FARO / EUROPROFI silage trailers - Alois Pöttinger Maschinenfabrik ...

FARO / EUROPROFI silage trailers - Alois Pöttinger Maschinenfabrik ...

FARO / EUROPROFI silage trailers - Alois Pöttinger Maschinenfabrik ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

97+121.02.0109<br />

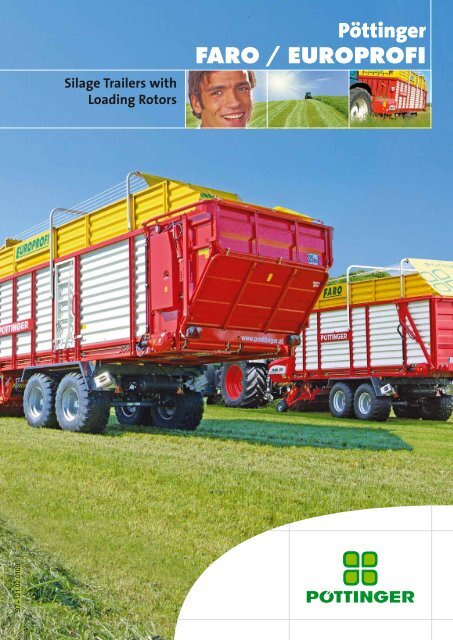

Silage Trailers with<br />

Loading Rotors<br />

<strong>Pöttinger</strong><br />

<strong>FARO</strong> / <strong>EUROPROFI</strong>

2<br />

Great technology<br />

for tractors<br />

from 85 hp / 63 kW

Silage <strong>trailers</strong> are the future. The tried and tested<br />

<strong>EUROPROFI</strong> and the new <strong>FARO</strong> model constitute an<br />

important part of <strong>Pöttinger</strong>’s <strong>silage</strong> trailer range.<br />

These powerful <strong>trailers</strong> are suitable for internal<br />

mechanisation or inter-company deployment.<br />

Harvest, load or compact?<br />

<strong>FARO</strong> and <strong>EUROPROFI</strong> are the cost-effective alter -<br />

natives. The low-drag rotor <strong>trailers</strong> can be towed by<br />

tractors of just 85 hp (63 kW) or higher. Short cut,<br />

optimum compaction and high power – exceptional<br />

and spellbinding.<br />

“To be exceptional means raising yourself above<br />

mediocrity and having the courage to explore<br />

hitherto unknown dimensions.”<br />

Sigrun Hopfensperger<br />

Pages 4 – 5<br />

There are many advantages of <strong>silage</strong><br />

<strong>trailers</strong><br />

Pages 6 – 23<br />

<strong>FARO</strong><br />

Pages 24 – 41<br />

<strong>EUROPROFI</strong><br />

Pages 42 – 43<br />

Operating variants<br />

Pages 44 – 45<br />

Fitting variants<br />

Pages 46 – 47<br />

Technical data<br />

Page 48<br />

Imprint<br />

3

Silage trailer, forage harvester or round baler? Several independent Agricultural Institutes<br />

have compared the three process chains. Result: Silage <strong>trailers</strong> have a clear advantage<br />

when it comes to organisation, manpower requirements and diesel consumption.<br />

There is no noticeable difference in <strong>silage</strong> quality.<br />

4<br />

There are many advantages<br />

of <strong>silage</strong> <strong>trailers</strong><br />

There is no patent remedy for deciding on the best crop procedure. The decision<br />

can only be made on an individual basis. Distances between field and farm,<br />

cropping areas, forage proceeds and available manpower are the most important<br />

decisive factors.<br />

However, as a rule of thumb it can be said that <strong>silage</strong> <strong>trailers</strong> are considerably<br />

more cost-effective than self-propelled forage harvesters if the distance between<br />

field and farm is less than 4.35 miles or 7 km. The <strong>silage</strong> trailer system presents<br />

the advantages of lower manpower requirement and simpler labour organisation.<br />

It is suitable for <strong>silage</strong>, green fodder, hay and straw harvesting.<br />

The advantage of the forage harvester is the high power, which comes in useful<br />

for cropping large parcels of land or if the distances between field and farm are<br />

large. However, this advantage only comes into play if transport logistics are<br />

suitable and if optimal compaction takes place at the silo.<br />

Round baling technology is user-friendly and is a good choice for small enterprises.<br />

The advantages of this procedure are low weather risk and flexibility of use.<br />

However, this procedure is not cost-effective for larger enterprises. Rule of thumb: it<br />

makes more sense to use <strong>silage</strong> <strong>trailers</strong> if you have more than 17.3 acres / 7 hectares<br />

of grassland.

Checking durability<br />

<strong>Pöttinger</strong> has established a modern test centre where the most demanding<br />

working conditions are simulated in order to determine maximum limits.<br />

The multi-axis shaker table (MAST) is the centre’s show piece. This simulates<br />

acceleration forces equal to those of a rocket launch and vibrations equal to those<br />

felt during an earthquake. Machines weighing upto 4.5 tonnes can be tested with<br />

this test facility, which is unique in the world of agricultural technology.<br />

The component part test facility contains highly sensitive and dynamic pneumatic<br />

and hydraulic cylinders: tools, frame constructions and chassis are tested for<br />

durability here.<br />

Transmission test Climate chamber<br />

5

<strong>FARO</strong> – a rotor trailer with great<br />

technology<br />

6<br />

Enthusiasm for development is as strong as ever at <strong>Pöttinger</strong>.<br />

A medium-sized <strong>silage</strong> trailer requiring lower horsepower has been<br />

developed in the form of the new <strong>FARO</strong> trailer. The name “<strong>FARO</strong>”<br />

is derived from the Spanish or Italian word for beacon – “faro”. This<br />

<strong>silage</strong> trailer is the way to go for grassland areas, and is intended<br />

for tractors of 85 hp (63 kW) or higher.

Pages 8 – 9<br />

Construction / body / drawbar<br />

Pages 10 – 11<br />

Transmission<br />

Pages 12 – 13<br />

Pickup<br />

Pages 14 – 15<br />

Loading system<br />

Pages 16 – 17<br />

Cutting unit<br />

Pages 18 – 19<br />

Loading and scraper floor<br />

Pages 20 – 21<br />

Unloading<br />

Pages 22 – 23<br />

Chassis and tyres<br />

Pages 42 – 43<br />

Control pads<br />

Pages 44 – 45<br />

Fittings<br />

Pages 46 – 47<br />

Technical data<br />

7

Construction<br />

Convincing details<br />

The professional user<br />

demands high quality for<br />

long-term use. <strong>Pöttinger</strong><br />

responds to this requirement<br />

with sophisticated techno -<br />

logy, top-quality materials<br />

and precise workmanship.<br />

This market leader has set<br />

new standards for <strong>silage</strong><br />

trailer technology with<br />

high-quality work and a<br />

modern design.<br />

The resistant cathodic<br />

electrodip powder coating<br />

finish is a real mark of<br />

quality.<br />

Powder coat paint proves<br />

itself in use thanks to its<br />

elasticity and durability.<br />

Automobile paint quality in<br />

agricultural technology!<br />

8<br />

Body<br />

The chassis of the <strong>FARO</strong> <strong>silage</strong><br />

trailer range is a bolted frame<br />

construction of<br />

<br />

C 220x70x50x5QSTE fine grain<br />

steel. The closed steel body is<br />

constructed to take heavy loads. Sturdy platform profiles, closely spaced, provide<br />

high stability. The straight side columns are bolted to the frame, not welded. What<br />

makes it special: fine-thread fitting for high stability.<br />

<br />

Profile panels with smooth sides and a special coating ensure that the forage<br />

is unloaded smoothly and completely.<br />

The access ladder provides easy access to the interior of the trailer. This is an<br />

optional feature for L-type <strong>trailers</strong> (<strong>trailers</strong> without proportioning).<br />

The roof section can be folded inwards. The extension frames can be lifted up<br />

4.72” or 12 cm on the <strong>FARO</strong> 6300 and 8000.<br />

Taut roof ropes prevent crop loss when loading or transporting the crop. The roof<br />

ropes of the <strong>FARO</strong> 6300 and 8000 can be replaced with roof profiles for dry<br />

forage or straw. The robust profiles provide better crop compaction. This can<br />

assist in reducing transport costs.<br />

Both the <strong>FARO</strong> 3500 and the <strong>FARO</strong> 4000 can be delivered with a dry forage<br />

extension. When this is hydraulically folded away, the <strong>trailers</strong> can be driven<br />

through barn and farmyard entrances of up to<br />

9.71 ft / 2.96 m in height. (Not available with<br />

an automatic loading system or for<br />

<strong>trailers</strong> with 3 loading<br />

rotors)

Drawbar systems<br />

The <strong>silage</strong> <strong>trailers</strong> can be fitted with a raised or lowered<br />

hitch. A lowered hitch puts more load on the<br />

front axle. This is an advantage when travelling on<br />

inclines and when passing over the horizontal silo.<br />

The standard drawbar is a pivoting drawbar with two<br />

double-acting cylinders (and optionally, a drawbar<br />

buffer). The trailer can pass over the horizontal silo<br />

with a clearance of 2.13 ft / 65 cm. Permitted drawbar<br />

load: 3307 lbs / 1,500 kg.<br />

The cables and hose lines are cleanly finished to<br />

ensure unhindered work. A pivotable support leg<br />

avoids troublesome cranking when attaching or<br />

removing the trailer without hampering the<br />

collection of swath.<br />

9

Transmission<br />

Unique drive line<br />

Drive elements that are used<br />

on mountain terrain must meet<br />

high standards. A high torque is<br />

a special feature of <strong>Pöttinger</strong><br />

drive technology. In the new<br />

<strong>Pöttinger</strong> Test Centre (TIZ) the<br />

drive elements are tested<br />

according to the most demanding<br />

working conditions possible.<br />

Putting it through its paces<br />

The performance of the drive elements is tested in the transmission<br />

test. The operating loads on the transmission chain<br />

are simulated. Transmission performance of up to 340 hp<br />

(250 kW) and torques of up to 5,000 Nm can be achieved<br />

independently of revs.<br />

10<br />

Loading rotor<br />

transmission<br />

The loading rotor transmission<br />

is protected and<br />

on the right-hand side of<br />

the trailer.<br />

The drive shaft is secured<br />

with a cam clutch<br />

coupling with 1,200 Nm.<br />

Two sturdy angular gear<br />

units transmit the power<br />

to the loading rotors.

The scraper floor<br />

transmission<br />

is positioned on the side<br />

and is driven by the tractor<br />

hydraulics.<br />

The speed can be freely<br />

controlled from the<br />

operating console.<br />

Rotor transmission<br />

The rotor is driven via a<br />

simple roller chain<br />

(1 1/2 inches) with<br />

automatic chuck.<br />

Inlet gear<br />

The robust, spiral toothed gear is ideally<br />

designed. The drive line leads from a single-row<br />

high-performance roller chain to the loading rotor<br />

and then on to the pickup.<br />

Automatic chain<br />

lubrication<br />

The transmission chains<br />

of the rotors and pickup<br />

are automatically lubricated<br />

when the pickup is<br />

elevated.<br />

Drive shaft<br />

The FORO <strong>silage</strong> <strong>trailers</strong><br />

are driven by a one-way<br />

wide-angle drive shaft<br />

(p.t.o. shaft speed<br />

1,000 rpm.). The inte gra -<br />

ted cam clutch coupling<br />

becomes active immediately<br />

if over loading<br />

occurs. After speed has<br />

been reduced the coup -<br />

ling restores the original<br />

drive line.<br />

Cam clutch coupling<br />

The torque is 1,400 Nm.<br />

The drive shaft shuts<br />

itself off if this value is<br />

exceeded. This system<br />

protects the entire<br />

transmission.<br />

11

Pickup<br />

Clean separation of forage from dirt<br />

High driving speeds necessitate<br />

a reliable and powerful<br />

pickup. Only a clean<br />

crop can guarantee a<br />

trouble-free fermentation<br />

process and <strong>silage</strong> that is<br />

easy to digest. Optimum<br />

ground hugging and protective<br />

forage collection and<br />

transfer have been tested in<br />

practice for many years at<br />

<strong>Pöttinger</strong>.<br />

The result: a unique pickup<br />

with sophisticated details.<br />

12<br />

The wide pickup delivers incredible cropping performance even with heavy or<br />

irregular swaths.<br />

The pickup has six rows of tines with super “C” steel tines. The central metal<br />

support disc provides high stability. The narrow tine spacing means that the<br />

forage is collected safely even at high driving speeds.<br />

Transfer plates separate the dirt from the forage. This protects the cutting unit.<br />

The scrapers are bolted four times in order to ensure high stability.<br />

<br />

Two-way tine control<br />

<br />

<br />

The pickup is controlled using two cam tracks made from steel with a solid<br />

centre . A control cap and a service cap are integrated into the housing. The<br />

control rollers, two-row, permanently lubricated groove bearings<br />

(diameter: 1.57” / 40 mm), are sturdy and designed for large amounts of forage.<br />

The pickup tines are swept back to prevent damage to turf, the throwing up<br />

of soil and unnecessary wear on the tines.<br />

Pickup width: 6.07 ft / 1.85 m (DIN 5.84 ft / 1.78 m)<br />

<br />

<br />

<br />

The pickup is lifted up<br />

hydraulically using two<br />

lifting cylinders (D-type<br />

<strong>trailers</strong> have automatic<br />

shutoff).<br />

The pickup can be<br />

adjusted to several<br />

heights – it is easy to<br />

modify the pickup for<br />

different forage<br />

conditions.

Perfect ground hugging<br />

<br />

<br />

Protects turf by hugging the ground. The <strong>FARO</strong> <strong>silage</strong> trailer has heightadjustable<br />

jockey wheels on both sides which are placed in an optimal<br />

position for tine contact. The wheels sweep the ground on the same line<br />

as the tines and guide the pickup perfectly through each hollow. The pickup<br />

tines are swept back to prevent damage to turf, the throwing up of soil<br />

and unnecessary wear on the tines.<br />

The pneumatic jockey wheels (15x6.0-6) are standard. In addition to this,<br />

auxiliary springs on both sides ensure a low, ground-protecting bearing<br />

pressure. Optional: steered jockey wheels (16x6.5-8) for 3500 / 4000 / 4500<br />

A height-adjustable baffle plate with a standard swath roller ensures perfect<br />

forage flow even when loading is fast and the crop is short and wet.<br />

13

The structure of the crop<br />

greatly determines its<br />

digestibility. The rotor must<br />

therefore be able to cut and<br />

compress the forage well<br />

even with a high flow.<br />

Rotomatic is at the heart<br />

of <strong>FARO</strong> <strong>silage</strong> <strong>trailers</strong>:<br />

powerful, robust and<br />

capable.<br />

14<br />

Roto matic<br />

Loading system<br />

The heart of the trailer<br />

The Rotomatic loading rotor has a diameter of 30.31”/ 770 mm and consists of<br />

7 rows of tines. The teeth are arranged in a helix in order to ensure jolt-free and<br />

smooth loading without torque peaks. Compaction area: 4.69 ft / 1.43 m.<br />

The hardened feed tines are made of fine-grain boron steel that is<br />

0.24”/ 6 mm thick.<br />

They ensure the continuous collection of the crop and the smooth preliminary<br />

pressing of the forage. This causes the loading chamber to be filled evenly.<br />

The Rotomatic loading rotor is located in a frame with self-aligning roller<br />

bearings. Minimal maintenance is required. The automatic chain lubrication for<br />

the main transmission and pickup is standard to the range.<br />

<br />

<br />

<strong>Pöttinger</strong> optimises the transfer of the <strong>silage</strong> crop from the rotor to the scraper<br />

floor by means of a shortened active feed height . An important detail for the<br />

user: this reduces horsepower by up to 15%.<br />

The scrapers are 0.47”/ 12 mm wide with a special layout<br />

The scrapers are positioned and bolted into place individually. Placing the scrapers<br />

at an ideal distance from the rotor teeth reduces energy demand. The scrapers<br />

have a large surface area, which prevents the forage from being crushed.<br />

<br />

Maintenance made easy<br />

<br />

The tine rings are clipped into the inner drum.<br />

Each ring can be replaced individually.

A precise and consistent<br />

cut is the basis for the best<br />

<strong>silage</strong> quality. The exceptional<br />

cutting quality of<br />

<strong>Pöttinger</strong> <strong>silage</strong> <strong>trailers</strong> has<br />

been confirmed in independent<br />

test reports.<br />

A unique solution at<br />

<strong>Pöttinger</strong>: the pivotable<br />

knife bank is exceptionally<br />

user-friendly.<br />

16<br />

Easy Move<br />

Short cut for productive forage<br />

Awarded the DLG silver<br />

medal<br />

… the cutting unit<br />

Knife maintenance made easy<br />

This unique-to-the-market pivotable knife bank is an option to the range. You can<br />

change the knives standing up.<br />

<br />

<br />

The original with a<br />

serrated knife<br />

<br />

The knives are made of hardened steel. The serration<br />

on one side ensures a precise cut even if the knife<br />

edge is dulled. The forage is always cut cleanly and<br />

not torn apart. The knife shape provides a continuous<br />

cut along the entire length.<br />

You can’t get simpler than this<br />

Easy lowering of knife bank by pressing the<br />

button on the left-hand side of the trailer.<br />

Undo the bolting mechanism bolts and<br />

pivot the bank out to the side.<br />

Release the knives using the lever.<br />

Excellent cutting quality:<br />

54 tine rings guide the forage over the 27 knives –<br />

2” / 51 mm forced cut for <strong>FARO</strong> 3500 / 4000 /<br />

4500.

Knife security<br />

A reassuring detail<br />

Time and cost pressures<br />

make machine idle time an<br />

expensive business. Foreign<br />

bodies are a danger to the<br />

most important element of<br />

the machine – the cutting<br />

unit. <strong>Pöttinger</strong> protects the<br />

heart of the <strong>silage</strong> trailer<br />

with an innovative setup –<br />

patented foreign body security.<br />

Each knife is individually<br />

secured.<br />

Functionality of the tried and tested knife security:<br />

1. If foreign bodies are picked up, the smaller<br />

pieces fall through baffle plates between the<br />

pickup and the rotor.<br />

2. Larger foreign bodies press the rotor onto the<br />

knife and move it briefly in the direction of<br />

rotation.<br />

3. The trigger roll at the back of the knife is lifted<br />

out of its holder and the knife releases the<br />

foreign body. The resistance is minimal, which<br />

protects the knife!<br />

4. After the foreign body has passed the cutting<br />

unit, the knife springs back to its original<br />

position.<br />

The triggering pressure is independent of the size and point of contact of the foreign body.<br />

17

Loading<br />

Automatic system to help loading (standard on 6300 and 8000)<br />

Users want a high volume<br />

of forage with even proportioning.<br />

In <strong>FARO</strong> <strong>silage</strong><br />

<strong>trailers</strong>, the forage must<br />

already be compacted in the<br />

feed channel. The automatic<br />

loading system (optional)<br />

ensures that the loading<br />

chamber is optimally filled.<br />

Standard for <strong>trailers</strong> with<br />

roof profiles.<br />

Unloading<br />

18<br />

<br />

<br />

The constant force progression when loading without<br />

torque peaks is a feature of the <strong>FARO</strong>. There are two<br />

integrated sensors for monitoring the status of loading.<br />

They check on the loading status and automatically<br />

control the scraper floor accordingly. This protects the<br />

transmission chain.<br />

Sensor on the front panel<br />

Even when loading damp, heavy grass, the crop is not<br />

“mashed” by excessive pressure on the loading rotor.<br />

Sensor on roof section<br />

This sensor measures the load status of the trailer so<br />

that the driver does not have to. This significantly<br />

improves the filling of the loading chamber. The scraper<br />

floor can also be manually controlled.<br />

“Trailer full” signal<br />

When the trailer is full, the pressure on the tailgate<br />

causes the scraper floor to be switched off. This prevents<br />

the trailer from being overloaded.<br />

Load sensing to save power<br />

<strong>Pöttinger</strong> <strong>silage</strong> <strong>trailers</strong> can be fitted with load-sensing equipment. The required<br />

quantity of oil and the pump pressure are measured constantly and adjusted in<br />

line with requirements. This saves up to 20 hp (15 kW).<br />

L-type <strong>trailers</strong><br />

Automatic unloading system:<br />

Sequence control of tailgate and scraper floor.<br />

The wide opening enables quick unloading.

Scraper floor<br />

Reliability for long service<br />

The scraper floor has four<br />

chains. The tempered scraper<br />

bars are separated and offset.<br />

The loading surface is a<br />

pressure-impregnated, durable<br />

wooden floor. The boards are<br />

tongue-in-groove and are<br />

bolted to the frame.<br />

Simple maintenance<br />

The front scraper floor shafts<br />

can be lubricated from the<br />

side of the trailer.<br />

Scraper floor transmission<br />

A heavy duty hydraulic motor<br />

provides the transmission. The<br />

speed can be freely controlled.<br />

The scraper floor can also be<br />

driven by a two-stage motor<br />

(optional).<br />

19

Unloading<br />

A uniform carpet of forage<br />

is a prerequisite for perfect<br />

compaction at the silo. The<br />

automatic unloading system<br />

for proportioning <strong>trailers</strong><br />

takes the stress off the driver<br />

and protects the machine.<br />

20<br />

Proportioning <strong>trailers</strong> (D-type)<br />

Automatic unloading system – for smooth distribution<br />

A pressure sensor in the loading rotor suspension measures the pressure created<br />

when the loading rotor is unloading. If the limit is reached the scraper floor automatically<br />

switches off. When the pressure on the loading rotor falls, the scraper<br />

floor switches back on. Trouble-free unloading of forage. This reduces the driver's<br />

workload.<br />

The cam clutch coupling torque is 1,200 Nm.<br />

Loading rotors – distributed precisely<br />

The trademarks of the oversized loading rotors are the aggressive tines. The<br />

loading rotors enable smooth unloading. The enclosed six-edge design prevents<br />

the forage from winding round them.<br />

The loading rotors can be dismantled.<br />

D-type <strong>trailers</strong> (proportioning steps)<br />

<br />

Normal proportioning<br />

with wide open tailgate<br />

for quickly unloading<br />

large crop quantities.<br />

The central segment <br />

is fixed at the tailgate.<br />

<br />

Fine proportioning for<br />

measured unloading at<br />

the horizontal silo. The<br />

central segment of<br />

the tailgate is fixed at<br />

the body.<br />

Universal tailgate<br />

The tailgate is closed hydraulically from inside the<br />

tractor. The tailgate closes automatically. There is no<br />

mechanical locking mechanism.<br />

<br />

Additional fine proportioning<br />

setting<br />

The tailgate can be<br />

changed by adjusting<br />

the cylinders on the<br />

bar so that it can only<br />

be opened from the<br />

bottom.<br />

If required: third<br />

unloading rotor for fine<br />

proportioning on the<br />

cross conveyor belt or<br />

particularly precise<br />

dispersal at the horizontal<br />

silo. The loading<br />

rotors can be removed<br />

if required.<br />

Hydraulic cross conveyor<br />

belt (only with<br />

3 rotors) – optional. The<br />

forage is precisely proportioned<br />

on the cross<br />

conveyor belt and can<br />

be unloaded to the left<br />

or to the right.

Chassis<br />

Exceptional handling<br />

Increasing load volumes<br />

and transport speeds<br />

necessitate robust, groundprotecting<br />

chassis.<br />

<strong>Pöttinger</strong> has made great<br />

efforts in this area. The<br />

answer comes in the form of<br />

wide-tread tyres and a<br />

stable chassis.<br />

22<br />

Spring-suspension tandem axles<br />

The compound suspension optimally distributes the ground pressure over both<br />

axles. When the trailer travels over large bumps in the ground, the force is distributed<br />

over both axles rather than being absorbed by the limit stops. Huge leaf<br />

springs (9 springs) provide the necessary safety. Excellent performance in fields,<br />

on roads, and when entering the horizontal silo. Spring spacing: 43.31” / 1,100 mm.<br />

Pneumatic brakes<br />

The 4-wheel pneumatic brake system with automatic load-dependent braking<br />

system (ALB) controls ensures safe braking at high speed and with heavy loads.<br />

Hydraulic braking<br />

Hydraulic brakes can be supplied for some<br />

countries.<br />

Jockey steering axle (optional)<br />

Protects the tyres and turf. Reduced traction<br />

when cornering. When reversing or driving<br />

at speed, the steering axle can be locked<br />

into place using a separate hydraulic fitting.

You have the<br />

choice …<br />

<strong>Pöttinger</strong> offers you a selection of tyres to suit your<br />

requirements.<br />

Vredestein<br />

FLOTATION+<br />

500/50-17<br />

For 13.3 t / 12 t total permissible<br />

weight at 24.86mph / 40km/h.<br />

Standard tyres<br />

Vredestein<br />

FLOTATION PRO<br />

560/45 R 22,5<br />

620/40 R 22,5<br />

For 13.2 t / 12 t total permissible<br />

weight at 37.28 mph / 60 km/h.<br />

23

24<br />

<strong>EUROPROFI</strong> – <strong>silage</strong> <strong>trailers</strong> for pro<br />

Silage trailer technology is constantly evolving. The new generation<br />

of <strong>trailers</strong> is considerable more powerful. The <strong>EUROPROFI</strong><br />

represents an excellent development for modern operators who<br />

value comfort and power. It is suitable for tractorsfrom 100 to<br />

180 hp or 74 to 132 kW.

fessional use<br />

Pages 26 – 27<br />

Construction / body / drawbar<br />

Pages 28 – 29<br />

Transmission<br />

Pages 30 – 31<br />

Pickup<br />

Pages 32 – 33<br />

Loading system<br />

Pages 34 – 35<br />

Cutting unit<br />

Pages 36 – 37<br />

Loading and scraper floor<br />

Pages 38 – 39<br />

Unloading<br />

Pages 40 – 41<br />

Chassis and tyres<br />

Pages 42 – 43<br />

Control pads<br />

Pages 44 – 45<br />

Fitting variants<br />

Pages 46 – 47<br />

Technical data<br />

Page 48<br />

Imprint<br />

25

Construction<br />

The details count<br />

The professional user<br />

demands high quality for<br />

long-term use. <strong>Pöttinger</strong><br />

responds to this requirement<br />

with sophisticated technology,<br />

top-quality materials<br />

and precise workmanship.<br />

This market leader has set<br />

new standards for <strong>silage</strong><br />

trailer technology with<br />

high-quality work and a<br />

modern design.<br />

The resistant cathodic electrodip<br />

powder coating finish<br />

is a real mark of quality.<br />

Powder coat paint proves<br />

itself in use thanks to its<br />

elasticity and durability.<br />

Automobile paint quality in<br />

agricultural technology!<br />

26<br />

Body<br />

The chassis of the <strong>EUROPROFI</strong> <strong>silage</strong> trailer<br />

range is a bolted frame construction of<br />

C 220x70x50x5QSTE fine grain steel. The<br />

<br />

closed steel body is constructed to take<br />

heavy loads. Sturdy platform profiles, closely<br />

spaced, provide high stability. The straight<br />

side columns are bolted to the frame, not welded. What makes it special: fine-thread<br />

fitting for high stability.<br />

Profile panels with smooth sides and a special coating ensure that the forage<br />

is unloaded completely and smoothly.<br />

<br />

<br />

The access ladder provides easy access to the<br />

interior of the trailer. This is an optional feature<br />

for L-type <strong>trailers</strong>.<br />

The roof section can<br />

be folded inwards.<br />

The extension frames<br />

can be lifted up<br />

4.72” / 12 cm (EURO-<br />

PROFI 4500 / 5000).<br />

Taut roof ropes prevent<br />

crop loss when loading<br />

or transporting the crop. The roof ropes can<br />

be replaced with roof profiles for dry<br />

forage or straw. The robust profiles provide<br />

better crop compaction. This can assist in<br />

reducing transport costs.<br />

The <strong>EUROPROFI</strong> 4000 can also be delivered<br />

with a dry forage extension. When this is<br />

hydraulically folded away, the <strong>trailers</strong> can<br />

be driven through barn and farmyard<br />

entrances of up to 10.11 ft / 3.08 m in height.<br />

Inner width of body: 6.89 ft / 2.10 m

Drawbar Systems<br />

The <strong>silage</strong> <strong>trailers</strong> can be fitted with a raised or lowered hitch. A lowered hitch puts more load on<br />

the front axle. This is an advantage when travelling on inclines and when passing over the<br />

horizontal silo.<br />

The standard drawbar is a pivoting drawbar with two double-acting cylinders (and optionally,<br />

a drawbar buffer). The trailer can pass over the horizontal silo with a clearance of 2.13 ft / 65 cm.<br />

Permitted drawbar load: 4,409 lbs / 2,000 kg<br />

The cables and hose lines are cleanly finished to ensure unhindered work.<br />

A pivotable support leg avoids troublesome cranking when attaching or removing the trailer<br />

without hampering the collection of swath.<br />

The Scharmüller drawbar<br />

ball coupling contributes to<br />

increased ease of driving.<br />

27

Transmission<br />

Unique drive line<br />

Drive elements that are used<br />

on mountain terrain and with<br />

powerful tractors must meet<br />

high standards. A high torque is<br />

a special feature of <strong>Pöttinger</strong><br />

drive technology. In the new<br />

<strong>Pöttinger</strong> Test Centre (TIZ) the<br />

drive elements are tested<br />

according to the most demanding<br />

working conditions pos -<br />

sible. Drive line for tractors<br />

from 100 to 180 hp<br />

(74 to 132 kW).<br />

Putting it through its paces<br />

The performance of the drive elements is tested in the transmission<br />

test. The operating loads on the transmission chain<br />

are simulated. Transmission performance of up to 340 hp<br />

(250 kW) and torques of up to 5,000 Nm can be achieved<br />

independently of revs.<br />

28<br />

Loading rotor<br />

transmission<br />

The loading rotor transmission<br />

is protected and<br />

on the right-hand side of<br />

the trailer.<br />

The drive shaft is<br />

secured with a cam<br />

clutch coupling with<br />

1,200 Nm.<br />

Two sturdy angular gear<br />

units transmit the power<br />

to the loading rotors.

The scraper floor<br />

transmission<br />

is positioned on the side<br />

and is driven by the<br />

tractor hydraulics.<br />

The speed can be freely<br />

controlled from the<br />

operating console.<br />

Rotor transmission<br />

The rotor is driven via a<br />

simple roller chain<br />

(1 1/2 inches) with<br />

automatic chuck.<br />

Automatic chain<br />

lubrication<br />

The transmission chains<br />

are automatically lubricated<br />

when the pickup is<br />

elevated.<br />

In the case of proportioning<br />

<strong>trailers</strong> (D-type <strong>trailers</strong>)<br />

this is not the case.<br />

Inlet gear<br />

The robust, spiraltoothed<br />

gear is ideally<br />

designed. The drive line<br />

leads from a single-row<br />

high-performance roller<br />

chain to the loading<br />

rotor and then on to the<br />

pickup.<br />

Drive shaft<br />

The <strong>EUROPROFI</strong> <strong>silage</strong><br />

<strong>trailers</strong> are driven by a<br />

one-way wide-angle<br />

drive shaft (p.t.o. shaft<br />

speed 1,000 rpm.). The<br />

integrated cam clutch<br />

coupling becomes active<br />

immediately if overload<br />

occurs. After speed has<br />

been reduced the coup -<br />

ling restores the original<br />

drive line.<br />

Cam clutch coupling<br />

The torque is 1,600 Nm.<br />

The drive shaft shuts<br />

itself off if this safety<br />

limit is exceeded. This<br />

system protects the<br />

entire transmission.<br />

29

Pendular pickup<br />

Clean separation of forage from dirt<br />

High driving speeds<br />

necessitate a reliable and<br />

powerful pickup. Only a<br />

clean crop can guarantee a<br />

trouble-free fermentation<br />

process and <strong>silage</strong> that is<br />

easy to digest. Optimum<br />

ground hugging and protective<br />

forage collection and<br />

transfer have been tested<br />

numerous times by<br />

<strong>Pöttinger</strong>.<br />

The result: a pickup with<br />

unique ground hugging.<br />

30<br />

The wide pickup delivers incredible cropping performance even with heavy or<br />

irregular swaths.<br />

The pickup has six rows of tines with super “C” steel tines. The central metal<br />

support disc provides high stability. The narrow tine spacing means that the<br />

forage is collected safely even at high driving speeds.<br />

Transfer plates separate the dirt from the forage. This protects the cutting unit.<br />

The scrapers are bolted four times in order to ensure high stability.<br />

<br />

Two-way tine control<br />

<br />

<br />

The pickup is controlled using two cam tracks made from steel with a solid<br />

centre . A control cap and a service cap are integrated into the housing. The<br />

control rollers, two-row, permanently lubricated groove bearings<br />

(diameter: 1.57” / 40 mm), are sturdy and designed for large amounts of forage.<br />

The pickup tines are swept back to prevent damage to turf, the throwing up<br />

of soil and unnecessary wear on the tines.<br />

<br />

<br />

The pickup is lifted up hydraulically using a lifting<br />

cylinder in the case of proportioning <strong>trailers</strong><br />

(D-type <strong>trailers</strong>) with automatic shutoff.<br />

The pickup can be adjusted to several heights –<br />

it is easy to modify the pickup for different forage<br />

conditions.<br />

A spring ensures a low, ground-protecting<br />

bearing pressure.<br />

Pickup width: 6.07 ft / 1.85 m (DIN 5.84 ft / 1.78 m)

Perfect ground hugging<br />

<br />

<br />

<br />

Protects turf by hugging the ground. The <strong>EUROPROFI</strong> <strong>silage</strong> trailer has<br />

height-adjustable jockey wheels on both sides which are placed in<br />

an optimal position for tine contact. The pneumatic jockey wheels<br />

(16x6.5-8) are standard. The wheels sweep the ground on the same line as<br />

the tines and guide the pickup perfectly through each hollow. Steered<br />

jockey tyres enable particularly good cornering.<br />

Swath roller encourages forage flow<br />

A height-adjustable baffle plate with a standard swath roller ensures perfect<br />

forage flow even when loading is fast and the crop is short and wet.<br />

31

The structure of the crop<br />

greatly determines its<br />

digestibility. The rotor must<br />

therefore be able to cut and<br />

compact the forage well<br />

even with a high flow.<br />

Euromatic is at the heart<br />

of <strong>EUROPROFI</strong> <strong>silage</strong><br />

<strong>trailers</strong>: powerful, robust<br />

and capable.<br />

32<br />

Euro matic<br />

Loading system<br />

The heart of the trailer<br />

The Euromatic loading rotor has a diameter of 31.50” / 800 mm and consists of<br />

8 rows of tines. The tines are arranged in a helix in order to ensure jolt-free and<br />

smooth loading without torque peaks. Compaction area: 4.76 ft / 1.45 m<br />

The feed tines ensure the continuous transfer of the crop and smooth preliminary<br />

compaction of the forage. This ensures optimum filling of the loading chamber.<br />

The Euromatic loading rotor is located in a frame with self-aligning roller<br />

bearings. This means that the bearings cannot be distorted.<br />

Hardened feed tines<br />

The feed tines are made of hardened fine-grain<br />

boron steel.<br />

Wide scrapers with a special layout<br />

The scrapers are positioned and bolted into place<br />

individually. Placing the scrapers at an ideal distance<br />

from the rotor tines reduces energy demand. The<br />

scrapers have a large surface area, which prevents<br />

the forage from being crushed.<br />

Maintenance made easy<br />

The tine rings are clipped into the inner drum.<br />

Each ring can be replaced individually.

Cost-effective horsepower<br />

The active feed height of the rotor is an<br />

important detail for the user: the relationship<br />

between loading performance and<br />

horsepower is particularly good in the case<br />

of the <strong>EUROPROFI</strong>.<br />

33

A precise and consistent<br />

cut is the basis for the best<br />

<strong>silage</strong> quality. The exceptional<br />

cutting quality of<br />

<strong>Pöttinger</strong> <strong>silage</strong> <strong>trailers</strong><br />

has been confirmed in<br />

independent test reports.<br />

A unique solution at<br />

<strong>Pöttinger</strong>: the pivotable<br />

knife bank is exceptionally<br />

user-friendly.<br />

34<br />

Easy Move<br />

Short cut for productive forage<br />

Awarded the DLG silver<br />

medal<br />

… the cutting unit<br />

Knife maintenance made easy<br />

This unique-to-the-market pivotable knife bank is standard to the range. You can<br />

change the knives comfortably.<br />

<br />

<br />

The original with a serrated<br />

knife<br />

The knives are made of hardened steel. The serration<br />

on one side ensures a precise cut even if the knife<br />

edge is dulled. The forage is always cut cleanly and<br />

not torn apart – pull-back cutting action. The blade<br />

shape provides a continuous sliding cut.<br />

<br />

You can’t get simpler than this<br />

Easy lowering of knife bank by pressing the<br />

button on the left-hand side of the trailer.<br />

Undo the bolting mechanism bolts and<br />

pivot the bank out to the side.<br />

Release the knives using the lever.<br />

Excellent cutting quality:<br />

62 tine rings guide the forage evenly over the<br />

31 knives – forced cut.

Knife security<br />

A reassuring detail<br />

Time and cost pressures<br />

make machine idle time an<br />

expensive business.<br />

Foreign bodies are a danger<br />

to the most important<br />

element of the trailer –<br />

the cutting unit. <strong>Pöttinger</strong><br />

protects the heart of the<br />

<strong>silage</strong> trailer with an<br />

innovative setup –<br />

patented foreign body<br />

security. Each knife is<br />

individually secured.<br />

Functionality of the tried and tested knife security:<br />

1. If foreign bodies are picked up, the smaller<br />

pieces fall through baffle plates between the<br />

pickup and the rotor.<br />

2. Larger foreign bodies press the rotor onto the<br />

knife and move it briefly in the direction of<br />

rotation.<br />

3. The trigger roll at the back of the knife is lifted<br />

out of its holder and the knife releases the<br />

foreign body. The resistance is minimal, which<br />

protects the knife!<br />

4. After the foreign body has passed the cutting<br />

unit, the knife springs back to its original<br />

position.<br />

The triggering pressure is independent of the size and point of contact of the foreign body.<br />

35

Loading<br />

Automatic system to help loading<br />

Users want a high volume<br />

of forage with even proportioning.<br />

In <strong>EUROPROFI</strong><br />

<strong>silage</strong> <strong>trailers</strong>, the forage<br />

must already be compacted<br />

in the feed channel. The<br />

automatic loading system<br />

(optional) ensures that the<br />

loading chamber is optimally<br />

filled.<br />

36<br />

Load sensing to save power<br />

Unloading L-type <strong>trailers</strong><br />

<br />

<br />

The constant force progression when loading without<br />

torque peaks is a feature of the <strong>EUROPROFI</strong>. There are<br />

two integrated sensors for monitoring the status of<br />

loading. They check on the loading status and automatically<br />

control the scraper floor accordingly. This protects<br />

the transmission chain.<br />

Sensor on the front panel<br />

Even when loading damp, heavy grass, the crop is not<br />

“mashed” by excessive pressure on the loading rotor.<br />

Sensor on roof section<br />

This sensor measures the load status of the trailer so<br />

that the driver does not have to. This significantly<br />

improves the filling of the loading chamber. The scraper<br />

floor can also be manually controlled.<br />

“Trailer full” signal<br />

When the trailer is full, the pressure on the tailgate<br />

causes the scraper floor to be switched off. This prevents<br />

the trailer from being overloaded.<br />

<strong>Pöttinger</strong> <strong>silage</strong> <strong>trailers</strong> can be fitted with load-sensing equipment. The required<br />

quantity of oil and the pump pressure are measured constantly and adjusted in<br />

line with requirements. This saves up to 20 hp (15 kW).<br />

Automatic unloading system:<br />

Sequence control of tailgate and scraper floor.<br />

The wide opening enables easy unloading.

Scraper floor<br />

Reliability for long service<br />

The scraper floor has four<br />

chains. The tempered scraper<br />

bars are separated and offset.<br />

The loading surface is a<br />

pressure-impregnated, durable<br />

wooden floor. The boards are<br />

tongue-in-groove and are<br />

bolted to the frame.<br />

Simple maintenance<br />

The front scraper floor shafts<br />

can be lubricated from the<br />

side of the trailer.<br />

Scraper floor transmission<br />

A heavy duty hydraulic motor<br />

provides the transmission. The<br />

speed can be freely controlled.<br />

The scraper floor can also be<br />

driven by a two-stage motor<br />

(optional).<br />

37

Unloading Proportioning <strong>trailers</strong> (D-type)<br />

A uniform carpet of forage<br />

is a prerequisite for perfect<br />

compaction. The automatic<br />

unloading system for proportioning<br />

<strong>trailers</strong> takes the<br />

stress off the driver and protects<br />

the machine.<br />

D-type <strong>trailers</strong> (proportioning steps)<br />

Normal proportioning<br />

with wide open tailgate<br />

for quickly unloading<br />

large crop quantities.<br />

The central segment <br />

is fixed at the tailgate.<br />

38<br />

<br />

Automatic unloading system – for smooth distribution<br />

A pressure sensor in the unloading rotor suspension measures the pressure<br />

created when the loading rotor is unloading. If the limit is reached the scraper<br />

floor automatically switches off. When the pressure on the unloading rotor falls,<br />

the scraper floor switches back on. Trouble-free unloading of forage. This reduces<br />

the driver's work load.<br />

The cam clutch coupling torque is 1,200 Nm.<br />

Unloading rotors – distributed precisely<br />

The trademarks of the oversized unloading rotors are the aggressive tines. The<br />

unloading rotors enable smooth unloading. The enclosed six-edge design<br />

prevents the forage from winding round them.<br />

The unloading rotors can be dismantled.<br />

Universal tailgate<br />

The tailgate is closed and locked hydraulically from inside the tractor. There is no<br />

mechanical locking mechanism.<br />

The universal tailgate enables several proportioning options.<br />

<br />

Fine proportioning for<br />

measured unloading at<br />

the horizontal silo. The<br />

central segment of<br />

the tailgate is fixed at<br />

the body.<br />

<br />

Additional fine proportioning<br />

setting<br />

The tailgate can be<br />

changed by adjusting<br />

the cylinders on the<br />

bar so that it can only<br />

be opened from the<br />

bottom.<br />

If required: third<br />

unloading rotor for fine<br />

proportioning on the<br />

cross conveyor belt or<br />

particularly precise dispersal<br />

at the horizontal<br />

silo. The loading rotors<br />

can be removed if<br />

required.<br />

Hydraulic cross conveyor<br />

belt (only with<br />

3 rotors) – optional. The<br />

forage is precisely proportioned<br />

on the cross<br />

conveyor belt and can<br />

be unloaded to the left<br />

or to the right.

Chassis<br />

Exceptional handling<br />

Increasing load volumes<br />

and transport speeds necessitate<br />

robust, groundprotecting<br />

chassis.<br />

<strong>Pöttinger</strong> has made great<br />

efforts in this area. The<br />

answer comes in the form of<br />

wide-tread tyres and a<br />

stable chassis.<br />

40<br />

Spring suspension tandem axle for 12 or 17 t total weight<br />

The compound suspension optimally distributes the ground pressure over both<br />

axles. When the trailer travels over large bumps in the ground, the force is distributed<br />

over both axles rather than being absorbed by the limit stops. Huge leaf<br />

springs (9 springs) provide the necessary safety. Excellent performance in fields,<br />

on roads, and when entering the drive-in silo. Spring spacing: 43.31” / 1,100 mm.<br />

Pneumatic braking<br />

The 4-wheel pneumatic<br />

brake with automatic<br />

load-dependent braking<br />

system (ALB) controls<br />

ensures safe braking at<br />

high speed and with<br />

heavy loads.<br />

Hydraulic brakes<br />

Hydraulic brakes can be<br />

supplied for some<br />

countries.<br />

18.7 t / 17 t axle (optional)<br />

The axle has parabolic suspension and 560/45R 22.5 tyres.<br />

The jockey steering axle (for 18.7 t / 17 t total weight) protects the tyres and the<br />

turf. Reduced traction<br />

when cornering. When<br />

reversing or driving at<br />

speed, the steering axle<br />

can be locked into place<br />

using a separate<br />

hydraulic fitting.

You have the choice …<br />

<strong>Pöttinger</strong> offers you a selection of tyres to suit your requirements.<br />

Vredestein<br />

FLOTATION PRO<br />

560/45 R 22.5<br />

For 13.2 t / 12 t or 18.7 t / 17 t total<br />

permissible weight at 37.28 mph /<br />

60 km/h.<br />

Standard tyres<br />

Vredestein<br />

FLOTATION PRO<br />

620/40 R 22,5<br />

For 13.2 t / 12 t or 18.7 t / 17 t total<br />

permissible weight at 37.28 mph /<br />

60 km/h.<br />

Option<br />

Vredestein<br />

FLOTATION+<br />

500/50-17<br />

For axles up to 13.2 t / 12 t total<br />

permissible weight at 24.86 mph /<br />

40 km/h.<br />

Less price<br />

41

Exceptionally user-friendly<br />

This is a benefit that every<br />

driver appreciates during<br />

long days of cropping. All<br />

functions can be carried out<br />

from the driver’s seat.<br />

<strong>Pöttinger</strong>’s future-safe<br />

control concept goes one<br />

step further: the ISOBUS<br />

system is integrated into the<br />

range. The possibility of<br />

controlling several<br />

machines from one tractor<br />

terminal is now a reality.<br />

<strong>FARO</strong> <strong>silage</strong> <strong>trailers</strong> and<br />

<strong>EUROPROFI</strong> L-type <strong>trailers</strong><br />

have DIRECT CONTROL.<br />

42<br />

<strong>EUROPROFI</strong> <strong>silage</strong> <strong>trailers</strong><br />

with proportioning systems<br />

have POWER CONTROL<br />

control pads.<br />

DIRECT CONTROL<br />

User-friendly electro-hydraulic controls for all <strong>silage</strong> trailer functions.<br />

Standard: Controls for:<br />

- Scraper floor speed<br />

- Pickup<br />

- “Trailer full” signal<br />

- Pivoting drawbar<br />

- Tailgate<br />

- Pivoting of cutting unit<br />

- Scraper floor<br />

- Automatic unloading system<br />

Loading function<br />

Unloading function<br />

Optional: controls for:<br />

- Dry forage extension<br />

Loading and unloading function

POWER CONTROL – ISOBUS-compatible<br />

All automatic and monitoring functions can be controlled directly from the pad.<br />

Error messages are also displayed. Data logging is integrated and can be transmitted<br />

to the PC via a PC interface.<br />

Loading pad<br />

Automatic loading system<br />

Load scraper floor<br />

Knife bank in<br />

Knife bank out<br />

Unloading pad<br />

Automatic unloading system<br />

(all functions)<br />

Scraper floor two-stage<br />

motor<br />

Fast / slow<br />

Loading rotors on<br />

Cross conveyor belt on<br />

Scraper floor forward<br />

Steering axle<br />

Tailgate open<br />

Tailgate closed<br />

Stop<br />

Pickup up<br />

Pickup down<br />

Pivoting drawbar up<br />

Pivoting drawbar down<br />

On / off<br />

Set: Hour / load counter<br />

Loading chamber lighting<br />

Feed additive<br />

Diagnostic system<br />

Pivoted cutting unit alert<br />

Online demo version: www.poettinger.at/powercontrol<br />

ISO CONTROL<br />

ISOBUS for controlling<br />

various machines from<br />

one tractor terminal.<br />

The advantages for the<br />

farmer at a glance:<br />

Clearly arranged operation of<br />

all machines from one terminal,<br />

monitoring of machine<br />

data, automatisation of work<br />

processes and efficient data<br />

logging.<br />

43

Technical data<br />

<strong>FARO</strong><br />

<strong>EUROPROFI</strong><br />

44<br />

Capacity<br />

ft 3 / m 3<br />

Capacity<br />

ft 3 / m 3<br />

Volume (DIN)<br />

ft 3 / m 3<br />

Volume (DIN)<br />

ft 3 / m 3<br />

Pickup width<br />

(ft/m) / DIN (ft/m)<br />

Pickup width<br />

(ft/m) / DIN (ft/m)<br />

Number of<br />

knives<br />

Number of<br />

knives<br />

Knife spacing<br />

in inches/mm<br />

Knife spacing<br />

in inches / mm<br />

Platform height<br />

in inches/mm<br />

3500 L 1,236 / 35 777 / 22.0 6.07’/1.85 / 5.81’/1.77 27 2.01 / 51 49.21 / 1,250<br />

3500 D 1,236 / 35 759 / 21.5 6.07’/1.85 / 5.81’/1.77 27 2.01 / 51 49.21 / 1,250<br />

4000 L 1,413 / 40 901 / 25.5 6.07’/1.85 / 5.81’/1.77 27 2.01 / 51 49.21 / 1,250<br />

4000 D 1,413 / 40 883 / 25.0 6.07’/1.85 / 5.81’/1.77 27 2.01 / 51 49.21 / 1,250<br />

4500 L 1,589 / 45 1,007 / 28.5 6.07’/1.85 / 5.81’/1.77 27 2.01 / 51 49.21 / 1,250<br />

6300 L 2,225 / 63 1,360 / 38.5 6.07’/1.85 / 5.81’/1.77 6 8.27 / 210 49.21 / 1,250<br />

8000 L 2,825 / 80 1,625 / 46.0 6.07’/1.85 / 5.81’/1.77 6 8.27 / 210 49.21 / 1,250<br />

Platform height<br />

in inches / mm<br />

4000 L 1,413 / 40 901 / 25.5 6.07’/1.85 / 5.81’/1.77 31 1.77 / 45 53.94 / 1,370<br />

4000 D 1,413 / 40 883 / 25.0 6.07’/1.85 / 5.81’/1.77 31 1.77 / 45 53.94 / 1,370<br />

4500 L 1,589 / 45 1,007 / 28.5 6.07’/1.85 / 5.81’/1.77 31 1.77 / 45 53.94 / 1,370<br />

4500 D 1,589 / 45 989 / 28.0 6.07’/1.85 / 5.81’/1.77 31 1.77 / 45 53.94 / 1,370<br />

5000 L 1,766 / 50 1,112 / 31.5 6.07’/1.85 / 5.81’/1.77 31 1.77 / 45 53.94 / 1,370<br />

5000 D 1,766 / 50 1,095 / 31.0 6.07’/1.85 / 5.81’/1.77 31 1.77 / 45 53.94 / 1,370<br />

All information is provided without obligation.<br />

Fittings can vary from country to country.

Loading chamber<br />

area in inches / m<br />

Loading chamber<br />

area in inches/mm<br />

Length in<br />

inches / mm<br />

Length in<br />

inches / mm<br />

Width in<br />

inches / mm<br />

Width in<br />

inches / mm<br />

Raised height in<br />

inches / mm<br />

Raised height in<br />

inches / mm<br />

Lowered height in<br />

inches / mm<br />

Lowered height in<br />

inches / mm<br />

Weight with<br />

standard axle<br />

lbs / kg<br />

196.85 x 82.68 / 5.0 x 2.1 306.30 / 7,780 95.28 / 2,420 140.15 / 3,560 116.54 / 2,960 8,818 / 4,000<br />

187.01 x 82.68 / 4.75 x 2.1 324.80 / 8,250 95.28 / 2,420 140.15 / 3,560 116.54 / 2,960 9,811 / 4,450<br />

223.62 x 82.68 / 5.68 x 2.1 333.07 / 8,460 95.28 / 2,420 140.15 / 3,560 116.54 / 2,960 9,149 / 4150<br />

213.78 x 82.68 / 5.43 x 2.1 351.57 / 8,930 95.28 / 2,420 140.15 / 3,560 116.54 / 2,960 10,141 / 4,600<br />

250.39 x 82.68 / 6.36 x 2.1 359.84 / 9140 95.26 / 2,420 140.15 / 3,560 – 10,915 / 4,950<br />

304.33 x 82.68 / 7.73 x 2.1 413.39 / 10,500 95.26 / 2,420 148.03 / 3,760 – 10,913 / 4,950<br />

304.33 x 82.68 / 7.73 x 2.1 424.80 / 10,790 98.43 / 2,500 156.69 / 3,980 – 11,574 / 5,250<br />

Weight with<br />

standard axle<br />

lbs / kg<br />

223.62 x 82.68 / 5.68 x 2.1 333.07 / 8,460 96.46 / 2,450 144.88 / 3,680 121.26 / 3,080 12,348 / 5,600<br />

213.78 x 82.68 / 5.43 x 2.1 351.57 / 8,930 96.46 / 2,450 144.88 / 3,680 121.26 / 3,080 13,230 / 6,000<br />

223.62 x 82.68 / 5.68 x 2.1 333.07 / 8,460 96.46 / 2,450 152.76 / 3,880 – 12,679 / 5,750<br />

213.78 x 82.68 / 5.43 x 2.1 351.57 / 8,930 96.46 / 2,450 152.76 / 3,880 – 13,561 / 6,150<br />

250.39 x 82.68 / 6.36 x 2.1 360.24 / 9,150 96.46 / 2,450 152.76 / 3,880 – 13,009 / 5,900<br />

240.55 x 82.68 / 6.11 x 2.1 378.74 / 9,620 96.46 / 2,450 152.76 / 3,880 – 13,891 / 6,300<br />

45

Fittings<br />

<strong>FARO</strong><br />

High-slung<br />

pivoting drawbar<br />

Low-slung<br />

pivoting drawbar<br />

Drawbar ball coupling Drawbar buffer<br />

3500/4000/4500 Country-specific Country-specific Optional Optional<br />

6300/8000 Country-specific Country-specific Optional Optional<br />

<strong>EUROPROFI</strong> Country-specific Country-specific Optional Optional<br />

<strong>FARO</strong><br />

Steering axle 17”<br />

for total weight<br />

Axle 22,5” for<br />

17 t total weight<br />

Steering axle 22,5”<br />

for 17 t total weight<br />

Pneumatic brake<br />

3500/4000/4500 Optional, 11,5 t – – Country-specific<br />

6300/8000 Optional, 12 t – – Country-specific<br />

<strong>EUROPROFI</strong> Optional, 12 t Optional Optional Country-specific<br />

<strong>FARO</strong><br />

Power control pad Two unloading rotors Third loading rotor Cross conveyor belt<br />

3500/4000/4500 L Optional – – –<br />

3500/4000/4500 D Standard Standard Optional Optional<br />

6300/8000 L – – – –<br />

<strong>EUROPROFI</strong> L Optional – – –<br />

<strong>EUROPROFI</strong> D Standard Standard Optional Optional<br />

Other optional fittings<br />

P.T.O. speed 540 rpm<br />

PTO shaft 1 3/8” 21 spline<br />

PTO shaft 8x32x38 8 spline<br />

Track width 76.77’/1950 mm in lieu of 72.83 ‘/1850 mm<br />

Mud guards for 24.85 mph / 40 km/h<br />

Automatic safety brakes for hydraulic brake<br />

46<br />

Power Control with lighting<br />

Power Control Wireless for D models<br />

ISOBUS-Control<br />

Flood light for loading chamber<br />

Hydraulic pick-up suspension for <strong>EUROPROFI</strong><br />

Load-sensing

Steered jockey<br />

wheels for pickup<br />

Pivotable cutting unit<br />

Knife bank with<br />

6 knives<br />

560/45R 22.5 tyres 620/40R 22,5 tyres<br />

Optional Optional Optional Optional Optional<br />

Optional – Standard Optional Optional<br />

Standard Standard – Standard Optional<br />

Hydraulic brake Dry forage extension Tailgate fixable<br />

Automatic<br />

loading system<br />

Metal roof profiles<br />

Country-specific Optional 3500 L / 4000 L Optional 3500 L / 4000 L Optional –<br />

Country-specific – – Standard Optional<br />

Country-specific Optional 4000 L Optional 4000 L Standard Optional 4500 L / 5000 L<br />

Side access door<br />

Snap-on panel<br />

for tailgate<br />

2-stage motor<br />

for scraper floor<br />

Rear switch<br />

for scraper floor<br />

Optional Optional Optional (Power Control) Optional<br />

Standard – Optional –<br />

Optional Standard 8000 – Optional<br />

Optional Optional Optional (Power Control) Optional<br />

Standard – Optional –<br />

Cable for control from the rear<br />

Oil pressure switch for dismounted beaters<br />

Outline marker and demarcation lights<br />

On-board hydraulics for conveyor belt (for tractos with less<br />

hydraulic performance<br />

All information is provided<br />

without obligation.<br />

Fittings can vary from<br />

country to country.<br />

47

<strong>Alois</strong> <strong>Pöttinger</strong><br />

<strong>Maschinenfabrik</strong> GmbH<br />

Industriegelände 1<br />

A-4710 Grieskirchen<br />

Phone: +43 (0) 7248/600-0<br />

Fax: +43 (0) 7248/600-2445<br />

Importer for UK:<br />

LandMec Pottinger<br />

Cantrell Works<br />

Bittaford, Ivybridge<br />

Devon PL21 OEZ<br />

England<br />

Phone: 01752 891285<br />

Fax: 01752 891392<br />

e-mail: info@landmecpottinger.co.uk<br />

www.landmecpottinger.co.uk<br />

Importer for Ireland:<br />

T. Traynor & Sons Ltd.<br />

Cashel Road, Clonmel<br />

Co. Tipperary<br />

Ireland<br />

Phone: 052/25 766<br />

Fax: 052/25 802<br />

e-mail: info@traynor.ie<br />

www.traynor.ie<br />

Sales & Service for Canada<br />

POETTINGER CANADA INC.<br />

650, Route 112<br />

St-Cesaire, J0L 1 T0, PQ<br />

CANADA<br />

Tel.: (450) 469-5594<br />

Fax: (450) 469-4466<br />

e-mail: sales.canada@poettinger.ca<br />

Sales & Service for the US<br />

POETTINGER CANADA INC.<br />

650, Route 112<br />

St.-Cesaire, J0L 1 T0, PQ<br />

CANADA<br />

Tel.: (450) 469-5594<br />

Fax: (450) 469-4466<br />

Cell: (450) 578-4081<br />

e-mail: sales.us@poettinger.ca<br />

Quality for the future<br />

Machines with the cloverleaf mark are internationally successful with reliable quality and service.<br />

Cathodic electrodip priming and powder coating – automobile paint quality<br />

Laser cutting machines for high-precision panel forming<br />

New durability centre for expendable parts<br />

The latest 3D construction<br />

Future-safe component part testing – at the new Grieskirchen Technology and Innovation Centre,<br />

the most demanding working conditions are simulated and maximum limits are determined<br />

<strong>Pöttinger</strong> original expendable parts offer added value at a glance: high durability, precise<br />

fitting accuracy and constant availability.<br />

Product delivery – Every <strong>Pöttinger</strong> customer has a right to the orderly delivery of the product<br />

by their <strong>Pöttinger</strong> sales agent, in order to ensure the guarantee.<br />

www.poettinger.at – e-mail: landtechnik@poettinger.at<br />

Poettinger Australia P/L<br />

15 Fordson Road<br />

Campbellfield, VIC 3061<br />

Australia<br />

Phone: +61 3 9359 2969<br />

Fax: +61 3 9359 6962<br />

e-mail:<br />

sales.au@poettinger.com.au<br />

www.poettinger.com.au<br />

Importer for New Zealand:<br />

Origin Agroup<br />

PO Box 673, 57 Hautapu Road<br />

Cambridge<br />

Phone: 064 7 823 7582<br />

Fax: 064 7 823 7583<br />

e-mail:<br />

info@originagroup.co.nz<br />

www.originagroup.co.nz<br />

Be more successful with<br />

Faro/Europrofi/uk/0209