Axor Starck Axor Citterio Axor Citterio M Axor Urquiola ... - Hansgrohe

Axor Starck Axor Citterio Axor Citterio M Axor Urquiola ... - Hansgrohe

Axor Starck Axor Citterio Axor Citterio M Axor Urquiola ... - Hansgrohe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

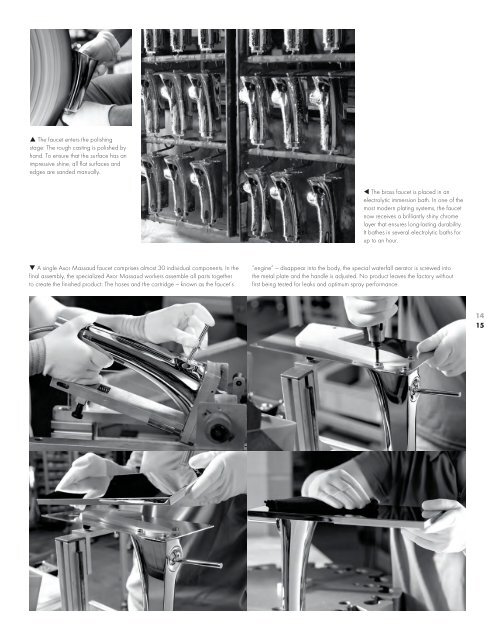

The faucet enters the polishing<br />

stage: The rough casting is polished by<br />

hand. To ensure that the surface has an<br />

impressive shine, all flat surfaces and<br />

edges are sanded manually.<br />

A single <strong>Axor</strong> Massaud faucet comprises almost 30 individual components. In the<br />

final assembly, the specialized <strong>Axor</strong> Massaud workers assemble all parts together<br />

to create the finished product: The hoses and the cartridge — known as the faucet’s<br />

The brass faucet is placed in an<br />

electrolytic immersion bath. In one of the<br />

most modern plating systems, the faucet<br />

now receives a brilliantly shiny chrome<br />

layer that ensures long-lasting durability.<br />

It bathes in several electrolytic baths for<br />

up to an hour.<br />

“engine” — disappear into the body, the special waterfall aerator is screwed into<br />

the metal plate and the handle is adjusted. No product leaves the factory without<br />

first being tested for leaks and optimum spray performance.<br />

14<br />

15