Flow Control KTM Ball Valves - Valves and Controls

Flow Control KTM Ball Valves - Valves and Controls

Flow Control KTM Ball Valves - Valves and Controls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>KTM</strong> markets a complete line of ball<br />

valves for the most dem<strong>and</strong>ing<br />

application requirements of the oil <strong>and</strong><br />

gas, power, chemical, petrochemical<br />

<strong>and</strong> other process industries. Types<br />

include floating <strong>and</strong> trunnion, 3-way,<br />

diverting <strong>and</strong> control along with premier<br />

specialty products with unique features.<br />

They feature several proprietary seat<br />

designs, <strong>and</strong> offer a wide range of<br />

performance; the E-seat, PTFE/PFE<br />

copolymer, Gratite ® high temperature<br />

seat with tight shut-off <strong>and</strong> Metaltite<br />

metal seat.<br />

<strong>KTM</strong> has developed a reputation for<br />

high quality, dependable valves backed<br />

by excellent service. Each valve is<br />

precision manufactured from foundry<br />

casting to final assembly.<br />

Special options are available, including<br />

stem extensions, body coating <strong>and</strong><br />

double block <strong>and</strong> bleed. Testing is also<br />

available for chlorine service, oxygen<br />

service, vacuum service, liquid<br />

penetrant, magnetic particle, ultra-sonic<br />

<strong>and</strong> x-ray.<br />

Advantages<br />

• The most complete line of ball valves<br />

in either a manual or an automated<br />

mode of operation.<br />

• St<strong>and</strong>ard, off-the-shelf, special <strong>and</strong><br />

custom-made valves.<br />

• Mill Test Reports (MTRs) available on<br />

all valves.<br />

• Material traceability.<br />

• Continuing source guarantees.<br />

• Product warranties.<br />

• Strategically located sales, service<br />

<strong>and</strong> distribution centers provide rapid<br />

delivery, service <strong>and</strong> repair.<br />

• Qualified service <strong>and</strong> engineering<br />

support.<br />

<strong>Flow</strong> <strong>Control</strong><br />

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

<strong>KTM</strong> manufactures the most complete line of quality ball valves,<br />

<strong>and</strong> can provide the exact ball valves <strong>and</strong> actuators to meet the<br />

most dem<strong>and</strong>ing application requirements.<br />

Floating/Trunnion<br />

Size Range:<br />

1/2" to 30"<br />

ASME Class: 150 <strong>and</strong> 2500<br />

Temperature Rating: -328°F to 932°F<br />

3-way<br />

Size Range:<br />

1/2" to 14"<br />

ASME Class: 150, 300, <strong>and</strong> 600<br />

3-way Patterns: L, T, <strong>and</strong> Y<br />

Temperature Rating: -20°F to 932°F<br />

Single V, VS11<br />

Size Range: 1" to 20"<br />

ASME Class: 150 <strong>and</strong> 300<br />

<strong>Control</strong> Valve Range: 100:1 rangeability<br />

Temperature Rating: -20°F to 518°F<br />

Dual V<br />

Size Range: 1" to 8"<br />

ASME Class: 150 <strong>and</strong> 300<br />

<strong>Control</strong> Valve Range: 250:1<br />

Temperature Rating: -20°F to 518°F<br />

<strong>KTM</strong> is either a trademark or registered trademark of Tyco International Services AG or its affiliates in<br />

the United States <strong>and</strong>/or other countries. All other br<strong>and</strong> names, product names, or trademarks belong<br />

to their respective holders.<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550-US-0906

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Contents<br />

Product Offering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8<br />

SB11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12<br />

Omni II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-23<br />

Metal Seated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26<br />

Energy Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-28<br />

3-Way . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Low Temperature <strong>and</strong><br />

29-37<br />

Cryogenic <strong>Valves</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-44<br />

Process, Production, Floating <strong>and</strong> Trunnion <strong>Valves</strong> . . . . . . . . . . . . . . . . . . . . . 45-52<br />

Single V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-56<br />

VS Rotary <strong>Control</strong> Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57-62<br />

Dual V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63-66<br />

Engineering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67-79<br />

How to Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80-81<br />

St<strong>and</strong>ards <strong>and</strong> Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Experience <strong>and</strong> Reputation<br />

For over 60 years, we have developed a<br />

reputation for high quality, dependable<br />

valves <strong>and</strong> outst<strong>and</strong>ing service for our<br />

customers.<br />

Totally Integrated<br />

Manufacturing Facility<br />

You can count on <strong>KTM</strong> ball valves for<br />

lasting, dependable service. Each valve<br />

is precision manufactured from foundry<br />

casting to final assembly. By controlling<br />

every component of manufacturing, we<br />

maintain total quality control.<br />

Dependable Quality<br />

<strong>and</strong> Performance<br />

In addition, unique design features help<br />

add to the life <strong>and</strong> performance of our<br />

valves, such as an incredibly high degree<br />

of accuracy that is machined into every<br />

ball – a sphericity of ± 0.0008" <strong>and</strong> a<br />

4 RMS finish.<br />

Process <strong>and</strong> Quality <strong>Control</strong><br />

(S.P.Q.C.)<br />

<strong>KTM</strong> is committed to Statistical Process<br />

Quality <strong>Control</strong>. Products are manufactured<br />

utilizing S.P.Q.C. as a powerful tool for<br />

producing quality products.<br />

Special Options <strong>and</strong><br />

Testings are Available<br />

Options<br />

• Stem extension<br />

• Body coating<br />

• Double block <strong>and</strong> bleed<br />

Tests<br />

• Chlorine service<br />

• Oxygen service<br />

• Vacuum service<br />

• Liquid penetrant<br />

• Magnetic particle<br />

• Ultra-sonic<br />

• X-ray<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

3

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

SB11<br />

(Pages 9-12)<br />

Model Number SB11 EB100/EB800/EB100-PL<br />

Type Split Body Split Body<br />

Floating <strong>Ball</strong> Floating <strong>Ball</strong><br />

Bi-directional Bi-directional<br />

RF Flanged Ends RF Flanged Ends<br />

Bore Full Full <strong>and</strong> Reduced<br />

Pressure Class ANSI 150 lb ANSI 150 lb<br />

ANSI 300 lb<br />

Size Range 1/2" to 8" 1/2" to 8" (Full)<br />

6" to 10" (Reduced)<br />

Body Material Carbon Steel Carbon Steel<br />

316 SS 316 SS<br />

304 SS<br />

Alloy 20<br />

Monel ®<br />

Special Alloys<br />

Trim Options 316 SS 316 SS<br />

304 SS<br />

Monel ®<br />

Alloy 20<br />

Hastelloy ® Maximum<br />

C<br />

Special Alloys<br />

Working<br />

Pressure<br />

285 psi 285 psi/720 psi<br />

Temperature<br />

Range<br />

-20°F up to 420°F -50°F up to 932°F<br />

Seat Options E E, K, F, M, T<br />

Features Anti-static Electricity Anti-static Electricity<br />

Blow-out Proof Stem Blow-out Proof Stem<br />

Cavity Relief Cavity Relief<br />

Fire-safe Cold-flow Resistance Seat<br />

ISO Integral Mounting Flange Fire-safe<br />

Locking Device Fugitive Emission <strong>Control</strong> Device<br />

Positive <strong>Flow</strong> Stem Indicator ISO Integral Mounting Flange<br />

Positive Shut-off Locking Device<br />

NACE MR01.75 Positive <strong>Flow</strong> Stem Indicator<br />

Positive Shut-off<br />

NACE MR01.75<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

4<br />

Omni II<br />

(Pages 13-21)

Floating<br />

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Metal Seated<br />

(Pages 24-26)<br />

Trunnion<br />

Model Number EB100/EO100 EO1200 EB100/EO100<br />

Type Split Body Split Body Split Body<br />

Floating <strong>Ball</strong> Trunnion Floating <strong>Ball</strong><br />

RF Flanged Ends Bi-directional Bi-directional<br />

Class V Seat Leakage RF Flanged Ends SE/SW Ends<br />

Bi-directional Class 5Seat Leakage<br />

Bore Full Full Full<br />

Pressure Class ANSI 150 lb ANSI 150 lb ANSI 300 lb<br />

ANSI 300 lb ANSI 300 lb ANSI 600 lb (also available in Flange<br />

ANSI 600 lb (Uni-directional) ANSI 600 lb End, sizes 1/2" to 4")<br />

Size Range 1/2" to 8" (150/300) 2" to 20" (150/300) 1/2" to 2"<br />

1/2" to 1 1/2" (600) 2" to 18" (600)<br />

Body Material Carbon Steel Carbon Steel Carbon Steel<br />

316 SS 316 SS 316 SS<br />

Special Alloys Special Alloys<br />

Trim Options 316 SS/329 SS 316 SS/329 SS 316 SS/329 SS<br />

Monel ® Monel ® Monel ®<br />

Hastelloy ® C Hastelloy ® C Hastelloy ® C<br />

Special Alloys Special Alloys Special Alloys<br />

Energy Process<br />

(Pages 27-28)<br />

Maximum<br />

Working<br />

Pressure<br />

285 psi/720 psi/1440 psi 285 psi/720 psi/1440 psi 285 psi/720 psi/1440 psi<br />

Temperature<br />

Range<br />

-20°F up to 932°F -20°F up to 932°F -50°F up to 932°F<br />

Seat Options M M F<br />

Features Anti-static Electricity Anti-static Electricity Anti-static Electricity<br />

Blow-out Proof Stem Blow-out Proof Stem Blow-out Proof Stem<br />

Cavity Relief Cavity Relief Fire-safe<br />

Fire-safe Fire-safe Fugitive Emission <strong>Control</strong> Device<br />

Fugitive Emission <strong>Control</strong> Device Fugitive Emission <strong>Control</strong> Device Locking Device<br />

Locking Device Positive <strong>Flow</strong> Stem Indicator Positive Shut-off<br />

Positive <strong>Flow</strong> Stem Indicator Positive <strong>Flow</strong> Stem Indicator NACE MR01.75<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

5

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

3-Way<br />

(Pages 29-37)<br />

Model Number EO3100/EO3800 E3200/E3900 EB100/EO100/EO1200<br />

Type 3-Way, 2-Seats 3-Way, 4-Seats Split Body<br />

Floating <strong>Ball</strong> Floating <strong>Ball</strong> Floating <strong>Ball</strong><br />

“L” Port “L” Port Trunnion<br />

RF Flanged Ends “T” Port<br />

Trunnion Available<br />

Bore Full <strong>and</strong> Reduced Full <strong>and</strong> Reduced Full<br />

Pressure Class ANSI 150 lb ANSI 150 lb (E3900 only) ANSI 150 lb<br />

ANSI 300 lb ANSI 300 lb (E3200) ANSI 300 lb<br />

ANSI 600 lb ANSI 600 lb ANSI 600 lb<br />

Size Range 1 1/2" to 8" (Full) 1/2" to 8" (Full) 1/2” to 30”<br />

6" to 10" (Reduced) 6" to 8" (Reduced)<br />

10" to 12" (Trunnion)<br />

Body Material Carbon Steel Carbon Steel Carbon Steel (LCC, LCB)<br />

316 SS 316 SS 316 SS<br />

Special Alloys<br />

Trim Options 316 SS 316 SS 304 SS<br />

Monel ® Monel ® 316 SS<br />

Hastelloy ® C Hastelloy ® C<br />

Special Alloys Special Alloys<br />

Maximum<br />

Working<br />

Pressure<br />

285 psi/720 psi/1440 psi 285 psi/720 psi/1440 psi 285 psi/720 psi/1440 psi<br />

Temperature<br />

Range<br />

-94°F up to 550 (932°F) -20°F up to 300°F -196°F to -320°F<br />

Seat Options E, G, K, T (F) T, G, E E, T, H<br />

Features Anti-static Electricity Anti-static Electricity Anti-static Electricity<br />

Blow-out Proof Stem Blow-out Proof Stem Block <strong>and</strong> Bleed<br />

Cavity Relief Cavity Relief Blow-out Proof Stem<br />

Fugitive Emission <strong>Control</strong> Device Fugitive Emission <strong>Control</strong> Device Cavity Relief<br />

Locking Device Locking Device Fire-safe<br />

Positive <strong>Flow</strong> Stem Indicator Positive <strong>Flow</strong> Stem Indicator Fugitive Emission <strong>Control</strong> Device<br />

Positive Shut-off Positive Shut-off NACE MR01.75<br />

NACE MR01.75 NACE MR01.75 Shell MESC 77/306<br />

BS 6755, BS 6364<br />

(valves for cryogenic service)<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

6

Low Temperature <strong>and</strong><br />

Cryogenic <strong>Valves</strong><br />

(Pages 38-44)<br />

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Process, Production, Floating <strong>and</strong><br />

Trunnion <strong>Valves</strong><br />

(Pages 45-52)<br />

Model Number EO1200/EO8200 EO1100/EO8100/EO100<br />

Type Split Body Split Body<br />

Trunnion Trunnion <strong>and</strong> Floating <strong>Ball</strong><br />

Bi-directional Bi-directional<br />

RF/RTJ/BW RF/RTJ/BW<br />

Bore Full <strong>and</strong> Reduced Full <strong>and</strong> Reduced<br />

Pressure Class ANSI 150 lb ANSI 150 lb<br />

ANSI 300 lb ANSI 300 lb<br />

ANSI 600 lb ANSI 600 lb<br />

ANSI 900 lb ANSI 900 lb<br />

ANSI 1500 lb ANSI 1500 lb<br />

ANSI 2500 lb<br />

Size Range 2" to 20" (150/300) 1/2" to 11/2" (600, Floating)<br />

2" to 26" (600) 2" to 20" (600)<br />

11/2" to 20" (900/1500)<br />

1/2" to 1" (900/1500, Floating)<br />

11/2" Model Number EB100/EO100/EO1200<br />

Type Split Body<br />

Floating <strong>Ball</strong><br />

Trunnion<br />

“T” Port<br />

Bore Full<br />

Pressure Class ANSI 150 lb<br />

ANSI 300 lb<br />

ANSI 600 lb<br />

Size Range 1/2" to 30"<br />

to 20" (900/1500)<br />

1/2" to 8" (2500)<br />

2" to 30" (150/300)<br />

Body Material Carbon Steel (LCC, LCB) Body Material Carbon Steel Carbon Steel<br />

316 SS<br />

316 SS 316 SS<br />

Trim Options 304 SS<br />

Trim Options 316 SS Carbon Steel<br />

316 SS<br />

ENP 316 SS<br />

HCR ENP<br />

HCR<br />

Maximum<br />

Working<br />

Pressure<br />

285 psi/720 psi/1440 psi<br />

Maximum<br />

Working<br />

Pressure<br />

285 psi/720 psi<br />

1440 psi/2220 psi/3600 psi<br />

285 psi/720 psi/1440 psi<br />

2220 psi/3600 psi/6000 psi<br />

Temperature<br />

Range<br />

-196°F to -320°F<br />

Temperature<br />

Range<br />

-20°F up to 500°F -20°F up to 300°F<br />

Seat Options E, T, H<br />

Seat Options H, K H<br />

Features Anti-static Electricity Features Anti-static Electricity Anti-static Electricity<br />

Block <strong>and</strong> Bleed<br />

Block <strong>and</strong> Bleed Block <strong>and</strong> Bleed<br />

Blow-out Proof Stem<br />

Blow-out Proof Stem Blow-out Proof Stem<br />

Cavity Relief<br />

Cavity Relief Cavity Relief<br />

Fire-safe<br />

Fire-safe Fire-safe<br />

Fugitive Emission <strong>Control</strong> Device Fugitive Emission <strong>Control</strong> Device Fugitive Emission <strong>Control</strong> Device<br />

NACE MR01.75<br />

Positive <strong>Flow</strong> Stem Indicator Positive <strong>Flow</strong> Stem Indicator<br />

Shell MESC 77/306<br />

Positive Shut-off Positive Shut-off<br />

BS 6755, BS 6364<br />

(valves for cryogenic service)<br />

NACE MR01.75 NACE MR01.75<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

7

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Single V<br />

(Pages 53-56)<br />

Model Number WO400/WO600/VS Type WA Series<br />

Dual V<br />

(Pages 63-66)<br />

Type Split Body One-Piece Body<br />

Trunnion Trunnion<br />

Uni-directional Uni-directional<br />

RF Flanged Ends RF Flanged Ends/Wafer Ends<br />

Class II, IV Seat Leakage Class V Seat Leakage<br />

VS Type - ISA S75.4<br />

Bore Full <strong>and</strong> Reduced Reduced<br />

Pressure Class ANSI 150 lb ANSI 150 lb<br />

ANSI 300 lb ANSI 300 lb<br />

ANSI 600 lb<br />

ISA<br />

Size Range 1" to 20" 1" to 8"<br />

Body Material Carbon Steel 316 SS<br />

316 SS<br />

Trim Options 316 SS/HCr 316 SS/HCr<br />

316 SS Stellited<br />

Maximum<br />

Working<br />

Pressure<br />

285 psi/720 psi/1440 psi 275 psi/720 psi<br />

Temperature<br />

Range<br />

-20°F up to 482°F -20°F up to 518°F<br />

Seat Options L, S M (316 SS Stellited)<br />

Features Locking Device Fugitive Emission <strong>Control</strong> Device<br />

Positive <strong>Flow</strong> Stem Indicator ISO Integral Mounting Flange<br />

NACE MR01.75<br />

Positive <strong>Flow</strong> Stem Indicator<br />

NACE MR01.75<br />

Locking Device<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

8

Features<br />

• Designed <strong>and</strong> manufactured to major<br />

international st<strong>and</strong>ards.<br />

• Designed for zero leakage with<br />

st<strong>and</strong>ard E-seat technology.<br />

• Pure white E-seat seal helps relieve<br />

concern over product contamination<br />

<strong>and</strong> possible “popcorning” in reactive<br />

monomer applications.<br />

• Anti-cold flow-integral seat lip<br />

designed to eliminate seat<br />

deformation <strong>and</strong> cold flow.<br />

• Fire-safe tested to API 607 4th Edition.<br />

• Secondary fire-safe metal-to-metal<br />

seat is st<strong>and</strong>ard.<br />

• Blow-out proof stem.<br />

• Static electricity grounding device.<br />

• CE marking to PED 97/23/EC.<br />

• ISO 5211 mounting pad.<br />

• SealMaster technology on packing<br />

area to meet most fugitive emission<br />

requirements.<br />

• Low operating torque for ease of<br />

operation <strong>and</strong> reduced actuator cost.<br />

• Automatic cavity pressure relief.<br />

Special Options<br />

• Stem extensions.<br />

• Special trim configurations for<br />

corrosive applications.<br />

• Special alloy body materials available<br />

upon request.<br />

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

SB11 ASME Floating <strong>Ball</strong> Valve, Cost-Effective, Two-Piece Split Body<br />

General Applications<br />

• Pulp <strong>and</strong> paper<br />

• Chemical<br />

• Reactive monomers<br />

• Oil <strong>and</strong> gas productions<br />

• Fire-safe <strong>and</strong> flammables<br />

• Food <strong>and</strong> beverage<br />

• Steam<br />

St<strong>and</strong>ards<br />

• API 598<br />

• ANSI B16.5, B16.10 <strong>and</strong> B16.34<br />

• Fire-safe approved, API 607 4th<br />

Edition<br />

• CE marking to PED 97/23/EC<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

9

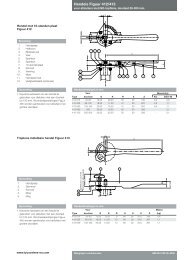

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

SB11 ASME Floating <strong>Ball</strong> Valve, Cost-Effective, Two-Piece Split Body<br />

H<strong>and</strong>le for valve size<br />

2 1/2" to 8" [65 to 200 mm]<br />

Parts <strong>and</strong> Materials<br />

24<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

10<br />

21<br />

22<br />

15<br />

17<br />

23<br />

2<br />

7a<br />

3<br />

7<br />

17<br />

23<br />

14<br />

13<br />

12<br />

11<br />

1<br />

15<br />

10<br />

9<br />

6<br />

5 8<br />

Materials<br />

No. Part Stainless Steel Body WCB Body Qty<br />

1 Body A351 Gr. CF8M A216 Gr. WCB 1<br />

2 Cap A351 Gr. CF8M A216 Gr. WCB 1<br />

3 <strong>Ball</strong> A351 Gr. CF8M A351 Gr. CF8M 1<br />

4 Stem A 276 Type 316 A 276 Type 316 1<br />

5 Seat PTFE/PFA Copolymer PTFE/PFA Copolymer 2<br />

6 1 Body seal PTFE PTFE 1<br />

7 Stud A 193 Gr. B8 A 193 Gr. B7 4 - 12<br />

7a Nut A 194 Gr. 8 A 194 Gr. 2H 4 - 12<br />

8 Lower tost washer 50% SS/50% PTFE 50% SS/50% PTFE 1<br />

9 Compress ring SUS 316 SUS 316 1<br />

10 1 Upper tost washer PTFE/PFA Copolymer PTFE/PFA Copolymer 1<br />

11 1 V-ring stem packing PTFE PTFE 1 set<br />

12 Tost washer PEEK PEEK 1<br />

13 Gl<strong>and</strong> SUS 304 SUS 304 1<br />

14 Belleville washer SUS 301 SUS 301 2<br />

15 Stem nut SUS 304 SUS 304 1 - 2<br />

16 Static ball SUS 304 SUS 304 1<br />

17 Lock saddle SUS 304 SUS 304 1<br />

18 Stop bolt SUS 304 SUS 304 1<br />

19 H<strong>and</strong>le ( 1/2" to 2") SUS 304 SUS 304 1<br />

20 H<strong>and</strong>le sleeve ( 1/2" to 2") Vinyl Vinyl 1<br />

21 H<strong>and</strong>le (2 1/2" to 8") SGP Zn Plating SGP Zn Plating 1<br />

22 H<strong>and</strong>le adapter (2 1/2" to 8") CF8 (2 1/2" to 4") A536 (6" to 8") 1<br />

23 Triangle stopper SUS 304 SUS 304 1<br />

24 Bolt (2 1/2" to 8") SUS 304 SUS 304 1<br />

4<br />

16<br />

19<br />

20<br />

H<strong>and</strong>le for valve size<br />

1/2" to 2" [15 to 50 mm]<br />

18<br />

Notes:Notes<br />

1. Option – For fire tested to API 607 4th Edition,<br />

packing material will be changed to Graphite.<br />

2. Other body materials available.

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

SB11 ASME Floating <strong>Ball</strong> Valve, Cost-Effective, Two-Piece Split Body<br />

L<br />

W<br />

H H<br />

1/2" to 2" [15 - 50 mm] 2 1/2" to 8" [65 - 200 mm]<br />

ANSI Class 150 Dimensions<br />

W<br />

L<br />

T<br />

ød øg øC øD<br />

Valve d L H W D C g f T N m H1 H2 H3 SW U ISO M Wt.<br />

Size Lbs.<br />

1/2" 0.59 4.25 3.54 4.92 3.50 2.38 1.38 0.06 0.44 4 0.63 0.89 0.47 0.08 0.25 1.18 F04 M5 4<br />

3/4" 0.79 4.62 3.68 4.92 3.86 2.76 1.69 0.06 0.44 4 0.63 0.87 0.49 0.08 0.25 1.18 F04 M5 7<br />

1" 1.00 5.00 4.09 5.94 4.25 3.13 2.01 0.06 0.44 4 0.63 0.93 0.51 0.12 0.31 1.38 F05 M6 9<br />

1 1/2" 1.50 6.50 4.90 7.24 5.00 3.88 2.87 0.06 0.56 4 0.63 1.06 0.55 0.12 0.37 2.17 F07 M8 15<br />

2" 2.00 7.00 5.24 7.24 5.99 4.74 3.62 0.06 0.63 4 0.75 1.06 0.55 0.12 0.37 2.17 F07 M8 18<br />

2 1/2" 2.50 7.50 6.38 19.49 7.01 5.49 4.13 0.06 0.69 4 0.75 1.81 0.96 0.12 0.67 2.76 F10 M10 31<br />

3" 3.00 8.00 6.77 19.49 7.48 6.00 5.00 0.06 0.75 4 0.75 1.81 0.98 0.12 0.67 2.76 F10 M10 40<br />

4" 4.00 9.00 7.76 23.43 9.02 7.50 6.18 0.06 0.94 8 0.75 2.05 1.18 0.12 0.67 2.76 F10 M10 60<br />

6" 6.00 15.50 11.06 31.50 10.98 9.51 8.50 0.06 1.00 8 0.87 2.68 1.61 0.12 0.91 3.35 F12 M12 165<br />

8" 8.00 18.00 12.48 43.31 13.50 11.75 10.63 0.06 1.13 8 0.87 2.68 1.61 0.12 0.91 3.35 F12 M12 282<br />

ANSI Class 150 Dimensions [mm, kg]<br />

15 15 108 90.0 125 89 60.5 35 1.6 11.2 4 16 22.5 12.0 2 6.3 30 F04 M5 2<br />

20 20 117 93.5 125 98 70.0 43 1.6 11.2 4 16 22.0 12.5 2 6.3 30 F04 M5 3<br />

25 25 127 104.0 151 108 79.5 51 1.6 11.2 4 16 23.5 13.0 3 8.0 35 F05 M6 4<br />

40 38 165 124.5 184 127 98.5 73 1.6 14.3 4 16 27.0 14.0 3 9.5 55 F07 M8 7<br />

50 50 178 133.0 184 152 120.5 92 1.6 15.9 4 19 27.0 14.0 3 9.5 55 F07 M8 8<br />

65 64 190 162.0 495 178 139.5 105 1.6 17.5 4 19 46.0 24.5 3 17.0 70 F10 M10 14<br />

80 76 203 172.0 495 190 152.5 127 1.6 19.1 4 19 46.0 25.0 3 17.0 70 F10 M10 18<br />

100 100 229 197.0 595 229 190.5 157 1.6 23.9 8 19 52.0 30.0 3 17.0 70 F10 M10 27<br />

150 150 394 280.0 800 279 241.5 216 1.6 25.4 8 22 68.0 41.0 3 23.0 85 F12 M12 75<br />

200 201 457 315.0 1100 343 298.5 270 1.6 28.6 8 22 68.0 41.0 3 23.0 85 F12 M12 128<br />

Pressure, psi [MPa]<br />

Pressure/Temperature Ratings<br />

868<br />

[6]<br />

723<br />

[5]<br />

579<br />

[4]<br />

434<br />

[3]<br />

289<br />

[2]<br />

145<br />

[1]<br />

0<br />

ANSI Class 300 Body Rating<br />

ANSI Class 150 Body Rating<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

11<br />

f<br />

Flange End<br />

N-øm<br />

-20 32 104 176 249 320 392 464<br />

[-29] [0] [40] [80] [120] [160] [200] [240]<br />

Temperature, °F [°C]<br />

D: Flange outside diameter<br />

C: Bolt pitch circle<br />

g: Raised face diameter<br />

f: Raised face height<br />

d: Bore diameter<br />

T: Flange thickness<br />

N: Number of bolts<br />

m: Bolt hole diameter<br />

H1<br />

SW<br />

H3<br />

M<br />

H2<br />

Valve Size:<br />

øU<br />

Top Works<br />

1/2" to 3/4" [15 to 20 mm]<br />

1" to 2 1/2" [25 to 60 mm]<br />

3" to 4" [80 to 100 mm]<br />

6" [150 mm]<br />

8" [200 mm]

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

SB11 ASME Floating <strong>Ball</strong> Valve, Cost-Effective, Two-Piece Split Body<br />

Stem Sealing<br />

SealMaster<br />

V-ring<br />

Stem Packing<br />

2<br />

Belleville<br />

Washers<br />

Stem Sealing Details<br />

1<br />

3<br />

B<br />

Main Features of SealMaster<br />

Patented Stem Seal Arrangement<br />

•“Multiple” sealings up to 6 areas (see Views 1-6) for<br />

pressure <strong>and</strong> high vacuum.<br />

• Encapsulated “Static” sealing achieved on upper<br />

tost seal.<br />

• Constant sealing force reflects to stem (see arrows<br />

“A”) <strong>and</strong> makes stem primary sealing “Positive.”<br />

A<br />

• Excellent wear resistance on lower tost seal (50% SS<br />

filled PTFE), 1000 times greater than that of PTFE to<br />

prolong the compensation of Belleville washers.<br />

C<br />

4<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

12<br />

6<br />

5<br />

Our extremely high cycle stem sealing design is accomplished<br />

by a double sealing system. The high performance of <strong>KTM</strong><br />

ball valves is mainly due to the unique SealMaster stem seal<br />

arrangement, which provides primary sealing. It has been<br />

specially designed <strong>and</strong> constructed to prevent line fluid<br />

permeation <strong>and</strong> resultant leakage. On top of this arrangement<br />

are multiple layers of V-ring stem packing, which act as<br />

secondary sealing. A set of Belleville washers automatically<br />

<strong>and</strong> constantly compresses the seals to adjust for wear,<br />

pressure <strong>and</strong> temperature fluctuations. Every <strong>KTM</strong> ball valve<br />

is a stalwart barrier against fugitive emissions.<br />

View 1 View 2 View 3<br />

View 4 View 5 View 6<br />

The live-loaded SealMaster is a combination of three<br />

components: (A) a cup <strong>and</strong> cone PFA/TFE upper tost seal;<br />

(B) a cup <strong>and</strong> cone sintered stainless steel 316 center load ring,<br />

<strong>and</strong> (C) a flat stainless steel/TFE lower tost seal. When tightened,<br />

the live loaded stem pulls up, compressing the stem tost seal.<br />

As this happens, material from upper <strong>and</strong> lower tost seal<br />

extrudes between stem <strong>and</strong> body enclosures (see Views 1-6).<br />

The surfaces between the bottom of the lower tost seal <strong>and</strong> top<br />

of the stem flange are smooth <strong>and</strong> all rotation occurs between<br />

these two surfaces, leaving the stem tost seal “static” to create<br />

the best possible seal. As rotation continues, components bed in<br />

<strong>and</strong> keep seal performance constant with usage. As operating<br />

wear takes place, the stem tost seal can be re-tightened to<br />

recommended torques multiple times.

The <strong>KTM</strong> Omni II is available in three<br />

basic style of seats – soft, hard <strong>and</strong><br />

metal-to-metal. Each offers a range of<br />

performance suitable to many<br />

applications.<br />

Seat Temperature Range<br />

• E-seat PTFE/PFA<br />

copolymer (st<strong>and</strong>ard) -148°F to 500°F<br />

• F-Gratite ® hard seat -50°F to 932°F<br />

• K-PEEK -20°F to 550°F<br />

• M-Metal seat -20°F to 932°F<br />

Features<br />

• Superior valve design at a competitive<br />

price.<br />

• Fugitive emissions control for<br />

flammable <strong>and</strong> non-flammable<br />

applications.<br />

• Machined ISO actuator mounting pad.<br />

• Designed for zero leakage with<br />

st<strong>and</strong>ard E-seat.<br />

• Pure white E-seat seal helps relieve<br />

concern over product contamination.<br />

• Positive alignment of split body.<br />

• Fire-safe design tested to API 607<br />

4th Edition.<br />

• Secondary fire-safe metal-to-metal<br />

seat is st<strong>and</strong>ard.<br />

• Blow-out proof stem.<br />

• Static electricity grounding device.<br />

• Sphericity tolerance of the balls,<br />

± 0.0008", <strong>and</strong> a 4 RMS surface<br />

finish are unsurpassed.<br />

• Reinforced PTFE bearing <strong>and</strong> packing<br />

rings reduce friction.<br />

• Lower operating torque for ease of<br />

operation <strong>and</strong> reduced actuator cost.<br />

• Positive position indication.<br />

• Meets NACE MR01.75 for sulfide<br />

cracking resistance.<br />

• Locking device capable.<br />

• Bi-directional shut-off.<br />

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Omni II Split Body Floating <strong>Ball</strong> Valve - Full <strong>and</strong> Reduced Bore<br />

Special Options<br />

• Stem extension<br />

• Special body coatings<br />

• Can be outfitted for cryogenic,<br />

chlorine, oxygen <strong>and</strong> vacuum<br />

services<br />

General Applications<br />

• Pulp <strong>and</strong> paper<br />

• Reactive monomers<br />

• Oil <strong>and</strong> gas production<br />

• Steam<br />

• Hot gases<br />

• Toxic <strong>and</strong> lethal<br />

• Fire-safe <strong>and</strong> flammables<br />

Special Tests<br />

• Liquid penetrant<br />

• Magnetic-particle<br />

• Ultra-sonic<br />

• X-ray<br />

Technical Data<br />

Size range: EB100 Full bore 1/2" to 8"<br />

EB800 Reduced bore<br />

6" to 10"<br />

St<strong>and</strong>ards: API 6D <strong>and</strong> 598<br />

ANSI B16.5, B16.10 <strong>and</strong><br />

B16.34<br />

Fire-safe approved API 607<br />

4th Edition, EXES 3-14-1-2A<br />

BS6755 Part 2<br />

BS5351<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

13

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Omni II Split Body Floating <strong>Ball</strong> Valve - Full <strong>and</strong> Reduced Bore<br />

Features<br />

ISO5211 Actuator Mounting<br />

Machined “automation pad” allows<br />

precise mounting of actuator; mounting<br />

bolts independent from stem-packing<br />

gl<strong>and</strong> bolts. Exact alignment reduces<br />

torque requirements <strong>and</strong> helps prevent<br />

out-of-line wear.<br />

Radial Tost Bearings<br />

Radial loading absorbed, <strong>and</strong> friction<br />

from axial stem loading reduced.<br />

Dual tost bearings support stem<br />

for extended cycle life <strong>and</strong> superior<br />

thermal characteristics.<br />

Blowout-proof Stem <strong>and</strong><br />

Primary Stem Seal<br />

Stem shoulder is an integral part<br />

of the stem, retained internally to<br />

help prevent stem blowout from<br />

pressure in body cavity. Primary<br />

stem seal prevents leakage to<br />

atmosphere, also serves as<br />

low-torque bearing.<br />

Precise, Smooth <strong>Ball</strong><br />

<strong>Ball</strong> sphericity <strong>and</strong> surface finish<br />

are key factors in valve life,<br />

pressure-holding capability,<br />

<strong>and</strong> operating torque. <strong>KTM</strong> ball<br />

specifications are unmatched:<br />

Sphericity : to ± 0.0008" <strong>and</strong><br />

surface finish 4 microinches RMS.<br />

Rigid Split Body<br />

Designed with extra bolts to assure<br />

positive alignment <strong>and</strong> maximum<br />

protection against bending stresses<br />

in the piping <strong>and</strong> forces produced by<br />

thermal distortion; seal is fire-safe<br />

metal-to-metal.<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

14<br />

Fugitive Emissions <strong>Control</strong><br />

Multiple layers of adjustable<br />

PTFE Chevron packing rings<br />

for non-flammable service,<br />

<strong>and</strong> Soft Carbon braided <strong>and</strong><br />

die-formed for flammable service.<br />

Live Loaded Seals<br />

Belleville washer keeps constant<br />

force on stem-seal packing for seal<br />

integrity <strong>and</strong> extended valve life.<br />

Cast Bleed-port Boss<br />

Provisions for drain bleed port if<br />

desired. (not shown)<br />

Anti-static Grounding<br />

Retained wire-ring provides positive<br />

ground for use with volatile or<br />

flammable liquids. (not shown)

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Omni II Split Body Floating <strong>Ball</strong> Valve - Full <strong>and</strong> Reduced Bore<br />

St<strong>and</strong>ard Primary Containment Seals<br />

Fugitive Emission <strong>Control</strong><br />

For flammable services<br />

Fire-safe tested per API 607 4th<br />

Edition/EXES 3-14-1-2A. Braided Soft<br />

Carbon for upper <strong>and</strong> lower rows,<br />

die-formed Soft Carbon for middle seal.<br />

For flammable services<br />

Double packing gl<strong>and</strong> elastomer seal<br />

<strong>and</strong> lantern ring.<br />

St<strong>and</strong>ard bonnet<br />

Extended bonnet<br />

For non-flammable services<br />

Fire-safe design with multi-layered,<br />

adjustable Chevron packing rings.<br />

Optional Secondary Containment Seals<br />

Fugitive Emission <strong>Control</strong> – Toxic <strong>and</strong> Lethal Applications<br />

For non-flammable services<br />

Double packing gl<strong>and</strong> elastomer seal<br />

<strong>and</strong> lantern ring.<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

15

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Omni II Split Body Floating <strong>Ball</strong> Valve - Full <strong>and</strong> Reduced Bore<br />

Seat Design Selection<br />

The Omni II is available in three basic styles of seats – soft, hard <strong>and</strong> metal, each<br />

offering a range of performance suitable to many applications.<br />

Soft Seat<br />

Choose from three soft seat materials:<br />

The st<strong>and</strong>ard E-seat PTFE/PFA<br />

copolymer, PEEK <strong>and</strong> PTFE. Each type<br />

of seat is retained in the same manner,<br />

with the valve body machined with a<br />

protective lip designed to eliminate seat<br />

deformation <strong>and</strong> cold flow. This same<br />

lip acts as a secondary back-up seal,<br />

which forms a metal-to-metal contact in<br />

the event the primary soft seal is<br />

destroyed in a fire.<br />

The E-seat offers process purity,<br />

strength, integrity, low permeability<br />

<strong>and</strong> high resiliency. It is composed of<br />

a unique molecularly enhanced<br />

copolymer of PTFE <strong>and</strong> PFA. It offers<br />

a full range of properties formerly<br />

requiring two separate materials. The<br />

E-seat provides pressure <strong>and</strong><br />

The Popcorn Factor<br />

The photographs show a virgin PTFE<br />

seat after attack by reactive monomers<br />

(in this case, styrene). The material’s<br />

molecular matrix has been penetrated<br />

by uninhibited monomers due to vapor<br />

pressure, allowing a polymeric reaction<br />

to take place. Commonly called<br />

“popcorn polymerization,” this reaction<br />

can totally destroy seat material.<br />

In the second photograph, you can see<br />

the results of a field test of the E-seat<br />

copolymer by <strong>KTM</strong>. Using butadiene,<br />

Pressure/Temperature Ratings<br />

This graph shows pressure <strong>and</strong><br />

temperature ratings of the three seat<br />

materials with a full bore of 3 <strong>and</strong> 4<br />

inches <strong>and</strong> a reduced bore of 4 inches.<br />

The E-seat provides characteristics<br />

identical to the carbon-filled material,<br />

while retaining its pure white color. The<br />

same is true at full bores ranging from<br />

1/2" to 8" <strong>and</strong> reduced bores of 6" to 10".<br />

temperature capabilities previously<br />

available only with glass or carbon<br />

fiber-reinforced PTFE. In hightemperature<br />

operations, the seat<br />

remains white, eliminating the risk of<br />

color contamination associated with<br />

seats made from darker reinforced<br />

materials. The E-seat is excellent on a<br />

wide variety of applications but is<br />

particularly recommended for use on<br />

styrene <strong>and</strong> butadiene, where low<br />

permeability is a performance factor;<br />

<strong>and</strong> on low-pressure steam, where<br />

flaking of virgin PTFE is a problem. It<br />

s also recommended for use on food<br />

<strong>and</strong> beverage, pharmaceutical <strong>and</strong><br />

biotech, paper, clean gas <strong>and</strong> any other<br />

applications where product purity <strong>and</strong><br />

the lack of foreign fillers are critical to<br />

success.<br />

generally considered the worst-case<br />

scenario due to its small molecular size,<br />

the test ran for two years at 120 psi <strong>and</strong><br />

180°F. The seats experienced minimum<br />

distortion <strong>and</strong>, after the two-year period,<br />

did not leak in service. Pressure tests<br />

after removal, at 1.1 times design, also<br />

showed no seat leakage. The photo<br />

shows two of the seats tested <strong>and</strong> for<br />

comparison, a new seat is shown in the<br />

foreground.<br />

<strong>KTM</strong>’s PTFE/PFA copolymer E-seat<br />

offers the protection from color<br />

contamination as with virgin PTFE<br />

seats – but, unlike virgin PTFE, it offers<br />

equal or better strength, integrity,<br />

permeability <strong>and</strong> resiliency previously<br />

associated only with reinforced PTFE.<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

16<br />

Pressure, psi<br />

Body Seat<br />

Lip<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

<strong>Ball</strong><br />

Burned<br />

Seat<br />

Body<br />

<strong>Ball</strong> Lip<br />

Fire-safe Seat Design<br />

300 lb Rating<br />

E-seat – G-Seat<br />

PTFE seat<br />

150 lb Rating<br />

0<br />

0 100 200 300 400 500<br />

Temperature (°F)

Gasket<br />

Cushion<br />

Seal<br />

Body<br />

Seat<br />

<strong>Ball</strong><br />

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Omni II Split Body Floating <strong>Ball</strong> Valve - Full <strong>and</strong> Reduced Bore<br />

Seat Design Selection<br />

Metaltite Metal Seat<br />

<strong>KTM</strong> utilizes proprietary processes with special lapping technologies, enabling us to<br />

provide a higher quality product with a superior level of performance. Suitable for a<br />

temperature range from -50°F to 932°F, the Metaltite metal seat is bi-directional <strong>and</strong><br />

provides a high performance solution to many difficult applications. Precision lapping<br />

of the ball-to-seat result in superior interfacing <strong>and</strong> a tight shut-off conforming to ANSI<br />

FCI 70-2 Class V <strong>and</strong> Class VI. Available with two different ball coatings: Hard chrome<br />

or Nickel alloy overlay. Durable stellited stainless seats are highly corrosion <strong>and</strong><br />

erosion resistant. RTFE or soft carbon stem seals are available.<br />

For complete information on Metal Seat, see page 26.<br />

Spring<br />

Hard Gratite ® Seat<br />

Seat<br />

Body<br />

<strong>Ball</strong><br />

Pressure/Temperature Ratings (Gratite ®)<br />

Pressure - psi<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

-20 100 200 300 400 500 600 700 800 900 1000<br />

Temperature - °F<br />

Body<br />

Cap<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

17<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

<strong>Ball</strong><br />

Seat<br />

Gasket<br />

A proprietary product for high-temperature, high-pressure, flammable <strong>and</strong> corrosive<br />

critical-process applications, the <strong>KTM</strong> Gratite ® seat offers superior performance <strong>and</strong><br />

reliability. Patented (U.S. Patent 4,269,391), it is designed to operate within a<br />

temperature range from -50°F to 932°F. Gratite ® is a bonded composite of hard<br />

graphite material. The cushion seal provides resiliency during thermal expansioncontraction.<br />

The result is a seat with physical properties that are far superior to<br />

conventional ball valve seats of carbon graphite construction.<br />

• More economical than Stellite.<br />

• High resistance to thermal shock.<br />

For complete information on<br />

Gratite ® seat, see page 20.<br />

CF8M-316 SS ASTM-A216 WCB - Carbon Steel<br />

ANSI Class 300<br />

ANSI<br />

Class 150<br />

Pressure - psi<br />

-50°F to 932°F<br />

Wide Temperature Range<br />

ANSI<br />

Class 150<br />

-20 100 200 300 400 500 600 700 800 900 1000<br />

Temperature - °F<br />

ANSI Class 300

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Omni II Split Body Floating <strong>Ball</strong> Valve - Full <strong>and</strong> Reduced Bore<br />

Technical Information<br />

W<br />

L<br />

L<br />

W<br />

H H<br />

Sizes 1/2" to 1" Sizes 1/2" to 2" Sizes 2 1/2" to 3" Sizes 4" to 8" 8" Gear operated Flange diameter<br />

150 lb. Class Dimensions, Full <strong>and</strong> Reduced Bore<br />

1/2" 0.50 4.25 2.38 5.13 0.25 5.0 – – – – – – 3.5 2.38 1.38 0.44 (4) 5/8<br />

3/4" 0.75 4.62 2.5 5.13 0.25 6.5 – – – – – – 3.86 2.76 1.69 0.44 (4) 5/8<br />

1" 1.0 5.0 3.0 6.31 0.31 10.0 – – – – – – 4.25 3.13 2.01 0.44 (4) 5/8<br />

1 1/2" 1.5 6.5 4.06 9.06 0.44 17.0 – – – – – – 5.0 3.88 2.87 0.56 (4) 5/8<br />

2" 2.0 7.0 4.5 9.06 0.44 23.0 – – – – – – 5.99 4.74 3.62 0.63 (4) 3/4<br />

2 1/2" 2.5 7.5 6.13 15.75 0.69 42.0 – – – – – – 7.01 5.49 4.13 0.69 (4) 3/4<br />

3" 3.0 8.0 6.5 15.75 0.69 51.0 – – – – – – 7.48 6.0 5.0 0.75 (4) 3/4<br />

4" 4.0 9.0 7.5 28.13 0.88 74.0 – – – – – – 9.02 7.5 6.18 0.94 (8) 3/4<br />

6" 6.0 15.5 10.75 45.06 1.06 151.0 5 10.5 10.0 28.13 1.06 121 10.98 9.51 8.5 1.0 (8) 7/8<br />

8" 8.0 18.0 13.5 59.0 1.42 238.0 6 11.5 10.75 45.06 1.25 182 13.5 11.75 10.63 1.13 (8) 7/8<br />

10" – – – – – – 8 13.0 15.94 59.45 1.42 267 15.98 14.25 12.76 1.19 (12) 1<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

18<br />

L<br />

W<br />

L<br />

W<br />

H H<br />

4 1/2"<br />

L<br />

8" to 16 3/16"<br />

T<br />

dG CD<br />

N-h<br />

Gear operator<br />

E<br />

13 3/4"<br />

Stem Top<br />

Valve EB100 Full Bore Weight EB800 Reduced Bore Weight 150 Lb. Flange<br />

Size (d) Bore L H W E Lbs. (d) Bore L H W E Lbs. D C G T (N) - h<br />

23 5/8"

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Omni II Split Body Floating <strong>Ball</strong> Valve - Full <strong>and</strong> Reduced Bore<br />

Technical Information<br />

300 lb. Class Dimensions, Full Bore<br />

Valve EB100 Full Bore 300 Lb. Flange Weight<br />

Size (d) Bore L H W E D C G T (N) -h Lbs.<br />

1/2" 0.5 5.5 2.25 5.13 0.28 3.74 2.62 1.38 0.56 (4) 5/8 5.5<br />

3/4" 0.75 6.0 2.5 5.13 0.28 4.61 3.25 1.69 0.63 (4) 3/4 7.0<br />

1" 1.0 6.5 3.0 6.25 0.31 4.88 3.5 2.01 0.69 (4) 3/4 11.0<br />

1 1/2" 1.5 7.5 3.75 9.5 0.47 6.14 4.51 2.87 0.81 (4) 7/8 24.0<br />

2" 2.0 8.5 4.25 9.5 0.47 6.5 5.0 3.62 0.88 (8) 3/4 33.0<br />

2 1/2" 2.5 9.5 5.5 15.75 0.67 7.48 5.87 4.13 1.0 (8) 7/8 52.0<br />

3" 3.0 11.13 6.0 15.75 0.67 8.27 6.61 5.0 1.13 (8) 7/8 79.0<br />

4" 4.0 12.0 7.0 27.5 0.87 10.0 7.87 6.18 1.25 (8) 7/8 91.0<br />

6" 6.0 15.88 10.75 43.25 1.06 12.52 10.63 8.5 1.44 (12) 7/8 233.0<br />

8" 8.0 19.75 13.5 59.0 1.42 15.0 12.99 10.63 1.63 (12) 1 267.0<br />

Weights for 6" <strong>and</strong> 8" are lever operated valves. For gear operated, add 30 lbs. for 6" <strong>and</strong> 55 lbs. for 8".<br />

Notes:<br />

1. Lever h<strong>and</strong>le st<strong>and</strong>ard up to 8". Gear operators<br />

are available. <strong>KTM</strong> furnishes a lever h<strong>and</strong>le for<br />

sizes up to 10" due to low operating torque. Gear<br />

operators are available at user’s option.<br />

2. <strong>KTM</strong> ball valves comply with one or more of the<br />

following st<strong>and</strong>ard specifications as to pressure,<br />

temperature ratings <strong>and</strong> dimensions:<br />

ANSI B1.20.1 Pipe Threads<br />

ANSI B16.5 Steel Pipe Flanges<br />

ANSI B16.10 Face-to-Face Dimensions<br />

ANSI B16.34 <strong>Valves</strong> - Flanged,<br />

threaded <strong>and</strong> welded end<br />

C v Values, Full <strong>and</strong> Reduced Bore<br />

1/2" 26 –<br />

3/4" 50 –<br />

1" 94 –<br />

11/2" 260 –<br />

2" 480 –<br />

21/2" Valve Size Full Reduced<br />

750 –<br />

3" 1300 –<br />

4" 2300 –<br />

6" 5400 1800<br />

8" 10000 2500<br />

10" – 4500<br />

Materials of Construction<br />

Body: Carbon Steel (A216, WCB)<br />

304 SS (CF8), 316 SS (CF8M)<br />

<strong>Ball</strong>: 304 SS (CF8), 316 SS (CF8M)<br />

Stem: 304 SS, 316 SS<br />

Seat: PTFE/PFA Copolymer<br />

Packing: PTFE or Soft Carbon<br />

Valve Class: 150 <strong>and</strong> 300<br />

Test pressure per API 6D:<br />

Shell (Hydrostatic)<br />

Class 150 – 425 psig (30 kgf/cm2) Class 300 – 1100 psig (77 kgf/cm2) Seat<br />

(Hydrostatic)<br />

Class 150 – 300 psig (21 kgf/cm2) Class 300 – 800 psig (56 kgf/cm2) (Air)<br />

Class 150 – 80 psig (6 kgf/cm2) Class 300 – 80 psig (6 kgf/cm2) Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

19

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Gratite ® Seat, Hi-Temp <strong>Ball</strong> <strong>Valves</strong><br />

<strong>KTM</strong>’s Hi-Temp ball valves are designed<br />

to operate within a temperature range<br />

from -50ºF to 932ºF. They incorporate<br />

valve seats of Gratite ® material<br />

(a bonded composite of graphite)<br />

formed with flexible graphite which is<br />

used to cushion seal. The result is a<br />

seat with physical properties that are<br />

far superior to conventional ball valve<br />

seats of carbon graphite construction.<br />

Features<br />

• More economical than metal seat.<br />

• High resistance to thermal shock.<br />

• High electro conductivity helps<br />

eliminate need for grounding device.<br />

• Seats <strong>and</strong> seals are virtually<br />

chemically inert.<br />

• Blow-out proof stem.<br />

• Two-piece body construction.<br />

• Fire-safe.<br />

• Easy actuator mounting.<br />

• Bi-directional flow.<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

20<br />

Special Options<br />

• Extension bonnet<br />

Special Tests<br />

• Liquid penetrant<br />

• X-ray<br />

St<strong>and</strong>ards<br />

Design: ASME B16.34<br />

End connection: ASME B16.5<br />

General Applications<br />

• Chemical plant<br />

• Oil refinery<br />

• Power plant<br />

• Pulp <strong>and</strong> paper<br />

• Steam<br />

• Dowtherm<br />

• Fused alkali<br />

• Fuel oil <strong>and</strong> gas<br />

Technical Data<br />

Models/Sizes: ASME Class 150,<br />

Full bore 1/2" to 8"<br />

ASME Class 300,<br />

Full bore 1/2" to 8"<br />

ASME Class 600,<br />

Full bore 1/2" to 4"<br />

(Reduced bore available upon request)<br />

Pressure rating: ASME Class 150,<br />

300 <strong>and</strong> 600<br />

Temperature: -50°F to 932°F<br />

For Pressure/Temperature:<br />

ANSI 150 <strong>and</strong> 300 – refer to chart<br />

on page 17.<br />

ANSI 600 – refer to chart on page 28.

Gratite ® Seat Hi-Temp <strong>Ball</strong> <strong>Valves</strong><br />

H H1<br />

L<br />

L1<br />

Sizes 1/2" to 4"<br />

Sizes 1/2" to 1 1/2"<br />

W<br />

ød<br />

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

W<br />

W<br />

H H1<br />

L<br />

L1<br />

Sizes 6" to 8"<br />

W<br />

ød<br />

D: Outside diameter<br />

C: Bolt circle diameter<br />

G: Raised face diameter<br />

T: Flange thickness<br />

N: Number of bolts<br />

h: Bolt hole size<br />

d: Bore diameter<br />

f: Raised face height<br />

N-h<br />

f<br />

T<br />

Flange Ends<br />

150 lb Class Dimensions<br />

Valve EB100 Full Bore Weight 150 lb Flange<br />

Size (d) Bore L L1 H H1 Lbs. D C G T f (N) - h<br />

1/2" 0.5 4.25 1.9 3.2 2.6 7.9 3.5 2.38 1.38 0.44 0.6 (4) 5/8<br />

3/4" 0.75 4.62 2.0 3.3 2.8 7.9 3.86 2.76 1.69 0.44 0.6 (4) 5/8<br />

1" 1.0 5.0 2.2 3.9 3.2 9.4 4.25 3.13 2.01 0.44 0.6 (4) 5/8<br />

11/2" 1.5 6.5 2.95 4.9 4.3 13.8 5.0 3.88 2.87 0.56 0.6 (4) 5/8<br />

2" 2.0 7.0 3.1 5.3 4.7 13.8 5.99 4.74 3.62 0.63 0.6 (4) 3/4<br />

3" 3.0 8.0 3.9 6.9 – 23.6 7.48 6.0 5.00 0.75 0.6 (4) 3/4<br />

4" 4.0 9.0 4.5 9.4 7.9 42.0 9.02 7.5 6.18 0.94 0.6 (8) 3/4<br />

6" 6.0 15.5 7.1 13.0 11.2 65.0 10.98 9.51 8.50 1.00 0.6 (8) 7/8<br />

8" 8.0 18.0 8.9 16.0 14.4 89.0 13.5 11.75 10.63 1.13 0.6 (8) 7/8<br />

300 lb Class Dimensions<br />

Valve EB100 Full Bore Weight 300 lb Flange<br />

Size (d) Bore L L1 H H1 Lbs. D C G T f (N) - h<br />

1/2" 0.5 5.5 2.4 3.2 2.6 7.9 3.74 2.62 1.38 0.56 0.6 (4) 5/8<br />

3/4" 0.75 6.0 2.8 3.3 2.8 7.9 4.61 3.25 1.69 0.63 0.6 (4) 3/4<br />

1" 1.0 6.5 2.9 3.9 3.2 9.4 4.88 3.50 2.01 0.69 0.6 (4) 3/4<br />

11/2" 1.5 7.5 3.1 4.9 4.3 13.8 6.14 4.51 2.87 0.81 0.6 (4) 7/8<br />

2" 2.0 8.5 3.5 5.3 4.7 13.8 6.5 5.0 3.62 0.88 0.6 (8) 3/4<br />

3" 3.0 11.13 4.7 6.9 – 23.6 8.27 6.61 5.00 1.13 0.6 (8) 7/8<br />

4" 4.0 12.0 5.7 9.4 7.9 42.0 10.0 7.87 6.18 1.25 0.6 (8) 7/8<br />

6" 6.0 15.88 7.5 13.0 11.2 65.0 12.52 10.63 8.50 1.44 0.6 (12) 7/8<br />

8" 8.0 19.75 9.3 16.0 14.4 89.0 15.0 12.99 10.63 1.63 0.6 (12) 1<br />

L<br />

L1<br />

W<br />

H1<br />

H2<br />

ød<br />

H<br />

L<br />

H<strong>and</strong>le for<br />

Valve Size 3"<br />

H<strong>and</strong>le for<br />

Valve Size 2"<br />

H<strong>and</strong>le for<br />

Valve Size 4"<br />

L1<br />

(Uni-directional flow)<br />

Sizes 2" to 3"<br />

W<br />

ød<br />

H1<br />

H2<br />

H<br />

W<br />

H1H<br />

D: Outside diameter<br />

C: Bolt circle diameter<br />

G: Raised face diameter<br />

T: Flange thickness<br />

N: Number of bolts<br />

h: Bolt hole size<br />

d: Bore diameter<br />

f: Raised face height<br />

d G C D<br />

N-h<br />

f<br />

T<br />

Flange Ends<br />

Valve EO100 Full Bore Weight 600 lb Flange<br />

Size (d) Bore L L1 H H1 Lbs. D C G T f N-h<br />

1/2" 0.5 6.5 2.9 3.9 3.0 9.4 3.7 2.6 1.37 0.56 0.25 (4)-16<br />

3/4" 0.75 7.5 3.4 4.1 3.2 9.4 4.6 3.2 1.7 0.63 0.25 (4)-19<br />

1" 1.0 8.5 3.9 4.9 4.0 13.8 4.9 3.5 2.0 0.69 0.25 (4)-19<br />

11/2" 600 lb Class Dimensions<br />

1.5 9.5 4.4 5.3 4.4 13.8 6.1 4.5 2.9 0.88 0.25 (4)-22<br />

2" 2.0 11.5 5.7 {5.0} 7.4 {7.0} 7.0 {6.7} 23.6 6.5 5.0 3.6 1.00 0.25 (8)-19<br />

3" 3.0 14.0 7.0 9.6 {8.8} 7.9 {7.1} 42.0 8.3 6.6 5.0 1.25 0.25 (8)-22<br />

4" 4.0 17.0 8.5 13.3 11.1 65.0 10.7 8.5 6.2 1.50 0.25 (8)-25<br />

{ } – Dimensions for Stainless Steel Body<br />

L<br />

L1<br />

(Uni-directional flow)<br />

Sizes 4"<br />

ød<br />

W<br />

H1<br />

H2<br />

H<br />

d G C D<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

21

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

NoFill Cavity Free Valve - Full Bore, EB100 Omni II Style<br />

Proprietary Micro-space<br />

Design Helps Reduce<br />

Reactive Buildup.<br />

A frequent problem in processing<br />

products ranging from reactive<br />

monomers such as styrene <strong>and</strong><br />

butadiene to starches <strong>and</strong> slurries is<br />

that they can, <strong>and</strong> do, build up – <strong>and</strong><br />

polymerize or ferment – within the<br />

“cavities” or open spaces inside the<br />

valves controlling the process.<br />

Until now the response to this problem<br />

has been to fill the cavities with PFA,<br />

FEP or another “foreign” material.<br />

A more complete solution is <strong>KTM</strong>’s<br />

NoFill valve. As its name implies, the<br />

NoFill uses no filling material of any<br />

kind. Instead, the cavity has been<br />

completely eliminated – except for the<br />

micro-space required for ball movement<br />

(shown here in red). Depending upon<br />

the valve size, that micro-space ranges<br />

from 0.5 to 1.0 millimeter. All wetted<br />

surfaces are stainless steel, polished to<br />

a mirror finish.<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

22<br />

This technology from <strong>KTM</strong> is superior<br />

because:<br />

• The micro-space is designed to<br />

severely restrict the area where<br />

product can collect <strong>and</strong> build up<br />

over time.<br />

• The mirror-finished interior helps<br />

drastically reduce the potential for<br />

bonding.<br />

• There is no excess material to flake<br />

off with wear, helping reduce product<br />

contamination.<br />

• Solidification of media is much more<br />

manageable, should a severe<br />

process change occur.<br />

• The stainless steel interior lasts much<br />

longer, resulting in less down-time.<br />

This, plus easy maintenance,<br />

translates to a lower total cost of<br />

ownership.<br />

Applications<br />

• Styrene<br />

• Butadiene<br />

• Methylene chloride<br />

• Starches<br />

• Slurries<br />

• Food processing<br />

• Fermentation<br />

• Pharmaceuticals

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

NoFill Cavity Free Valve - Full Bore, EB100 Omni II Style<br />

The micro-space required for<br />

ball movement is highlighted<br />

in red for emphasis.<br />

5 2<br />

More Reasons to Choose<br />

<strong>KTM</strong>’s NoFill<br />

The <strong>KTM</strong> NoFill features a bi-directional<br />

floating design with maximum Cv values<br />

that provide minimal pressure drop<br />

through the valve.<br />

The NoFill’s spherical-shaped seats<br />

help ensure 360° sealing. The seat itself<br />

is <strong>KTM</strong>’s E-seat, a unique molecularlyenhanced<br />

copolymer of PTFE <strong>and</strong> PFA.<br />

This strong, low-permeability material<br />

provides chemical resistance to reactive<br />

monomers. In high temperature<br />

operations, the seat remains white,<br />

eliminating the risk of color<br />

contamination associated with seats<br />

made from darker reinforced materials.<br />

For abrasive processes, the NoFill is<br />

also available with metal seats.<br />

The NoFill valve comes in two-way <strong>and</strong><br />

Y-pattern diverter configurations.<br />

4<br />

1<br />

3<br />

Specifications<br />

Valve Model<br />

Full Bore,<br />

EB100 Omni II Style<br />

Body Material<br />

A-351, Gr. CF8M<br />

A-351, Gr. CF8<br />

<strong>Ball</strong>/Stem A-276, Tp. 316 SS<br />

Material A-276, Tp. 304 SS<br />

Seat Material PTFE/PFA Copolymer<br />

Gl<strong>and</strong> Packing TFE (St<strong>and</strong>ard)<br />

Material GRAFOIL ® (Optional)<br />

ANSI Class<br />

150<br />

300<br />

Mounting Pad ISO 5211 (not shown)<br />

L = Lever<br />

Operator W = Oval H<strong>and</strong>wheel<br />

G = Gear<br />

Special Feature NoFill Micro-space Design<br />

Size Range 0.5" to 8.0" Full Port<br />

1. Rugged stainless steel body design.<br />

2. Bi-directional floating design.<br />

3. Mirror-finish stainless steel surface on<br />

all wetted areas.<br />

4. Strict “micro-space” ball clearance<br />

tolerances:<br />

• 0.5 mm for valves sized 1/2" to 2"<br />

• 1.0 mm for valves sized 21/2" to 8"<br />

5. Spherically-shaped seats ensure<br />

positive 360° sealing.<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

23

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Metaltite Metal Seated <strong>Valves</strong> - 1/2" to 20"<br />

Features<br />

• Superior quality <strong>and</strong> dependability:<br />

We make sure the quality is built-in,<br />

beginning at our own foundries <strong>and</strong><br />

through rigorous testing each step of<br />

our fully integrated manufacturing<br />

process. Every <strong>KTM</strong> valve is<br />

serialized <strong>and</strong> comes with a complete<br />

set of mill test reports that ensures its<br />

quality – <strong>and</strong> guarantees its<br />

performance. Very few valve<br />

manufacturers can match this feature.<br />

• Long life: Built rugged to withst<strong>and</strong><br />

the toughest operating conditions,<br />

<strong>KTM</strong> valves have a documented<br />

history of long, uninterrupted service.<br />

• Broad product range: We offer a wide<br />

selection of specifications that allow<br />

you to select the right valve to meet<br />

the requirements of your operating<br />

process.<br />

• Availability: Historically designed as<br />

customized products to meet specific<br />

customer needs, our metal seated<br />

valves today are mass produced,<br />

which means they are available “off<br />

the shelf.” No long wait for delivery.<br />

• Experience: <strong>KTM</strong> has been making<br />

metal seated valves for more than a<br />

quarter of a century. Our worldwide<br />

installed base is very large.<br />

• Conformance: Precision lapping of<br />

ball to seat <strong>and</strong> high-precision<br />

machining result in superior ball<br />

<strong>and</strong> seat interfacing for tight shut-off,<br />

conforming to ANSI FCI 70-2 Class V<br />

<strong>and</strong> Class VI.<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

24<br />

General Applications<br />

• Clean liquids<br />

• Dirty liquids<br />

• High viscosity<br />

• Scaling liquids<br />

• Corrosive<br />

• Erosive<br />

• Waste treatment<br />

• Sludge<br />

• Pulp stock<br />

• Saturated steam<br />

• Superheated steam<br />

• Wet slurries:<br />

- Pellets<br />

- Monomers<br />

- Abrasive<br />

- Fibers<br />

• Dry slurries:<br />

- Powder<br />

- Polymer fluff<br />

- Pellets<br />

• Clean gasses<br />

• Dirty gasses<br />

• High temperature<br />

• High velocity

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Metaltite Metal Seated <strong>Valves</strong> - 1/2" to 20"<br />

V-Port <strong>Valves</strong> for Dual Function,<br />

On/Off or Modulating<br />

<strong>KTM</strong>’s Single V <strong>and</strong> Dual V are rugged<br />

dual-function valves that can be used<br />

in On/Off applications as well as<br />

modulating applications. These valves<br />

are designed to provide solutions to<br />

specific operating needs.<br />

Single V Offers:<br />

• Shearing action<br />

• Low torque<br />

• Upstream single-seat trunnion design<br />

• Non-clogging<br />

• 100:1 rangeability<br />

• No body cavity<br />

• No downstream seat allows media<br />

to flow freely <strong>and</strong> smoothly, help<br />

prevent buildup<br />

• Rugged split-body design<br />

• Adjustable gl<strong>and</strong> packing<br />

• Inherently fire-safe design<br />

• Anti-static grounding device<br />

• Blow-out proof stem<br />

Dual V Offers:<br />

• Shearing action<br />

• Low torque<br />

• Upstream single-seat trunnion design<br />

• Non-clogging<br />

• 250:1 rangeability<br />

• No body cavity<br />

• No downstream seat allows media<br />

to flow freely <strong>and</strong> smoothly, helps<br />

prevent buildup<br />

• Compact unibody design<br />

• Class V shut-off<br />

• Integral ISO mounting pad<br />

• Easy installation, versatile end<br />

connections<br />

• Adjustable gl<strong>and</strong> packing<br />

• Inherently fire-safe design<br />

• Anti-static grounding device<br />

• Flanged <strong>and</strong> wafer designs<br />

• Blow-out proof stem<br />

Omni <strong>and</strong> Y-Pattern <strong>Valves</strong> for<br />

On/Off Applications<br />

<strong>KTM</strong>’s Omni family of valves are<br />

unmatched in general-purpose On/Off<br />

applications. Our Y-Pattern valve adds<br />

dependable diverter capabilities where<br />

operations require them.<br />

Omni II Offers:<br />

• Fugitive emission control<br />

• Integral ISO mounting pad<br />

• Rugged split-body design<br />

• Live-loaded adjustable gl<strong>and</strong> packing<br />

• Inherently fire-safe design<br />

• Anti-static grounding device<br />

• Blow-out proof stem<br />

• Radial tost bearing<br />

Trunnion Offers:<br />

• Double block <strong>and</strong> bleed<br />

• True trunnion design<br />

• Rugged split-body design<br />

• Integral mounting pad<br />

• Adjustable gl<strong>and</strong> packing<br />

• Low torque<br />

• Inherently fire-Safe design<br />

• Anti-static grounding device<br />

• Powder guard feature<br />

• Blow-out proof stem<br />

Y-Pattern Offers:<br />

• Slurry diverter service<br />

• Minimum body cavity<br />

• Polished bore<br />

• 135° operation<br />

• Piggability<br />

• Top entry<br />

• Adjustable gl<strong>and</strong> packing<br />

• Inherently fire-safe design<br />

• Anti-static grounding device<br />

• Blow-out proof stem<br />

• No mixing of media when<br />

changing flow<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

25

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Metaltite Metal Seated <strong>Valves</strong> - 1/2" to 20"<br />

Valve Selection <strong>and</strong> Seat Designs<br />

Valve Type: Single V<br />

Model No.: (WO 400/600)<br />

Seat Design/ A-1/Class IV<br />

Seal Class: A-2/Class II<br />

Characteristics:<br />

Temp -20°F to 482°F, Single seat<br />

Uni-directional Trunnion Design<br />

ANSI 150/300, 1" to 20"<br />

Modulating, On/Off<br />

Valve Type: Dual V<br />

Model No.: (WA Series)<br />

Seat Design/Seal Class: B/Class V<br />

Characteristics:<br />

Temp -20°F to 518°F, Single seat<br />

Uni-directional Trunnion Design<br />

ANSI 150/300, 1" to 8"<br />

Modulating, On/Off<br />

Valve Type: Omni II<br />

Model No.: (EB100)<br />

Seat Design/Seal Class: C/Class V<br />

Characteristics:<br />

Temp -20°F to 932°F, Two seats<br />

Bi-directional Floating Design<br />

ANSI 150/300, 1/2" to 8"<br />

On/Off<br />

Valve Type: Trunnion<br />

Model No.: (EO1200)<br />

Seat Design/ D/Class V<br />

Seal Class: E/Class V<br />

F/Class V<br />

G/Class V<br />

Characteristics:<br />

Temp -20°F to 932°F, Two seats<br />

Bi-directional or Single seat<br />

Uni-directional Trunnion Design<br />

ANSI 150/300, 2" to 20"<br />

ANSI 600, 2" to 16"<br />

On/Off<br />

Valve Type: Y-Pattern Diverter<br />

Model No.: (E3700)<br />

Seat Design/Seal Class: H/Class V<br />

Characteristics:<br />

Temp -20°F to 482°F, Three seats<br />

Trunnion Design<br />

ANSI 150/300, 1" to 12"<br />

ANSI 600, 1" to 3"<br />

Diverting<br />

Wonder Wonder Valve Valve (V-port) (V-port)<br />

Omni 2<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

26<br />

Omni 2<br />

A-1 A-2<br />

Class IV, Laminated seat Class II, Thick seat<br />

B<br />

D-D<br />

6" to 20"<br />

Same seat applies to both sides.<br />

Class V, Spring loaded stellited seat<br />

C-1 C-2<br />

Bi-directional: Preferred flow is cap to body.<br />

Scraper type with powder guard seals max. temp. 482°F<br />

F-F<br />

G-G<br />

6" to 20"<br />

H<br />

St<strong>and</strong>ard type<br />

max. temp. 482°F<br />

E-E<br />

2" to 4"<br />

High temperature<br />

applications max. temp.<br />

932°F

Energy <strong>and</strong> Process Valve - 1/2" to 2"<br />

Features<br />

• Patented seat design has proven<br />

performance in both energy <strong>and</strong><br />

process applications.<br />

• Valve seats are Gratite ® (a bonded<br />

composite of hard graphite) which<br />

forms the seat along with soft carbon<br />

used for the cushion seal.<br />

• The result is a seat with physical<br />

properties that are far superior to<br />

conventional ball valve seats of<br />

carbon graphite construction.<br />

• Designed for zero leakage (liquid<br />

service).<br />

• Full bore.<br />

• Full ANSI rating <strong>and</strong> suitable for<br />

ON-OFF service up to 932°F.<br />

• Reduces energy costs.<br />

• Seats <strong>and</strong> seals virtually chemically<br />

inert.<br />

• Blow-out proof stem.<br />

• Higher CV than gate or globe valves.<br />

• Inherently fire-safe.<br />

• Designed to resist thermal <strong>and</strong><br />

pressure shock.<br />

• Can be welded in line without<br />

disassembly.<br />

• Easy parts replacement.<br />

• Two-piece body.<br />

• Sphericity tolerance of the balls,<br />

± 0.0008", <strong>and</strong> a 4 RMS surface<br />

finish are unsurpassed.<br />

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

General Applications<br />

Process:<br />

• Vacuum service<br />

• Refinery products<br />

• Slurry service<br />

• Viscous materials<br />

• Air<br />

• Water<br />

Energy:<br />

• Steam<br />

• Hot liquids<br />

• Hot gases<br />

• BTU conservation<br />

Technical Data<br />

Size range: Full bore<br />

1/2" to 2"<br />

ANSI Class 300 <strong>and</strong> 600<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

27

<strong>KTM</strong> <strong>Ball</strong> <strong>Valves</strong><br />

Energy <strong>and</strong> Process Valve - 1/2" to 2"<br />

2<br />

3<br />

4<br />

13<br />

14<br />

1<br />

Notes:<br />

1. * Denotes Spare Parts<br />

2. After Model No. add “SE” for Screw Ends or<br />

“SW” for Socket Weld<br />

U.S. Patent 4,269,391<br />

Pressure/Temperature Ratings<br />

Pressure - psi<br />

18<br />

6<br />

3<br />

Detail “A”<br />

12<br />

15<br />

11<br />

7<br />

21<br />

16<br />

8<br />

16<br />

21<br />

5<br />

10<br />

S<br />

1<br />

20<br />

19<br />

CF8M-316 SS<br />

L<br />

1600<br />

1400<br />

1200<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

-20 100 200 300 400 500 600 700 800 900 1000<br />

Temperature - °F<br />

ANSI Class 600<br />

ANSI Class 300<br />

Note: ANSI B16.34 temperature limitation is 800°F on WCB material.<br />

17<br />

L 1<br />

9<br />

W<br />

See Detail “A”<br />

Dimensions <strong>and</strong> C V Value<br />

Material <strong>and</strong> Model Numbers<br />

Copyright © 2009 Tyco <strong>Flow</strong> <strong>Control</strong>. All rights reserved. <strong>KTM</strong>MC-0550<br />

28<br />

d<br />

H<br />

No. Part EB162-32/39FU-30 EB132-32/39FU-30<br />

1 Body A216 Gr. WCB Gr. CF8M<br />

or A105 or 316 SS<br />

2 Body Cap A216 Gr. WCB A351 Gr. CF8M<br />

or A105 or 316 SS<br />

3 <strong>Ball</strong> 316 SS 316 SS<br />

*4 Gasket Soft Carbon Soft Carbon<br />

5 Stem 329 SS 329 SS<br />

*6 Seat Carbon Carbon<br />

7 Gl<strong>and</strong> Flange Carbon Steel 304 SS<br />

*8 Gl<strong>and</strong> Packing Soft Carbon Soft Carbon<br />

9 Live Loading Spring 304 SS 304 SS<br />

10 Tost Bearing 316 SS 316 SS<br />

11 Stopper Carbon Steel 304 SS<br />

12 H<strong>and</strong>le Ductile Iron Ductile Iron<br />

13 Stud A193 Gr. B7 304 SS<br />

14 Nut A194 Gr. 2H 304 SS<br />

15 Snap Ring Steel 304 SS<br />

16 Tost Washer 316 SS 316 SS<br />

17 Gl<strong>and</strong> Bolt 304 SS 304 SS<br />

*18 Seat Retainer 316 SS 316 SS<br />

19 Inner Ring 316 SS 316 SS<br />

*20 Cushion Soft Carbon Soft Carbon<br />

*21 Stem Bearing Soft Carbon Soft Carbon<br />

Valve<br />

Size Bore (d) L L 1 H W S C V<br />

1/2" 0.50 5.51 2.76 2.60 7.87 0.28 26<br />

3/4" 0.75 5.98 3.00 2.76 7.87 0.28 50<br />