Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4 <strong>Rieter</strong> . <strong>LINK</strong> 52 . 1 /2008<br />

TECHNOLOGY<br />

Processing SPV viscose using <strong>Rieter</strong><br />

R 40 rotor spinning technology<br />

The combination of SPV viscose fibers with <strong>Rieter</strong> R 40 rotor spinning<br />

technology enables rotor speeds of 130 000 rpm and delivery speeds of<br />

175 m/min to be achieved with Ne 30/1 yarns while maintaining very<br />

good running properties and optimum yarn structure for downstream<br />

processing of the yarn. The twist factor for processing SPV viscose is<br />

ideally within the αm 100-110 range. A mean twist factor of αm 105 can<br />

be recommended for weaving and knitting applications.<br />

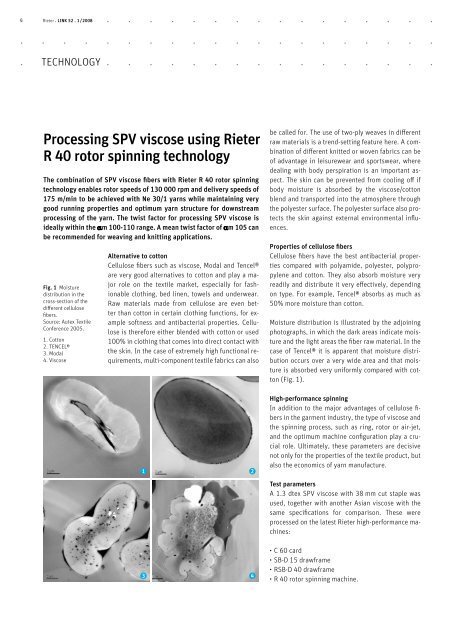

Fig. 1 Moisture<br />

distribution in the<br />

cross-section of the<br />

different cellulose<br />

fibers.<br />

Source: Autex Textile<br />

Conference 2005.<br />

1. Cotton<br />

2. TENCEL®<br />

3. Modal<br />

4. Viscose<br />

Alternative to cotton<br />

Cellulose fibers such as viscose, Modal and Tencel®<br />

are very good alternatives to cotton and play a major<br />

role on the textile market, especially for fashionable<br />

clothing, bed linen, towels and underwear.<br />

Raw materials made from cellulose are even better<br />

than cotton in certain clothing functions, for example<br />

softness and antibacterial properties. Cellulose<br />

is therefore either blended with cotton or used<br />

100% in clothing that comes into direct contact with<br />

the skin. In the case of extremely high functional requirements,<br />

multi-component textile fabrics can also<br />

1 2<br />

3 4<br />

be called for. The use of two-ply weaves in different<br />

raw materials is a trend-setting feature here. A combination<br />

of different knitted or woven fabrics can be<br />

of advantage in leisurewear and sportswear, where<br />

dealing with body perspiration is an important aspect.<br />

The skin can be prevented from cooling off if<br />

body moisture is absorbed by the viscose/cotton<br />

blend and transported into the atmosphere through<br />

the polyester surface. The polyester surface also protects<br />

the skin against external environmental influences.<br />

Properties of cellulose fibers<br />

Cellulose fibers have the best antibacterial properties<br />

compared with polyamide, polyester, polypropylene<br />

and cotton. They also absorb moisture very<br />

readily and distribute it very effectively, depending<br />

on type. For example, Tencel® absorbs as much as<br />

50% more moisture than cotton.<br />

Moisture distribution is illustrated by the adjoining<br />

photographs, in which the dark areas indicate moisture<br />

and the light areas the fiber raw material. In the<br />

case of Tencel® it is apparent that moisture distribution<br />

occurs over a very wide area and that moisture<br />

is absorbed very uniformly compared with cotton<br />

(Fig. 1).<br />

High-performance spinning<br />

In addition to the major advantages of cellulose fibers<br />

in the garment industry, the type of viscose and<br />

the spinning process, such as ring, rotor or air-jet,<br />

and the optimum machine configuration play a crucial<br />

role. Ultimately, these parameters are decisive<br />

not only for the properties of the textile product, but<br />

also the economics of yarn manufacture.<br />

Test parameters<br />

A 1.3 dtex SPV viscose with 38 mm cut staple was<br />

used, together with another Asian viscose with the<br />

same specifications for comparison. These were<br />

processed on the latest <strong>Rieter</strong> high-performance machines:<br />

• C 60 card<br />

• SB-D 15 drawframe<br />

• RSB-D 40 drawframe<br />

• R 40 rotor spinning machine.