Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6 <strong>Rieter</strong> . <strong>LINK</strong> 52 . 1 /2008<br />

TECHNOLOGY<br />

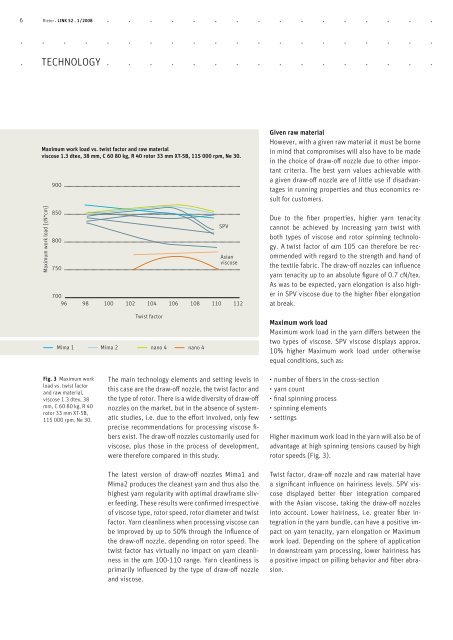

Maximum work load vs. twist factor and raw material<br />

viscose 1.3 dtex, 38 mm, C 60 80 kg, R 40 rotor 33 mm XT-5B, 115 000 rpm, Ne 30.<br />

Maximum work load [cN*cm]<br />

900<br />

850<br />

800<br />

750<br />

700<br />

96 98 100 102 104 106 108 110 112<br />

Mima 1 Mima 2 nano 4 nano 4<br />

Fig. 3 Maximum work<br />

load vs. twist factor<br />

and raw material,<br />

viscose 1.3 dtex, 38<br />

mm, C 60 80 kg, R 40<br />

rotor 33 mm XT-5B,<br />

115 000 rpm, Ne 30.<br />

Twist factor<br />

SPV<br />

Asian<br />

viscose<br />

The main technology elements and setting levels in<br />

this case are the draw-off nozzle, the twist factor and<br />

the type of rotor. There is a wide diversity of draw-off<br />

nozzles on the market, but in the absence of systematic<br />

studies, i.e. due to the effort involved, only few<br />

precise recommendations for processing viscose fibers<br />

exist. The draw-off nozzles customarily used for<br />

viscose, plus those in the process of development,<br />

were therefore compared in this study.<br />

The latest version of draw-off nozzles Mima1 and<br />

Mima2 produces the cleanest yarn and thus also the<br />

highest yarn regularity with optimal drawframe sliver<br />

feeding. These results were confirmed irrespective<br />

of viscose type, rotor speed, rotor diameter and twist<br />

factor. Yarn cleanliness when processing viscose can<br />

be improved by up to 50% through the influence of<br />

the draw-off nozzle, depending on rotor speed. The<br />

twist factor has virtually no impact on yarn cleanliness<br />

in the αm 100-110 range. Yarn cleanliness is<br />

primarily influenced by the type of draw-off nozzle<br />

and viscose.<br />

Given raw material<br />

However, with a given raw material it must be borne<br />

in mind that compromises will also have to be made<br />

in the choice of draw-off nozzle due to other important<br />

criteria. The best yarn values achievable with<br />

a given draw-off nozzle are of little use if disadvantages<br />

in running properties and thus economics result<br />

for customers.<br />

Due to the fiber properties, higher yarn tenacity<br />

cannot be achieved by increasing yarn twist with<br />

both types of viscose and rotor spinning technology.<br />

A twist factor of αm 105 can therefore be recommended<br />

with regard to the strength and hand of<br />

the textile fabric. The draw-off nozzles can influence<br />

yarn tenacity up to an absolute figure of 0.7 cN/tex.<br />

As was to be expected, yarn elongation is also higher<br />

in SPV viscose due to the higher fiber elongation<br />

at break.<br />

Maximum work load<br />

Maximum work load in the yarn differs between the<br />

two types of viscose. SPV viscose displays approx.<br />

10% higher Maximum work load under otherwise<br />

equal conditions, such as:<br />

• number of fibers in the cross-section<br />

• yarn count<br />

• final spinning process<br />

• spinning elements<br />

• settings<br />

Higher maximum work load in the yarn will also be of<br />

advantage at high spinning tensions caused by high<br />

rotor speeds (Fig. 3).<br />

Twist factor, draw-off nozzle and raw material have<br />

a significant influence on hairiness levels. SPV viscose<br />

displayed better fiber integration compared<br />

with the Asian viscose, taking the draw-off nozzles<br />

into account. Lower hairiness, i.e. greater fiber integration<br />

in the yarn bundle, can have a positive impact<br />

on yarn tenacity, yarn elongation or Maximum<br />

work load. Depending on the sphere of application<br />

in downstream yarn processing, lower hairiness has<br />

a positive impact on pilling behavior and fiber abrasion.