Analytical Modeling of Chatter Stability in Turning and Boring ...

Analytical Modeling of Chatter Stability in Turning and Boring ...

Analytical Modeling of Chatter Stability in Turning and Boring ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

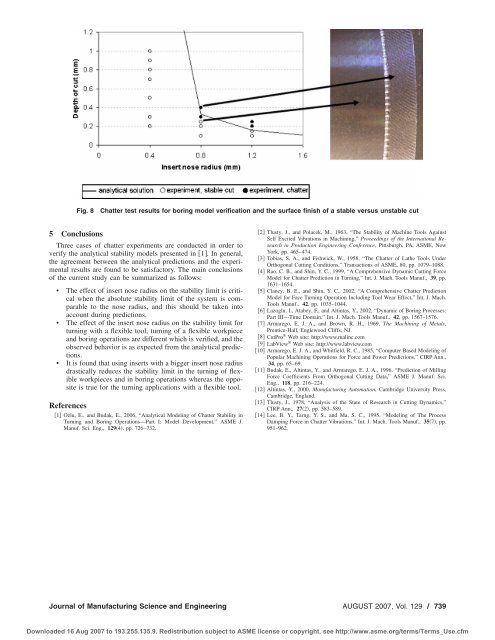

5 Conclusions<br />

Three cases <strong>of</strong> chatter experiments are conducted <strong>in</strong> order to<br />

verify the analytical stability models presented <strong>in</strong> �1�. In general,<br />

the agreement between the analytical predictions <strong>and</strong> the experimental<br />

results are found to be satisfactory. The ma<strong>in</strong> conclusions<br />

<strong>of</strong> the current study can be summarized as follows:<br />

• The effect <strong>of</strong> <strong>in</strong>sert nose radius on the stability limit is critical<br />

when the absolute stability limit <strong>of</strong> the system is comparable<br />

to the nose radius, <strong>and</strong> this should be taken <strong>in</strong>to<br />

account dur<strong>in</strong>g predictions.<br />

• The effect <strong>of</strong> the <strong>in</strong>sert nose radius on the stability limit for<br />

turn<strong>in</strong>g with a flexible tool, turn<strong>in</strong>g <strong>of</strong> a flexible workpiece<br />

<strong>and</strong> bor<strong>in</strong>g operations are different which is verified, <strong>and</strong> the<br />

observed behavior is as expected from the analytical predictions.<br />

• It is found that us<strong>in</strong>g <strong>in</strong>serts with a bigger <strong>in</strong>sert nose radius<br />

drastically reduces the stability limit <strong>in</strong> the turn<strong>in</strong>g <strong>of</strong> flexible<br />

workpieces <strong>and</strong> <strong>in</strong> bor<strong>in</strong>g operations whereas the opposite<br />

is true for the turn<strong>in</strong>g applications with a flexible tool.<br />

References<br />

Fig. 8 <strong>Chatter</strong> test results for bor<strong>in</strong>g model verification <strong>and</strong> the surface f<strong>in</strong>ish <strong>of</strong> a stable versus unstable cut<br />

�1� Ozlu, E., <strong>and</strong> Budak, E., 2006, “<strong>Analytical</strong> <strong>Model<strong>in</strong>g</strong> <strong>of</strong> <strong>Chatter</strong> <strong>Stability</strong> <strong>in</strong><br />

Turn<strong>in</strong>g <strong>and</strong> Bor<strong>in</strong>g Operations—Part I: Model Development,” ASME J.<br />

Manuf. Sci. Eng., 129�4�, pp. 726–732.<br />

�2� Tlusty, J., <strong>and</strong> Polacek, M., 1963, “The <strong>Stability</strong> <strong>of</strong> Mach<strong>in</strong>e Tools Aga<strong>in</strong>st<br />

Self Excited Vibrations <strong>in</strong> Mach<strong>in</strong><strong>in</strong>g,” Proceed<strong>in</strong>gs <strong>of</strong> the International Research<br />

<strong>in</strong> Production Eng<strong>in</strong>eer<strong>in</strong>g Conference, Pittsburgh, PA, ASME, New<br />

York, pp. 465–474.<br />

�3� Tobias, S. A., <strong>and</strong> Fishwick, W., 1958, “The <strong>Chatter</strong> <strong>of</strong> Lathe Tools Under<br />

Orthogonal Cutt<strong>in</strong>g Conditions,” Transactions <strong>of</strong> ASME, 80, pp. 1079–1088.<br />

�4� Rao, C. B., <strong>and</strong> Sh<strong>in</strong>, Y. C., 1999, “A Comprehensive Dynamic Cutt<strong>in</strong>g Force<br />

Model for <strong>Chatter</strong> Prediction <strong>in</strong> Turn<strong>in</strong>g,” Int. J. Mach. Tools Manuf., 39, pp.<br />

1631–1654.<br />

�5� Clancy, B. E., <strong>and</strong> Sh<strong>in</strong>, Y. C., 2002, “A Comprehensive <strong>Chatter</strong> Prediction<br />

Model for Face Turn<strong>in</strong>g Operation Includ<strong>in</strong>g Tool Wear Effect,” Int. J. Mach.<br />

Tools Manuf., 42, pp. 1035–1044.<br />

�6� Lazoglu, I., Atabey, F., <strong>and</strong> Alt<strong>in</strong>tas, Y., 2002, “Dynamic <strong>of</strong> Bor<strong>in</strong>g Processes:<br />

Part III—Time Doma<strong>in</strong>,” Int. J. Mach. Tools Manuf., 42, pp. 1567–1576.<br />

�7� Armarego, E. J. A., <strong>and</strong> Brown, R. H., 1969, The Mach<strong>in</strong><strong>in</strong>g <strong>of</strong> Metals,<br />

Prentice-Hall, Englewood Cliffs, NJ.<br />

�8� CutPro ® Web site: http://www.mal<strong>in</strong>c.com<br />

�9� LabView ® Web site: http://www.labview.com<br />

�10� Armarego, E. J. A., <strong>and</strong> Whitfield, R. C., 1985, “Computer Based <strong>Model<strong>in</strong>g</strong> <strong>of</strong><br />

Popular Mach<strong>in</strong><strong>in</strong>g Operations for Force <strong>and</strong> Power Predictions,” CIRP Ann.,<br />

34, pp. 65–69.<br />

�11� Budak, E., Alt<strong>in</strong>tas, Y., <strong>and</strong> Armarego, E. J. A., 1996, “Prediction <strong>of</strong> Mill<strong>in</strong>g<br />

Force Coefficients From Orthogonal Cutt<strong>in</strong>g Data,” ASME J. Manuf. Sci.<br />

Eng., 118, pp. 216–224.<br />

�12� Alt<strong>in</strong>tas, Y., 2000, Manufactur<strong>in</strong>g Automation, Cambridge University Press,<br />

Cambridge, Engl<strong>and</strong>.<br />

�13� Tlusty, J., 1978, “Analysis <strong>of</strong> the State <strong>of</strong> Research <strong>in</strong> Cutt<strong>in</strong>g Dynamics,”<br />

CIRP Ann., 27�2�, pp. 583–589.<br />

�14� Lee, B. Y., Tarng, Y. S., <strong>and</strong> Ma, S. C., 1995, “<strong>Model<strong>in</strong>g</strong> <strong>of</strong> The Process<br />

Damp<strong>in</strong>g Force <strong>in</strong> <strong>Chatter</strong> Vibrations,” Int. J. Mach. Tools Manuf., 35�7�, pp.<br />

951–962.<br />

Journal <strong>of</strong> Manufactur<strong>in</strong>g Science <strong>and</strong> Eng<strong>in</strong>eer<strong>in</strong>g AUGUST 2007, Vol. 129 / 739<br />

Downloaded 16 Aug 2007 to 193.255.135.9. Redistribution subject to ASME license or copyright, see http://www.asme.org/terms/Terms_Use.cfm