Flow Control KTM Ball Valves - Valves and Controls

Flow Control KTM Ball Valves - Valves and Controls

Flow Control KTM Ball Valves - Valves and Controls

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

SB11 ASME Floating <strong>Ball</strong> Valve, Cost-Effective, Two-Piece Split Body<br />

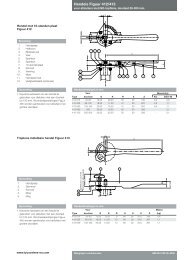

Stem Sealing<br />

SealMaster<br />

V-ring<br />

Stem Packing<br />

2<br />

Belleville<br />

Washers<br />

Stem Sealing Details<br />

1<br />

3<br />

B<br />

Main Features of SealMaster<br />

Patented Stem Seal Arrangement<br />

•“Multiple” sealings up to 6 areas (see Views 1-6) for<br />

pressure <strong>and</strong> high vacuum.<br />

• Encapsulated “Static” sealing achieved on upper<br />

tost seal.<br />

• Constant sealing force reflects to stem (see arrows<br />

“A”) <strong>and</strong> makes stem primary sealing “Positive.”<br />

A<br />

• Excellent wear resistance on lower tost seal (50% SS<br />

filled PTFE), 1000 times greater than that of PTFE to<br />

prolong the compensation of Belleville washers.<br />

C<br />

4<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

12<br />

6<br />

5<br />

Our extremely high cycle stem sealing design is accomplished<br />

by a double sealing system. The high performance of <strong>KTM</strong><br />

ball valves is mainly due to the unique SealMaster stem seal<br />

arrangement, which provides primary sealing. It has been<br />

specially designed <strong>and</strong> constructed to prevent line fluid<br />

permeation <strong>and</strong> resultant leakage. On top of this arrangement<br />

are multiple layers of V-ring stem packing, which act as<br />

secondary sealing. A set of Belleville washers automatically<br />

<strong>and</strong> constantly compresses the seals to adjust for wear,<br />

pressure <strong>and</strong> temperature fluctuations. Every <strong>KTM</strong> ball valve<br />

is a stalwart barrier against fugitive emissions.<br />

View 1 View 2 View 3<br />

View 4 View 5 View 6<br />

The live-loaded SealMaster is a combination of three<br />

components: (A) a cup <strong>and</strong> cone PFA/TFE upper tost seal;<br />

(B) a cup <strong>and</strong> cone sintered stainless steel 316 center load ring,<br />

<strong>and</strong> (C) a flat stainless steel/TFE lower tost seal. When tightened,<br />

the live loaded stem pulls up, compressing the stem tost seal.<br />

As this happens, material from upper <strong>and</strong> lower tost seal<br />

extrudes between stem <strong>and</strong> body enclosures (see Views 1-6).<br />

The surfaces between the bottom of the lower tost seal <strong>and</strong> top<br />

of the stem flange are smooth <strong>and</strong> all rotation occurs between<br />

these two surfaces, leaving the stem tost seal “static” to create<br />

the best possible seal. As rotation continues, components bed in<br />

<strong>and</strong> keep seal performance constant with usage. As operating<br />

wear takes place, the stem tost seal can be re-tightened to<br />

recommended torques multiple times.