />

a transparent PARAGLAS SOUNDSTOP sound wall.<br />

Example 2. Consider a highway curve with the following geometry:<br />

Two lanes of traffic in each direction<br />

The cars moving in opposite directions approach each other, they are in the inside lanes<br />

Each lane is 10-ft wide<br />

The radius of curvature is 840 feet (very tight for a highway)<br />

The driver is 50 years old and looking straight ahead along the middle of the lane<br />

A background luminance of 0.026-cd/ft2 (an unlighted roadway at night)<br />

A headlamp luminous intensity of 42,500-cd and 29,440-cd at 2° left of center<br />

The cars on the outside of the curve (represented by vehicle A) will cross paths with both reflected light<br />

(indirect glare) from the PARAGLAS SOUNDSTOP sound wall panels coming from the cars on the inside<br />

of the curve (represented by vehicle B in Example 2) and then, afterwards, direct light (direct glare)<br />

coming from the same cars (vehicle B). The light from vehicle B’s headlamps will strike the PARAGLAS<br />

SOUNDSTOP sound wall after traveling a distance of 225 feet. The incident light will be reduced in<br />

intensity by 40% when it strikes the PARAGLAS SOUNDSTOP panel at an angle of 8°. The reflected<br />

light will then travel a distance of approximately 185 feet and will cross the path of vehicle A at an angle<br />

of 2°. The illuminance of the glare reaching the drivers eyes is .10-fc and therefore, an object in the<br />

roadway will need to have its luminance increased 13-fold in order to be seen.<br />

If we compare the 13-fold increase in contrast threshold for reflected light from a PARAGLAS SOUND-<br />

STOP sound wall with the over 40-fold increase for direct glare from an oncoming headlight it is easy to<br />

understand why indirect glare from a PARAGLAS SOUNDSTOP sound wall has not created any known<br />

complaints.<br />

Figure 4<br />

Example 2<br />

—— 4 of 5 ——

Definitions<br />

Glare occurs when the intensity of a light is greater<br />

than that to which the eyes are accustomed. It is<br />

usually defined as a bright light or a brilliant reflection.<br />

Direct glare is caused by light sources in the field of<br />

view and reflected glare is a bright reflection from a<br />

polished or glassy surface (for example, the vehicles<br />

side view mirror). Disability glare is caused by light<br />

scattered within the eye, causing a haze of veiling<br />

luminance that decreases contrast and reduces<br />

visibility.<br />

Reflectance is a measure of the reflected incident light<br />

(illuminance) that is reflected away from a surface.<br />

Reflectance will depend on the surface properties<br />

of the material as well as the angle from which it is<br />

illuminated.<br />

Luminous intensity is the light-producing power<br />

of a source, measured as the luminous flux per unit<br />

solid angle in a given direction. It is a measure of the<br />

strength of the visible light given off by a source of light<br />

in a specific direction. In this brief luminous intensity is<br />

expressed in terms of candelas (cd).<br />

Luminance is the amount of luminous flux reflected or<br />

transmitted by a surface into a solid angle per unit of<br />

area perpendicular to a given direction. It is a physical<br />

measure of the amount of light reflected or emitted from<br />

a surface and roughly corresponds to the subjective<br />

impression of “brightness”. Luminance does not vary<br />

with distance. It may be computed by dividing the<br />

luminous intensity by the source area, or by multiplying<br />

illuminance and reflectance.<br />

Illuminance is the amount of light incident per unit<br />

area of a surface at any given point on the surface. The<br />

illuminance E at a surface is related to the luminous<br />

intensity I of a source by the inverse square law E = I/<br />

d 2 , where d is the distance between the source and the<br />

surface. In this brief illuminance is expressed in terms<br />

of foot-candles (fc).<br />

Fire Precautions<br />

PARAGLAS SOUNDSTOP sheet is a combustible thermoplastic. Precautions should be taken to protect<br />

this material from flames and high heat sources. PARAGLAS SOUNDSTOP sheet usually burns rapidly to<br />

completion if not extinguished. The products of combustion, if sufficient air is present are carbon dioxide and<br />

water. However, in many fires sufficient air will not be available and toxic carbon monoxide will be formed,<br />

as it will when other common combustible materials are burned. We urge good judgement in the use of this<br />

versatile material and recommend that building codes be followed carefully to assure it is used properly.<br />

Compatibility<br />

Like other plastic materials, PARAGLAS SOUNDSTOP sheet is subject to crazing, cracking or discoloration<br />

if brought into contact with incompatible materials. These materials may include cleaners, polishes, adhesives,<br />

sealants, gasketing or packaging materials, cutting emulsions, etc.<br />

Important Notice:<br />

The information and statements herein are believed to be reliable but are not to be construed as a warranty<br />

or representation for which we assume legal responsibility. Users should undertake sufficient verification and<br />

testing to determine the suitability for their own particular purpose of any information or products referred<br />

to herein. NO WARRANTY OF FITNESS FOR PARTICULAR PURPOSE IS MADE. Nothing herein is to be<br />

taken as permission, inducement or recommendation to practice any patented invention without a license.<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary<br />

of Degussa.<br />

PARAGLAS Soundstop®<br />

is a registered trademark<br />

of CYRO Industries.

PARAGLAS SOUNDSTOP ®<br />

READY-FIT PANEL<br />

The Adaptable<br />

Transparent Noise<br />

Barrier<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

T E C H B R I E F<br />

Product Details<br />

Transparent PARAGLAS SOUNDSTOP ® Noise<br />

Barrier Sheet panels installed.<br />

Complete steel frame and panel assembly for<br />

an “off-the-shelf” turnkey-solution.<br />

Compatible with all steel and/or concrete<br />

H-posts and/or H-columns.<br />

Easily inserted where needed in a standard<br />

sound wall.<br />

Use alone or in combination with<br />

non-transparent panels.<br />

Will not turn yellow or become brittle due to<br />

sunlight exposure.<br />

Low maintenance required. Panels are<br />

self-cleaning.<br />

Light weight. Large panels can be used to reduce<br />

cost and enhance aesthetics.<br />

Excellent sound insulation properties despite<br />

its lightweight feature.<br />

Meets or exceeds applicable FHWA guidelines.<br />

Graffiti is removed quickly and easily with powerwasher<br />

and approved cleaners.<br />

Highly cost effective.<br />

Available in:<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

Panel Heights of 4, 6, or 8 feet.<br />

Fits post spaces from 10 through 20 feet.<br />

for sales and technical<br />

information contact.<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary of<br />

Degussa.<br />

PARAGLAS Soundstop® is<br />

a registered trademark of<br />

CYRO Industries.

PARAGLAS SOUNDSTOP ®<br />

N E W S<br />

FROM THE LEADER IN SPECIALTY<br />

ACRYLIC SOLUTIONS<br />

“This wall is a very unique<br />

project, and there is not<br />

another noise barrier like<br />

this in North America.”<br />

- Mike Edwards, Durisol, USA Inc.<br />

NOISE BARRIER SHEET<br />

SOUNDING OFF ABOUT TRANSPARENT<br />

HIGHWAY NOISE BARRIERS<br />

When the Alaska Department of Transportation<br />

(ADOT) sponsored a project to mitigate<br />

highway noise for a local residential area, it<br />

encountered some obstacles. The heavily<br />

traveled highway to Anchorage Airport bordered<br />

a community that had long enjoyed<br />

scenic views of the local Chugach Mountain<br />

range. The noise barrier would approximately<br />

run a 4,000-foot stretch of highway<br />

and vary from 10-17 feet high. Due to the<br />

community’s orientation to the sun, a solid<br />

17-foot noise barrier would cast a permanent<br />

dark shadow on these yards and deny<br />

the few hours of sunlight that reached them.<br />

CYRO’s transparent PARAGLAS SOUNDSTOP sheet provides 92% light transmission, and excellent<br />

noise protection.<br />

Known as the C Street project, ADOT<br />

along with local authorities ultimately<br />

concluded that a transparent noise barrier<br />

was the only acceptable solution. Uncommon<br />

in North American, transparent noise<br />

barriers �rst emerged in Europe to mitigate<br />

sound while preserv ing the natural landscape.<br />

This barrier would be a unique<br />

structure in North America.<br />

With over 50 years’ experience manufacturing<br />

noise barriers, Durisol, USA Inc.<br />

(McLean, VA) an exterior environmental<br />

noise mitigation company, proposed a<br />

®<br />

unique solution: new PARAGLAS SOUND-<br />

STOP Noise Barrier sheet from CYRO<br />

Industries. Available in Europe and only<br />

recently introduced to North America,<br />

® PARAGLAS SOUNDSTOP sheet o�ers<br />

superior UV stability and weather resistance<br />

over other transparent materials such as<br />

polycarbonate plastic. This helps ensure<br />

long-term clarity to preserve pristine views.<br />

Broadening The Spec<br />

ADOT originally speci�ed the noise barrier<br />

to be a translucent sound absorptive structure<br />

with a Noise Reduction Coe�cient<br />

(NRC) of 0.60 and provide a minimum of<br />

80% light transmission. An entirely translucent<br />

wall could not provide the light<br />

transmission quality sought by the project<br />

engineers. “We alerted ADOT and<br />

worked to open the spec to Durisol panels<br />

and transpar ent PARAGLAS SOUNDSTOP<br />

sheets and formulated a design proposal<br />

that would �t this spec,” remarks Mike<br />

Edwards, Vice President, Durisol, USA Inc.<br />

Durisol manufactures sound absorptive<br />

panels made of a proprietary wood aggregate<br />

concrete mix that provides signi�cant<br />

acoustic dampening and sound absorption.<br />

The Durisol panels would provide the noise<br />

absorption for the barrier wall, while CYRO’s<br />

transparent PARAGLAS SOUNDSTOP sheet<br />

would provide 92% light transmission, and<br />

additional noise protection for the barrier.

PARAGLAS SOUNDSTOP ®<br />

N E W S<br />

FROM THE LEADER IN SPECIALTY<br />

ACRYLIC SOLUTIONS<br />

NOISE BARRIER SHEET<br />

“The sun rides low in the winter, and the residents want-<br />

ed to maintain their view of the Chugach Mountain<br />

range. This barrier is the best of both worlds, providing<br />

noise abatement and an attractive view.”<br />

- Harold Henderson, Alaska Department of Transportation<br />

PARAGLAS SOUNDSTOP provides excellent light transmittance, great impact strength, and easy gra�ti removal.<br />

The solution chosen by the committee<br />

was a unique wall designed by Durisol<br />

incorporating solid Durisol panels along<br />

the bottom to absorb sound and transparent<br />

PARAGLAS SOUNDSTOP panels<br />

along the top. To enhance durability and<br />

ease maintenance issues, Durisol placed the<br />

PARAGLAS glazing above solid Durisol<br />

panels that have an architectural �nish.<br />

This design provides the necessary NRC<br />

to meet ADOT’s spec, while limiting the<br />

perceived height of the wall. The use of<br />

transparent panels at the top of the structure<br />

allows light to pass through PARAGLAS<br />

SOUNDSTOP sheet without casting shadows<br />

and preserving the views of the natural<br />

mountain landscape.<br />

Material Performance<br />

The absorptive barrier qualities derive<br />

from Durisol’s proprietary wood aggregate<br />

panels along the bottom of the wall and<br />

covering the supporting posts. The posts<br />

are covered with an absorptive cladding to<br />

maximize the sound absorptive surface area<br />

of the barrier. The pre-cast frames with<br />

absorptive surface, designed and manufactured<br />

by Durisol, seat the PARAGLAS<br />

SOUNDSTOP panels. The Durisol panels<br />

give the wall an NRC of 0.80 – 0.85, easily<br />

exceeding the ADOT spec and further<br />

reducing the noise levels heard from the<br />

highway.<br />

“Durisol is not a plastics expert, but we’ve<br />

seen some polycarbonate walls on tour in<br />

San Diego that had yellowed and been<br />

replaced by acrylic, which immediately<br />

directed us to CYRO when bidding this<br />

project. No other material was even<br />

considered,” notes Edwards.<br />

Gra�ti was another issue with the barrier<br />

wall. The speci�cation called for materials<br />

that only required a hot pressure wash to<br />

remove gra�ti. Both the Durisol panels<br />

and CYRO’s PARAGLAS SOUNDSTOP sheet<br />

use a simple process requiring a solvent to<br />

remove paint.

PARAGLAS SOUNDSTOP ®<br />

N E W S<br />

FROM THE LEADER IN SPECIALTY<br />

ACRYLIC SOLUTIONS<br />

NOISE BARRIER SHEET<br />

Glaring Issues<br />

Transparent noise barriers raise some concerns<br />

about re�ected glare and whether a<br />

matte �nish is necessary. Having conducted<br />

studies on this issue in Europe, CYRO<br />

was able to provide data demonstrating<br />

that glare is not a signi�cant cause of<br />

driver distraction. In addition to this data,<br />

CYRO was also able to supply the com-<br />

“PARAGLAS SOUNDSTOP exhibited more of the proper-<br />

ties we were looking for with this project. With excellent<br />

light transmittance, great impact strength, and easy gra�ti<br />

removal, the material outperformed the competition.”<br />

- Harold Henderson, Alaska Department of Transportation<br />

The design provides necessary noise abatement while preserving the views of the mountain landscape for homeowners.<br />

mittee with samples of frosted PARAGLAS<br />

SOUNDSTOP sheet for review. After comparing<br />

the sheet and noting the height of<br />

the panels, the matte �nish was determined<br />

to be unnecessary and the committee<br />

selected the transparent sheet for the project.<br />

The committee also speci�ed Smoky<br />

Brown tinted panels in certain areas of the<br />

wall where visibility and light transmission<br />

were not an issue. The Smoky Brown<br />

tinted panels were chosen because they<br />

matched the colors of the wall.<br />

“We proved to the state that we could<br />

produce a wall to meet its requirements,<br />

whether it was color-matched tints or di�erent<br />

surface options,” notes Steve Barratt,<br />

market manager, Noise Protection Products,<br />

CYRO Industries.

PARAGLAS SOUNDSTOP ®<br />

N E W S<br />

FROM THE LEADER IN SPECIALTY<br />

ACRYLIC SOLUTIONS<br />

Interested in PARAGLAS<br />

SOUNDSTOP ® Noise<br />

Barrier Sheet?<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a wholly-owned<br />

subsidiary of Degussa.<br />

PARAGLAS Soundstop® is a registered<br />

trademark of CYRO Industries.<br />

N O I S E B A R R I E R S HEE T<br />

Building The Great Wall<br />

Cost-e ective construction processes o -<br />

set minor cost variations in the proposals<br />

and lowered the total project cost of the<br />

Durisol barrier below the competition.<br />

Most highway noise barrier foundations<br />

designed by Durisol consist of augured<br />

or drilled shaft foundations, however in<br />

Alaska driving piles is the more common<br />

practice. The eight and ten inch diameter<br />

piles were precisely spaced within a<br />

one inch mar gin and driven 15-16 feet deep<br />

to properly support the wall panels. Noise<br />

wall H-posts were bolted to a welded plate<br />

on the pilings. Durisol designed the H-posts<br />

for this project to accommodate<br />

additional absorptive cladding and properly<br />

suppor t the transparent glazing. The<br />

framed transparent panels were completely<br />

pre-assembled before being lowered<br />

into place between the posts.<br />

Materials were shipped a total of 7,000<br />

miles from CYRO’s Arkansas plant, and<br />

from the Durisol plant in Canada without<br />

damage or delay. At the end of the<br />

project, a total of 18,000 square feet of<br />

PARAGLAS SOUNDSTOP Sheet, 32,500<br />

square feet of Durisol panels, and 363<br />

concrete frames were produced, shipped<br />

and installed. The result is an attractive<br />

noise barrier wall that s nicely within<br />

the context of the land and the community.<br />

PARAGLAS SOUNDSTOP Noise Barrier Sheet remains clear and will not yellow like polycarbonate<br />

materials.<br />

“Since the bar rier’s completion we’ve<br />

received nothing but positive feedback<br />

on the project from local homeowners as<br />

well as passersby on the highway . People<br />

are genuinely impressed with the<br />

wall’s appearance and performance,”<br />

concludes Henderson.

For over 30 years,<br />

CYRO Industries, and<br />

its parent company Degussa,<br />

have the highest quality<br />

transparent noise barrier<br />

products around the world.<br />

For more information or c<br />

questions about your project,<br />

contact CYRO’s noisewall<br />

specialists.<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary of<br />

Degussa.<br />

PARAGLAS Soundstop® is a<br />

registered trademark of CYRO Industries.<br />

PARAGLAS SOUNDSTOP ®<br />

N O I S E<br />

B A R R I E R<br />

S HEE T<br />

PARAGLAS SOUNDSTOP ®<br />

Noise Barrier Products<br />

IMPORTANT NOTICE: The information and statements herein are believed to be reliable but are not to be construed as a warranty or<br />

representation for which we assume legal responsibility. Users should undertake<br />

ver and testing to determine the<br />

suitability for their own particular purpose of any information or products referred to herein. NO WARRANTY OF FITNESS FOR<br />

PARTICULAR PURPOSE IS MADE. Nothing herein is to be taken as permission, inducement or recommendation to practice any<br />

patented invention without a license.<br />

FIRE PRECAUTIONS: PARAGLAS SOUNDSTOP sheet is a combustible thermoplastic. Precautions should be taken to protect this material<br />

from and high heat sources. PARAGLAS SOUNDSTOP sheet usually burns rapidly to completion if not extinguished. The<br />

products of combustion, if air is present are carbon dioxide and water. However, in many air will not be<br />

available and toxic carbon monoxide will be formed, as it will when other common combustible materials are burned. We urge good<br />

judgement in the use of this versatile material and recommend that building codes be followed carefully to assure it is used properly.<br />

COMPATIBILITY: Like other plastic materials, PARAGLAS SOUNDSTOP sheet is subject to crazing, cracking or discoloration if brought<br />

into contact with incompatible materials. These materials may include cleaners, polishes, adhesives, sealants, gasketing or packaging<br />

materials, cutting emulsions, etc.<br />

Transparent for Visibility and Outstanding Light Transmission<br />

Long Service Life Measured in Decades<br />

Approved by State DOTs including CALTRANS and New York

PARAGLAS SOUNDSTOP ® Designers can get the of a tall wall while<br />

avoiding the corresponding visual impact.<br />

The Aesthetic Solution for Noise Walls<br />

Performance Advantages Sound Reduction/Weight<br />

Impact Strength Meets criteria of the Dade County Large missile (2x4 board)<br />

impact test.<br />

Maintenance Free Hard non-porous surface stays clean through exposure to rain.<br />

Light Weight A 56 square foot panel weighs as little as 225 pounds.<br />

Chemical Resistance Tolerates exposure to many chemicals including ice-melt<br />

chemicals, glass etching compounds and dilute acids without<br />

adverse ects.<br />

Gr Removal is removed easily and quickly involving only a spray-on<br />

application of solvent followed by power washing.<br />

Durability A very hard surface resists scratches from natural causes such<br />

as windblown sand and damage from impact by stones and<br />

other small objects thrown against it by c.<br />

Wind Load Resistance Excellent physical strength allows it to resist high wind loads.<br />

PARAGLAS SOUNDSTOP sheet is available in 15 mm, 20 mm<br />

and 25 mm thickness.<br />

Sheet ASTM E90 STC Weight per<br />

Thickness Rating (dB) sq. ft. (psf)<br />

15 mm (19/32”) 34 3.66<br />

20 mm (25/32”) 35 4.86<br />

25 mm (1”) 37 6.1<br />

Available in 7 colors, the sheets<br />

can be treated to make them visible<br />

to birds either by embedding<br />

or adding surface markings.<br />

PARAGLAS SOUNDSTOP<br />

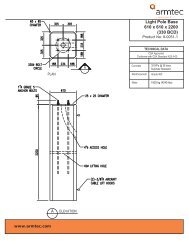

Ready-Fit Noise Barrier Panels<br />

PARAGLAS SOUNDSTOP Ready-Fit Panels are<br />

fully fabricated frame and panel assemblies<br />

designed for use with concrete columns,<br />

pilasters or structural steel H posts. The frame is<br />

made from structural steel or aluminum and<br />

can be to match surrounding materials.<br />

The transparent portion of the Ready-Fit Panel is<br />

PARAGLAS SOUNDSTOP noise barrier sheet.<br />

The assembly can be adapted to post spacings from six to twenty-four feet<br />

and in panel heights of four, six and eight feet.The Ready-Fit Panel is installed<br />

in the same drop-in manner as the conventional panels within the noise<br />

barrier.<br />

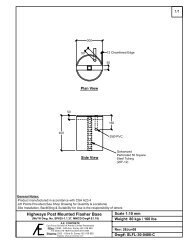

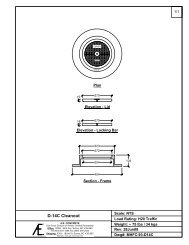

Framing Options<br />

Designers can easily adapt PARAGLAS SOUNDSTOP<br />

to almost any design. These framing system<br />

options work well with PARAGLAS SOUNDSTOP.<br />

PARAGLAS SOUNDSTOP<br />

SHEET<br />

Compatible<br />

Rubber Gasket<br />

PARAGLAS SOUNDSTOP<br />

SHEET<br />

Compatible<br />

Rubber Gasket<br />

PARAGLAS SOUNDSTOP<br />

SHEET<br />

Compatible<br />

Rubber Gasket<br />

PARAGLAS SOUNDSTOP<br />

SHEET<br />

Compatible<br />

Rubber Gasket<br />

PARAGLAS SOUNDSTOP<br />

SHEET<br />

Compatible<br />

Rubber Gasket<br />

PARAGLAS SOUNDSTOP<br />

SHEET<br />

Gasket<br />

Lag Screw<br />

8” x 8” SYP<br />

Typical<br />

Bushing/<br />

Spacer<br />

Bushing/<br />

Spacer<br />

Bushing/<br />

Spacer<br />

2” x 6”<br />

SYP<br />

Typical

PARAGLAS SOUNDSTOP ®<br />

N O I S E B A RRI ER SHEET<br />

Transparent Noise Barriers<br />

PARAGLAS SOUNDSTOP ® TL4 System<br />

Ultra Low Dead Load<br />

Crash Tested<br />

FHWA Approved

Cover:<br />

PARAGLAS SOUNDSTOP® TL4 System<br />

Test Facility, Lincoln, NE<br />

18,000 pound truck impacts<br />

the TL4 System at 50 MPH and<br />

at an angle of 15°<br />

Transparent Noise Barriers<br />

Complete turnkey solution for transparent noise barriers, vandal shields or<br />

FHWA approved for structures<br />

Components meet or exceed FHWA and DOT standards<br />

Meets NCHRP 350 level 4 crash test conditions<br />

Light weight, e. g. 200 lbs per linear foot<br />

Incorporates PARAGLAS SOUNDSTOP®GS CC noise barrier sheet with<br />

integrated fragment retention, meeting international standards, e. g. EN 1794<br />

Excellent sound insulating properties<br />

Transparent for visibility and light transmission<br />

Damaged areas show how the<br />

PARAGLAS SOUNDSTOP® TL4 System stabilizes the<br />

vehicle and reduces the severity of the crash.<br />

Very low maintenance, panels will retain clarity and physical strength despite<br />

decades of exposure to sunlight (ASTM D 1003 & D 4812 test methods)

NCHRP 350 Test Level 4<br />

Midwest Roadside Safety Facility,<br />

Lincoln, NE, USA<br />

» … the crash performance of the concrete<br />

safety shapes is essentially improved by limiting<br />

vehicle climb to some extent and b cantly<br />

reducing the roll angle of larger vehicles. «<br />

Excerpt from FHWA approval letter<br />

» That is the most stable TL4 crash test I‘ve ever seen. «<br />

Senior FHWA O cial in the O ce of Safety Design<br />

A 4,400 lb pickup truck<br />

impacts the TL4 System at<br />

60 mph at a 25° angle

Product ering<br />

PARAGLAS SOUNDSTOP ®<br />

TL4 System<br />

Available from<br />

2.5 to 5.0 meters high<br />

Post spacing 2.5 meters<br />

PARAGLAS SOUNDSTOP® GS CC<br />

has embedded poly laments<br />

to contain broken fragments<br />

resulting from collision damage.<br />

This complies with EN 1794-2.<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

Colors<br />

Transparent Barrier:<br />

Clear<br />

Midnight Blue<br />

Steel Blue<br />

Sky Blue<br />

Forest Green<br />

Sea Green<br />

Spring Green<br />

Smoky Brown<br />

This information and all further technical advice are based on Degussa’s present knowledge and experience. However, Degussa assumes no liability<br />

for providing such information and advice including the extent to which such information and advice may relate to existing third party intellectual<br />

property rights, especially patent rights. In particular, Degussa disclaims all CONDITIONS AND WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING THE<br />

IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY. DEGUSSA SHALL NOT BE RESPON-SIBLE FOR CONSEQUENTIAL, INDIRECT OR<br />

INCIDENTAL DAMAGES (INCLUDING LOSS OF PROFITS) OF ANY KIND. Degussa reserves the right to make any changes according to technological progress or<br />

further developments. It is the customer’s responsibility and obligation to carefully inspect and test any incoming goods. Performance of the product(s)<br />

described herein should be v ed by testing and carried out only b ed experts. It is the sole responsibility of the customer to carry out and<br />

arrange for any such testing. Reference to trade names used by other companies is neither a recommendation, nor an endorsement of any product and<br />

does not imply that similar products could not be used.<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

Non-Transparent Barrier Colors<br />

available for:<br />

• sight screens<br />

• as paneling for concrete structures<br />

• glare screens3452<br />

for sales and technical<br />

information contact.<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary of<br />

Degussa.<br />

PARAGLAS Soundstop ® is a<br />

registered trademark of CYRO Industries.

PARAGLAS SOUNDSTOP ®<br />

N O I S E B A RRI ER SHEET<br />

PARAGLAS SOUNDSTOP ®<br />

Transparent Noise Barriers

PARAGLAS SOUNDSTOP® GS CC<br />

With additional integrated sliver retention<br />

according to EN 1793, EN 1794<br />

ZTV-Lsw 88, Section 3.4.2.<br />

No further restraint systems<br />

are required.<br />

Transparent Noise Barriers<br />

highly transparent and crystal-clear<br />

extremely resistant to weathering and aging<br />

easy to form and fabricate<br />

lightweight<br />

meet the requirements of ZTV-Lsw 88,<br />

EN 1793 and EN 1794<br />

with 10-year guarantee (according to guarantee conditions)<br />

can be recycled and returned to us<br />

available in clear and seven transparent colors<br />

Colorless Clear<br />

Colors<br />

Shades of<br />

blue Midnight Blue<br />

Steel Blue<br />

Sky Blue<br />

Shades of<br />

green Forest Green<br />

Sea Green<br />

Spring Green<br />

Shades of<br />

brown Smoky Brown

Photo on cover page, left:<br />

PARAGLAS SOUNDSTOP® GS<br />

Railroad section Frankfurt – Mannheim,<br />

Germany<br />

Photo on cover page, right:<br />

PARAGLAS SOUNDSTOP® XT<br />

Velperbroek highway A12<br />

Netherlands<br />

Products<br />

PARAGLAS SOUNDSTOP® GS CC<br />

Type Thickness in mm Size in mm Miscellaneous<br />

PARAGLAS<br />

SOUNDSTOP® XT<br />

PARAGLAS<br />

SOUNDSTOP® GS<br />

PARAGLAS<br />

SOUNDSTOP® GS CC<br />

Tsuruoka, Japan<br />

15 · 20 · 25 2,000 x up to 6,000 Various thicknesses,<br />

lengths of more than<br />

6,000 mm, width 2,050<br />

mm on request<br />

15 · 20 · 25 2,500 x 2,000<br />

3,000 x 2,000<br />

4,200 x 2,000<br />

5,000 x 2,000<br />

15 · 20 · 25 2,500 x 2,000<br />

3,000 x 2,000<br />

4,200 x 2,000<br />

5,000 x 2,000<br />

5,000 x 2,300<br />

3,300 x 2,500<br />

on request<br />

With sliver-retaining<br />

black polyamide threads,<br />

embedded horizontally<br />

or vertically. Clear<br />

threads available on<br />

request<br />

5,000 x 2,300<br />

3,300 x 2,500<br />

on request<br />

PARAGLAS SOUNDSTOP® XT<br />

Monte Barro tunnel entrance<br />

Accessories<br />

We o�er EPDM gaskets for<br />

the correct installation of<br />

PARAGLAS SOUNDSTOP® in<br />

15, 20 and 25 mm thickness.<br />

Lecco, Italy

Properties<br />

PARAGLAS<br />

SOUNDSTOP®<br />

XT<br />

PARAGLAS SOUNDSTOP® GS CC<br />

Baraki, Japan<br />

PARAGLAS<br />

SOUNDSTOP®<br />

GS, GS CC<br />

Unit Test Method<br />

Tensile strength min. 70 min. 70 MPa ISO 527-2/1B/5<br />

Elongation at break 5 5 % ISO 527-2/1B/5<br />

Flexural strength min. 98 min. 98 MPa ISO 178<br />

Elastic modulus min. 3,300 min. 3,300 MPa ISO 527-2/1B/5<br />

Thickness tolerances ISO 7823-1<br />

Density 1,19 1,19 g/cm 3 ISO 1183<br />

70.10 -6 70.10 -6 1/K DIN 53752-A<br />

Max. service temperature 70 70 °C –––<br />

Vicat softening temperature 102 110 °C ISO 306/B50<br />

Light transmission of crystal-clear sheets min. 90 min. 90 % DIN 5036<br />

PARAGLAS SOUNDSTOP® XT<br />

Weighted sound reduction index DL R 15 mm 30 30 dB EN 1793-2 / ZTV- Lsw 88<br />

Bewertetes Schalldämmmaß DL R 20 mm 32 32 dB EN 1793-2 / ZTV- Lsw 88<br />

Bewertetes Schalldämmmaß DL R 25 mm 33 33 dB EN 1793-2 / ZTV- Lsw 88<br />

High-speed train section<br />

Rome-Naples, Italy

Service<br />

W er you<br />

• cut-to-size sheets<br />

• surface-treated sheets<br />

(e.g. matte stripes, coatings)<br />

• sheets with line-bent edges and<br />

thermoformed elements<br />

• technical support<br />

Exclusive North American Distributor<br />

For Sales and Technical Information Contact:<br />

Durisol USA, Inc.<br />

8270 Greensboro Drive, Suite 810<br />

McLean, VA, USA 22102<br />

Phone: (866) 801-0999<br />

Fax: (877) 268-8813<br />

www.durisol.com<br />

PARAGLAS SOUNDSTOP®<br />

PARAGLAS SOUNDSTOP® GS CC is the only<br />

material approved for use along bridges<br />

without additional restraint systems accord-<br />

ing to EN 1794 Parts 1 and 2. The threads<br />

incorporated into the sheets prevent slivers<br />

from falling onto the road surface, e.g. in the<br />

event of damage during a road accident.<br />

Standards and Directives<br />

The legal regulations that apply to transpar-<br />

ent noise barriers are ZTV-Lsw 88 in Germany<br />

(additional technical regulations and direc-<br />

tives for the construction of noise barriers<br />

along roads), issued by the German Ministry<br />

of Transportation, and European standards<br />

EN 1793 Parts 1 to 3 and EN 1794 Parts 1<br />

devices.”<br />

Durisol Inc.<br />

67 Frid Street<br />

Hamilton, ON, Canada L8P 4M3<br />

Phone: (905) 521-0999<br />

Fax: (905) 521-8658<br />

10-Year Guarantee<br />

PARAGLAS SOUNDSTOP® meets the require-<br />

ments of ZTV-Lsw 88, EN 1793 Parts 1-3 and<br />

EN 1794 Parts 1 and 2.<br />

Loadbearing Capacity. The loadbearing<br />

capacity of the sheets is determined via the<br />

elastic modulus, measured according to ISO 527.<br />

Stability. This is proved by the tensile<br />

strength of the sheets, measured according<br />

to ISO 527.<br />

Light Transmission.<br />

PARAGLAS SOUNDSTOP® retains its high light<br />

transmission for many years. This is proved<br />

by measurement according to DIN 5036 Part<br />

3 Illuminant C.<br />

Sliver Retention. The sliver retention of<br />

PARAGLAS SOUNDSTOP® GS CC is described<br />

and tested by an impact test to EN 1794-2<br />

Appendix B.<br />

Manufactured by:<br />

Degussa/CYRO<br />

379 Interpace Parkway<br />

Parsippany, NJ 07054<br />

1.800.631.5384<br />

<strong>paraglas</strong>@degussa.com<br />

CYRO Industries is a<br />

wholly-owned subsidiary of<br />

Degussa.<br />

PARAGLAS Soundstop ® is a<br />

registered trademark of CYRO Industries.

Hearing is Believing!<br />

… with Ready-Fit Invisible Noise Barriers<br />

PARAGLAS SOUNDSTOP ®<br />

NOISE BARRIER SHEET<br />

The Aesthetic Solution for Noise Walls<br />

Impact Strength Meets criteria of the Dade County Large missile (2x4 board)<br />

impact test.<br />

Sheet ASTM E90 STC Weight per<br />