You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

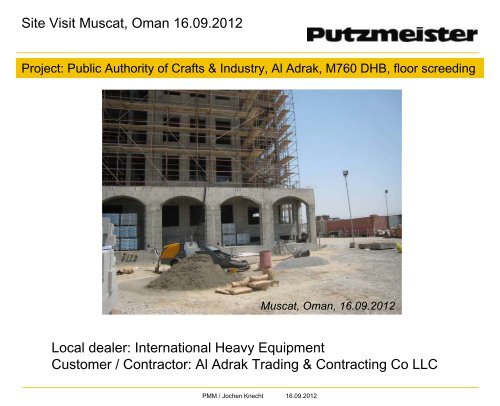

Site Visit <strong>Muscat</strong>, <strong>Oman</strong> <strong>16.09.2012</strong><br />

Project: Public Authority of Crafts & Industry, Al Adrak, M760 DHB, floor screeding<br />

PMM / Jochen Knecht <strong>16.09.2012</strong><br />

<strong>Muscat</strong>, <strong>Oman</strong>, <strong>16.09.2012</strong><br />

Local dealer: International Heavy Equipment<br />

Customer / Contractor: Al Adrak Trading & Contracting Co LLC

Site Visit <strong>Muscat</strong>, <strong>Oman</strong> <strong>16.09.2012</strong><br />

Project: Public Authority of Crafts & Industry,Al Adrak, M760 DHB, floor screeding<br />

Building:<br />

- 6 storey building<br />

Commissioning the M760 DHB on site:<br />

- M760 DHB, year 2012<br />

- 5 pcs. ID65 hoses à 20m = 100m<br />

- Aluminium 3-pod output stand<br />

Screed material (site mix)<br />

- Washed sand 3/16’, moist condition 0-4mm<br />

- OPC (cement)<br />

- Water<br />

- chemical additive: NO<br />

PMM / Jochen Knecht <strong>16.09.2012</strong><br />

sand<br />

0-4mm washed, moist condition<br />

cement<br />

water<br />

<strong>16.09.2012</strong>

Site Visit <strong>Muscat</strong>, <strong>Oman</strong> <strong>16.09.2012</strong><br />

Al Adrak, M760 DHB, floor screeding, Project: Public Authority of Crafts & Industry<br />

Recipe and operation:<br />

1. Start the machine with the mixer “ON”<br />

2. Fill 50% of the 260l vessel with moist sand (6 buckets)<br />

2. Add 1 bucket of water (7l)<br />

3. Add 50 kg of cement (3 buckets)<br />

4. Add ½ bucket of water<br />

5. Fill vessel with the rest of the moist sand<br />

! If the sand is not moist, add more water accordingly !<br />

6. Mix for 2 min.<br />

7. Make sure the red and blue handle are in “1:30h” position<br />

8. Close the vessel and start pumping<br />

Check vessel pressure at the lower pressure gauge:<br />

It should climb to 3-5 bar<br />

a. If it is less than 3 bar:<br />

- increase vessel pressure (turn blue handle upwards)<br />

- and reduce pipe pressure (turn red handle slightly downwards)<br />

b. If it is more than 3 bar<br />

- reduce vessel pressure (turn blue handle downwards)<br />

- increase pipe pressure (turn red handle upwards)<br />

PMM / Jochen Knecht <strong>16.09.2012</strong>

Site Visit <strong>Muscat</strong>, <strong>Oman</strong> <strong>16.09.2012</strong><br />

Result: Semi-dry floor screed<br />

1. Mixing 2. Pumping to 5th floor,<br />

100m delivery line ID65mm<br />

Tip: Add a “water reducer”<br />

chemical to the mix (approx.<br />

0,25l/vessel load).<br />

⇒ less water in the mix<br />

⇒ therefore less cement required<br />

⇒ less cracks<br />

⇒ easier pumping<br />

⇒ better compaction & strength<br />

⇒ quicker drying time!<br />

Tip: Minimum every 15-20m :<br />

Place a loop with the mortar<br />

hoses in order to ensure the<br />

requested “pocket-delivery”.<br />

Tip: Cover the finished screed for<br />

approx. 5-7 days with plastic foil<br />

to ensure a slow curing process<br />

-> less risk of cracks<br />

PMM / Jochen Knecht <strong>16.09.2012</strong><br />

3. Placing on 5th floor<br />

Perfect semi-dry screed mix!

Site Visit <strong>Muscat</strong>, <strong>Oman</strong> <strong>16.09.2012</strong><br />

Thank you!<br />

Putzmeister Mortar Machines – Rep Office Middle East<br />

P.O. Box 454720<br />

Elite Business Centre, Office 210<br />

Al Barsha 1<br />

Dubai – U.A.E.<br />

Contact:<br />

Mr. Jochen Knecht<br />

knechtj@pmw.de<br />

+971 55 4710 229<br />

PMM / Jochen Knecht <strong>16.09.2012</strong>