Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Unique Unique Features Features<br />

Features<br />

Orbital Orbital Welding Welding Equipment<br />

Equipment<br />

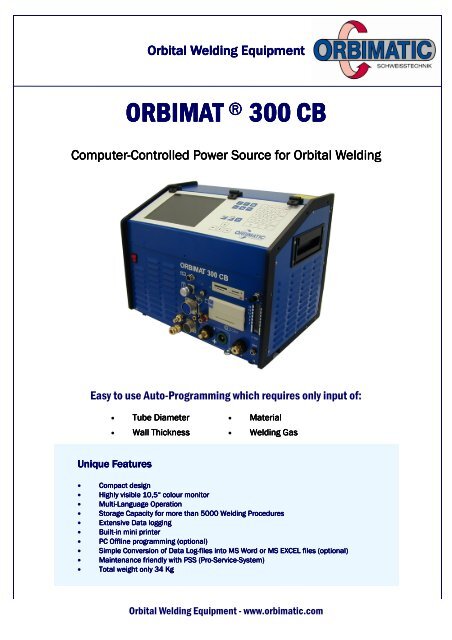

<strong>ORBIMAT</strong> <strong>ORBIMAT</strong> ® 300 300 CB<br />

CB<br />

Computer Computer-Controlled Computer Controlled Power Power Source Source for for for Orbital Orbital Welding<br />

Welding<br />

Easy to use Auto-Programming which requires only input of:<br />

• Tube Tube Diameter Diameter<br />

• Material<br />

Material<br />

• Wall Wall Thickness Thickness<br />

• Welding Welding Gas<br />

Gas<br />

• Compact Compact design<br />

design<br />

• Highly Highly visible visible 10,5“ 10,5“ colour colour colour monitor<br />

monitor<br />

• Multi Multi-Language Multi Language Operation<br />

• Storage Storage Capacity Capacity for for more more than than 5000 5000 Welding Welding Procedures<br />

Procedures<br />

• Extensive Extensive Data Data Data logging<br />

logging<br />

• Built Built-in Built in mini printer<br />

• PC PC PC Offline Offline programming programming (optional)<br />

(optional)<br />

• Simple Simple Conversion Conversion of of Data Data Log Log-files Log files files into MS Word or MS EXCEL files (optional) (optional)<br />

• Maintenance Maintenance friendly friendly with with PSS PSS (Pro (Pro-Service<br />

(Pro Service Service-System)<br />

Service System)<br />

• Total Total weight weight only only 34 34 Kg<br />

Kg<br />

Orbital Welding Equipment - www.orbimatic.com

Features eatures <strong>ORBIMAT</strong> <strong>ORBIMAT</strong> 300 300 CB<br />

CB<br />

The new <strong>ORBIMAT</strong> 300 CBasic implements a completely newly developed computer system, which sets with its various field of<br />

applications new dimensions in Orbital Welding Technology. Use of the latest power-electronic components allows a more<br />

compact design which gives massive reductions in weight. Weighting only 26 kg (incl.<br />

water cooling!) and with dimensions of 530 x 370 x 220 mm, the <strong>ORBIMAT</strong> 300 CBasic is<br />

unequalled world-wide in relation to size and output. Obviously the <strong>ORBIMAT</strong> 300 CBasic<br />

includes the well proven <strong>ORBIMAT</strong>IC AUTOPROGRAMMING with easy weld procedure<br />

generation, which requires input of Diameter, Wall thickness, Material and Gas, as well<br />

as the current slope function between a maximum 99 different Welding Levels.<br />

The standard version of the <strong>ORBIMAT</strong> 300 CBasic includes the control system for coldwire-feeding<br />

and is therefore able to run the complete range of <strong>ORBIMAT</strong>IC Weld heads.<br />

Data ata ata-Logging<br />

ata Logging<br />

You have a wide range of Data-Logging available with multiple choice of documentation<br />

and archiving. With the use of the full function keyboard (supplied with the machine) New New New 10,5“ 10,5“ colour colour display<br />

display<br />

additional information can be added to the data log file such as electrode type, welder’s<br />

name, detailed application description and so on. Since printing after every weld may not<br />

be practical under some conditions, the data log files can be saved temporarily on a COMPACT-FLASH-Card. <strong>ORBIMAT</strong>IC offers<br />

even an OFFLINE Soft/Hardware package, to allow transfer of Data Log files to any PC for achieving and administration.<br />

PSS<br />

PSS<br />

PSS Pro Pro Service Service Service System System<br />

System<br />

The new PSS (Pro-Service-System) brings a new dimension to Orbital Welding. PSS allows the operator to easily detect any<br />

failures on the system, which provides rapid maintenance on site. With a very systematic<br />

order of each component, all parts are easy to locate and exchange. Key<br />

components are connected by simple plugs. An LED panel is located on the rear<br />

side of the machine and this allows the operator to identify an future problems without<br />

having any technical knowledge, or the need for any other instruments.<br />

ORBITWIN RBITWIN 300<br />

300<br />

Furthermore specific control functions of the system can be temporarily switched off<br />

in order to complete, with extreme care, an immediate application on site. The machine<br />

can then be taken to a workshop to be serviced and repair the fault .<br />

For maximum production the ORBITWIN 300 can be used to allow simultaneous connect of 2 weld heads. The ORBITWIN<br />

300 will allow the connection of two different head models. Each weld head can be assigned a separate welding procedure<br />

and the ORBITWIN 300 will automatically transfer all services to the weld head in use and recall the associated procedure.<br />

While one head is in use the other is isolated, allowing the operator to set one head while the other is welding.<br />

Technical Technical Data:<br />

Data:<br />

Input Input Power Power<br />

3x400 3x400 VAC VAC + +- + 15% 15%<br />

Welding Welding Welding current current current<br />

3-300A 300A 300A<br />

Output Output Output Range Range<br />

100% 100% at at 200A<br />

200A<br />

60% 60% at at 300A<br />

300A<br />

Weight Weight without without ORBICOOL ORBICOOL<br />

34 34 Kg<br />

Kg<br />

with with ORBICOOL ORBICOOL<br />

48 48 Kg Kg<br />

Kg<br />

Dimensions Dimensions without without ORBICOOL ORBICOOL<br />

530x420x320 530x420x320 mm<br />

mm<br />

with with ORBICOOL ORBICOOL<br />

530x580x320 mm<br />

<strong>ORBIMAT</strong>IC <strong>ORBIMAT</strong>IC GmbH,<br />

GmbH,<br />

Floesser Floesser Weg Weg 17,<br />

17,<br />

D-35418 35418 Buseck, Germany<br />

Phone: Phone: ++49 ++49 6408 6408 9026 9026 0,<br />

0,<br />

Fax: Fax: ++49 ++49 6408 6408 9026 9026 50<br />

50<br />

Email: Email: orbimatic@t<br />

orbimatic@t-online.de<br />

orbimatic@t online.de<br />

www.orbimtatic.com<br />

www.orbimtatic.com