New logistics concept for Husqvarna CEE network ... - Geis Group

New logistics concept for Husqvarna CEE network ... - Geis Group

New logistics concept for Husqvarna CEE network ... - Geis Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

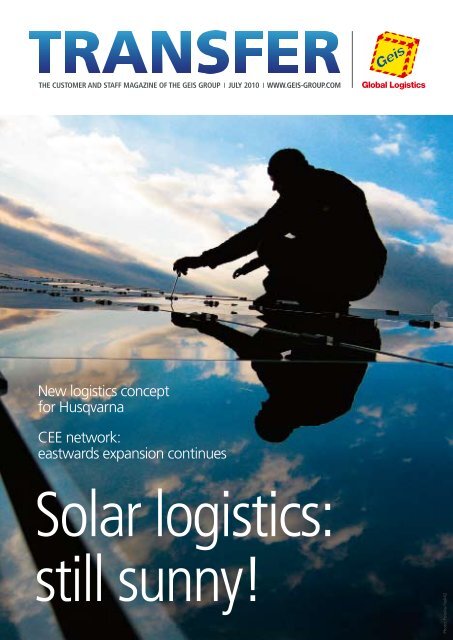

The cusTomer and sTaff magazine of The geis group July 2010 www.geis-group.com<br />

<strong>New</strong> <strong>logistics</strong> <strong>concept</strong><br />

<strong>for</strong> <strong>Husqvarna</strong><br />

<strong>CEE</strong> <strong>network</strong>:<br />

eastwards expansion continues<br />

Solar <strong>logistics</strong>:<br />

still sunny!<br />

Photo: Fotolia / heli42

2 | editorial<br />

Dear readers,<br />

„The <strong>Geis</strong> <strong>Group</strong> handled the economic crisis in<br />

2009 very well“ – this is how our business per<strong>for</strong>mance<br />

in 2009 could essentially be summarized.<br />

Although the net turnover of the <strong>Geis</strong> <strong>Group</strong> declined<br />

by 13.2 percent to 528.9 million euros, our<br />

high quality, strong service orientation and strict<br />

We used both the past year and the first months of<br />

this year to develop our company and strategically<br />

prepare ourselves <strong>for</strong> the emergent economic recovery.<br />

Our aim in 2010 is to achieve a significant increase<br />

in turnover and profit.<br />

There<strong>for</strong>e we are focusing on promising new<br />

sectors such as the solar industry. Hardly any sector<br />

has grown as strongly over the past years as the<br />

photovoltaics sector, with turnover expected to increase<br />

by more than 20 percent this year in Germany<br />

alone. Due to the sensitive nature of solar<br />

modules and the urgency by which they are usually<br />

required, the sector needs experienced and reliable<br />

service providers that are able to deliver them quickly<br />

and securely to customers. We, together with our<br />

Logistics World Alliance contract <strong>logistics</strong> partners,<br />

have already been doing precisely this <strong>for</strong> one<br />

of the leading suppliers <strong>for</strong> the past two years. You<br />

can read more about our handling of the solar supply<br />

chain <strong>for</strong> SunPower and the solar sector from page 4<br />

onwards.<br />

In this edition we will also be shedding light on another<br />

of the <strong>Geis</strong> <strong>Group</strong>‘s focus areas: The ongoing<br />

expansion of our <strong>network</strong> and strategy in Central and<br />

Eastern Europe. We manage the <strong>logistics</strong> of some of<br />

the world‘s leading companies in the region, including<br />

the Schaeffler <strong>Group</strong> and the <strong>Husqvarna</strong> <strong>Group</strong><br />

– learn more on pages 8, 10 and 12.<br />

Focus on new and promising sectors<br />

cost controls, including short-time, meant that all<br />

our business areas remained in the black. In view of<br />

the unprecedented scale of the economic and financial<br />

crisis, this is a highly satisfactory result.<br />

The crisis has shown that having three business areas<br />

serves our company well. Our „Logistics Services“ division<br />

succeeded in going against the trend and in increasing<br />

turnover by two percent. This area includes<br />

contract <strong>logistics</strong> activities such as storage and picking,<br />

as well as complete outsourcing solutions, also<br />

<strong>for</strong> assembly and special packaging. „Road Services“,<br />

our Germany- and Europe-wide road services division,<br />

recorded a downturn in turnover of 12.7 percent,<br />

while „Air + Sea Services“ fell by 26 percent.<br />

At the end of 2009, around 3,300 people were employed<br />

at our 87 sites across Europe. Last year, they<br />

processed around 9.3 million transport and <strong>logistics</strong><br />

orders <strong>for</strong> our customers, i.e. around 20,000 more<br />

shipments than in 2008. The total number of parcel<br />

shipments was 5.43 million, almost a million more<br />

than in 2008.<br />

On 14 June we began constructing the first section of<br />

our new <strong>logistics</strong> and technology centre. By November,<br />

the 30,000 m 2 multi-user centre will be ready <strong>for</strong><br />

use. Later on we plan to build another two <strong>logistics</strong><br />

facilities on the site. Learn more on page 15 of this<br />

edition of Transfer.<br />

Our magazine has been given a new, more modern<br />

layout, and remains the best place to find out the latest<br />

news about the <strong>Geis</strong> <strong>Group</strong>. We hope you enjoy<br />

reading it!<br />

Yours sincerely,<br />

Hans-Georg <strong>Geis</strong> and Wolfgang <strong>Geis</strong>,<br />

Managing Partners of the <strong>Geis</strong> <strong>Group</strong>

04<br />

08<br />

12<br />

16<br />

top StorY<br />

04 Still sunny<br />

06 Solar <strong>logistics</strong> with <strong>Geis</strong><br />

road ServiceS<br />

08 <strong>CEE</strong> <strong>network</strong>: eastwards expansion continues<br />

10 Working <strong>for</strong> Schaeffler on the west-east axis<br />

10 Quality ranking: TSG‘s success confirmed<br />

11 AEO status speeds up supply chain<br />

11 <strong>Geis</strong> uses hybrid truck<br />

11 Secure air freight in the IDS system<br />

logiSticS ServiceS<br />

12 <strong>Husqvarna</strong>: <strong>logistics</strong> reorganized<br />

coNteNtS |<br />

3<br />

14 „Automotive industry-level per<strong>for</strong>mance achieved“<br />

14 A logistical sales aid<br />

15 <strong>Geis</strong> builds a multi-user <strong>logistics</strong> and technology centre<br />

15 „Green“ packaging <strong>concept</strong><br />

air + Sea ServiceS<br />

16 Thousands of tonnes right across Pakistan<br />

17 Hamburg: Air and sea freight under one roof<br />

17 Aerospace Logistics bundles together skills<br />

17 A surprise in Africa<br />

geNeral NeWS<br />

18 „Making clear the difference...“<br />

18 <strong>New</strong> Sales and Marketing Manager at <strong>Geis</strong> SDV<br />

19 Artistic-bike world champion works <strong>for</strong> <strong>Geis</strong><br />

19 The Nuremberg Company Run: <strong>Geis</strong> took part<br />

19 Anniversaries<br />

Published by<br />

Hans <strong>Geis</strong> GmbH + Co Internationale Spedition<br />

Rudolf-Diesel-Ring 24, 97616 Bad Neustadt/Saale<br />

Tel.: +49 9771 603-0, Fax: +49 9771 603-109<br />

www.geis-group.com<br />

Responsible <strong>for</strong> the contents<br />

Geschäftsführung der <strong>Geis</strong>-Gruppe<br />

Editorial<br />

STROOMER PR | Concept GmbH<br />

Christian Stephan, Sonja Objartel.<br />

Kristine Wegner, Christoph Goldammer (Design)<br />

Rellinger Straße 64a, 20257 Hamburg<br />

Phone: +49 40 853133 0, Fax +49 40 853133 22<br />

E-Mail: mail@stroomer-pr.de

4<br />

Still Sunny<br />

The sun is set to shine <strong>for</strong> another four billion years, so the outlook is bright <strong>for</strong> the<br />

solar energy industry and its service providers.<br />

Photo: BSW-Solar / Langrock

Despite the economic crisis, increasing<br />

non-European competition and the lowering<br />

of state subsidies <strong>for</strong> solar energy,<br />

the solar module market will continue to<br />

grow. The German photovoltaics industry alone expects<br />

turnover to increase by more than 20 percent<br />

this year. In addition, it expects increased levels of<br />

investment and another increase in the number of<br />

people employed in the industry (see in<strong>for</strong>mation<br />

graphic).<br />

All the signs are pointing to growth in our sunblessed<br />

neighbouring European countries too. Italy<br />

is considered the market with the greatest potential,<br />

with alternative energy <strong>for</strong>ms being supported by<br />

legislation and state subsidies. France is currently<br />

way behind Germany in the use of solar energy. But<br />

there too state subsidies are being used to promote<br />

the industry.<br />

sunny energy. There are a number of reasons <strong>for</strong><br />

the positive <strong>for</strong>ecasts. First of all, there is a growing<br />

widespread consensus that solar energy is vital to the<br />

future of the world as an alternative to fossil fuels<br />

and nuclear energy. In just a few decades time, the<br />

earth‘s oil and uranium reserves will have been exhausted.<br />

The sun however will remain with us as an<br />

energy source until time indefinite, and won‘t cause<br />

any oil catastrophes or generate nuclear waste.<br />

Not least because of this, solar energy has an unbeatable<br />

image as clean and regenerative energy.<br />

This coupled with financial incentives by the state<br />

also means an increased willingness among private<br />

individuals to use the technology. Last year in Germany<br />

alone, home owners spent more than six billion<br />

euros on solar modules. This is more than the<br />

large German energy producers invested together in<br />

the construction and expansion of new and existing<br />

power plants. Although lower state subsidies will<br />

temporarily slow down the rate of expansion, there<br />

is no possibility of it coming to a halt.<br />

Solar energy is also becoming increasingly interesting<br />

<strong>for</strong> those with limited financial resources and no<br />

property of their own. The solar sector reckons that<br />

in just a few years‘ time end-users will be able to obtain<br />

solar energy <strong>for</strong> the price of conventional electricity.<br />

This will become possible through technical<br />

progress and the accelerated expansion of the photovoltaics<br />

market. Solar energy will then no longer lag<br />

behind other <strong>for</strong>ms of energy in terms of cost.<br />

pictUre leFt: the thermal solar energy system<br />

on the roof of the Federal government‘s press<br />

and in<strong>for</strong>mation office in Berlin helps power<br />

the building‘s air-conditioning system<br />

sunny logisTics. These developments in the solar<br />

energy sector open up a large number of opportunities<br />

<strong>for</strong> the <strong>logistics</strong> industry. Solar <strong>logistics</strong> is still<br />

a very new area, and those who react quickly and<br />

flexibly to the needs of this dynamic sector will profit<br />

from its continuous growth in the future. Since<br />

2008, the <strong>Geis</strong> <strong>Group</strong> has been handling solar supply<br />

chains and has developed solutions that are tailored<br />

to the needs of the industry.<br />

Alongside procurement <strong>logistics</strong> and appropriate<br />

storage solutions, <strong>Geis</strong> also guarantees on-time delivery<br />

of the sensitive solar products to end customers.<br />

„The particular challenge when it comes to solar<br />

<strong>logistics</strong> is to be able to cope with the extreme fluctuations<br />

in shipping quantities“, says <strong>Geis</strong> Managing<br />

Director Dr. Johannes Söllner. „We guarantee this<br />

flexibility through specially-developed logistical<br />

processes that we adhere to strictly with the help of<br />

various IT solutions.“ —<br />

Solar energy companies create jobs in Germany<br />

Number of jobs<br />

Solar heating and solar electricity<br />

top StorY |<br />

5<br />

the <strong>logistics</strong><br />

industry is also<br />

benefitting from<br />

the continuous<br />

growth of the<br />

solar industry.

6 | top StorY<br />

Solar logiSticS<br />

with geiS<br />

International solar technology group SunPower relies on <strong>Geis</strong>‘ concentrated logistical energy<br />

<strong>for</strong> its solar <strong>logistics</strong> within Germany.<br />

SunPower is considered the world-leader in the<br />

development of high-efficiency solar modules,<br />

and distributes its products all around the<br />

world (see info box). Such a high-flying company<br />

naturally requires a reliable and flexible <strong>logistics</strong><br />

partner in Europe. Consequently, the NASDAQlisted<br />

company opted <strong>for</strong> the European contract <strong>logistics</strong><br />

cooperation Logistics World Alliance (LWA)<br />

in August 2008. It includes seven powerful European<br />

<strong>logistics</strong> service providers and combines under<br />

one roof comprehensive sector expertise, knowledge<br />

of regional markets, and flexible warehousing<br />

and transport solutions (see info box, page 7). „We<br />

were looking <strong>for</strong> a European <strong>logistics</strong> partner with<br />

precisely this type of profile“, says Nicholas Hyner,<br />

SunPower RLC EU Operations Manager.<br />

The LWA partner <strong>for</strong> Germany, the Czech Republic<br />

and Slovakia is <strong>Geis</strong>. Thanks to the close integration<br />

of its Road Services and Logistics Services divisions,<br />

the <strong>Geis</strong> <strong>Group</strong> is able to provide top-notch <strong>logistics</strong><br />

services <strong>for</strong> the high-tech products of SunPower<br />

within Germany.<br />

sophisTicaTed TransporT logisTics. From Rotterdam,<br />

LWA partners convey the goods to their<br />

European distribution centres, located in Milan,<br />

Lyon, Nuremberg, and elsewhere. Transporting<br />

solar components is no easy task because the solar<br />

modules are very fragile and highly sensitive. The<br />

goods conveyed also include articles <strong>for</strong> final assembly<br />

such as cables and spare parts. „Transporting the<br />

sensitive and in some cases bulky freight safely calls<br />

<strong>for</strong> knowledge, circumspection, sensitive handling<br />

and special equipment“, says Hans-Peter Schneider,<br />

Managing Director of the Logistics World Alliance.<br />

SunPower<br />

Photo: Istock / LL28<br />

The US group, according to<br />

its own statement, has been<br />

designing, manufacturing and<br />

delivering the planet’s most<br />

powerful solar technology<br />

broadly available today <strong>for</strong><br />

the past 25 years. SunPower<br />

is considered the worldleader<br />

in the development of<br />

high-efficiency solar solutions,<br />

with SunPower solar modules<br />

supplying up to 50 percent<br />

more energy than conventional<br />

modules. Today SunPower<br />

calls four continents home,<br />

serving utilities, commercial,<br />

and residential customers<br />

across the globe.

flexible sTorage and disTribuTion. Storage of the<br />

goods also calls <strong>for</strong> sensitivity and a high degree of<br />

flexibility. All new warehouse locations are initially<br />

operated using the cross-docking system. Later on,<br />

when the market has stabilized, flexible warehouses<br />

are set up. One example of a flexible warehouse is<br />

<strong>Geis</strong>‘ warehouse in Nuremberg, where SunPower‘<br />

solar modules and accessories and, as of late, marketing<br />

material too are stored. The entire warehouse is<br />

completely turned over twice a month. At the end of<br />

each cycle, demanding handling peaks are encountered,<br />

with <strong>Geis</strong> employees having to deal with a<br />

high volume of goods, both inbound and outbound.<br />

During these times, everything needs to run like<br />

clockwork. Each product has a serial number, which<br />

is recorded during entry scanning, and picking is<br />

voucherless using local IT systems.<br />

As soon as the solar components leave the warehouse,<br />

the Nuremberg warehouse‘s outgoing-goods<br />

processing system in<strong>for</strong>ms SunPower of the serial<br />

numbers that are on their way to each customer. Sun-<br />

Power‘s customer service department then passes on<br />

this in<strong>for</strong>mation to its customers‘ upstream dealers,<br />

so that they can start with the preparations. „Providing<br />

this advance notice is especially important, as<br />

the modules have to be installed in series <strong>for</strong> optimal<br />

electricity generation“, says Werner Dettenthaler,<br />

<strong>Geis</strong> Site Manager in Nuremberg.<br />

Once out of the warehouse, <strong>Geis</strong> also takes care of<br />

delivery within Germany - including right up to the<br />

doorstep if necessary. „Some of SunPower‘s customers<br />

live in very remote places. Despite this, <strong>Geis</strong> always<br />

delivers on time. <strong>Geis</strong> drivers also always call<br />

customers in advance as part of our standard service“,<br />

explains <strong>Geis</strong> Managing Director Dr. Johannes Söllner.<br />

„As soon as the solar products have been handed<br />

over, a message is sent to SunPower on the same day<br />

confirming delivery.“<br />

clever added-value services. Without reliable<br />

IT systems, international procurement, intermediate<br />

storage at partner sites and Europe-wide distribution<br />

would be next-to-impossible tasks. For this reason, the<br />

IT systems used by the LWA partners are linked to<br />

each other and to SunPower‘s system. „For SunPower<br />

and its customers this means maximum transparency<br />

and exact preparation because we display all status in<strong>for</strong>mation<br />

in real time“, explains Dr. Johannes Söllner.<br />

„The system can also be flexibly expanded.“<br />

<strong>Geis</strong>‘ added-value services to SunPower don‘t end<br />

there, however. Alongside clever IT solutions, our<br />

service portfolio also includes preassembly of solar<br />

modules out of more than 80 individual components,<br />

and if a solar module needs to be replaced following<br />

a complaint, <strong>Geis</strong> implements its so-called „Swap<br />

Service“, with the faulty components exchanged <strong>for</strong><br />

new components, and the original components returned<br />

to the supplier.<br />

<strong>Geis</strong> also stands out on account of its expertise in the<br />

area of packing services. The group has developed a<br />

new kind of packaging that enables individual solar<br />

panels too to be sent securely. „We consider it important<br />

that we not only fulfil SunPower‘s requests<br />

and requirements, but also that we continually expand<br />

the range of services offered to them. We are<br />

there<strong>for</strong>e also planning to significantly increase the<br />

size of our Nuremberg warehouse in the near future,<br />

specifically <strong>for</strong> SunPower“, says Dr. Johannes<br />

Söllner. „Together with our LWA partners, we want<br />

to provide SunPower with the best-possible service,<br />

and thereby provide a place in the sun <strong>for</strong> as many<br />

solar modules as possible.“ —<br />

www.sunpower.com<br />

Photo: BSW-Solar<br />

top StorY | 7<br />

Logistics<br />

World Alliance<br />

the <strong>logistics</strong> World alliance<br />

(lWa), which is based in<br />

luxembourg, was founded<br />

in March 2006 and offers<br />

customers europe-wide<br />

contract <strong>logistics</strong> services.<br />

its cooperation partners<br />

include aditro <strong>logistics</strong>,<br />

Bibby distribution, the<br />

geis group, log Service<br />

europe, MgF logistique,<br />

p&o Ferrymasters and redur.<br />

the cooperation partners<br />

operate more than 300 sites<br />

across europe and have<br />

access to almost two million<br />

square metres of storage<br />

space. together they<br />

employ around 18,000<br />

people and generate an<br />

annual turnover of more<br />

than 2.1 billion euros.<br />

the latest technology:<br />

solar-cell manufacture is<br />

highly-specialized

oad ServiceS |<br />

9<br />

Eastwards expansion continues<br />

The <strong>Geis</strong> <strong>Group</strong> is continuing to gradually expand its East-West traffic, with customers being<br />

the main beneficiaries. Below is an interview with <strong>Geis</strong> Managing Director Klaus Stäblein about the<br />

<strong>network</strong> in Central and Eastern Europe (<strong>CEE</strong>) and the strategy of the <strong>Geis</strong> <strong>Group</strong>.<br />

Klaus Stäblein,<br />

Managing director<br />

Hans geis gmbH + co<br />

mr stäblein, the geis group claims<br />

to provide also full-coverage transport <strong>logistics</strong><br />

in cee countries. how do you manage to<br />

do this?<br />

Klaus Stäblein: It‘s all in the mix. First of all, the<br />

<strong>Geis</strong> <strong>Group</strong> has its own full-coverage <strong>network</strong>s in<br />

the Czech Republic and Slovakia. With 13 sites<br />

in the Czech Republic, <strong>Geis</strong> CZ covers the entire<br />

country, while Slovakia is covered by the 7 sites of<br />

our local subsidiary TEN Expres. Secondly, we use<br />

strong local partners. Thanks to this setup, we can<br />

choose the best partner <strong>for</strong> each country - to the benefit<br />

of <strong>Geis</strong> customers.<br />

Which benefits and services are offered<br />

to <strong>Geis</strong> customers with respect to traffic to<br />

central and eastern europe<br />

Klaus Stäblein: We offer daily services to all the<br />

countries of Central and Eastern Europe, with defined<br />

delivery times directly from our German sites<br />

and via our <strong>CEE</strong> gateway in Nuremberg. This applies<br />

in relation to both cargo and groupage freight,<br />

as well <strong>for</strong> direct journeys, express journeys and parcel<br />

shipments. In total, there are 75 regular services<br />

each week from Nuremberg to the <strong>CEE</strong> countries.<br />

The important thing <strong>for</strong> many customers is to be<br />

kept constantly in<strong>for</strong>med about the current status of<br />

their shipment. In Hungary, Poland, Slovakia, Czech<br />

Republic, Bulgaria, and the Baltic countries we offer<br />

systematic Tracking & Tracing. IT integration on<br />

the basis of EDIFACT/IFTMIN is also possible.<br />

are these services available in the opposite<br />

direction as well?<br />

Klaus Stäblein: Yes they are. We not only distribute<br />

goods in these countries but also organize the procurement<br />

<strong>logistics</strong> <strong>for</strong> goods being sent to Western<br />

Europe. As a result, the customer has just one service<br />

provider and one central contact <strong>for</strong> incoming<br />

and outgoing goods. Combining procurement and<br />

distribution is sound practice – we, <strong>for</strong> example, take<br />

care of all the transport <strong>logistics</strong> <strong>for</strong> the Schaeffler<br />

<strong>Group</strong> on the west-east axis route (see article on<br />

page 10).<br />

what role do the geis companies<br />

in the czech republic and slovakia play in this?<br />

Klaus Stäblein: They enable us to offer our customers<br />

more extensive <strong>logistics</strong> services.<br />

what does that mean exactly?<br />

Klaus Stäblein: It means that we can offer customers<br />

the full range of services we offer them in Germany,<br />

including contract <strong>logistics</strong> projects <strong>for</strong> local<br />

customers as well as national and international procurement<br />

and distribution. One example is the new<br />

Eastern Europe Central Warehouse <strong>for</strong> <strong>Husqvarna</strong><br />

in the east of the Czech Republic (see page 12). This<br />

is where we warehouse and distribute <strong>Husqvarna</strong><br />

goods throughout the Czech Republic and Slovakia.<br />

are there also customers who use the<br />

geis group <strong>for</strong> their transport <strong>logistics</strong> from<br />

eastern europe to germany?<br />

Klaus Stäblein: Yes, and their numbers are in-<br />

creasing. For example, at the beginning of the year<br />

we took on a project <strong>for</strong> fittings manufacturer VAG,<br />

which is based in Mannheim. The Czech company<br />

JMA, based in Hodonin, is a subsidiary of the VAG<br />

<strong>Group</strong>. JMA manufactures fittings <strong>for</strong> water management,<br />

e.g. hydrants, sliders and valves. <strong>Geis</strong> CZ<br />

is now responsible <strong>for</strong> distributing their products<br />

across Europe. The most important market <strong>for</strong> the<br />

company is Germany, and accordingly, just <strong>for</strong> this<br />

customer we have established a new daily service<br />

between our Rajhrad <strong>logistics</strong> centre near Brno and<br />

Nuremberg, enabling us to offer a 48-hour delivery<br />

service throughout Germany, and a 24-hour service<br />

in Austria. The project also makes full use of our<br />

direct services via our Czech <strong>network</strong> to Slovakia,<br />

Poland, Hungary, Italy, Spain, Portugal and Switzerland.<br />

Thank you very much <strong>for</strong> your time!

10 | road ServiceS<br />

Working <strong>for</strong> Schaeffler on the west-east axis<br />

Almost everyone who drives a car uses them: INA engine parts, FAG roller bearings or LuK clutches.<br />

But these three Schaeffler <strong>Group</strong> brand products are used in other industrial sectors too, <strong>for</strong> example the aerospace sector.<br />

Since February of this year, the <strong>Geis</strong> <strong>Group</strong> has been responsible <strong>for</strong> transporting them along the west-east axis.<br />

Photos: Schaeffler <strong>Group</strong><br />

The Schaeffler <strong>Group</strong> with its brands INA, FAG<br />

and LuK has 180 sites in more than 50 countries.<br />

Although its main markets have traditionally been<br />

Central and Western Europe, North America and<br />

the growing markets of Asia and Eastern Europe are<br />

becoming increasingly important.<br />

a dense neTwork and sTrong parTners: In<br />

order to optimize its transport <strong>logistics</strong> to and from<br />

Eastern Europe even further, Schaeffler last year<br />

put the contract out to tender. Its aims in doing so<br />

were to reduce the number of service providers, to<br />

optimize processes and costs and to improve the<br />

integration of the service provider. In addition,<br />

Schaeffler Technologies wanted a dense <strong>network</strong>,<br />

a strong partnership structure and a <strong>network</strong>ed IT<br />

infrastructure. „We won the tender because of our<br />

close-knit <strong>network</strong> in Eastern and Western Europe<br />

and our clear <strong>concept</strong>“, says Werner Dettenthaler,<br />

<strong>Geis</strong> Eurocargo‘s Site Manager at Nuremberg.<br />

„Since February we have been operating a strongly<br />

consolidated service <strong>for</strong> Schaeffler via Nuremberg<br />

with daily departures to Eastern Europe.“<br />

<strong>Geis</strong> operates services in the opposite direction as<br />

well, also via Nuremberg. For example, if a supplier<br />

in Romania has a consignment ready <strong>for</strong> a German<br />

Schaeffler plant, he places a shipping order via the<br />

Schaeffler internet portal. <strong>Geis</strong> receives the in<strong>for</strong>mation<br />

and arranges collection. The goods are<br />

transported on the daily Romania-Nuremberg ser-<br />

vice, consolidated in Nuremberg, and delivered to<br />

the relevant plants.<br />

35,000 Tonnes per year. „Within Germany we<br />

use the <strong>network</strong> of the general cargo cooperation<br />

IDS to collect and deliver goods, while in Eastern<br />

Europe and <strong>for</strong> further distribution in Western Europe<br />

we use our direct services to and from Nuremberg“,<br />

explains Werner Dettenthaler. „Using this<br />

<strong>concept</strong> we now process a total of around 35,000<br />

tonnes per year <strong>for</strong> the Schaeffler <strong>Group</strong>, and everything<br />

is running smoothly.“ —<br />

iNa‘s headquarters in Herzogenaurach<br />

IDS Quality Ranking: TSG‘s success confirmed<br />

<strong>Geis</strong> company Thüringer Speditionsgesellschaft mbH<br />

(TSG), based in Ohrdruf, is top of the list in the latest<br />

Quality Ranking of the general cargo cooperation<br />

IDS, confirming its success during the past year.<br />

Each year the IDS Quality Control Department assesses<br />

the entire range of services provided by all 44<br />

IDS sites in Germany. Procedures, status notifications,<br />

quality records and market appearance are all assessed.<br />

TSG was number one in the Quality Ranking in 2008<br />

too. „The fact that we have once again been successful<br />

shows that we continue to provide our customers<br />

with a top-quality service“, says TSG Site Manager<br />

Marc <strong>Geis</strong>. „And we plan to continue doing so in the<br />

future as well.“ —

Photo: Mercedes-Benz<br />

<strong>Geis</strong> uses hybrid truck<br />

An important step <strong>for</strong>ward <strong>for</strong> the environment: From 2011 the <strong>Geis</strong> <strong>Group</strong> will be using a Mercedes<br />

Atego BlueTec Hybrid truck.<br />

This makes <strong>Geis</strong> one of the first <strong>logistics</strong> companies<br />

in Germany to test the groundbreaking hybrid technology<br />

on a daily basis. The Hybrid truck is part of<br />

a 50-vehicle „Innovation Fleet“ which will be used<br />

to test the suitability <strong>for</strong> daily use and environmental<br />

potential of the technology. The Atego 1222 L<br />

has been designed <strong>for</strong> distribution transport, and the<br />

Hybrid version combines a compact and light fourcylinder<br />

diesel engine with a 44-kW electric motor.<br />

The e-motor primarily supports the diesel engine in<br />

the low and medium speed ranges. Start-up is mostly<br />

emission-free thanks to the electric motor.<br />

mercedes-benz claims that the innovative technology<br />

will reduce consumption by between 10 to<br />

15 percent. CO 2 emissions are reduced by the same<br />

extent – an especially strong argument in <strong>Geis</strong>‘ view.<br />

„Resource conservation and environmental protection<br />

have been among our corporate aims <strong>for</strong> many<br />

years. By using hybrid technology, we will be a step<br />

closer to achieving these aims. We look <strong>for</strong>ward to<br />

being a pioneer in this area“, says <strong>Geis</strong> Managing<br />

Director Klaus Stäblein. —<br />

<strong>New</strong>: Secure air freight in the IDS system<br />

The German Air Safety Law requires that air-freight<br />

goods be transported within a secure supply chain.<br />

<strong>Geis</strong>‘ Bad Neustadt and Nuremberg sites now offer<br />

such a secure supply chain to customers who send<br />

their goods to the airport via the IDS system. The<br />

new, straight<strong>for</strong>ward and low-cost service is called<br />

Luftfracht Secured.<br />

The enhanced security level begins when a consignment<br />

is picked up by specially-trained drivers who<br />

ensure that their vehicles are locked at all times.<br />

Luftfracht Secured goods are then handled in an area<br />

of the warehouse that is comprehensively monitored<br />

and to which only authorized personnel have access.<br />

Specially trained staff are also used to transport<br />

freight to Frankfurt and Nuremberg Airport and to<br />

deliver it to consignees. <strong>Geis</strong> in collaboration with<br />

IDS has there<strong>for</strong>e created a secure supply chain. —<br />

www.ids-logistik.de<br />

<strong>New</strong> label <strong>for</strong><br />

maximum security<br />

road ServiceS | 11<br />

AEO status speeds up<br />

supply chain<br />

The German customs<br />

authorities have awarded<br />

„Authorized Economic<br />

Operator“ (AEO) status<br />

to the <strong>Geis</strong> companies<br />

TSG Thüringer Speditionsgesellschaft<br />

in Ohrdruf,<br />

Bischoff International<br />

in Naila, <strong>Geis</strong> Eurocargo<br />

GmbH in Nuremberg<br />

and Satteldorf and to<br />

<strong>Geis</strong> Industrie-Service<br />

with its 20 sites.<br />

The exact status awarded<br />

to the <strong>Geis</strong> companies<br />

is AEO-F, and thereby<br />

encompasses customs<br />

simplification and safety<br />

standards. The main<br />

beneficiaries will be <strong>Geis</strong>‘<br />

customers because simplified<br />

custom rules mean<br />

that goods can now be<br />

cleared more quickly,<br />

and consequently reach<br />

consignees faster.<br />

Moreover it proves that<br />

<strong>Geis</strong> operates high safety<br />

standards, because AEO<br />

status requires that<br />

stringent standards be<br />

met in terms of reliability,<br />

financial solvency and<br />

the fulfilment of certain<br />

safety regulations.<br />

<strong>Geis</strong> SDV and Hans <strong>Geis</strong><br />

GmbH were awarded<br />

the coveted AEO status<br />

last year. —

Photo: Fotolia / endostock

logiSticS<br />

reorganized<br />

T<br />

he <strong>Husqvarna</strong> brand and its subsidiary company<br />

Gardena have long been familiar to gardening<br />

enthusiasts and professional landscape<br />

designers. And no wonder: The Swedish manufacturer<br />

is the world‘s largest manufacturer of lawnmowers,<br />

chainsaws, portable petrol-driven gardening<br />

equipment, watering systems and gardening tools.<br />

since The end of lasT year <strong>Geis</strong> has been implementing<br />

a new central warehouse <strong>concept</strong> <strong>for</strong> <strong>Husqvarna</strong><br />

in Czech Republic and Slovakia. Instead of<br />

having several small regional warehouses, <strong>Geis</strong> now<br />

concentrates <strong>Husqvarna</strong> product handling <strong>for</strong> the<br />

Czech Republic and Slovakia in Ostrava in the east of<br />

the Czech Republic.<br />

The two companies know each other well: „We have<br />

worked <strong>for</strong> <strong>Husqvarna</strong> at Bad Neustadt/Salz <strong>for</strong> many<br />

years. We also worked <strong>for</strong> <strong>Husqvarna</strong>‘ subsidiary Gardena<br />

in the Czech town of Rajhrad near Brno be<strong>for</strong>e<br />

the central warehouse <strong>concept</strong> was implemented“,<br />

says Erik Lassen, Managing Director of <strong>Geis</strong> Industrie-Service<br />

GmbH. „In the autumn of 2009, the<br />

Gardena products warehouse and the two <strong>Husqvarna</strong><br />

products warehouses in Prague and the Slovakian<br />

town of Liptovský Mikulás were closed and transferred<br />

to Ostrava.“<br />

<strong>Geis</strong> now offers <strong>Husqvarna</strong> a complete package of logistical<br />

services from a single source. It encompasses<br />

warehousing <strong>for</strong> finished goods and spare parts, as well<br />

as their entire distribution in the Czech Republic and<br />

Slovakia – including general and parcel shipments.“<br />

To implemenT its central warehouse solution, <strong>Geis</strong><br />

has leased part of a newly-constructed <strong>logistics</strong> park<br />

in Ostrava. „The warehouse <strong>logistics</strong> <strong>for</strong> the Czech<br />

Republic and Slovakia are currently managed on an<br />

area covering 7,000 square metres“, explains <strong>Geis</strong><br />

Project Manager Pavel Křížek. „We have 6,000 shelf<br />

pallet spaces in our shelf storage facility <strong>for</strong> storing<br />

smaller products, which can encompass everything<br />

from rose shears to chainsaws. Larger products<br />

such as garden tractors, lawnmowers and scythes in<br />

contrast are stored in blocks.“ These products take<br />

up a lot of space. We currently store around 800<br />

<strong>Husqvarna</strong> tractors alone in Ostrava, and during the<br />

course of the season, this number is set to increase<br />

even further.<br />

Did you know?<br />

The <strong>Husqvarna</strong> logo shows<br />

the barrel of a gun seen<br />

from the front. The reason:<br />

The company was established<br />

in Sweden in 1689 as a<br />

manufacturer of muskets.<br />

<strong>Husqvarna</strong> is accordingly one<br />

of the oldest industrial<br />

companies in the world.<br />

After manufacturing sewing<br />

machines, household<br />

appliances, bicycles and<br />

motorcycles, the company<br />

today is the world‘s largest<br />

producer of outdoor<br />

power products. With the<br />

Gardena brand, <strong>Husqvarna</strong><br />

is also Europe‘s number<br />

one company <strong>for</strong> watering<br />

systems.<br />

logiSticS ServiceS | 13<br />

Garden and <strong>for</strong>estry equipment manufacturer <strong>Husqvarna</strong> <strong>Group</strong> has reorganized its <strong>logistics</strong> in the<br />

Czech Republic and Slovakia. The company‘s <strong>logistics</strong> partner is now the <strong>Geis</strong> <strong>Group</strong>, which is<br />

successfully implementing a central warehouse <strong>concept</strong>.<br />

www.husqvarna.com<br />

Photos: <strong>Husqvarna</strong><br />

Close to where these large items of equipment are<br />

kept, <strong>Geis</strong> stores the spare parts <strong>for</strong> <strong>Husqvarna</strong> products.<br />

The warehouse holds up to 40,000 different<br />

parts, ranging from small screws to replacement motors<br />

<strong>for</strong> garden tractors. In order to make optimal<br />

use of and be able to manage these 40,000 different<br />

sections, <strong>Geis</strong> uses the LFS warehouse <strong>logistics</strong> system,<br />

which is linked via interfaces to <strong>Husqvarna</strong>’s<br />

software systems. Data exchange takes place entirely<br />

via EDI.<br />

more Than 35 geis employees currently work <strong>for</strong><br />

<strong>Husqvarna</strong> in Ostrava. Outside the season, they pick<br />

and pack around six truckloads each day. During<br />

the season, the daily volume increases severalfold to<br />

between 13 and 15 truckloads. The <strong>Geis</strong> <strong>Group</strong> also<br />

takes care of distribution <strong>logistics</strong> <strong>for</strong> <strong>Husqvarna</strong><br />

in the Czech Republic and Slovakia, using its own<br />

nationwide parcel and cargo service <strong>network</strong>s <strong>Geis</strong><br />

CZ, <strong>Geis</strong> SK and General Parcel Čechy.<br />

Erik Lassen: „The project has started smoothly, with<br />

our experience with Gardena products naturally<br />

standing us in good stead. We are currently in the<br />

middle of the high season, and our extremely flexible<br />

employee <strong>concept</strong> is enabling us to easily handle<br />

these peaks too.“ —

14 | logiSticS ServiceS<br />

„Automotive industry-level achieved“<br />

Hand-in-hand with <strong>Geis</strong> Industrie-Service, Wincor Nixdorf has reorganized its production flow at its Ilmenau plant.<br />

It now runs on the basis of the principle of order-based picking of individual consignments.<br />

At its Thuringian plant, Wincor Nixdorf primarily<br />

produces retail empties collection systems. For<br />

the past four years, <strong>Geis</strong> has managed the entire<br />

warehousing, supply and disposal <strong>for</strong> the plant from<br />

its <strong>logistics</strong> centre in Ohrdruf. „In order to be able<br />

to react more flexibly to fluctuations in demand and<br />

in response to the growing number of models, we<br />

have reorganized our production flow“, explains Oliver<br />

Loske, Head of Operations at Wincor Nixdorf.<br />

„Instead of batch-producing a particular model type,<br />

we now produce different model types directly after<br />

each other on an assembly line.“<br />

As a result, changes had to be made in the logistical<br />

supply. „We now supply the parts on a just-in-sequence<br />

basis to the assembly line“, explains Jochen Creutzburg,<br />

Site Manager of the Ohrdruf Logistics Centre.<br />

„Moreover, we have set up a separate order picking<br />

Photo Barthelmess <strong>Group</strong><br />

A logistical sales aid<br />

picking and placing directly in<br />

the assembly frame<br />

Three times a year, Barthelmess‘ subsidiary decorado<br />

GmbH issues a catalogue containing around 6,000<br />

decorative, promotional items <strong>for</strong> shop windows,<br />

shops and shopping centres. Since June, the contract<br />

<strong>logistics</strong> <strong>for</strong> these has been outsourced to <strong>Geis</strong> Industrie-Service<br />

GmbH, with the work carried out at<br />

<strong>Geis</strong>‘ warehouse in Seubtendorf in Thuringia.<br />

Here <strong>Geis</strong> employees are not only responsible <strong>for</strong><br />

warehouse procedures but also <strong>for</strong> incoming and<br />

outgoing consignments. This is because <strong>Geis</strong>‘ subsidiary<br />

Bischoff International has also, since June,<br />

been responsible, together with a parcel service<br />

company, <strong>for</strong> procuring and distributing the decorative<br />

articles throughout Europe.<br />

area, called the assembly warehouse, where we store<br />

around 400 different articles which are directly picked<br />

and placed by our employees in specially-developed<br />

transport/assembly racks.“<br />

The challenge <strong>for</strong> <strong>Geis</strong> employees is twofold. First,<br />

just one picking error can result in Wincor Nixdorf‘s<br />

assembly line coming to a halt, and secondly the products<br />

in question are largely final-painted sheet metal<br />

parts that require careful handling. „We introduced<br />

a system of final checks years ago. These are carried<br />

out be<strong>for</strong>e the parts are transported by shuttle to the<br />

assembly plant. The system is proving to be especially<br />

valuable at the moment“, says Jochen Creutzburg.<br />

„The order-based individual picking system has<br />

been running smoothly right from the word go. This<br />

means that our per<strong>for</strong>mance is equal to the high-level<br />

of per<strong>for</strong>mance of the automotive industry.“ —<br />

„We help you sell“ – this is the Barthelmess <strong>Group</strong>‘s motto, and <strong>Geis</strong> now manages their <strong>logistics</strong>.<br />

Barthelmess‘ head office<br />

By outsourcing the <strong>logistics</strong>, Barthelmess is simultaneously<br />

realizing several aims: „First of all in relation<br />

to contract <strong>logistics</strong> we want to secure a significant<br />

acceleration in order processing speed and efficiency“,<br />

explains Wolfgang Bastert, CEO of the Barthelmess<br />

<strong>Group</strong>. „And by reorganizing our transport <strong>logistics</strong>,<br />

we can significantly shorten our delivery times in Europe.<br />

At the same time we‘re benefitting from a later<br />

cut-off time and thereby significantly extending the<br />

last-order deadline <strong>for</strong> order processing.“ —

<strong>Geis</strong> builds a multi-user<br />

<strong>logistics</strong> and technology centre<br />

Large-scale project begun: In the Franconian city of Erlangen, work has<br />

started on the construction of the <strong>Geis</strong> <strong>Group</strong>‘s new 30,000 m 2 multi-user<br />

<strong>logistics</strong> centre. The centre is set to go into operation in November.<br />

Situated right next to A3 autobahn, with a rail connection<br />

and its own harbour on the Main-Danube<br />

canal, the location of the new building couldn‘t be<br />

more convenient. The <strong>logistics</strong> centre is being built<br />

on a 15 hectare site in Erlangen‘s Industriepark Frauenaurach.<br />

It will encompass almost 30,000 square metres<br />

of <strong>logistics</strong> area and up to 3,000 square metres<br />

of office and administration area. „The Nuremberg/<br />

Erlangen metropolitan region has ideal connections<br />

<strong>for</strong> distribution to Eastern and Western Europe“, say<br />

Hans-Georg <strong>Geis</strong> and Wolfgang <strong>Geis</strong>.<br />

The new building is 165 x 175 metres large and is<br />

multi-user-compatible. It can be divided into up to<br />

six same-size sections with around 5,000 square metres<br />

of area in each. Every section has six loading bays<br />

and a ground-floor access gate. In total the hall has 36<br />

this is how the new <strong>logistics</strong> and technology centre will look<br />

Under construction next to the a3 and the Main-danube canal:<br />

the new <strong>logistics</strong> and technology centre (centre). above and right: optional extension buildings<br />

loading bays and six access gates. Inside the distance<br />

between the ground and the lower edge of the roof<br />

construction is 10.50 metres. It also includes a sprinkler<br />

system.<br />

„At the site we have bundled together expertise on<br />

plant supply, spare-parts and new-goods distribution,<br />

assembly and packing work - including <strong>for</strong> heavy<br />

goods“, explains Dr. Johannes Söllner, Managing<br />

Director <strong>for</strong> the Logistics Services area. „Once the<br />

centre is ready, it will be used <strong>for</strong> contract <strong>logistics</strong>,<br />

assembly work and packing <strong>for</strong> several clients. There<br />

will still be sufficient space <strong>for</strong> additional customers in<br />

the current building and in extensions.“ —<br />

facility.management@geis-group.de<br />

logiSticS ServiceS | 15<br />

„Green“<br />

packaging <strong>concept</strong><br />

How can ecology and economy<br />

be reconciled in packaging?<br />

Through recycling, <strong>for</strong> example.<br />

A team from Siemens Healthcare<br />

and <strong>Geis</strong> has now developed a<br />

<strong>concept</strong> that successfully<br />

combines both.<br />

Packaging <strong>for</strong> high-tech products<br />

is especially complex,<br />

as it has to provide optimal<br />

protection to sensitive devices<br />

and manufacturing costs<br />

are correspondingly high.<br />

To optimize efficiency and<br />

simultaneously improve the<br />

environmental-friendliness of<br />

packaging, <strong>Geis</strong>‘ and Siemens‘<br />

experts have developed a<br />

new packaging <strong>concept</strong> and<br />

are already using it successfully<br />

<strong>for</strong> Siemens‘ mammography<br />

systems.<br />

The packaging consists of<br />

a special pallet, a dust cover<br />

and plastic linings, and the<br />

modules are returned to the<br />

<strong>Geis</strong> Logistics Centre in<br />

Forchheim from all over Europe.<br />

„Once here, we examine<br />

the packaging systems <strong>for</strong><br />

completeness and damage“,<br />

says <strong>Geis</strong> Site Manager<br />

Gerhard Schindler.<br />

„In addition, we replace all<br />

the modules‘ standard parts<br />

prior to storage <strong>for</strong> safety<br />

reasons.“<br />

Each packaging module<br />

is accordingly used up to<br />

ten times. „In the past year<br />

alone we saved more than<br />

30,000 euros by having<br />

packaging returned“, says<br />

Hans-Joachim Schumm,<br />

Purchaser at Siemens<br />

Healthcare. „The <strong>concept</strong> is<br />

a winner <strong>for</strong> us and the<br />

environment!“ —

16 | air + Sea ServiceS<br />

thousands oF tonnes<br />

right across pakistan<br />

11 diesel engines weighing 320 tonnes each, 28 heavy components with an individual weight of between<br />

60 and 90 tonnes, and around 30,000 tonnes of freight – <strong>for</strong> MAN Diesel & Turbo SE Augsburg SDV<br />

Projects (a wholly-owned subsidiary of <strong>Geis</strong> SDV) delivered all these items destined <strong>for</strong> use in a future<br />

power plant safely and on time near Lahore/Pakistan.<br />

In March 2009, SDV Projects‘ team of experts set<br />

about organizing the large-scale order. The initial<br />

project phase involved transporting the heavy<br />

components to various European harbours, from<br />

where they were shipped to Port Qasim/Pakistan.<br />

The second phase and “real” work <strong>for</strong> the SDV<br />

Projects team began as soon as the shipments arrived<br />

in Qasim in Pakistan, however. The heavy cargo<br />

then had to be transported 1,500 kilometres across<br />

mountainous terrain. Prior to shipping the goods,<br />

SDV carefully had examined the route.<br />

„The roads were often in very bad condition. But<br />

thanks to our careful examinations, we were prepared<br />

<strong>for</strong> every eventuality and all the deliveries between<br />

Karachi/Port Qasim and Lahore - hundreds<br />

of them in total - went smoothly“, says Jens Fürstenau,<br />

SDV Projects Project Manager.<br />

follow-on work included: Once the consignments<br />

had reached their destination, specialists hired<br />

on behalf of SDV Projects unloaded the heavy items,<br />

positioned them on their respective foundations and<br />

aligned them precisely. After a total of ten months,<br />

the large-scale logistical order was completed in<br />

January 2010. „MAN Diesel & Turbo SE Augsburg<br />

are very happy with our work“, says Managing Director<br />

Heinz Niclas. „And we‘re delighted that everything<br />

went to plan.“ —<br />

carefully examined in advance:<br />

transporting goods along unpaved<br />

roads and through mountainous<br />

terrain represented a considerable<br />

challenge <strong>for</strong> the Sdv projects team.<br />

the 1,500-km-long journey across<br />

pakistan ultimately went precisely<br />

to plan, however.

Hamburg:<br />

Air and sea freight under<br />

one roof<br />

An increased local presence and the use of<br />

synergies - these are the two main reasons<br />

<strong>for</strong> bringing together the air and sea freight<br />

areas of <strong>Geis</strong> SDV in Hamburg.<br />

On 12 December 2009, the entire <strong>Geis</strong> SDV<br />

sea freight team, including the management,<br />

moved into the air freight office.<br />

The new joint address is:<br />

Obenhauptstr. 11, 22335 Hamburg<br />

„By having a common office, we‘re not only<br />

making optimal use of synergies but also promoting<br />

the uni<strong>for</strong>m image of <strong>Geis</strong> SDV to<br />

the outside world“, says Site Manager Claus<br />

Freydag.<br />

SDV Projects employees moved to Obenhauptstraße<br />

two weeks be<strong>for</strong>e the sea freight<br />

team. More than 100 employees now work<br />

here under one roof. —<br />

Aerospace Logistics<br />

bundles together skills<br />

<strong>Geis</strong> SDV is investing strongly in its Aerospace<br />

Logistics product area in order to bundle<br />

together skills and expertise. The main<br />

beneficiaries of the subsequent shorter decision<br />

paths and faster allocation of experienced<br />

advisors will be customers.<br />

Since January, Jan Kleine-Lasthues has<br />

worked as Director Aerospace Sales Germany<br />

and is responsible <strong>for</strong> German sales activities,<br />

while Jens Elsner, as Director Aerospace<br />

Operations Germany, is responsible<br />

<strong>for</strong> the operational side of the business. Jens<br />

Elsner, who on 1 February 2010 was conferred<br />

power of attorney <strong>for</strong> <strong>Geis</strong> SDV, manages<br />

the operational area as an independent<br />

profit centre. These changes have already<br />

been implemented at Hamburg and Frankfurt,<br />

with Munich to follow<br />

on 1 January 2011. —<br />

Jens elsner,<br />

director aerospace<br />

operations germany<br />

a surprise<br />

in aFrica<br />

air + Sea ServiceS | 17<br />

Shipping goods from Kenya to Zimbabwe is normally<br />

routine work <strong>for</strong> <strong>Geis</strong> SDV. However, when one shipment<br />

contained 21 tonnes of medical materials, things took<br />

an unexpected turn.<br />

Originally, around 1,200 packs of medicines and medical supplies were<br />

to be transported by road from Nairobi to Harare on behalf of the<br />

Tübingen-based Deutsches Institut für Ärztliche Mission e.V. (German<br />

Institute <strong>for</strong> Medical Mission). But then everything changed: At the end of November<br />

2009, just as the <strong>Geis</strong> SDV Stuttgart team and local colleagues were<br />

about to load the truck, the government of Zimbabwe closed its borders to medical<br />

shipments due to increased smuggling of counterfeit drugs.<br />

To ensure ThaT The urgenTly required medicines did reach their destination,<br />

<strong>Geis</strong> SDV and SDV‘s experts kept their cool and overnight drew up an alternative<br />

plan. They separated the medicines from the remainder of the shipment and flew<br />

them with the approval of the Medicine Control Authority Zimbabwe to Harare,<br />

while the remaining goods were sent as planned by road to Zimbabwe. „At the airport,<br />

the medicines went through customs without any problems and arrived on time<br />

with the customer - the Zimbabwe Association of Church Related Hospitals, as did<br />

the truck shipments“, says Joachim Wittner, head of <strong>Geis</strong> SDV‘s Stuttgart office,<br />

which oversaw the project. —<br />

Foto: Fotolia/Sabrina Gwerder

18 | geNeral NeWS<br />

„Making clear<br />

the difference...“<br />

Since 1 January 2010, Hans-Peter Schneider (51) has been responsible<br />

<strong>for</strong> <strong>Geis</strong> <strong>Group</strong> distribution activities outside the <strong>Geis</strong> core region.<br />

In the interview below, he discusses his work and targets.<br />

mr schneider, part of your<br />

work is to acquire new customers.<br />

how do you go about this?<br />

Hans-Peter Schneider: In future I plan to focus<br />

on potential customers in non-typical „<strong>Geis</strong> regions“.<br />

There are two basic reasons <strong>for</strong> this. First<br />

of all demand has changed. Logistics chains are<br />

now more specialized, international, and sectorspecific.<br />

It is more important than ever be<strong>for</strong>e<br />

<strong>for</strong> customers to find the right <strong>logistics</strong> partner,<br />

i.e. one that is capable of meeting their specific<br />

requirements. <strong>Geis</strong> has excellent references, and<br />

we see considerable potential <strong>for</strong> it to expand<br />

further, including outside its regional catchment<br />

area. The second reason is that, since studying<br />

business administration at university, I have always<br />

worked in the <strong>logistics</strong> sector, and <strong>for</strong> many<br />

years I have worked in the field of European sales<br />

activities. Over the course of time I have made<br />

many valuable contacts, which I can now use <strong>for</strong><br />

the benefit of <strong>Geis</strong>.<br />

Hans-peter Schneider<br />

in the interview<br />

why should customers choose<br />

the geis group?<br />

Hans-Peter Schneider: As Managing Director<br />

of the contract <strong>logistics</strong> cooperation Logistics<br />

World Alliance – a role I continue to occupy – I<br />

got to know <strong>Geis</strong> as an extremely reliable partner<br />

and a rock-solid, mid-size structured company<br />

with clear aims and innovative ideas. These<br />

characteristics combined with a very flexible<br />

management are what make <strong>Geis</strong> different from<br />

the other companies in the market. We have to<br />

make this difference clear to customers, and my<br />

colleagues and I will be pulling out all the stops<br />

in this respect.<br />

What do you personally find fascinating<br />

about geis?<br />

Hans-Peter Schneider: The <strong>Geis</strong> <strong>Group</strong> primarily<br />

stands out from the competition because<br />

of its high-quality service and outstanding customer<br />

references. By developing personal contacts<br />

and implementing suitable marketing<br />

measures, my colleagues and I want to communicate<br />

and promote these and other <strong>Geis</strong> <strong>Group</strong><br />

strongpoints even more strongly within Germany<br />

and Europe. These measures have already<br />

resulted in us acquiring new customers <strong>for</strong> <strong>Geis</strong><br />

Eurocargo and <strong>Geis</strong> CZ.<br />

Thank you very much <strong>for</strong> your time!<br />

<strong>New</strong> Sales and<br />

Marketing Manager<br />

at <strong>Geis</strong> SDV<br />

Since 1 October 2009,<br />

Jörn Schmersahl (48) has<br />

been the new Business<br />

Manager of <strong>Geis</strong> SDV‘s<br />

Sales and Marketing<br />

Germany division in<br />

Hamburg. A qualified<br />

shipping and chartering<br />

manager, he has longstanding<br />

operational and<br />

management experience<br />

in various areas of the<br />

international transport<br />

and <strong>logistics</strong> sector in<br />

Germany and abroad.<br />

Jörn Schmersahl was last<br />

employed as Sea Freight<br />

Manager at Agility Logistics,<br />

with responsibility <strong>for</strong><br />

Germany, the Netherlands,<br />

Belgium and Poland as<br />

well as <strong>for</strong> the development<br />

of various sales and<br />

marketing areas.<br />

„One of my main tasks<br />

at <strong>Geis</strong> SDV is to expand<br />

our core products area<br />

to include other products<br />

besides our successful<br />

healthcare and aerospace<br />

products“, says Jörn<br />

Schmersahl. „In addition,<br />

we have already<br />

started to strengthen our<br />

presence nationwide<br />

via key account management<br />

and trade lane<br />

management.“ —

The Nuremberg Company Run:<br />

<strong>Geis</strong> took part<br />

Artistic-bike world<br />

champion works <strong>for</strong> <strong>Geis</strong><br />

Whether it‘s jumping from the saddle onto<br />

the handlebars, or riding backwards on the<br />

rear wheel with no hands, no one in the world<br />

can currently hold a candle to <strong>Geis</strong> employee<br />

David Schnabel in the world of bicycle acrobatics.<br />

The 25-year-old proved this once<br />

again at the 54 th UCI Indoor Cycling World<br />

Championship, held at the end of 2009 in Tavira/Portugal,<br />

in which he beat competitors<br />

from 18 nations to become World Champion<br />

in the Men‘s Single artistic cycling competition.<br />

This is the fourth world championship<br />

title <strong>for</strong> the per<strong>for</strong>mance athlete, who trains<br />

<strong>for</strong> two hours three evenings a week.<br />

During the day, David Schnabel works as an<br />

administrator in <strong>Geis</strong>‘ distribution <strong>logistics</strong><br />

and warehousing area in Würzburg. „We<br />

are proud to have a world-class sportsman<br />

as part of our team“, says <strong>Geis</strong> Site Manager<br />

Marco Weißensel. David Schnabel is modest<br />

about his achievements: „I‘m happy that my<br />

sporting activities are viewed so positively at<br />

<strong>Geis</strong>.“ —<br />

On 6 May, almost 10,000 runners proved their sporting fitness by taking part in this year‘s Nuremberg<br />

Company Run. Among them were 30 runners from the <strong>Geis</strong> <strong>Group</strong>. The focus as always was on enjoyment<br />

rather than on running time. On the six-kilometre run, runners ran around the Dutzendteich lake.<br />

„This is the third time in a row that we have taken part in the Nuremberg Company Run. Despite the<br />

cold, wet weather, all the participants once again had a great deal of fun and once past the finishing line<br />

celebrated together in front of the Nuremberg Stone Grandstand“, says <strong>Geis</strong> Site Manager Werner<br />

Dettenthaler. „We definitely want to take part again next year.“ —<br />

geNeral NeWS |<br />

19<br />

Over the past few months, four <strong>Geis</strong><br />

employees have celebrated their<br />

25 th anniversary with the company.<br />

Renate Scharrer,<br />

who joined the<br />

<strong>Geis</strong> <strong>Group</strong> from<br />

Siemens Med in the<br />

course of a transfer,<br />

celebrated her<br />

25th anniversary at the Forchheim<br />

office on 7 January 2010. She retired<br />

in June 2010. We would like to thank<br />

her <strong>for</strong> her longstanding work in<br />

the small-parts warehouse.<br />

He first worked<br />

<strong>for</strong> Siemens Med,<br />

and then <strong>for</strong> <strong>Geis</strong>:<br />

Jürgen Petschl<br />

celebrated his 25th anniversary with<br />

the company on 21 January 2010.<br />

He works at Forchheim in goods<br />

receiving.<br />

Günther Wichert<br />

also joined <strong>Geis</strong><br />

from Siemens Med.<br />

He has worked in<br />

goods receiving at<br />

the Röthelheimpark<br />

site since 18 February 1985.<br />

Klaus Räder<br />

began his career<br />

on 1 April 1985<br />

at Hans <strong>Geis</strong> in<br />

Bad Neustadt as a<br />

<strong>for</strong>warding clerk.<br />

Here, he has been responsible <strong>for</strong> the<br />

company‘s fleet of vehicles since<br />

May 1998.<br />

The <strong>Geis</strong> <strong>Group</strong> would like to say<br />

a big thank you to all of them!

SucceSS<br />

in logiSticS<br />

iS eaSy...<br />

…if you have a strong partner at your side. <strong>Geis</strong> offers<br />

professional and flexible <strong>logistics</strong> services, including<br />

procurement, warehousing and distribution, as well as<br />

comprehensive value-added services.<br />

Success guaranteed!<br />

www.geis-group.com