Modern Plastics Worldwide - October 2007 - dae uptlax

Modern Plastics Worldwide - October 2007 - dae uptlax

Modern Plastics Worldwide - October 2007 - dae uptlax

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MODERN EXECUTIVE<br />

R.I.P. $0.40/lb PE<br />

By Tony Deligio<br />

Bowie, currently COO of Resin<br />

Technology Inc. (RTi), a resin purchasing<br />

consulting firm in Fort Worth,<br />

TX, has been in the plastics industry<br />

overall for 25 years, starting out in processing<br />

at a film operation and then an<br />

injection molding business, before<br />

launching RTi with a partner in 1998,<br />

giving him the long view on resin prices.<br />

“[Resin prices] are extremely volatile,”<br />

Bowie says, “and it’s volatile at a step<br />

above where it was even two to three<br />

years ago, which was a step above what<br />

it was six or seven years ago.”<br />

As his company works to help processors<br />

negotiating an increasingly harrowing<br />

resin-buying minefield, it’s tracking<br />

four larger, meta issues that are truly<br />

making these interesting times in plastics.<br />

Globalization: In simplest terms, “The<br />

world is opening up and competing with<br />

North America,” Bowie says.<br />

Repercussions include downward pressure<br />

on labor and products, with possible<br />

lessons to be gleaned from industries like<br />

textiles and automotive, which have been<br />

exposed to worldwide competition longer<br />

and enjoyed varying levels of success.<br />

Supplier Consolidation: “When there were<br />

14 guys making polypropylene, you could<br />

always find someone who was a little tight<br />

on cash and just wanted to turn some<br />

inventory and cut you a deal,” Bowie<br />

says. Those days are gone, with larger<br />

companies wielding greater leverage and a<br />

weak dollar leaving an export valve to<br />

release inventory pressure for producers.<br />

Energy: Call it unlucky 7s, as in $7/mm<br />

BTU natural gas and $70 barrels of oil.<br />

“I don’t like the word never,” Bowie<br />

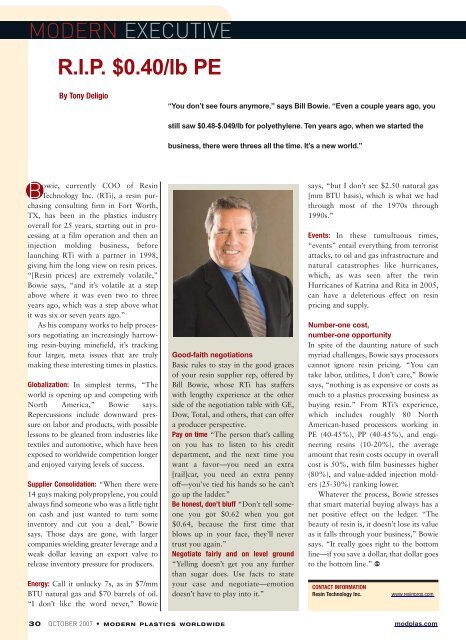

“You don’t see fours anymore,” says Bill Bowie. “Even a couple years ago, you<br />

still saw $0.48-$.049/lb for polyethylene. Ten years ago, when we started the<br />

business, there were threes all the time. It’s a new world.”<br />

Good-faith negotiations<br />

Basic rules to stay in the good graces<br />

of your resin supplier rep, offered by<br />

Bill Bowie, whose RTi has staffers<br />

with lengthy experience at the other<br />

side of the negotiation table with GE,<br />

Dow, Total, and others, that can offer<br />

a producer perspective.<br />

Pay on time “The person that’s calling<br />

on you has to listen to his credit<br />

department, and the next time you<br />

want a favor—you need an extra<br />

[rail]car, you need an extra penny<br />

off—you’ve tied his hands so he can’t<br />

go up the ladder.”<br />

Be honest, don’t bluff “Don’t tell someone<br />

you got $0.62 when you got<br />

$0.64, because the first time that<br />

blows up in your face, they’ll never<br />

trust you again.”<br />

Negotiate fairly and on level ground<br />

“Yelling doesn’t get you any further<br />

than sugar does. Use facts to state<br />

your case and negotiate—emotion<br />

doesn’t have to play into it.”<br />

says, “but I don’t see $2.50 natural gas<br />

[mm BTU basis), which is what we had<br />

through most of the 1970s through<br />

1990s.”<br />

Events: In these tumultuous times,<br />

“events” entail everything from terrorist<br />

attacks, to oil and gas infrastructure and<br />

natural catastrophes like hurricanes,<br />

which, as was seen after the twin<br />

Hurricanes of Katrina and Rita in 2005,<br />

can have a deleterious effect on resin<br />

pricing and supply.<br />

Number-one cost,<br />

number-one opportunity<br />

In spite of the daunting nature of such<br />

myriad challenges, Bowie says processors<br />

cannot ignore resin pricing. “You can<br />

take labor, utilities, I don’t care,” Bowie<br />

says, “nothing is as expensive or costs as<br />

much to a plastics processing business as<br />

buying resin.” From RTi’s experience,<br />

which includes roughly 80 North<br />

American-based processors working in<br />

PE (40-45%), PP (40-45%), and engineering<br />

resins (10-20%), the average<br />

amount that resin costs occupy in overall<br />

cost is 50%, with film businesses higher<br />

(80%), and value-added injection molders<br />

(25-30%) ranking lower.<br />

Whatever the process, Bowie stresses<br />

that smart material buying always has a<br />

net positive effect on the ledger. “The<br />

beauty of resin is, it doesn’t lose its value<br />

as it falls through your business,” Bowie<br />

says. “It really goes right to the bottom<br />

line—if you save a dollar, that dollar goes<br />

MPW<br />

to the bottom line.”<br />

CONTACT INFORMATION<br />

Resin Technology Inc. www.resinpros.com<br />

30 OCTOBER <strong>2007</strong> • MODERN PLASTICS WORLDWIDE modplas.com