Product Data

Product Data

Product Data

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Features/Benefits (cont)<br />

The benefits are many<br />

• fully assembled units<br />

• capacities to 40 tons<br />

• system design flexibility<br />

• commercial and industrial<br />

application<br />

• for use with most refrigerants<br />

• special-order combinations available<br />

on request<br />

Accurate system design<br />

Broad range of sizes allows selection<br />

of evaporator coil or chiller to<br />

form a well-balanced system. Capacity<br />

will closely match the system load requirements,<br />

and provide efficient,<br />

energy-saving, economical operation<br />

at maximum load conditions.<br />

A unit for all load conditions is<br />

offered, from refrigeration to air<br />

conditioning duty. Units have shelland-tube<br />

condensers. All are compactly<br />

designed to take minimum floor<br />

space. The 07 Series units are built<br />

and tested to comply with ASME<br />

(American Society of Mechanical<br />

Engineers) Code for unfired pressure<br />

vessels, and ANSI/ASHRAE 15<br />

(American National Standards<br />

Institute/American Society of Heating,<br />

Refrigeration and Air Conditioning<br />

Engineers) latest revision safety<br />

standard.<br />

2<br />

Economical operation<br />

Capacity control valves are provided<br />

in all 07 Series units, except<br />

07DA203 models, giving a built-in<br />

system for conserving power and water<br />

and assuring accurate control. When<br />

only partial load operation is needed,<br />

capacity control valves automatically<br />

step down compressor capacity. Refrigeration<br />

output can be reduced to<br />

about one third of full load in direct response<br />

to suction pressure changes.<br />

When system load is reduced, power<br />

and water usage are also reduced. Suction<br />

cutoff unloading further reduces<br />

energy usage during unloaded operation.<br />

Valve body shuts off passage from<br />

suction manifold, preventing charge<br />

from unnecessarily being pulled into<br />

the cylinder. This results in an EER<br />

(Energy Efficiency Ratio) improvement<br />

of as much as 39.5% at 33% load.<br />

Built-in reliability<br />

Condenser includes a pressure relief<br />

device which protects the system<br />

against overpressure.<br />

Compressor has motor overtemperature<br />

protection. On 07E models,<br />

manually reset 3-phase circuit breakers<br />

protect against power irregularities.<br />

High- and low-pressure switches are<br />

standard. Oil-pressure switch is<br />

standard on 07D and 07E models. An<br />

automatically reversible oil pump with<br />

automatic pressure regulator keeps<br />

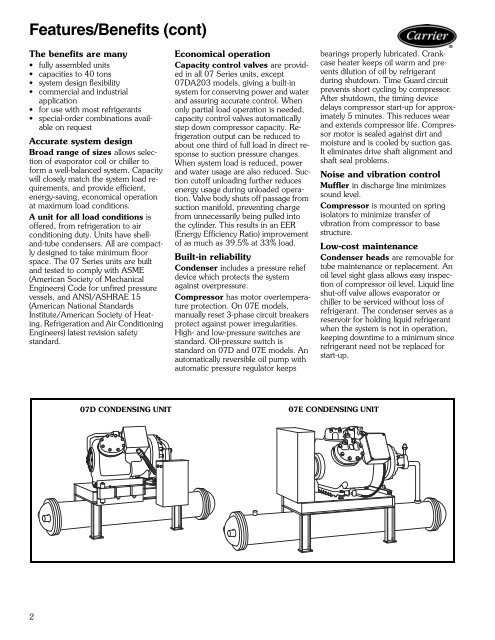

07D CONDENSING UNIT 07E CONDENSING UNIT<br />

bearings properly lubricated. Crankcase<br />

heater keeps oil warm and prevents<br />

dilution of oil by refrigerant<br />

during shutdown. Time Guard circuit<br />

prevents short cycling by compressor.<br />

After shutdown, the timing device<br />

delays compressor start-up for approximately<br />

5 minutes. This reduces wear<br />

and extends compressor life. Compressor<br />

motor is sealed against dirt and<br />

moisture and is cooled by suction gas.<br />

It eliminates drive shaft alignment and<br />

shaft seal problems.<br />

Noise and vibration control<br />

Muffler in discharge line minimizes<br />

sound level.<br />

Compressor is mounted on spring<br />

isolators to minimize transfer of<br />

vibration from compressor to base<br />

structure.<br />

Low-cost maintenance<br />

Condenser heads are removable for<br />

tube maintenance or replacement. An<br />

oil level sight glass allows easy inspection<br />

of compressor oil level. Liquid line<br />

shut-off valve allows evaporator or<br />

chiller to be serviced without loss of<br />

refrigerant. The condenser serves as a<br />

reservoir for holding liquid refrigerant<br />

when the system is not in operation,<br />

keeping downtime to a minimum since<br />

refrigerant need not be replaced for<br />

start-up.