- Page 1 and 2:

AFFDL- TR-78-151 IRVIN INDUSTRIES I

- Page 3 and 4:

UNCLASSIFIED SECURITY CLASSIFICATIO

- Page 5 and 6:

. . . . . . . . . . . . CHAPTE R IN

- Page 7 and 8:

. . . . . . . . . . . . . CHAPTER 4

- Page 9 and 10:

CHAPTE R 6 (Cont) RELIABILITY Typic

- Page 11 and 12:

GURE 1.2 1.4 1.5 1 10 1-1 1 12 1 13

- Page 13 and 14:

FIGURE 3.40 3.41 3.42 3.43 3.44 3.4

- Page 15 and 16:

FIGURE 6AD 10A 10B . . . . . . . .

- Page 17 and 18:

LIST OF ILLUSTRATIONS (Continued) U

- Page 19 and 20:

FIGURE 7.45 7.4 7 7.48 7.49 LIST OF

- Page 21 and 22:

i'Jz dl.'lI/b"W"O","'"' J! L E 101

- Page 23 and 24:

GDA LIST Of SYM BO LS - Area (cross

- Page 25 and 26:

ob Mass of Body I ncluded Mass Any

- Page 27 and 28:

X-r r/c SYMBOLS (Continued) - Numbe

- Page 29 and 30:

Inertial Elasticity Canopy ventilat

- Page 32 and 33:

INTRODUCTION Recovery is a term pop

- Page 34 and 35:

deceleration stages were possible b

- Page 36 and 37:

TABLE B WEIGHTS AND MEASURES Length

- Page 38 and 39:

Z, (- y% T AS LE C PROPERTIES OF EA

- Page 40:

TABLE D TYPICAL GROUND WIND VELOCIT

- Page 43 and 44:

VEHICLE RECOVERY Vehicle!; that hav

- Page 45 and 46:

. . Recovery was initiated with pne

- Page 47 and 48:

vehicle enters the continuum flow a

- Page 49 and 50:

They "re scheduled to arrive in Dec

- Page 51 and 52:

SeparB riot! Entrv Figure 1. T=O Fi

- Page 53 and 54:

TABLE 1.1 TECHNICAL DATA OF THE MER

- Page 55 and 56:

as lsed 0, the Mercury C:8psule. AI

- Page 57 and 58:

Three Main rachut:s Fxtracted by Mo

- Page 59 and 60:

Back-up Drogue Chute PIV Steel Cabl

- Page 61 and 62:

95 Suspension Lines Number of parac

- Page 63 and 64:

Reference 32 suggests certain appli

- Page 65 and 66:

chute and slightly decreases the ve

- Page 67 and 68:

TABLE 1. S. NAVY PERSONNEL EMERGENC

- Page 69 and 70:

pilot chute extraction, independent

- Page 71 and 72:

Canopy Inflated Survival Kit Releas

- Page 73 and 74:

58 Encapsulated Seat. The 8-58 airc

- Page 75 and 76:

300 tOO 'l1j V- C- Stabilization Br

- Page 77 and 78:

TABLE 1.8 AIRCRAFT USED FOR AI'DROP

- Page 79 and 80:

These requirements have resulted in

- Page 81 and 82:

The advantages of the LAPES airdrop

- Page 83 and 84:

Con:ainer, Platform Piatform Weight

- Page 85 and 86:

defeated the low cost aspect. ::ffo

- Page 87 and 88:

, , Figure 26 10. Personnel Troop P

- Page 89 and 90:

Design TABLE 1 13 T. 10 PARACHUTE A

- Page 91 and 92:

In operation, the a rcraft pilot ma

- Page 93 and 94:

ment bag should closely contain the

- Page 95 and 96:

' TABLE 1. PARACHUTE SYSTEMS FOR SP

- Page 97 and 98:

ORDNANCE The application of aerodyn

- Page 99 and 100:

Figure 33 Mark 82 AID Inflation 0 ;

- Page 101 and 102:

AERIAL PICKUP Aerial pickup is one

- Page 103 and 104:

Figure 34 Trapaze/Helicopter (HH-53

- Page 105 and 106:

Main Parachute as Suspension Lines

- Page 107 and 108:

Other Mid.air Retrieval Concepts. B

- Page 109 and 110:

apid turn rates. and minimal weight

- Page 111 and 112:

door of a cradle rrounted platf:rm

- Page 114 and 115:

CHAPTER 2 DEPLOYABLE AERODYNAMIC DE

- Page 116 and 117:

TABLE . 2. SOLID TEXTILE PARACHUTES

- Page 118 and 119:

Type Taja, TU Slots, etc. LeMoigne

- Page 120 and 121:

BIAS il BLOCK Figure 2. Flet Patter

- Page 122 and 123:

Specific; rdcrcncc data are listed

- Page 124 and 125:

.( Con ical. The ca'loPY is constru

- Page 126 and 127:

! , Trj. Conical. The canopy is co,

- Page 128 and 129:

Full Extended Skirt. The canopy is

- Page 130 and 131:

Guide Surface, Ribbed. The canopy i

- Page 132 and 133:

Panels ROOF PATTRN X/I1, .70 Y/X 60

- Page 134 and 135:

- = Cross. The cross parachute, a F

- Page 136 and 137:

Slotted Canopy Parachutes Flat Circ

- Page 138 and 139:

Hemisflo. The constructed shape of

- Page 140 and 141:

--- Ringsail. This parachute design

- Page 142 and 143:

Rotating Parachutes Rotation Df par

- Page 144 and 145:

Low G!ide Parachutes gliding paracr

- Page 146 and 147:

'" Parawing, Single Keel. Tfe canep

- Page 148 and 149:

Parafoil. The canopy is cOlstructed

- Page 150 and 151:

DECELERATORS OTHER THAN PARACHUTES

- Page 152 and 153:

CHAPTER 3 COMPONENTS AN SU BSYSTEMS

- Page 154 and 155:

drogue and starts the timer which o

- Page 156 and 157:

alloth r is the pyrotechnic delay t

- Page 158 and 159:

that an'! Ai r- Iaunched from a car

- Page 160 and 161:

Catapult/Telescoping Thruster. Tele

- Page 162 and 163:

Inflation Phase Actuators. Pym/mech

- Page 164 and 165:

\()\ \, '.. , i. ,, / " .. $) -' .,

- Page 166 and 167:

Figure 18 Cargo Parachute Release 5

- Page 168 and 169:

Figure 21 AlP 28S-2 Personnel Harne

- Page 170 and 171:

wiDensi on Linlis 'I, Gre;ur.d t_C

- Page 172 and 173:

Bridles. A bridle IS :J connectirg

- Page 174 and 175:

Sus,GfinsiQn Line Sigh -Sleeve Mout

- Page 176 and 177:

Figure 38 Representative Cargo Harn

- Page 178 and 179: , ':"' -." (, ::. :: - , :..' ' , .

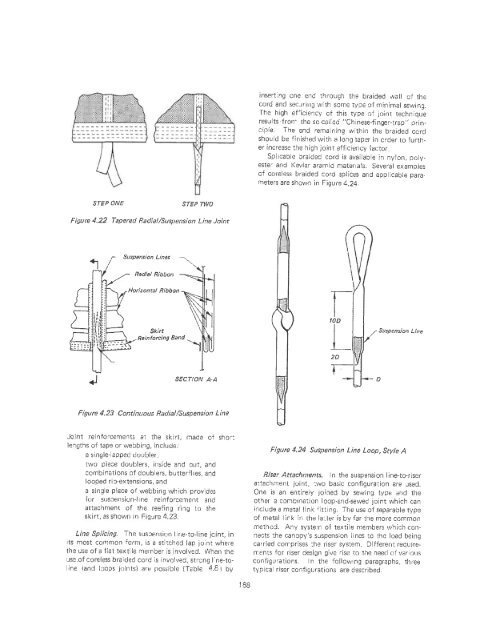

- Page 180 and 181: sharp edged corner knifes into the

- Page 182: compartments or in ex ernal fairing

- Page 185 and 186: from the air , and hydrogen from wa

- Page 187 and 188: ather tran measuring its cross-sect

- Page 189 and 190: tion potential. The first !;::lunll

- Page 191 and 192: (%) TABLE 4. (cont'd) MECHANICAL PR

- Page 193 and 194: 'R 1000 800 600 400 200 1000 800 60

- Page 195 and 196: For a hypothetical fabric composed

- Page 197 and 198: TABLE 4. NYLON SEWING THREADS Data

- Page 199 and 200: TABLE 4. THREAD , NYLON , NON MELTI

- Page 201 and 202: Type Iia Iii I'la -1!L VII VIII XII

- Page 203 and 204: Narrow Woven Fabrics. The strength

- Page 205 and 206: 111 Yarn: Color: Ident Use: Min. Br

- Page 207 and 208: TABLE 4. 19 POLYESTER WEBBING, IMPR

- Page 209 and 210: TABLE 4. 23 (Continued) Dqta horn M

- Page 211 and 212: (%) TABLE 4. RAYON TAPE AND WEBBING

- Page 213 and 214: (%) TABLE 4 a from MI ranee 260 Cia

- Page 215 and 216: Type III Weave: Finish: Use: TABLE

- Page 217 and 218: TABLE 4. NYLON DUCK Data from MI L-

- Page 219 and 220: yarns. In order to achieve low air

- Page 221 and 222: !. Entrapped air in the cells contr

- Page 223 and 224: method of joining textiles. Strong,

- Page 225 and 226: However. if tile strength of the cl

- Page 227: ;: =::~~~~~~~~~ ::: ::.. "':;.. - -

- Page 231 and 232: --- -".. , ;;;" / . ----- ------- -

- Page 233 and 234: width sec ion dimensions based on t

- Page 235 and 236: and length depend on the type parac

- Page 237 and 238: has become cOr/mon practice to x-ra

- Page 239 and 240: TEST METHODS AND CAPABILITIES Selec

- Page 241 and 242: cescent, drift terden::es, and ethe

- Page 243 and 244: supported at other bases including

- Page 245 and 246: stant of release, the free-flving p

- Page 247 and 248: Figure 5.7 for the same type in wat

- Page 249 and 250: Function and Performance Checks. Re

- Page 251 and 252: Laboratorv apparatus has been assem

- Page 253 and 254: The coeff icient of sl idin g frict

- Page 255 and 256: White Sands Misslfe Range Texas Hol

- Page 257 and 258: TABLE 5. DECELERATOR TESTING, PRINC

- Page 259 and 260: allistics tEst tracks and special p

- Page 261 and 262: atmospheric wind tunnel Tre test se

- Page 263 and 264: i ng and launching models wh de the

- Page 265 and 266: TEST VEHICLES In a free flght test

- Page 267 and 268: Load-Searing Platform Paper Honeyco

- Page 269 and 270: 338 with an operation has been obta

- Page 271 and 272: 1, Central part of housing 2. Upper

- Page 273 and 274: to the appl ied stifTl lus. In gene

- Page 275 and 276: :ll€thod available is provided by

- Page 277 and 278: The different deployrrent methoDs f

- Page 279 and 280:

a: 30 .. 60 t: 20 18 10 AV6r6ge New

- Page 281 and 282:

.q:.Q 1.0 002 -- ,. ,. '0. 1.. P (C

- Page 283 and 284:

2000 1000 Lbs Force Snatch Farce bp

- Page 285 and 286:

,\ )\' ""' Ij, !i!t: a) Opening of

- Page 287 and 288:

1.0 HORIZONiAL TRAJECTORY ft H. S.

- Page 289 and 290:

The Inflation 0 " clustered canopie

- Page 291 and 292:

"' area across the canopy s the gov

- Page 293 and 294:

j '" . =: qlide) and ringsail desig

- Page 295 and 296:

Canopy Type C-9 Canopy Con fig A Sn

- Page 297 and 298:

si'" 9 Configuration: 9 ConfiglJrti

- Page 299 and 300:

::. ::". :::. , " .:.' I I Ii 1! l4

- Page 301 and 302:

Figure 6, j; 5"O 540 u. :z 12 o 1.

- Page 303 and 304:

Fioure 27 Opening Force- Time Histo

- Page 305 and 306:

'" Axial Force Coefficient I t is c

- Page 307 and 308:

CAo 35 OM-O. a, Degrees Angle of At

- Page 309 and 310:

. /;. ;. - .'; , . .\. . ~~~ : ;:.

- Page 311 and 312:

LID .. .. Hlen Gliding: W"'W FC08(J

- Page 313 and 314:

Proiect System Descent Parachute We

- Page 315 and 316:

;J = I .. !-- 1// 10. i- ,\;y q.. C

- Page 317 and 318:

-.rQ W/. '" 300 '" 2.35 PSF TURN RA

- Page 319 and 320:

db == p' Mgr ,, ". .. al Velocity D

- Page 321 and 322:

;. ti c: 1). 0.4 C-' -.- --- .. - '

- Page 323 and 324:

TABLE 6.9 MID-AIR RETRIEVAL SYSTEM

- Page 325 and 326:

three dimensional body ha'Je been s

- Page 327 and 328:

;'1 Fig. 6. 55. For a given Mach nU

- Page 329 and 330:

CDo 0.4 'siD LJ 0,. 0 1. Ipd 4.70 0

- Page 331 and 332:

-- I- l- -2 /:INCR c)-200 lo/in Nyl

- Page 333 and 334:

(J f. :' ' - ... . -- ' ;,' ; .; '-

- Page 335 and 336:

p. 'e- - - - - - - - - - - - - ven)

- Page 337 and 338:

2 0. 0.4 0. REEFING RATIO D,ID Figu

- Page 339 and 340:

lengths during deplovment and openi

- Page 341 and 342:

(CoSJ o varies with in the same way

- Page 343 and 344:

Flar Circular Conical 10'1 Extended

- Page 345 and 346:

-2.4 1.6 1.2 -0.4 0.4 0.4 a! Model

- Page 347 and 348:

flralleJ and the (-- to X Axis Cent

- Page 349 and 350:

a) Tap View of MARS Axis SV5tems OI

- Page 351 and 352:

- ----- --- Figure 6. 48 Ft Ribbon

- Page 353 and 354:

""' . it -; 1. " _._,.- 0.4 measure

- Page 355 and 356:

:9 0. 20. 0.40 Q; O. 10 -0_05 0. -0

- Page 357 and 358:

ing points of poIY'TIers , their sp

- Page 359 and 360:

2500 (A) Ascent 2000 1500 100 500 I

- Page 361 and 362:

Water Impact (Spla$hdown) In a wate

- Page 363 and 364:

where is the instantaneous r:eight

- Page 365 and 366:

Bag 'Material.NvllJn Cloth! Narsyn

- Page 367 and 368:

.. , , ; . '(. ., ' .. . ! '.: \ '

- Page 369 and 370:

Human error is more difficult to de

- Page 371 and 372:

TABLE 14 8-YEAR SUPPL Y/EQUIPMENT D

- Page 373 and 374:

Scale Camp ressibillty Factor Fluid

- Page 375 and 376:

"' been unlocked. :he bag offers ve

- Page 377 and 378:

() = Drogue Parachute Angle of Atta

- Page 379 and 380:

270 180 o - 120 Pe rcent Per See 6

- Page 381 and 382:

€ = PI .. velocity of mass added

- Page 383 and 384:

e f312JK PICoSJ1I2 (C (CDS! n((CD S

- Page 385 and 386:

D fDrii(! Coeffcient For Ul1iform M

- Page 387 and 388:

:: . 0. .. Aluminum Canopies fDp 6.

- Page 389 and 390:

axial and radial acceleration of th

- Page 391 and 392:

Iy in Figs. 7. 14b and c. Inflating

- Page 393 and 394:

p, '" '" inflowin9 air is subjected

- Page 395 and 396:

Gore Dimensions Warp or Fil Inflate

- Page 397 and 398:

The posi tive internal differential

- Page 399 and 400:

d) View of Plane A- el View of Plan

- Page 401 and 402:

area '" (R/ /2Jf2(J-sin := g., The

- Page 403 and 404:

COMPUTE ,,, ASSUME TRIAL CONVERGENC

- Page 405 and 406:

Note: ABterisk denote, inPt/f bvana

- Page 407 and 408:

at a) Canopy Tension Approach Tsnoe

- Page 409 and 410:

_-- "" - .. -.. (fnviscid) Wake Qf

- Page 411 and 412:

easonable to use Reynolds and Nusse

- Page 413 and 414:

Figure 7. ReD x 10 t: 3. 'V 4.42 .

- Page 415 and 416:

= 10. iFf: = 1. 86 x 10 Deg. Deg ,!

- Page 417 and 418:

If/db Figure 34 Wake Coefficients v

- Page 419 and 420:

A prima ry and obvious limitation o

- Page 421 and 422:

tive drag stabilizer because of ii:

- Page 423 and 424:

tVa (min- (min. ) . '" M/M .4 . Mr!

- Page 425 and 426:

Angle of Atteck Deg S R8 &12 See In

- Page 427 and 428:

'" 0.4 Ex"eriment iSSinger Nt) Adju

- Page 429 and 430:

Jt (See XI0) e IGz J (3) (4) FPS (6

- Page 431 and 432:

point the discharge or tices open.

- Page 433 and 434:

FPS K. 10. f( 60 80 100 - Lb Sec/Lb

- Page 435 and 436:

they are analogm.. s to the inacleq

- Page 437 and 438:

"" usr=d in th 8 computations. The

- Page 439 and 440:

desc-ibed in References 285 and 552

- Page 441 and 442:

pre-seleCting the final confidence-

- Page 443 and 444:

g., system is to be identified. Thi

- Page 445 and 446:

'/, too heavy., too bulky or too lo

- Page 447 and 448:

t. 14 -- .: Jlten d ed SkI Ffar Cir

- Page 449 and 450:

Surface af Revolution: ; -1 Gore La

- Page 451 and 452:

TABLE 8.3 SYSTEM A OPENING FORCES (

- Page 453 and 454:

'" '" '" "" 156 '" 3 D,IDo 10 (reef

- Page 455 and 456:

TABLE 8. RECOMMENDED PARACHUTE DeSI

- Page 457 and 458:

adial distance a, ong the surf"ce f

- Page 459 and 460:

TABLE 8. STEERABLE PARACHUTE COMPAR

- Page 461 and 462:

Portion of canopy Sockiri up Fourth

- Page 463 and 464:

followed to create a sequence of ca

- Page 465 and 466:

ond /db =" 8. 3/5 7 D /CDt; Appra,s

- Page 467 and 468:

I'ne rraterfal required is 18 1583

- Page 469 and 470:

Unlock Action Riser Closure Flaps (

- Page 471 and 472:

'" "" "" = . where (see Page 344) p

- Page 473 and 474:

'), w m.rif 305 Mo' ar weight, m 18

- Page 475 and 476:

ecause the le1gth of riser branches

- Page 478 and 479:

( .,." ' 727J . ' LIST OF REFEi=ENC

- Page 480 and 481:

104 LIST OF REFERENCES (Continued!

- Page 482 and 483:

138 141 144 146 147 148 149 150 151

- Page 484 and 485:

206 207 208 209 210 Z), 212 213 214

- Page 486 and 487:

290 291' 293 294 295 296 297 298 29

- Page 488 and 489:

353 354 355 356 357 358 359 364 365

- Page 490 and 491:

411 412 413 414 415 416 417 418 419

- Page 492 and 493:

463 464 465 466 467 468 469 470 471

- Page 494 and 495:

..'- 524 525 526 527 533 534 535 53

- Page 496 and 497:

Acceleration Measurement, 232 Actua

- Page 498 and 499:

Pressure Distribution , 227 Strain,