Download Satelite no. 27 (June 2005) - Satair.com

Download Satelite no. 27 (June 2005) - Satair.com

Download Satelite no. 27 (June 2005) - Satair.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

N O . 2 7 J U N E 2 0 0 5<br />

2 Editorial<br />

4<br />

3<br />

46th International Paris Air<br />

Show – 13-19 <strong>June</strong> <strong>2005</strong><br />

European Regions Airline<br />

Association designate <strong>Satair</strong><br />

‘Preferred Supplier’<br />

<strong>Satair</strong> launches a next<br />

generation supply chain<br />

service<br />

New faces<br />

Mangement changes<br />

5<br />

10-year anniversary for<br />

<strong>Satair</strong> China<br />

<strong>Satair</strong> appointed exclusive<br />

distributor for CBS-Carsten<br />

Daus GmbH<br />

<strong>Satair</strong> takes over AOG Service<br />

Telex Communications – world<br />

leader in <strong>com</strong>mercial aviation<br />

Australian International Air<br />

Show – Avalon Victoria <strong>2005</strong><br />

Aircraft Interiors Expo Asia<br />

news and update by <strong>Satair</strong> - a leading <strong>com</strong>pany within aircraft parts distribution<br />

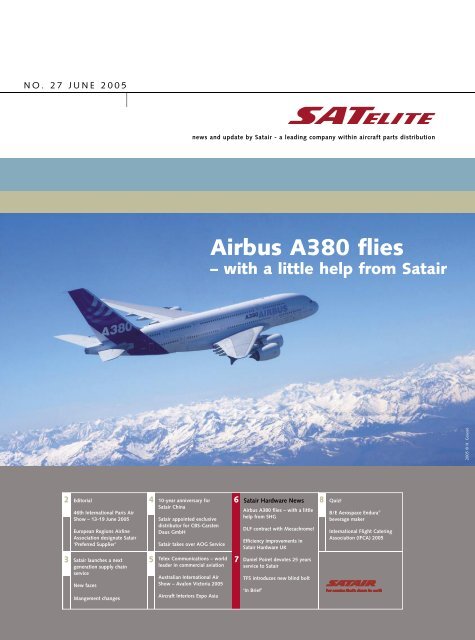

Airbus A380 flies<br />

– with a little help from <strong>Satair</strong><br />

6<br />

7<br />

<strong>Satair</strong> Hardware News<br />

Airbus A380 flies – with a little<br />

help from SHG<br />

DLF contract with Mecachrome!<br />

Efficiency improvements in<br />

<strong>Satair</strong> Hardware UK<br />

Daniel Poiret devotes 25 years<br />

service to <strong>Satair</strong><br />

TFS introduces new blind bolt<br />

‘In Brief’<br />

8 Quiz!<br />

B/E Aerospace Endura ®<br />

beverage maker<br />

International Flight Catering<br />

Association (IFCA) <strong>2005</strong><br />

<strong>2005</strong> © H. Goussé

NO. <strong>27</strong> JUNE <strong>2005</strong><br />

Publisher: <strong>Satair</strong> A/S, Copenhagen, Denmark<br />

E-mail: satelite@satair.<strong>com</strong><br />

Editor: Camilla Schuricht<br />

Design & Layout: Relevans<br />

Print: Glumsø Bogtryk<br />

Circulation: 10,000<br />

<strong>Satelite</strong> is published twice a year by <strong>Satair</strong>.<br />

All rights reserved. No part of this publication<br />

may be reproduced, stored in retrieval system<br />

or transmitted, in any form or by any means,<br />

without prior written permission by the publisher.<br />

SATAIR A/S<br />

Group Head Office<br />

Amager Landevej 147A<br />

<strong>27</strong>70 Kastrup, Denmark<br />

Phone: +45 3247 0100<br />

Fax: +45 3251 3434<br />

AOG Service: +45 4040 1224<br />

SITA: CPHSA7X<br />

SATAIR USA, Inc.<br />

3993 Tradeport Boulevard<br />

Atlanta, GA 30354, USA<br />

Phone: +1 404 675 6333<br />

Fax: +1 404 675 6311<br />

AOG Service: +1 404 310 1966<br />

SITA: ATLSA7X<br />

SATAIR ASIA Pte. Ltd.<br />

8 Loyang Link<br />

508897 Singapore<br />

Phone: +65 6543 0977<br />

Fax: +65 6543 0737<br />

AOG Service: +65 6543 0977<br />

SITA: SINSA7X<br />

SATAIR MALAYSIA<br />

Foreign Branch<br />

311, Block E, Kelana Parkview<br />

No. 1, Jalan SS6/2, Kelana Jaya<br />

47301 Petaling Jaya<br />

Selangor Darul Ehsan, Malaysia<br />

Phone: +603 704 6657/6670<br />

Fax: +603 704 6691<br />

SITA: KULSA7X<br />

SATAIR CHINA<br />

Representative Office<br />

CASC Airbus<br />

Tianzhu Airport Industrial Zone<br />

Tianwei Erjie<br />

Shunyi County, P.O. Box 3412<br />

101312 Beijing<br />

People's Republic of China<br />

Phone: +86 10 8048 6340<br />

Fax: +86 10 8048 6599<br />

www.satair.<strong>com</strong><br />

SATAIR HARDWARE UK LTD.<br />

Head Office<br />

Shoreham Airport<br />

Shoreham by Sea<br />

West Sussex BN43 5FN, United Kingdom<br />

Phone: +44 0 1<strong>27</strong>3 464046<br />

Fax: +44 0 1<strong>27</strong>3 464577<br />

SATAIR HARDWARE UK LTD.<br />

Purdeys Way<br />

Purdeys Industrial Estate<br />

Rochford<br />

Essex SS4 1NE, United Kingdom<br />

Phone: +44 0 1702 560700<br />

Fax: +44 0 1702 560750<br />

SATAIR HARDWARE A/S<br />

Amager Landevej 147A<br />

<strong>27</strong>70 Kastrup, Denmark<br />

Phone: +45 3247 0100<br />

Fax: +45 3247 0192<br />

SATAIR HARDWARE S.A.S.<br />

<strong>27</strong> Av. Etienne Audibert<br />

BP 30169<br />

60305 Senlis Cedex, France<br />

Phone: +33 3 4421 6868<br />

Fax: +33 3 4453 4999<br />

SATAIR HARDWARE INC.<br />

650 SW 34th Street<br />

Suite 304<br />

Ft Lauderdale<br />

Florida, FL 33315, USA<br />

Phone: +1 954 359 1694<br />

Fax: +1 954 359 1698<br />

www.satairhg.<strong>com</strong><br />

editorial<br />

I am pleased that the aviation industry steadily<br />

continues to move in a positive direction, and<br />

that even small improvements can have a<br />

domi<strong>no</strong> effect throughout the industry.<br />

The increase in passenger volumes continues,<br />

and as a consequence the Aftermarkets in<br />

Europe, Asia, and North America report of<br />

continued improvement in market conditions.<br />

The improved market conditions are directly reflected in the<br />

fact that all regions are reporting of activity levels well above<br />

the pre-9/11 activity level.<br />

Furthermore, it is a general feature in the markets in Europe,<br />

the Middle East and Asia/Pacific that customer demand is<br />

on the rebound primarily due to growth in the number of<br />

passenger travelling and the resulting increase in the need for<br />

maintenance. At the same time several upgrading projects<br />

for old aircraft have been launched and this, too, helps boost<br />

demand.<br />

After several years of decline in aircraft production there are<br />

<strong>no</strong>w signs of a recovery in production levels as well, which<br />

positively affects the market conditions in the OEM market.<br />

As you k<strong>no</strong>w, <strong>Satair</strong> has progressively increased its business<br />

since the beginning in 1957. Moving from one continent<br />

to a<strong>no</strong>ther, <strong>Satair</strong> has during the years opened offices<br />

throughout the world strengthening the logistics support<br />

needed to service our customers from regional based<br />

locations.<br />

I 1995, <strong>Satair</strong> opened an office in Beijing, China and we<br />

are pleased that we, today, in <strong>2005</strong>, are able to celebrate<br />

10 successful years in China - and with that many more to<br />

<strong>com</strong>e. Needless to say, the Chinese market has changed a<br />

lot during these past 10 years. However, with the help of<br />

our dedicated staff at our Beijing office, <strong>Satair</strong> has developed<br />

several close business relations throughout the region and<br />

with a continuously fast growing OEM and Aftermarket we<br />

are looking forward to the years ahead of us.<br />

<strong>Satair</strong> will be exhibiting at the China Expo in September and<br />

we encourage you to <strong>com</strong>e and visit us.<br />

If you are <strong>no</strong>t able to meet with us in China, then <strong>com</strong>e and<br />

see us in Paris. The 46th Paris Air Show runs 13 – 19 <strong>June</strong><br />

and you will find <strong>Satair</strong> in Hall 4, stand G7.<br />

For further information on where <strong>Satair</strong> will be exhibiting in<br />

<strong>2005</strong> please visit www.satair.<strong>com</strong> where you will find a list of<br />

our up<strong>com</strong>ing exhibition activities. We look forward to your<br />

visit.<br />

Hope you enjoy this issue of <strong>Satelite</strong>.<br />

Paris Air Show – Le Bourget 13-19 <strong>June</strong> <strong>2005</strong><br />

By Camilla Gregor Schuricht, Marketing Coordinator, <strong>Satair</strong> A/S<br />

<strong>Satair</strong> wel<strong>com</strong>es you to this year’s Paris Air Show at Le<br />

Bourget.<br />

The recent positive developments within the industry are set<br />

to benefit the Paris Air Show <strong>2005</strong>. The show is bigger than<br />

ever with 1,728 exhibitors from 42 countries.<br />

<strong>Satair</strong> will be exhibiting in a brand new hall, which was built<br />

at Le Bourget this year. At the 120 m 2 big stand we will<br />

show <strong>Satair</strong>’s capabilities within the main business segments<br />

– <strong>com</strong>mercial aftermarket and OEM support. You will find<br />

products on display from all <strong>Satair</strong>’s major suppliers and <strong>Satair</strong><br />

staff will be there to help you with any questions you may<br />

have.<br />

Some of <strong>Satair</strong>’s principals will be exhibiting together with us,<br />

giving visitors a direct contact with the manufacturers.<br />

B/E Aerospace will display and demonstrate its Endura ® and<br />

Espresso beverage maker as well as its Oxygen System. Pall<br />

Aerospace will be there to display and inform visitors about<br />

its filtration products and which products Pall Aerospace will<br />

supply to the A380.<br />

John Staer, CEO<br />

If you visit the stand, you can also hear more about <strong>Satair</strong><br />

Hardware’s DLF service. Using a full size DLF rag, scanner<br />

and printer we will show you how the service works when<br />

implemented at the customers.<br />

We look very much forward to seeing you at <strong>Satair</strong>’s stand.<br />

Visit us in Hall 4 - Stand G7<br />

European Regions Airline Association designates<br />

<strong>Satair</strong> ‘Preferred Supplier’<br />

In ERA’s publication ‘Regional International – April <strong>2005</strong>’,<br />

<strong>Satair</strong> has, together with a number of other reputable<br />

<strong>com</strong>panies, been designated ‘Preferred Supplier’ by ERA.<br />

It is recognition for an outstanding value proposition in the<br />

mentioned categories of products.<br />

Such designation can<strong>no</strong>t be bought – they are an indication<br />

that fellow ERA members have been happy with these<br />

<strong>com</strong>panies’ services.<br />

<strong>Satair</strong> is motioned in the product category Filters and<br />

Filaments.

<strong>Satair</strong> launches a next generation supply chain service<br />

By Claus Gaarskaer, Director Services, <strong>Satair</strong> A/S<br />

The supply of consumable and expendable parts for aircraft<br />

maintenance is a <strong>com</strong>plex business requiring thousands of<br />

parts from a vast number of different suppliers. On top,<br />

maintenance practises vary highly from airline to airline<br />

and material requirements are unpredictable resulting in an<br />

inefficient management of the end-to-end flow of parts.<br />

Today, <strong>Satair</strong> already offers its airline customers an integrated<br />

supply chain service by the name of IPP ® . The IPP has<br />

been operating since August 1999 and during the past five<br />

years <strong>Satair</strong> has gained valuable experience managing a<br />

collaborative customer/supplier project. We have a stabilized<br />

supply channel, and the efforts to demonstrate operating<br />

improvements are paying off.<br />

As a global leader in aerospace distribution services, <strong>Satair</strong>,<br />

continuously, strives at being a value-adding gateway<br />

between manufacturers and operators making it possible for<br />

both parties to achieve greater efficiency. One way for us to<br />

do this is by monitoring the market thereby assuring that our<br />

portfolio of services reflects the market conditions and needs<br />

of customers.<br />

The dilemma facing the operators<br />

Much has changed since the launch of IPP and so the need<br />

for a new and further enhanced supply chain solution. Today,<br />

many operators are eagerly seeking ways of minimizing the<br />

impacts of an insufficient management of their <strong>com</strong>plete<br />

supply chain process. In general, operators are looking at<br />

reducing tangible symptoms like:<br />

■ Large inventories of parts, both in volume and<br />

in numbers<br />

■ Unsuccessful attempts to optimise supply chain<br />

processes including consolidation of the vendor base<br />

■ Depreciation and obsolesce<br />

■ High cost of inventory holding<br />

New faces<br />

Brian Hunter has joined <strong>Satair</strong> Asia as Business Manager,<br />

Australia-Pacific. Brian Hunter <strong>com</strong>es from a position<br />

as Account Director with Smiths Aerospace in Brisbane,<br />

Australia.<br />

Kuay Soong Teck has joined <strong>Satair</strong> Asia as Product Manager<br />

for Pall Aerospace for Asia Pacific. Kuay Soong Teck has<br />

a strong engineering and <strong>com</strong>mercial background from<br />

his recent position with International Engine Component<br />

Overhaul (IECO).<br />

Mark O’Shaughnessy has joined <strong>Satair</strong> USA as Product<br />

Manager for Electrical Products with an emphasis on the<br />

North and South American markets. Mark <strong>com</strong>es from a<br />

position as Flight Operations Technical Manager (757/767<br />

fleet) with Delta Airlines.<br />

Troy Jones has joined <strong>Satair</strong> USA as Product Manager for B/E<br />

Aerospace Oxygen and Beverage products with an emphasis<br />

on the North and South American markets. Troy Jones <strong>com</strong>es<br />

from a position as Flight Operations Technical Manager (737<br />

fleet) with Delta Airlines.<br />

Nina Jenkins has joined <strong>Satair</strong> A/S as Sales Manager for<br />

Germany. Nina Jenkinks has worked within the aviation<br />

industry since 1990, most recent for Flair Aviation mainly<br />

working on helping start up airlines with initial provisioning<br />

for line and base maintenance.<br />

– an integrated supply chain solution for expendable and consumable parts<br />

■ Inventory handling costs exceeding the price for<br />

the part itself<br />

■ Undefined service level and expectations towards<br />

maintenance activities.<br />

■ A low turn rate due to inventory based on historical sale,<br />

maintenance events and out-phased aircraft types<br />

■ Difficulties in predicting future demand and<br />

requirements for parts.<br />

The <strong>Satair</strong> solution<br />

With the above in mind, <strong>Satair</strong> is proud to offer you a<br />

next generation supply chain solution targeting these<br />

exact symptoms. Basically, <strong>Satair</strong> is broadening its current<br />

distribution and clustered shopping activities offering a<br />

<strong>com</strong>petitive and in<strong>no</strong>vative supply chain solution, which<br />

exceeds the requirements from both its customers and<br />

suppliers.<br />

The cornerstone of the new <strong>Satair</strong> service is to optimise onsite<br />

inventories according usage and requirements and at<br />

the same time provide easy and quick access to low or <strong>no</strong>nmoving<br />

parts.<br />

As part of a Vendor Managed Inventory (VMI) or Direct<br />

Line Feed (DLF) program <strong>Satair</strong> takes full - or partial -<br />

responsibility for business functions including:<br />

■ Engineering and specification of products<br />

■ Quality and documentation<br />

■ Planning, sourcing and procurement<br />

■ Storage, receiving, inspection and kitting<br />

■ Financing of inventory<br />

■ Program management and regular performance reviews<br />

Benefits of an integrated <strong>Satair</strong> supply chain solution<br />

By entering into an integrated supply chain solution with<br />

<strong>Satair</strong>, the operator can expect a significant reduction in<br />

the total cost across all supply chain activities. Overall, the<br />

operator also achieves cost savings in other areas such as:<br />

Michael Hoejgaard has joined <strong>Satair</strong> A/S as Chief Financial<br />

Officer (CFO). Michael Hoejgaard <strong>com</strong>es from a position<br />

in the management of the Financial Department of Maersk<br />

Sealand.<br />

1 4<br />

2<br />

3<br />

5<br />

6<br />

■ Keeping strategic priorities by effective sourcing of parts<br />

■ Ease the physical and financial cost of inventory<br />

■ Efficient and reliable material supply eliminating the<br />

number of ‘11th hour’ emergency shipments<br />

■ Improved detailed product k<strong>no</strong>wledge<br />

■ State-of-the-art logistic solutions including<br />

transportation, bar-coding and automated storage<br />

solutions<br />

■ Improved end-to-end supply chain visibility<br />

■ Defined service levels resulting in fewer stock outs<br />

or shortages.<br />

In other words, <strong>Satair</strong> offers you the opportunity of a<br />

smoother, more efficient and more profitable way of running<br />

your business allowing you to improve your <strong>com</strong>petitive<br />

position and increase profits.<br />

Contact us today and hear why customers like Airbus, EADS<br />

etc. have already chosen <strong>Satair</strong> as partner for their service<br />

provider programs.<br />

For further information and to discuss future solutions on<br />

procurement and inventory management, please contact:<br />

Claus Gaarskaer by phone at +45 3247 0260 or<br />

e-mail: clg@satair.<strong>com</strong>.<br />

Management changes<br />

Morten Olsen has joined <strong>Satair</strong>’s Executive Board with the<br />

title of Chief Operating Officer (COO). Morten joined <strong>Satair</strong><br />

in 1985 and worked in a number of sales functions before<br />

being appointed to his previous position of Group VP, Sales<br />

Steen Karsbo is appointed Director, Marketing and Business<br />

Development and his responsibilities include product<br />

management, marketing and business development activities<br />

in the Aftermarket.<br />

Jens P. Pedersen moves to a position as Director, Corporate<br />

Business Development with responsibility for strategic<br />

business development.<br />

Claus Gaarskaer is appointed Services Director and his main<br />

responsibilities include service provider development.<br />

Steen Bruhn is appointed IPP Manager for the IPP Group.<br />

Steen Bruhn has worked for <strong>Satair</strong> for six years as Sales<br />

Manager for Germany and Austria.<br />

Esther Pang is appointed Operation Manager and will be<br />

responsible for all logistics, warehouse, purchasing and other<br />

supply chain activities. Esther Pang be<strong>com</strong>es a member of<br />

<strong>Satair</strong> Asia Executive Management team<br />

Anette Hagelsten is appointed HR Director, with the overall<br />

responsibility for <strong>Satair</strong>’s Human Resource.<br />

N O : 2 7 : J U N E : 0 5<br />

3

4Lin<br />

Hai OEM Sales Manager, Wu Meng Inside Sales Manager, Sun Xiaozheng Customer Service Executive, Zhao Xiaoli ADM Assitant &<br />

Customer Service Executive, Li Xu Sales Assistant, Zhang Yuan Area Sales Manager, Hu Yongdong Chief Representative<br />

10-year anniversary for <strong>Satair</strong> China<br />

By Hu Yongdong, Chief Representative, <strong>Satair</strong> China<br />

On 20 <strong>June</strong> <strong>2005</strong> <strong>Satair</strong> China celebrates its 10-year<br />

anniversary in China.<br />

Since 1988, <strong>Satair</strong> Asia, Singapore had developed a wide<br />

product support throughout the Asian Region, including<br />

China, but the fast growing Chinese market called for<br />

immediate and firm initiatives in order for <strong>Satair</strong> to live up to<br />

its <strong>com</strong>mitments towards the Chinese customers.<br />

<strong>Satair</strong> had for a long time actively developed plans to support<br />

the rapidly growing aerospace industry in China – <strong>no</strong>t just the<br />

aftermarket, but also a large and fast growing OEM market,<br />

and on 20 <strong>June</strong> 1995 <strong>Satair</strong> opened an office in Beijing, China.<br />

Sales management<br />

In 1995, the office had two employees. Today, under<br />

<strong>Satair</strong> Asia’s management, <strong>Satair</strong> China consists of eight<br />

professionals. To service the airline aftermarket, there are two<br />

area sales managers and three customer service executives,<br />

and to service, primarily, the OEM market one sales engineer<br />

and one assistant, but they both assist with different activities<br />

in respect to the airline aftermarket.<br />

The office is located at the CASC/ Airbus Customer Support<br />

Centre in Beijing together with the warehouse, which is<br />

integrated with the Airbus warehouse.<br />

The market<br />

The aviation industry in China has been growing dramatically<br />

during the last ten years. Traffic growth rate is at 14% over<br />

the years. The fleet has been increased from less than 100<br />

aircraft to more than 800 aircraft. Since 2001, around 100<br />

new airplanes have entered the Chinese market each year,<br />

and according to CAAC and their market forecast, 1,500<br />

new aircraft will be required to service the increasing demand<br />

for travel inside China by 2010. The OEM industry has<br />

developed to a phase where both local and subcontracting<br />

program have been increasing dramatically.<br />

N O : 2 7 : J U N E : 0 5<br />

Market position<br />

During the past ten years, <strong>Satair</strong> China has been a part of<br />

this market development, and has be<strong>com</strong>e one of the bestpositioned<br />

distributors within the aerospace sector in China.<br />

<strong>Satair</strong> has a very good reputation in the Chinese market, and<br />

the <strong>Satair</strong> brand stands for honesty, openness, service and<br />

support.<br />

<strong>Satair</strong> makes business directly with all the operators, MROs<br />

and OEMs in China plus the different import/export<br />

organizations, which may be linked to some of the operators<br />

and we sell on open accounts.<br />

Furthermore, we are working on developing the <strong>no</strong>rmal<br />

supplier/customers relation to a more partnership-like<br />

relation. This has already been achieved at several of the<br />

most important customers by entering long-term agreements,<br />

exclusive buying agreement etc<br />

The Chinese market is the fastest growing aerospace market<br />

in the world, and will stay this way the next decade to <strong>com</strong>e.<br />

<strong>Satair</strong> has over the past 3-4 years experienced growth figures<br />

above10% annually and with double digit growth well above<br />

market growth for year <strong>2005</strong>.<br />

<strong>Satair</strong>’s OEM activities in China is steadily increasing and<br />

the OEM group is constantly securing <strong>Satair</strong> principals new<br />

applications on many of the existing programs and programs<br />

under developed, both on fix wing and helicopter programs.<br />

The customers<br />

<strong>Satair</strong> China’s customers have been increased to 40 in the<br />

aftermarket and to 15 in the OEM market over the years.<br />

At the same time <strong>Satair</strong> has established a good network<br />

within customer organizations from low level to top<br />

management, including strategic important functions such<br />

as engineering, purchasing, planning and repair/overhaul<br />

<strong>Satair</strong> appointed exclusive distributor for CBS-<br />

Carsten Daus GmbH<br />

By Steen Bruhn, IPP Manager, <strong>Satair</strong> A/S<br />

We are pleased to inform you that FSCM/CAGE CODE:<br />

DL161, CBS - Carsten Daus GmbH, has appointed <strong>Satair</strong><br />

as exclusive worldwide distributor and AOG Centre for its<br />

product portfolio.<br />

To serve the global customer base, <strong>Satair</strong> will stock the range<br />

of specially designed soap dispenser systems for Airbus<br />

(A300, A310, A320 family, A330, A340 & A380), Boeing<br />

(737, 747, 757, 767, 777), Bombardier, Embraer, Fairchild<br />

Dornier, Saab, Fokker, Iljuschin, Tupolew, etc. along with the<br />

liquid soap and break-down spare parts needed for these<br />

systems.<br />

The new distributorship is managed by <strong>Satair</strong>’s Integrated<br />

Purchasing Program, which is an integrated purchasing<br />

concept developed in cooperation with Airbus as a part of the<br />

Airbus Spares Consumables & Expendables Services (CES).<br />

The contract was signed during the Aircraft Interiors Expo,<br />

Hamburg in April <strong>2005</strong>.<br />

Please contact <strong>Satair</strong> for your requirement for specially<br />

developed liquid hand soap and soap dispenser systems<br />

manufactured by CBS - Carsten Daus GmbH.<br />

For further information on <strong>Satair</strong>’s portfolio of products<br />

from CBS, please contact your local <strong>Satair</strong> distribution<br />

representative.<br />

Warehouse, <strong>Satair</strong> China<br />

etc. This network has enabled <strong>Satair</strong> to work specifically<br />

and successfully on special projects like initial provisioning<br />

programs for new aircraft and the associated SFE/BFE product<br />

selection, retrofit programs and like. On OEM market, <strong>Satair</strong><br />

has been heavily involved in design and engineering of local<br />

programs.<br />

For several of <strong>Satair</strong>’s key customers the close business<br />

relationship has turned into long- term supply agreements. As<br />

a result <strong>Satair</strong> is ranked in the top 10-supplier list in terms of<br />

revenue at key customers.<br />

Perspectives<br />

<strong>Satair</strong>’s long-term strategy is to enhance its market presence<br />

in China, and develop an even stronger business relationship<br />

with its customers in the Chinese market.<br />

In the Chinese culture, the number ‘10’ means ‘perfect’<br />

– <strong>Satair</strong> do hope that the lucky number will bring the <strong>Satair</strong><br />

business to a<strong>no</strong>ther prospective 10 years and in the future.<br />

China Expo <strong>2005</strong><br />

<strong>Satair</strong> participates once again at the<br />

successful China Expo in Beijing, running<br />

from September 21-24 this year.<br />

We invite our business partners to join us<br />

during the show for a discussion on how<br />

<strong>Satair</strong>, continuously, can support and service<br />

the Chinese operators and OEMs.<br />

You will find us in Hall 8, Stand E2<br />

<strong>Satair</strong> takes over<br />

AOG Service<br />

By Steen Bruhn, IPP Manager, <strong>Satair</strong> A/S<br />

Becker Flugfunkwerk GmbH (FSCM D2356),<br />

manufacturer of avionic and inter<strong>com</strong> systems, and Fire<br />

Fighting Enterprises Ltd. (FSCM U3061), manufacturer<br />

of hand held fire extinguishers and automatic lavatory<br />

extinguishers (lavex units) have agreed with <strong>Satair</strong> A/S to<br />

the latter taking over their AOG services.<br />

Both <strong>com</strong>panies are managed by <strong>Satair</strong>’s Integrated<br />

Purchasing Program and we hope to have the full AOG<br />

service in place <strong>no</strong> later than the beginning of August<br />

<strong>2005</strong>.<br />

For more information about <strong>Satair</strong>’s AOG service please<br />

visit www.satair.<strong>com</strong>. For AOGs within <strong>no</strong>rmal business<br />

hours please contact your local <strong>Satair</strong> offices. For AOGs<br />

outside <strong>no</strong>rmal business hours please call one of the<br />

following numbers:<br />

Europe, Africa & the Middle East<br />

<strong>Satair</strong> A/S, Denmark: +45 4040 1224<br />

Asia & the Pacific<br />

<strong>Satair</strong> Asia, Singapore: +65 6543 0977<br />

North & South America<br />

<strong>Satair</strong> USA, Atlanta: +1 404 310 1966

Telex Communications - world leader in <strong>com</strong>mercial aviation<br />

By Jennie Bjornson, Marketing Manager, Telex Communications<br />

Telex Communications, a world leader in <strong>com</strong>mercial aviation<br />

headsets, uses <strong>Satair</strong> as a distributor for the <strong>com</strong>plete range<br />

of Telex <strong>com</strong>munication aircraft products. <strong>Satair</strong> is a critical<br />

partner due for Telex to their extensive experience in the<br />

aviation industry, according to John Weaver, director of<br />

sales for Telex Communications ‘<strong>Satair</strong> is uniquely positioned<br />

to help Telex grow our international presence in both<br />

<strong>com</strong>mercial and general aviation market segments’. Weaver<br />

continued, ‘Over the years, <strong>Satair</strong> has demonstrated<br />

unwavering <strong>com</strong>mitment to their customers and suppliers,<br />

and we have great confidence in their ability’.<br />

In the early eighties, Boeing qualified the Telex Airman 750<br />

for use in their <strong>com</strong>mercial jets, and since that time <strong>Satair</strong><br />

has played a critical role in the growth of the Airman 750<br />

headset. Today, jets all over the world <strong>com</strong>e standard with<br />

the Telex Airman 750 <strong>com</strong>mercial headset - making it the<br />

world’s best selling aviation headset.<br />

In late 2003, Telex introduced the Airman ANR 850<br />

<strong>com</strong>mercial aviation headset and it is quickly be<strong>com</strong>ing the<br />

headset of choice for <strong>com</strong>mercial pilots. With active <strong>no</strong>ise<br />

reduction (ANR) tech<strong>no</strong>logy the Telex Airman 850 provides<br />

superior hearing protection and ensures clear <strong>com</strong>munication<br />

with the tower and co-pilots. What sets the Airman ANR 850<br />

apart is the fact that it requires <strong>no</strong> batteries. Power for the<br />

active <strong>no</strong>ise reduction tech<strong>no</strong>logy is pulled from the<br />

microphone bias. Having <strong>no</strong> batteries to worry about, stow or<br />

carry is a relief to pilots who like the added hearing<br />

protection of ANR.<br />

Australian International Air Show<br />

– Avalon Victoria March <strong>2005</strong><br />

In addition to a growing line of products for professional<br />

pilots and airline <strong>com</strong>panies, <strong>Satair</strong> will <strong>no</strong>w be able to offer<br />

the <strong>com</strong>plete line Telex branded general aviation headsets for<br />

a wide variety of pilots from students to hobbyists, and from<br />

sport to business jet pilots. As an example, the<br />

Stratus 50-D is the premier full-cushion active <strong>no</strong>ise<br />

reduction headset from Telex. Now available through <strong>Satair</strong>,<br />

the Telex Stratus 50-D offers a greater degree of <strong>no</strong>ise<br />

cancellation than any other headset available. Superior <strong>no</strong>ise<br />

cancellation is an important step to protect hearing, ensure<br />

clear <strong>com</strong>munications and reduce fatigue. However, equally<br />

important to pilots is <strong>com</strong>fort, and the Stratus 50-D was<br />

designed to be customized for the ultimate in <strong>com</strong>fort. With a<br />

few quick and easy clicks, the patented ComfortCam<br />

tension adjustment allows each wearer to set the headset<br />

tension to their own preference and needs. The unique<br />

tension adjustment eliminates painful clamping so <strong>com</strong>monly<br />

found on full-cushion headsets. The ear cups also use heat<br />

sensitive, memory foam to create a custom seal providing<br />

superior <strong>com</strong>fort and ensuring the best <strong>no</strong>ise attenuation.<br />

If you are interested in more information on Telex<br />

<strong>com</strong>munication products, please contact Nils Karlsen,<br />

Product Manager, <strong>Satair</strong> A/S (e-mail nbk@satair.<strong>com</strong> or<br />

tel: +45 3247 0100)<br />

By Brian Hunter, Business Manager for Australia/Pacific & Jenny Li, Senior Sales Manager, <strong>Satair</strong> Asia<br />

The weather in Melbourne was cooled down very much in<br />

March. If there is one place you still can experience the heat<br />

of summer, that is the maintenance base in D’Avalon, where<br />

the <strong>2005</strong> Australian International Airshow is held. The roaring<br />

flight demonstration and exciting crowd have delayed the<br />

departure of summer.<br />

From humble beginnings in the early 1990’s, the Australian<br />

International Air Show has grown into one of the major<br />

events on the aviation calendar. This year’s show was <strong>no</strong><br />

exception with a large contingent of both trade exhibitors<br />

and aircraft on display both static and flying.<br />

‘The shape of things to <strong>com</strong>e’ was the theme for this years<br />

show reflecting the Australian market as a powerhouse of<br />

growth and in<strong>no</strong>vation in the international arena, in<br />

particular the defense sectors. On display this year both<br />

flying and static were some of Australia’s newest<br />

tech<strong>no</strong>logy platforms such as the ARH Tiger, MRH 90 and<br />

the odd looking Wedgetail which is a modified B737NG<br />

providing Australia with AWAC capability.<br />

The usual showstoppers also performed including the USAF<br />

F15 and F16 fighters. The Australians also put on a<br />

performance with the classic F/A18 Hornet and the always<br />

spectacular and crowd pleasing F111, fondly referred to as<br />

the ‘Pig’.<br />

The G/A family put on a good display with a range of smaller<br />

sport aircraft. The Gulfstream V burned up the runway and<br />

attracts a lot of attention from the audience. Bombardier<br />

proudly presented the Q400 in Qantas outfit. Many of the<br />

visitors anxiously queued up to go into the cabin in order to<br />

have a close look at of this beauty.<br />

Cementing the Australian Air Show as a significant event,<br />

the number of delegations attending this show reached an<br />

all time high of 34, <strong>com</strong>ing from countries such as the US,<br />

Europe, the Middle East and Asia. These missions identifying<br />

that Australian industry is capable of providing some unique<br />

tech<strong>no</strong>logies and services and are extremely <strong>com</strong>petitive on<br />

the international stage.<br />

<strong>Satair</strong> was represented at the show this year by Peter<br />

Lundberg, Managing Director, <strong>Satair</strong> Asia, Jenny Li, Senior<br />

Area Sales Manager, <strong>Satair</strong> Asia and Brian Hunter, Business<br />

Manager for Australia/Pacific. <strong>Satair</strong> firmly believes in the<br />

growing dynamics of Australian aviation industry. The local<br />

establishment shows our faith and <strong>com</strong>mitment in being part<br />

of this growth. Trust our various customers in the Pacific<br />

region will receive a more focused, responsive and customized<br />

service with the enhanced presence of <strong>Satair</strong>.<br />

Stratus 50-D<br />

Airman ANR 850<br />

The Aircraft Interiors Expo goes to Asia for the first time.<br />

The location is the high tech Hong Kong Convention and<br />

Exhibition Centre in the heart of downtown Hong Kong,<br />

China.<br />

<strong>Satair</strong> will be exhibiting in Hong Kong and looks forward to<br />

meeting with current and future business partners. Please<br />

make a <strong>no</strong>te in your calendar to visit <strong>Satair</strong>’s booth, stand<br />

B104 on 14–16 September <strong>2005</strong>.<br />

Did you<br />

k<strong>no</strong>w that…..<br />

…<strong>Satair</strong> has 11 product managers at its<br />

offices worldwide. They are responsible<br />

for product and marketing support for all<br />

<strong>Satair</strong>’s major product lines.<br />

For more information about <strong>Satair</strong> please<br />

visit www.satair.<strong>com</strong>.<br />

N O : 2 7 : J U N E : 0 5<br />

5

Airbus A380 flies – with a little help from SHG!<br />

By Rod Scott, CEO, <strong>Satair</strong> Hardware Group<br />

The A380 superjumbo successfully performed its maiden<br />

flight from Toulouse on 28 April. This huge doubledecker<br />

passenger aircraft is seen as a major engineering<br />

triumph between the European partners in France, the UK,<br />

Germany and Spain, as well as hundreds of globally-based<br />

subcontactors. It is expected to enter service with Singapore<br />

Airlines towards the end of next year.<br />

‘<strong>Satair</strong> Hardware is pleased to have played its small part in<br />

helping the Airbus A380 get off the ground’, says Rod Scott,<br />

CEO, ‘we wish Airbus every success with this magnificent<br />

aircraft’.<br />

The Value Stream Mapping (VSM) tool came into its own for<br />

the Goods Receipt/Inspection Department at <strong>Satair</strong> Hardware<br />

UK, reducing the backlog of goods waiting to be booked into<br />

the warehouse from up to six weeks to less than one.<br />

Angela Goldberg, Continuous Improvement Specialist<br />

was seconded to the department to perform the Value<br />

Stream Mapping exercise and then implement the newly<br />

designed process and provide training for the new Priority<br />

Administrator, Goods Receipt Processor and Inspectors.<br />

Angela mapped the process from goods receipt to placing<br />

the parts on the stores bench to them being put away. ‘The<br />

exercise involved actually ’working’ the process to uncover<br />

all of the tasks that the Goods Receipt Processor and the<br />

Inspectors were required to do’ Angela explains. Angela then<br />

identified the different tasks as ‘value added’ and ‘<strong>no</strong>n-value<br />

added’ which highlighted the areas for improvement.<br />

The proposed changes were supported at Director level,<br />

through the Goods Inward Improvement Team (Arnie<br />

Sivertsen - Warehouse Manager, Tim Williams - Quality<br />

Manager, Brian Mullen - Inspection Team Leader and Nigel<br />

Thomas - Managing Director) who reviewed, authorised<br />

changes and took actions in order for the new Goods Inward<br />

Process to be a success.<br />

The entire Goods Receipt/Inspection Department required<br />

repositioning to reduce the distance staff had to walk in order<br />

to process parts through the system. Analysis also showed that<br />

the Inspectors were spending less than 20% of their available<br />

N O : 2 7 : J U N E : 0 5<br />

SHG has supplied a wide range of products which include<br />

■ Textron Aerospace Fasteners and other hardware on<br />

airframe and engine nacelle structure, including<br />

<strong>com</strong>posite applications<br />

■ Avibank Hook and Pressure relief latches on engine<br />

cowlings<br />

■ Clickbond <strong>com</strong>posite fasteners onto IFS/Thrust reverser<br />

blanket attachment<br />

Efficiency improvements in <strong>Satair</strong> Hardware UK<br />

By Angela Goldberg, Continuous Improvement Specialist<br />

time inspecting parts, with the rest of their time spent<br />

unpacking parts and looking for priority parts for customers.<br />

The Goods receipt process has <strong>no</strong>w been re-engineered<br />

allowing the Goods Receipt Processor to unpack deliveries<br />

without involving the Inspection staff. ‘We <strong>no</strong>w have a<br />

Priority Administrator to locate priority deliveries and assist<br />

with unpacking when necessary’ Angela said. ‘Certificate<br />

scanning is <strong>no</strong>w undertaken by an existing resource, which<br />

frees the Inspectors to inspect product’.<br />

TOTAL TIME SAVED<br />

PER TRANSACTION (MINUTES)<br />

Before<br />

changes<br />

After<br />

changes<br />

Time<br />

saved<br />

<strong>2005</strong> © F. Espinasse<br />

■ LISI MONADNOCK spacers and stand off on airframe<br />

fuselage<br />

■ MONOGRAM fasteners on airframe and nacelle<br />

structures<br />

■ Mortorq and other hardware products on Goodrich<br />

power generators<br />

■ Hardware products from SHG’s manufacturing facility<br />

■ Hardware on fluid control systems for the Rolls Royce<br />

Trent 900<br />

Avibank Hook and Pressure relief latches on engine cowlings<br />

‘This means that the Inspectors are <strong>no</strong>w spending 80% of<br />

available time inspecting parts, and in just one month<br />

have seen these changes result in the backlog of goods<br />

waiting to be booked into the warehouse being reduced<br />

to just one week - a great demonstration of continuous<br />

improvement’ Angela concluded.<br />

CHANGE IN NUMBER OF<br />

PARTS PROCESSED DAILY<br />

Unpack Book-in Total

Mecachrome<br />

Daniel Poiret devotes 25 years service to <strong>Satair</strong><br />

By Paula McEnaney, Communications Co-ordinator ■ AURORA Bearings<br />

Daniel Poiret, Managing<br />

Director France, <strong>com</strong>pleted<br />

25 years service with <strong>Satair</strong><br />

on 25 <strong>June</strong> <strong>2005</strong>.<br />

He cast his mind back to<br />

1979 when he started as an<br />

internal Sales Engineer for<br />

CoMET, supporting customer<br />

services. A year later he<br />

joined TECNIMATIC as Sales<br />

Manager, which involved<br />

Daniel Poiret<br />

visiting customers. Daniel<br />

took the post of Director of<br />

Sales in 1992 and when TECNIMATIC merged in 1998 with<br />

<strong>Satair</strong> he became Managing Director for <strong>Satair</strong> Hardware<br />

based in Senelis, France. He is also Vice President for the<br />

<strong>Satair</strong> Group.<br />

TFS introduces new blind bolt<br />

By Rod Scott, CEO, <strong>Satair</strong> Hardware Group<br />

TEXTRON FASTENING SYSTEMS (TFS) have introduced a<br />

new blind bolt fastener called<br />

’MAXIBOLT PLUS’. This new product enhances the<br />

proven reliability and performance of MS 21140/21141<br />

MAXIBOLTTM by providing a more simple installation<br />

process.<br />

A tool equipped with the same pulling head can install three<br />

different diameters, a feature that reduces the tooling cost<br />

and facilitates robotic applications.<br />

MAXIBOLT PLUS provides greater spindle flushness once<br />

installed, with the blind side of the fastener enhanced to<br />

provide additional grip overlap and improved performance<br />

on sloped surfaces. The bulbing concept is suitable for both<br />

metallic and <strong>no</strong>n-metallic applications.<br />

Daniel, aged 48, has been married for <strong>27</strong> years and has a son<br />

of 25 years old and a daughter of 20.<br />

Daniel must have seen some major changes over the 25<br />

years with <strong>Satair</strong>? ‘I started to work for a <strong>com</strong>pany that<br />

covered only the French market and <strong>no</strong>w SHG deals with<br />

all major <strong>com</strong>panies in the aerospace industry worldwide.<br />

The French aerospace operation included four employees<br />

back in 1991 and in <strong>2005</strong> <strong>no</strong>w employs 30 staff. The fastest<br />

<strong>com</strong>munication tool was the telex, and <strong>com</strong>pared to current<br />

tech<strong>no</strong>logy, the gap is absolutely huge!’<br />

So what has kept Daniel motivated for the last 25 years? ‘I<br />

still have faith in what I ac<strong>com</strong>plish and I learn new things<br />

every single day’ he replied. <strong>Satelite</strong> asked Daniel what he<br />

would like to see for <strong>Satair</strong> in 25 years time if he could see<br />

into the future. ‘SHG be<strong>com</strong>ing the largest distributor of<br />

products and services to aerospace OEMs’ he said simply.<br />

SHG wins 5-year DLF contract with Mecachrome<br />

By Olivier Bourgine, Regional Sales Manager, <strong>Satair</strong> Hardware SAS<br />

SHG is delighted to have secured a major Direct Line Feed<br />

(DLF) contract with Mecachrome in France. Founded in 1937,<br />

the Mecachrome Group today employs around 1700 people<br />

across seven facilities in Europe and Canada. Historically<br />

specialising in the manufacture of parts and engines for the<br />

motor sports industry, the two French sites have increasingly<br />

taken on assembly work for aerospace customers. The<br />

Aubigny site carries out assembly work for Rolls Royce,<br />

Eurocopter and Hurel Hispa<strong>no</strong>, while the Amboise site is<br />

entirely dedicated to Airbus.<br />

MAXIBOLT PLUS is available in Cres Steel and Titanium<br />

materials and with different head styles. It is covered by EN<br />

6122/61<strong>27</strong>/6128/6129 standards.<br />

TFS and SHG have teamed up to ensure that there are a<br />

number of MAXIBOLT PLUS applications on the Airbus<br />

A380.<br />

TFS addition to European team<br />

Textron Fastening Systems have<br />

strengthened their European<br />

technical sales team with the<br />

addition of Claude Couillandeau<br />

who is based in France.<br />

Mecachrome was very keen to have a lean DLF solution<br />

for its standard hardware requirements, and after a careful<br />

benchmarking exercise, SHG was selected as the ideal single<br />

source partner. ‘This is a significant contract which, together<br />

with EADS Socata, strengthens SHG’s position as a leading<br />

European supplier for this type of service’, says Daniel Poiret,<br />

VP sales.<br />

SHG delegates at the annual sales conference, Chantilly, France<br />

‘In Brief’<br />

<strong>Satair</strong> Hardware Group is proud to an<strong>no</strong>unce that it became<br />

the exclusive distributor in Europe for AURORA Bearings on<br />

22 March <strong>2005</strong>.<br />

AURORA Bearings manufacture journal bushings, rod ends<br />

and spherical bearings for the aerospace industry and their<br />

product range includes parts covered by MS/BAC and ABS<br />

specifications.<br />

‘We <strong>no</strong>w have the right to distribute their products to<br />

both OEM and after-market segments’ said Daniel Poiret,<br />

Managing Director France. ‘This range of products will<br />

definitively <strong>com</strong>plete our package for direct line feed<br />

requirements’.<br />

SHG will develop technical sales supported by Branko De<br />

Blauw, the AURORA technical representative located in<br />

Belgium.<br />

■ SH UK finalists for Westland Transmissions awards<br />

<strong>Satair</strong> Hardware UK could feel very proud of their efforts<br />

for July to December 2004 when they were finalists for<br />

two prestigious awards at Westland Transmissions’ annual<br />

Supplier of the Year conference in February.<br />

The two categories - Emerging Supplier of the Year, and Most<br />

In<strong>no</strong>vative Supplier of the Year show that Westland really<br />

appreciated the difference made by SH UK and the value<br />

they have added to the management of the supply base since<br />

winning the contract in Q3 last year. It is the second DLF on<br />

the Yeovil site, the other is for Westland Helicopters.<br />

Congratulations to everyone involved in supporting this key<br />

contract, continued success next year should see SH UK<br />

winning awards.<br />

■ Korean Air<br />

Rod Scott receives DLF appreciation award from K. H. Kwon,<br />

Vice President of Korean Air <strong>com</strong>mercial aircraft plant.<br />

■ New agent in Spain<br />

No stranger to the aerospace industry is Felix Gonzalez,<br />

aged 58, who was appointed Representative Agent for<br />

Spain in September 2004. With his vast experience within<br />

the industry he is well qualified to fulfil his responsibilities in<br />

this region. In addition to representing Lentern Aircraft for<br />

ten years, Felix has been involved with a number of other<br />

organisations including Indra, Acutronic, Ampex and Summit.<br />

Most of Felix’s customers are based around Madrid, where<br />

he lives with his wife. <strong>Satair</strong> Hardware currently has two main<br />

contracts running in Spain, a DLF contract with Cesa, and<br />

also one with Airbus.<br />

N O : 2 7 : J U N E : 0 5<br />

7

Participate!<br />

Congratulations to the winners:<br />

1. Yu Wei, Taikoo Aircraft Eng. Co<br />

2. Paul Barden, Britannia Airways<br />

3. Evelyn Travet, Air Support<br />

4. Jens-Uwe Rothörl, Lufthansa Cargo AG<br />

5. WS Kim, Korean Air<br />

6. Kahl Christian, Austrian Airforce<br />

7. Jerry Dvorak, UPS Procurement Services<br />

8. Gary Curtis, Air New Zealand<br />

9. Richard Hansen, Icelandair<br />

10. Macé Hubert, Air Caledonie<br />

Q U I Z N O : 2 7 : J U N E : 0 5<br />

1. Which <strong>com</strong>pany has <strong>Satair</strong> signed a distributor<br />

agreement with for liquid hand soap and soap<br />

dispenser systems?<br />

2. Which anniversary can <strong>Satair</strong> China celebrate in <strong>2005</strong>?<br />

3. Who has SHG secured a major Direct Line Feed (DLF)<br />

contract with?<br />

4. Who became SHG exclusive distributor in Europe<br />

for on 22nd March <strong>2005</strong>?<br />

<strong>Satair</strong> & <strong>Satair</strong> Hardware employees and their relatives can<strong>no</strong>t enter the<br />

<strong>com</strong>petition.<br />

Company:<br />

Name:<br />

Title:<br />

Address:<br />

Postal code/City:<br />

Country:<br />

Fax or e-mail your answers to <strong>Satair</strong><br />

before November 1, <strong>2005</strong><br />

<strong>Satair</strong> A/S, Amager Landevej 147A<br />

DK-<strong>27</strong>70 Kastrup, Denmark<br />

Telefax: (45) 3251 3434<br />

Email: satelite@satair.<strong>com</strong><br />

Attn.: Camilla Schuricht<br />

N O : 2 7 : J U N E : 0 5<br />

1 prize<br />

1 leatherman tool +<br />

Stelton USB memorystick. 256 MB<br />

2-10 prize<br />

Stelton USB memorystick. 256 MB<br />

B/E Aerospace Endura ® Beverage Maker<br />

By Will Aronson, Product Line Manager, B/E Aerospace,<br />

Lenexa Business Unit<br />

In<strong>no</strong>vation is brewing<br />

The new B/E Aerospace Endura ® Beverage Maker <strong>com</strong>bines<br />

the latest in in<strong>no</strong>vative tech<strong>no</strong>logies with a sleek, ergo<strong>no</strong>mic<br />

design to offer a beverage maker with unparalleled benefits<br />

to the airlines. Created specifically to address the issues<br />

of coffee brew quality, reliability, maintainability and<br />

<strong>com</strong>patibility, the Endura ® is the result of thousands of hours<br />

of advanced design, development, and reliability testing<br />

efforts.<br />

An expert team of designers: Our airline partners<br />

Prior to its final design, several airlines were invited to<br />

participate in facilitated, open forum sessions to help guide<br />

the development efforts for the Endura ® . Their valuable input<br />

contributed to the guiding principals that ultimately were<br />

used to direct the development activities.<br />

Utilizing these inputs in concert with over 40 years experience<br />

with aircraft galley equipment resulted in a coffee maker<br />

with many features <strong>no</strong>t seen previously. Dual LED lights,<br />

10%+ weight reduction, form-fit ergo<strong>no</strong>mic user interfaces,<br />

and numerous in<strong>no</strong>vations designed specifically to ease<br />

maintenance are but a sampling of the multitude of features<br />

that have been designed in to the Endura ® .<br />

Good to the Last Row<br />

Early in the project, B/E teamed with Thermos ® , the worlds<br />

leading expert in developing insulated containers. Combining<br />

the expertise of both organizations led to the development of<br />

the first vacuum insulated coffee server designed and certified<br />

for use on <strong>com</strong>mercial aircraft. Attractive and functional,<br />

the server features true brew-in capability, and is backwards<br />

<strong>com</strong>patible for use on new and existing B/E coffee makers.<br />

The vacuum insulation allows the coffee to stay hot without<br />

the need to heat or ‘cook’ the coffee after brewing. It also<br />

keeps the coffee at preferred serving temperatures for<br />

extended periods. These two factors <strong>com</strong>bine to improve the<br />

coffee flavor and reduce the amount of coffee that airlines<br />

must discard. Throughout the brewing and serving cycles,<br />

the brushed stainless steel exterior always remains cool to the<br />

touch. This provides a greater degree of <strong>com</strong>fort and safety<br />

for the flight attendants.<br />

Forwards and backwards<br />

While the Endura ® is intended to support the needs of the<br />

airlines into the future, it has been designed to work in<br />

existing aircraft as well. Designed to fit on the same rail<br />

as existing B/E coffee makers, the Endura ® is also lower<br />

in weight, and requires less power than similar B/E legacy<br />

designs and most <strong>com</strong>petitor’s products. It even works with<br />

existing coffee servers should an airline choose to continue<br />

using them.<br />

Options and accolades<br />

By utilizing a modular, platform design, the Endura ® is able to<br />

provide a wide array of optional configurations. This allows<br />

the units to be configured correctly for installation on existing<br />

aircraft and to offer features that meet the unique needs of<br />

each airline customer.<br />

All of these efforts have <strong>no</strong>t gone un<strong>no</strong>ticed. Since its<br />

introduction last year, the Endura ® has been recognized for<br />

excellence in product design. In 2004, both the Red Dot<br />

Design Award for Product Design and the IDEA Industrial<br />

Design Excellence Award have been bestowed upon the<br />

Endura ® .<br />

We expect these to be the first of many accolades yet to<br />

<strong>com</strong>e.<br />

Can we build one for you?<br />

International Flight Catering Association (IFCA) <strong>2005</strong><br />

By Karina Bergstroem Larsen, Product Manager, <strong>Satair</strong> A/S<br />

IFCA March <strong>2005</strong> was held in Bella Centre, Copenhagen on<br />

9 – 11 March, <strong>2005</strong>. Many airline representatives came to<br />

view the latest tech<strong>no</strong>logy of galley products, and taste a<br />

wide verity of food and beverages available for the industry.<br />

B/E Aerospace demonstrated their latest tech<strong>no</strong>logy of ovens,<br />

refrigerators, chillers and their latest beverage maker Endura ®<br />

and served the visitors with hot coffee, tea, cappucci<strong>no</strong>, ice<br />

crème and champagne.<br />

Last year, the Endura beverage maker won the precious<br />

European Red Dot design award. The Endura ® will also be<br />

demonstrated at <strong>Satair</strong>’s booth at the Paris Airshow on<br />

13 – 20 <strong>June</strong>, <strong>2005</strong> in Hall 4, booth G/7, where B/E<br />

Aerospace and <strong>Satair</strong> representatives will be available to<br />

demonstrate the beverage maker machine, which has<br />

be<strong>com</strong>e a preferred choice for a number of airlines around<br />

the world.<br />

B/E Aerospace booth at IFCA <strong>2005</strong>