FARO / EUROPROFI silage trailers - Alois Pöttinger Maschinenfabrik ...

FARO / EUROPROFI silage trailers - Alois Pöttinger Maschinenfabrik ...

FARO / EUROPROFI silage trailers - Alois Pöttinger Maschinenfabrik ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

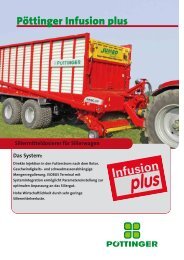

The structure of the crop<br />

greatly determines its<br />

digestibility. The rotor must<br />

therefore be able to cut and<br />

compress the forage well<br />

even with a high flow.<br />

Rotomatic is at the heart<br />

of <strong>FARO</strong> <strong>silage</strong> <strong>trailers</strong>:<br />

powerful, robust and<br />

capable.<br />

14<br />

Roto matic<br />

Loading system<br />

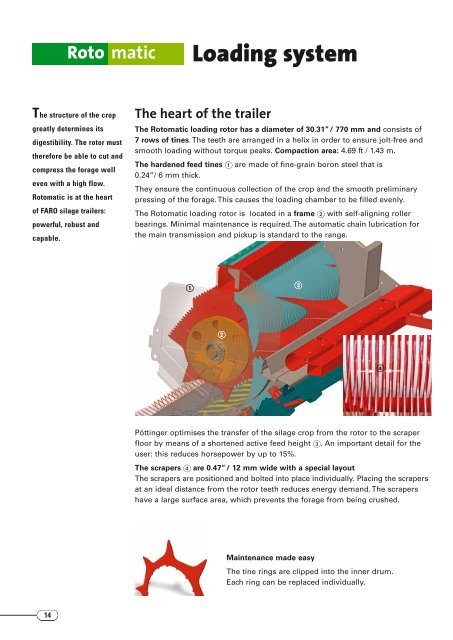

The heart of the trailer<br />

The Rotomatic loading rotor has a diameter of 30.31”/ 770 mm and consists of<br />

7 rows of tines. The teeth are arranged in a helix in order to ensure jolt-free and<br />

smooth loading without torque peaks. Compaction area: 4.69 ft / 1.43 m.<br />

The hardened feed tines are made of fine-grain boron steel that is<br />

0.24”/ 6 mm thick.<br />

They ensure the continuous collection of the crop and the smooth preliminary<br />

pressing of the forage. This causes the loading chamber to be filled evenly.<br />

The Rotomatic loading rotor is located in a frame with self-aligning roller<br />

bearings. Minimal maintenance is required. The automatic chain lubrication for<br />

the main transmission and pickup is standard to the range.<br />

<br />

<br />

<strong>Pöttinger</strong> optimises the transfer of the <strong>silage</strong> crop from the rotor to the scraper<br />

floor by means of a shortened active feed height . An important detail for the<br />

user: this reduces horsepower by up to 15%.<br />

The scrapers are 0.47”/ 12 mm wide with a special layout<br />

The scrapers are positioned and bolted into place individually. Placing the scrapers<br />

at an ideal distance from the rotor teeth reduces energy demand. The scrapers<br />

have a large surface area, which prevents the forage from being crushed.<br />

<br />

Maintenance made easy<br />

<br />

The tine rings are clipped into the inner drum.<br />

Each ring can be replaced individually.