triart®-technique | Sets 4407- 4408 - Kometdental.de

triart®-technique | Sets 4407- 4408 - Kometdental.de

triart®-technique | Sets 4407- 4408 - Kometdental.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

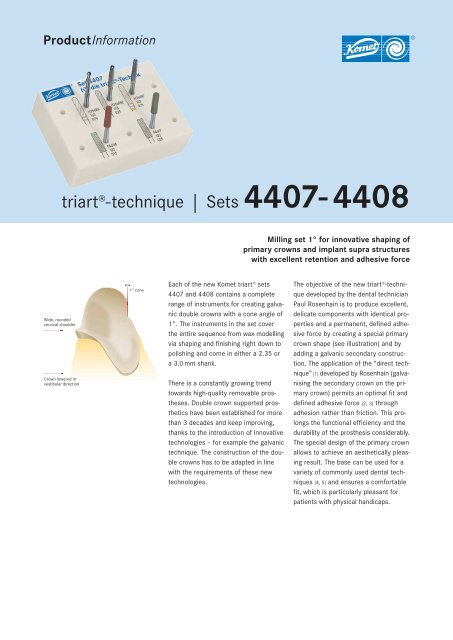

ProductInformation<br />

Wi<strong>de</strong>, roun<strong>de</strong>d<br />

cervical shoul<strong>de</strong>r<br />

Crown lowered in<br />

vestibular direction<br />

triart ® -<strong>technique</strong> | <strong>Sets</strong> <strong>4407</strong>- <strong>4408</strong><br />

1° cone<br />

Each of the new Komet triart ® sets<br />

<strong>4407</strong> and <strong>4408</strong> contains a complete<br />

range of instruments for creating galvanic<br />

double crowns with a cone angle of<br />

1°. The instruments in the set cover<br />

the entire sequence from wax mo<strong>de</strong>lling<br />

via shaping and finishing right down to<br />

polishing and come in either a 2.35 or<br />

a 3.0 mm shank.<br />

There is a constantly growing trend<br />

towards high-quality removable prostheses.<br />

Double crown supported prosthetics<br />

have been established for more<br />

than 3 <strong>de</strong>ca<strong>de</strong>s and keep improving,<br />

thanks to the introduction of innovative<br />

technologies – for example the galvanic<br />

<strong>technique</strong>. The construction of the double<br />

crowns has to be adapted in line<br />

with the requirements of these new<br />

technologies.<br />

Milling set 1° for innovative shaping of<br />

primary crowns and implant supra structures<br />

with excellent retention and adhesive force<br />

The objective of the new triart ® -<strong>technique</strong><br />

<strong>de</strong>veloped by the <strong>de</strong>ntal technician<br />

Paul Rosenhain is to produce excellent,<br />

<strong>de</strong>licate components with i<strong>de</strong>ntical properties<br />

and a permanent, <strong>de</strong>fined adhesive<br />

force by creating a special primary<br />

crown shape (see illustration) and by<br />

adding a galvanic secondary construction.<br />

The application of the “direct <strong>technique</strong>”<br />

(1) <strong>de</strong>veloped by Rosenhain (galvanising<br />

the secondary crown on the primary<br />

crown) permits an optimal fit and<br />

<strong>de</strong>fined adhesive force (2, 3) through<br />

adhesion rather than friction. This prolongs<br />

the functional efficiency and the<br />

durability of the prosthesis consi<strong>de</strong>rably.<br />

The special <strong>de</strong>sign of the primary crown<br />

allows to achieve an aesthetically pleasing<br />

result. The base can be used for a<br />

variety of commonly used <strong>de</strong>ntal <strong>technique</strong>s<br />

(4, 5) and ensures a comfortable<br />

fit, which is particularly pleasant for<br />

patients with physical handicaps.

The right tool leads to success<br />

1° Wax cutter, shaping and finishing<br />

instruments H356RA, H356RSE and<br />

H356RF. The minimum cone angle of<br />

1° solves the problem of the <strong>de</strong>creasing<br />

adhesive force of conventional double<br />

crowns caused by an increasing<br />

cone angle. Contrary to telescopic double<br />

crowns, the prosthesis cannot jam<br />

during insertion and removal, which<br />

would cause severe problems to el<strong>de</strong>rly<br />

and physically handicapped patients.<br />

The conveniently large radius at the tip<br />

of the 1° Komet instruments for the<br />

triart ® -<strong>technique</strong> permits the creation<br />

of excellent shoul<strong>de</strong>rs. They create<br />

sufficient space for the individual components<br />

of the galvanic secondary and<br />

tertiary constructions, which is the precondition<br />

for <strong>de</strong>licate, natural looking<br />

teeth. Even in case of shorter abutment<br />

teeth, the creation of a roun<strong>de</strong>d cervical<br />

shoul<strong>de</strong>r (chamfer) helps to provi<strong>de</strong> a<br />

sufficiently large surface to ensure<br />

optimum adhesive force.<br />

The smooth, low-vibrating operation<br />

and the effective substance removal<br />

allow controlled, yet time-saving work<br />

and the creation of beautifully smooth<br />

surfaces. The final scaling of the wax<br />

surfaces – once a common procedure<br />

– can now be omitted, and the cast<br />

work pieces are optimally prepared to<br />

polishing stage with the help of the<br />

congruent Komet cutters. The laser<br />

marking on the shank indicating the<br />

<strong>de</strong>gree of the cone angle allows quick<br />

recognition of the appropriate 1° cutter.<br />

1<br />

2<br />

3<br />

H356RA.103.029<br />

H356RSE.103.029<br />

H356RF.103.029<br />

Recommendations for use<br />

The cutters are exclusively used in<br />

the milling <strong>de</strong>vice.<br />

1. Work on wax is to be carried out<br />

with instrument H356RA and Waxit, at<br />

a speed of 3 000 rpm (clockwise<br />

rotation)<br />

2. Instrument H356SE is recommen<strong>de</strong>d<br />

for shaping, at a speed of<br />

10 000 rpm (counter rotation),<br />

using milling oil and wax<br />

3. Optimal surfaces are created<br />

when instrument H356RF is used for<br />

finishing at a speed of 3 000 rpm<br />

(counter rotation), using milling oil<br />

and wax.

The new Komet polishing<br />

system for the milling <strong>technique</strong><br />

1° polishers 9441M and 9441F are<br />

used for polishing and high-shine<br />

polishing. The innovative, time-saving<br />

Komet polishing system is <strong>de</strong>signed<br />

for use in the milling <strong>de</strong>vice. Its special<br />

construction allows to achieve surfaces<br />

of outstanding precision.<br />

Thanks to their small diameter, these<br />

polishers can get into hard-to-reach<br />

areas such as lowered, cervical shoul<strong>de</strong>rs<br />

without time-consuming dressing.<br />

Mirror-like surfaces are created without<br />

effort.<br />

The special polishing material adapts<br />

optimally to roun<strong>de</strong>d shoul<strong>de</strong>rs, whereas<br />

the carrier in the core ensures axial<br />

stability.<br />

4<br />

5<br />

9441M.103.035<br />

9441F.103.035<br />

Application<br />

The polishers are used in the milling<br />

<strong>de</strong>vice only, applying low contact<br />

pressure.<br />

4. The polisher 9441M is to be<br />

used for dry polishing, at a speed<br />

of 6 000 rpm.<br />

5. High-shine polishing is done with<br />

polisher 9441F, again dry and at a<br />

speed of 6 000 rpm.

Set <strong>4407</strong><br />

H356RA.103.029<br />

H356RSE.103.029<br />

H356RF.103.029<br />

9441M.103.035<br />

9441F.103.035<br />

Set <strong>4408</strong><br />

H356RA.123.029<br />

H356RSE.123.029<br />

H356RF.123.029<br />

9441M.123.035<br />

9441F.123.035<br />

Literature:<br />

(1) Rosenhain P.: Die Herstellung <strong>de</strong>r Primärund<br />

Sekundärteile auf galvanischem Weg.<br />

Vi<strong>de</strong>o A-G-C System: Impressionen;<br />

Wieland Pforzheim 1990<br />

(2) Bongartz B., Faber F.-J., Kerschbaum T.:<br />

Evaluation of removable bridges with electoformed<br />

402711V0 ·<br />

telescopic retainers, Kongress <strong>de</strong>r <strong>de</strong>utschen<br />

Gesellschaft für Zahn-, Mund- und Kieferheilkun<strong>de</strong>;<br />

HB/1 ·<br />

Hannover 2002<br />

(3) Diese steht in Abhängigkeit zur Kronenanzahl<br />

(Minimum vier Zähne), vgl. Faber F.-J. , Huber C.:<br />

Germany in<br />

Ursache und Begrenzung <strong>de</strong>r Haftkraft bei<br />

Galvano- Teleskopkronen; Universität zu Köln 2003<br />

Printed ·<br />

(4) Diedrichs G., Rosenhain P.: Bio-Ästhitik in<br />

<strong>de</strong>r restaurativen Zahnheilkun<strong>de</strong>. Neuer Merkur;<br />

Technical advisor:<br />

München 1995<br />

Germany ·<br />

Paul Rosenhain<br />

(5) Hahn, L., Weigel, P., Lauer, H-CH., Hamacher, O.:<br />

In vitromo<strong>de</strong>ll for the wear of tape crown sytems.<br />

Address correspon<strong>de</strong>nce to:<br />

30. Jahrestagung <strong>de</strong>r Arbeitsgemeinschaft für<br />

<strong>de</strong>paro@t-online.<strong>de</strong><br />

Grundlagenforschung in <strong>de</strong>r DGZMK; Mainz. T15 1998<br />

BRASSELER GEBR. · 03/2005<br />

GEBR. BRASSELER GmbH & Co.KG · Postfach 160 · 32631 Lemgo · Germany · Telefon: +49 (0) 5261 701-0 · Telefax: +49 (0) 5261 701-289 · info@brasseler.<strong>de</strong> · www.brasseler.<strong>de</strong> ©