The new "thru-wall" look at Sellafield - Mirion Technologies

The new "thru-wall" look at Sellafield - Mirion Technologies

The new "thru-wall" look at Sellafield - Mirion Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

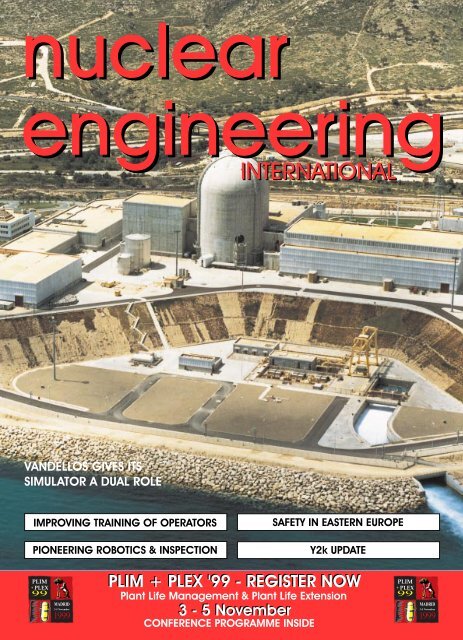

nuclear<br />

engineering<br />

VANDELLOS GIVES ITS<br />

SIMULATOR A DUAL ROLE<br />

IMPROVING TRAINING OF OPERATORS<br />

PLIM<br />

+ PLEX<br />

99<br />

MADRID<br />

3-5 November<br />

1999<br />

PLIM + PLEX '99 - REGISTER NOW<br />

Plant Life Management & Plant Life Extension<br />

3 - 5 November<br />

CONFERENCE PROGRAMME INSIDE<br />

INTERNATIONAL<br />

SAFETY IN EASTERN EUROPE<br />

PIONEERING ROBOTICS & INSPECTION Y2k UPDATE<br />

PLIM<br />

+ PLEX<br />

99<br />

MADRID<br />

3-5 November<br />

1999

INSPECTION & ROBOTICS ROUND-UP<br />

<strong>The</strong> <strong>new</strong> "<strong>thru</strong>-wall" <strong>look</strong> <strong>at</strong> <strong>Sellafield</strong><br />

BNFL and IST-rees have been<br />

working together to develop high<br />

performance optical inspection systems<br />

for viewing through shield walls of active cells<br />

for many years. <strong>The</strong> l<strong>at</strong>est version, a "<strong>thru</strong>-wall"<br />

(and roof) endoscope camera system, will be fitted<br />

into the <strong>Sellafield</strong> Drypack Plant (SDP). <strong>The</strong><br />

system optically relays a view of the inside of a<br />

cell to a ccd cameral on the cold side of the wall,<br />

elimin<strong>at</strong>ing the cumbersome process of withdrawing<br />

the camera assembly and its associ<strong>at</strong>ed<br />

shield plug from the wall for maintenance. This<br />

significantly reduces maintenance costs and staff<br />

dose uptake. <strong>The</strong> system offers standard and wide<br />

angle fields of view with 6:1 zoom range.<br />

<strong>The</strong> endoscope provides shielding against the<br />

radi<strong>at</strong>ion shine p<strong>at</strong>h by placing fused silica blocks<br />

in the viewing p<strong>at</strong>h allowing standard ccd cameras<br />

to be used r<strong>at</strong>her than radi<strong>at</strong>ion tolerant cameras.<br />

This enables the system to be simply upgraded<br />

as ccd technology advances.<br />

<strong>The</strong> design of the <strong>new</strong> modular endoscope<br />

system benefited from the experience of the first<br />

two endoscope projects <strong>at</strong> <strong>Sellafield</strong>, for the vitrific<strong>at</strong>ion<br />

plant (VIT Line 3) and the Silo Emptying<br />

Plant (SEP). <strong>The</strong> first used the first modular<br />

design to gener<strong>at</strong>e through-wall endoscope<br />

systems for wall thickness of 1000 mm and 1550<br />

mm incorpor<strong>at</strong>ing double prism technology in a<br />

viewing head for image correction. <strong>The</strong> SEP<br />

project called for developing a wider angle of<br />

view and through-roof variant using the same<br />

endoscope assembly. This required the second<br />

image correcting prism to be loc<strong>at</strong>ed within the<br />

endoscope and not part of the viewing head.<br />

<strong>The</strong> l<strong>at</strong>est modular version was inspired by<br />

SDP which has a number of different wall thicknesses<br />

and through roof variants. It combines the<br />

technologies developed on VIT 3 and SEP.<br />

<strong>The</strong> system provides an oper<strong>at</strong>or with full<br />

hemisphere viewing through a single non-browning<br />

glass viewing dome loc<strong>at</strong>ed inside the cell,<br />

taking up very little space and providing a biological<br />

shield. This is achieved using a rot<strong>at</strong>ing<br />

and tilting prism loc<strong>at</strong>ed in a viewing assembly,<br />

32<br />

Non-browning<br />

Glass Dome<br />

Silo Emptying Plant (SEP) Endoscope on a transport trolley<br />

Thru-wall endoscope<br />

Optical Head Filler Liner Alpha Liner Endoscope<br />

Diagram of the IST-Rees '<strong>thru</strong>-wall' endoscope<br />

tested for 30 year oper<strong>at</strong>ion, <strong>at</strong> the front of the<br />

system. This prism is driven from control electronics<br />

on the cold side via drive shafts.<br />

<strong>The</strong> endoscope is loc<strong>at</strong>ed behind this front<br />

prism in order to relay the image to a ccd camera<br />

on the cold side. This endoscope contains a<br />

second rot<strong>at</strong>ing prism for image correction which<br />

is driven off the same rot<strong>at</strong>e drive shaft as the<br />

front prism. <strong>The</strong> difference between through wall<br />

and roof systems is simply the rot<strong>at</strong>ional speed<br />

rel<strong>at</strong>ionship between the two prisms, which can<br />

be changed via a gearbox.<br />

At the rear of the system, on cold side, is an<br />

electronics enclosure containing the ccd camera,<br />

telemetry receiver card and all the drive electronics.<br />

In the case of a through wall system, an<br />

addition control card is fitted, developed by<br />

BNFL Product development Centre <strong>at</strong><br />

Capenhurst, which enables the system to emul<strong>at</strong>e<br />

a standard pan<br />

and tilt system.<br />

This important fe<strong>at</strong>ure<br />

ensures th<strong>at</strong><br />

the system can be<br />

controlled intuitively<br />

by the oper<strong>at</strong>or<br />

making the<br />

system user<br />

friendly and reducing<br />

training times.<br />

<strong>The</strong> endoscopes<br />

are made up<br />

of a combin<strong>at</strong>ion of<br />

standard modules,<br />

which enable the<br />

Electronics<br />

Enclosure<br />

system to c<strong>at</strong>er for wall/roof thicknesses from<br />

750 mm to 2000 mm in steps of 250 mm. <strong>The</strong>re<br />

is a choice of front module between wide and<br />

standard fields of view.<br />

<strong>The</strong> viewing head, endoscope, drive shafts<br />

and electronics enclosure form one assembly<br />

which is fitted into an Alpha liner (on which is<br />

mounted the non-browning glass dome). This<br />

enables the oper<strong>at</strong>ional parts of the system to be<br />

removed, without breaking biological containment,<br />

should any maintenance be required. <strong>The</strong><br />

whole system will fit into a minimum of 150 mm<br />

encast liner, thus removing the civil engineering<br />

issues associ<strong>at</strong>ed with larger encast liners. Large<br />

encast liners can be c<strong>at</strong>ered for using filler liners<br />

within the system.<br />

Nuclear Engineering Intern<strong>at</strong>ional<br />

n