ProSoft's “Phased Migration” Solutions - Control Design

ProSoft's “Phased Migration” Solutions - Control Design

ProSoft's “Phased Migration” Solutions - Control Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DESIGN<br />

OF ALL THE REASONS TO CONSIDER INTRINSIC SAFETY (IS) FOR YOUR OPERATIONS,<br />

THE FIRST ONE IS THAT THESE INSTALLATIONS REDUCE THE OVERALL RISK<br />

INTRINSIC SAFETY (IS) MAKES IT POSSIBLE TO PERFORM LIVE<br />

maintenance at any point in the control loop because, by its nature,<br />

IS always keeps the amount of available energy on the wire pair below<br />

the ignition point for the gases/environment in which it’s installed.<br />

There are two aspects to determining the hazardous area requirements<br />

for an installation: area classification (the type of gas present and<br />

the likelihood of it being present) and the temperature classification<br />

(maximum surface temperature of the device or apparatus).<br />

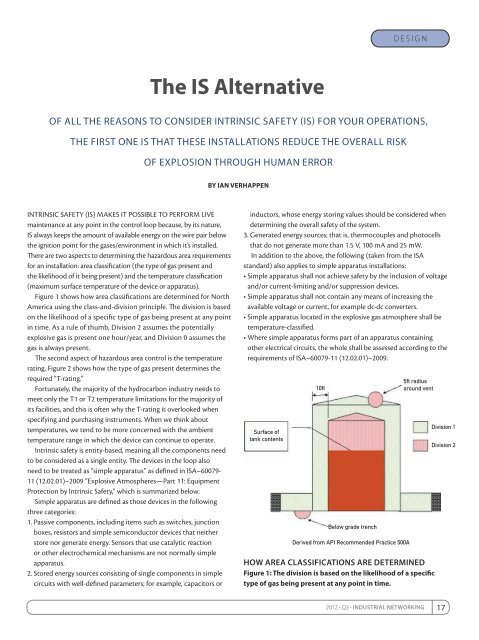

Figure 1 shows how area classifications are determined for North<br />

America using the class-and-division principle. The division is based<br />

on the likelihood of a specific type of gas being present at any point<br />

in time. As a rule of thumb, Division 2 assumes the potentially<br />

explosive gas is present one hour/year, and Division 0 assumes the<br />

gas is always present.<br />

The second aspect of hazardous area control is the temperature<br />

rating. Figure 2 shows how the type of gas present determines the<br />

required “T-rating.”<br />

Fortunately, the majority of the hydrocarbon industry needs to<br />

meet only the T1 or T2 temperature limitations for the majority of<br />

its facilities, and this is often why the T-rating is overlooked when<br />

specifying and purchasing instruments. When we think about<br />

temperatures, we tend to be more concerned with the ambient<br />

temperature range in which the device can continue to operate.<br />

Intrinsic safety is entity-based, meaning all the components need<br />

to be considered as a single entity. The devices in the loop also<br />

need to be treated as “simple apparatus” as defined in ISA–60079-<br />

11 (12.02.01)–2009 “Explosive Atmospheres—Part 11: Equipment<br />

Protection by Intrinsic Safety,” which is summarized below:<br />

Simple apparatus are defined as those devices in the following<br />

three categories:<br />

1. Passive components, including items such as switches, junction<br />

boxes, resistors and simple semiconductor devices that neither<br />

store nor generate energy. Sensors that use catalytic reaction<br />

or other electrochemical mechanisms are not normally simple<br />

apparatus.<br />

2. Stored energy sources consisting of single components in simple<br />

circuits with well-defined parameters; for example, capacitors or<br />

The IS Alternative<br />

OF EXPLOSION THROUGH HUMAN ERROR<br />

BY IAN VERHAPPEN<br />

inductors, whose energy storing values should be considered when<br />

determining the overall safety of the system.<br />

3. Generated energy sources; that is, thermocouples and photocells<br />

that do not generate more than 1.5 V, 100 mA and 25 mW.<br />

In addition to the above, the following (taken from the ISA<br />

standard) also applies to simple apparatus installations:<br />

�������������������������������������������������������������������������<br />

and/or current-limiting and/or suppression devices.<br />

������������������������������������������������������������������<br />

available voltage or current, for example dc-dc converters.<br />

���������������������������������������������������������������������<br />

temperature-classified.<br />

����������������������������������������������������������������<br />

other electrical circuits, the whole shall be assessed according to the<br />

requirements of ISA–60079-11 (12.02.01)–2009.<br />

Surface of<br />

tank contents<br />

10ft<br />

Below grade trench<br />

Derived from API Recommended Practice 500A<br />

5ft radius<br />

around vent<br />

HOW AREA CLASSIFICATIONS ARE DETERMINED<br />

Figure 1: The division is based on the likelihood of a specific<br />

type of gas being present at any point in time.<br />

2012 � Q3 � INDUSTRIAL NETWORKING<br />

Division 1<br />

Division 2<br />

17