Dräger Polytron 7000 Measuring Unit, Installation Instructions

Dräger Polytron 7000 Measuring Unit, Installation Instructions

Dräger Polytron 7000 Measuring Unit, Installation Instructions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> <strong>Measuring</strong> <strong>Unit</strong>, <strong>Installation</strong> <strong>Instructions</strong><br />

Operation of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> or <strong>Dräger</strong> Docking Station (Part No. 83 17 990) requires<br />

full understanding and strict observance of the <strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong><br />

(Part No. 90 23 758)!<br />

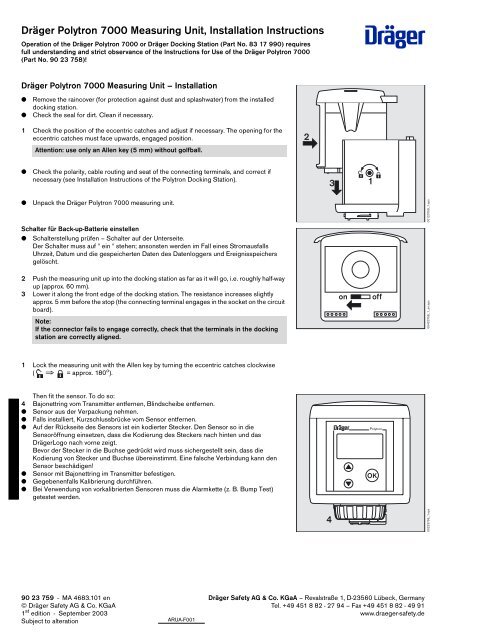

<strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> <strong>Measuring</strong> <strong>Unit</strong> – <strong>Installation</strong><br />

● Remove the raincover (for protection against dust and splashwater) from the installed<br />

docking station.<br />

● Check the seal for dirt. Clean if necessary.<br />

1 Check the position of the eccentric catches and adjust if necessary. The opening for the<br />

eccentric catches must face upwards, engaged position.<br />

Attention: use only an Allen key (5 mm) without golfball.<br />

● Check the polarity, cable routing and seat of the connecting terminals, and correct if<br />

necessary (see <strong>Installation</strong> <strong>Instructions</strong> of the <strong>Polytron</strong> Docking Station).<br />

● Unpack the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> measuring unit.<br />

Schalter für Back-up-Batterie einstellen<br />

● Schalterstellung prüfen – Schalter auf der Unterseite.<br />

Der Schalter muss auf " ein " stehen; ansonsten werden im Fall eines Stromausfalls<br />

Uhrzeit, Datum und die gespeicherten Daten des Datenloggers und Ereignisspeichers<br />

gelöscht.<br />

2 Push the measuring unit up into the docking station as far as it will go, i.e. roughly half-way<br />

up (approx. 60 mm).<br />

3 Lower it along the front edge of the docking station. The resistance increases slightly<br />

approx. 5 mm before the stop (the connecting terminal engages in the socket on the circuit<br />

board).<br />

Note:<br />

If the connector fails to engage correctly, check that the terminals in the docking<br />

station are correctly aligned.<br />

1 Lock the measuring unit with the Allen key by turning the eccentric catches clockwise<br />

( ⇒ = approx. 180 o ).<br />

Then fit the sensor. To do so:<br />

4 Bajonettring vom Transmitter entfernen, Blindscheibe entfernen.<br />

● Sensor aus der Verpackung nehmen.<br />

● Falls installiert, Kurzschlussbrücke vom Sensor entfernen.<br />

● Auf der Rückseite des Sensors ist ein kodierter Stecker. Den Sensor so in die<br />

Sensoröffnung einsetzen, dass die Kodierung des Steckers nach hinten und das<br />

<strong>Dräger</strong>Logo nach vorne zeigt.<br />

Bevor der Stecker in die Buchse gedrückt wird muss sichergestellt sein, dass die<br />

Kodierung von Stecker und Buchse übereinstimmt. Eine falsche Verbindung kann den<br />

Sensor beschädigen!<br />

● Sensor mit Bajonettring im Transmitter befestigen.<br />

● Gegebenenfalls Kalibrierung durchführen.<br />

● Bei Verwendung von vorkalibrierten Sensoren muss die Alarmkette (z. B. Bump Test)<br />

getestet werden.<br />

90 23 759 - MA 4683.101 en<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

1 st edition - September 2003<br />

Subject to alteration<br />

ARUA-F001<br />

2<br />

D<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.de<br />

3<br />

4<br />

1<br />

on off<br />

<strong>Polytron</strong><br />

OK<br />

00123759_1.eps<br />

05423758_1_en.eps<br />

00223759_1.eps

<strong>Dräger</strong> Docking Station, <strong>Installation</strong> <strong>Instructions</strong><br />

Operation of the <strong>Dräger</strong> <strong>Polytron</strong> 3000 or <strong>Polytron</strong> <strong>7000</strong> measuring unit or of the <strong>Dräger</strong><br />

Docking Station (Part No. 83 17 990) requires full understanding and strict observance of the<br />

<strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> 3000 or <strong>Polytron</strong> <strong>7000</strong>!<br />

Installing the Docking Station<br />

— The docking station must be installed vertically (transmitter with sensor facing down) in<br />

a place having low vibrations and stable temperature – close to a possible leak.<br />

— A clear space of at least 15 cm must be maintained above the transmitter to allow for<br />

installation of the measuring unit.<br />

— A clear space of at least 10 cm – recommended 30 cm – must be maintained below<br />

the transmitter to ensure accessibility for maintenance.<br />

● Unpack the cocking station.<br />

1 Remove the raincover (protection against dust and splash-water).<br />

If using the <strong>Polytron</strong> 3000:<br />

2 Remove the 2-pin connecting terminal. Keep it in a safe place and refit it when installation<br />

is complete.<br />

If using the <strong>Polytron</strong> <strong>7000</strong>:<br />

3 Remove the 4-pin connecting terminal. Keep it in a safe place and refit it when installation<br />

is complete.<br />

● Screw the docking station into place (drilling template: see pale grey illustration in the<br />

background). Spacing between holes: 66 ±4 mm.<br />

Attention:<br />

Spacers (e.g. mounting bracket 68 09 772) must be used to prevent any twisting of<br />

the housing when installed on uneven surfaces.<br />

If the <strong>Dräger</strong> <strong>Polytron</strong> 3000/<strong>7000</strong> measuring unit is not yet installed:<br />

● Refit the raincover (protection against dust and splash-water).<br />

Installing the electrical connections – <strong>Dräger</strong> <strong>Polytron</strong> 3000<br />

— Connect to the central unit with at least a 2-core cable, 0.5 to 2.5 mm 2 (e.g. LiY, LiYCY).<br />

— If a current between 0 and 22 mA is applied, a DC voltage of between 12 V DC and<br />

30 V DC must be present at the transmitter.<br />

Install the 4 to 20 mA current loop<br />

● Insert the 2-wire connecting cable in the cable gland, cut it to length and strip the insulation<br />

(approx. 80 mm).<br />

● Shorten the shield, if fitted, so that no short-circuits can occur.<br />

● Connect the cable:<br />

1 2-pin terminal for <strong>Dräger</strong> <strong>Polytron</strong> 3000 – check polarity. Cut excess wires short<br />

or<br />

2 Fasten in 4-pin terminal.<br />

1 Slide the connecting terminal back into the holder.<br />

● Fasten cable in guide.<br />

● Fold up these <strong>Installation</strong> <strong>Instructions</strong> and place them inside the <strong>Dräger</strong> Docking Station<br />

ready for commissioning/start-up.<br />

● Refit the raincover (protection against dust and splash-water).<br />

D<br />

If installing the transmitter in Zone 0 or Zone 1 explosion-hazard areas:<br />

— Zwischen Transmitter und Zentralgerät, Sicherheitsbarriere mit entsprechender Explosionsschutz-Zulassung (Gerätekategorie 1 bzw. 2)<br />

einbauen.<br />

— Es dürfen nur Sicherheitsbarrieren mit folgenden Kennwerten verwendet werden: U max ≤30 V, I max ≤0,3 A, P max ≤ 700 mW.<br />

— Darauf achten, dass die maximal an die Sicherheitsbarriere anschließbare Kapazität und Induktivität nicht überschritten wird (Leitung berücksichtigen).<br />

Die sicherheitstechnischen Eingangsparameter des Transmitters betragen: C i = 0 µF, L i = 50 µH<br />

● Non-isolated barriers: connect shield to the equipotential bonding or to 0 V (Ex-i).<br />

4 to 20 mA<br />

+24 V<br />

Ex-hazard area zone 0 or zone 1<br />

Non-Ex-hazard area<br />

Ex i<br />

Safety barrier<br />

PA<br />

Equipotential bond<br />

1<br />

1<br />

3<br />

2<br />

2<br />

+<br />

4 ... 20 mA<br />

0 V<br />

+<br />

–<br />

Central controller<br />

00123760_1.eps<br />

00223760_1.eps<br />

00623760_1.eps<br />

00423760_1_en.eps

● Potential-free barriers: connect to the negative Ex-i connection.<br />

If installing the transmitter in Zone 2 explosion-hazard area:<br />

— Nur Speisegeräte der Gerätekategorie 3 verwenden.<br />

— Darauf achten, dass die maximal an das Speisegerät anschließbare Kapazität und Induktivität nicht überschritten wird (Leitung berücksichtigen).<br />

Die sicherheitstechnischen Eingangsparameter des Transmitters betragen: C i = 0 µF, L i = 50 µH.<br />

Caution:<br />

Kategorie 1-Kennzeichnung an vorgesehener Stelle aus dem Typenschild-Anhänger herausschneiden. Das Gerät darf nach dem<br />

erstmaligen Betrieb gemäß dieser <strong>Installation</strong> nicht mehr in explosionsgefährdeten Bereichen der Zone 0 und Zone 1<br />

(Gerätekategorie 1 oder 2) installiert werden.<br />

If installing the transmitter in areas not exposed to explosion hazard:<br />

Caution:<br />

Ex-Schutz Kennzeichnung vom Transmitter entfernen. Der Transmitter darf nach dem erstmaligen Betrieb gemäß dieser <strong>Installation</strong><br />

nicht mehr in explosionsgefährdeten Bereichen installiert werden.<br />

– +<br />

4 to 20 mA<br />

+24 V<br />

+<br />

–<br />

Ex-hazard area zone 0 or zone 1<br />

Non-es-hazard area<br />

Installing the electrical connections – <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong><br />

Non-Ex-hazard area<br />

Caution:<br />

By retrofitting the relay module and/or pump module to the <strong>Polytron</strong> <strong>7000</strong>, the overall device loses its “Ex” explosion-proof approval.<br />

The operator must ensure that there is no approved explosion-proof approval displayed when pump and/or relay module are installed.<br />

Remove approval label from transmitter.<br />

The <strong>Polytron</strong> <strong>7000</strong> with installed pump module and/or relay module must not be used in explosion hazard areas.<br />

2-core connection<br />

— Connect to the central unit with at least a 2-core cable, 0.5 to 2.5 mm 2 (e.g. LiY, LiYCY).<br />

— If a current between 0 and 22 mA is applied, a DC voltage of between 16.5 V DC and<br />

30 V DC must be present at the transmitter.<br />

Safety barrier<br />

● Install the 4 to 20 mA current loop<br />

● Insert the 2-wire connecting cable in the cable gland, cut it to length and strip the insulation<br />

(approx. 80 mm).<br />

● Shorten the shield, if fitted, so that no short-circuits can occur.<br />

● Connect the cable:<br />

1 4-pin terminal for <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> – observe polarity. Cut excess wires short or<br />

2 Fasten in the middle terminals.<br />

● Fasten the cable in the holder.<br />

● Fold up these <strong>Installation</strong> <strong>Instructions</strong> and place them inside the <strong>Dräger</strong> Docking Station<br />

ready for commissioning/start-up.<br />

● Refit the raincover (protection against dust and splash-water).<br />

Ex i<br />

PA<br />

Equipotential<br />

2<br />

+<br />

4 ... 20 mA<br />

0 V<br />

+<br />

–<br />

Central controller<br />

+<br />

4 ... 20 mA<br />

0 V<br />

+<br />

–<br />

Central controller<br />

+24 V<br />

0 V<br />

0 V<br />

Signal<br />

1<br />

00523760_1_en.eps<br />

00323760_1_en.eps<br />

01023760_1.eps

If installing the transmitter in Zone 0 or Zone 1 explosion-hazard areas:<br />

— Zwischen Transmitter und Zentralgerät, Sicherheitsbarriere mit entsprechender Explosionsschutz-Zulassung (Gerätekategorie 1 bzw. 2)<br />

einbauen.<br />

— Es dürfen nur Sicherheitsbarrieren mit folgenden Kennwerten verwendet werden: U max ≤30 V, I max ≤0,3 A, P max ≤700 mW.<br />

— Darauf achten, dass die maximal an die Sicherheitsbarriere anschließbare Kapazität und Induktivität nicht überschritten wird (Leitung berücksichtigen).<br />

Die sicherheitstechnischen Eingangsparameter des Transmitters betragen: C i = 5 nF, L i = 50 µH.<br />

● Non-isolated barriers: connect shield to the equipotential bonding or to 0 V (Ex-i).<br />

4 to 20 mA<br />

+24 V<br />

● Potential-free barriers: connect to the negative Ex-i connection.<br />

4 to 20 mA<br />

+24 V<br />

Ex-hazard area zone 0 or zone 1<br />

If installing the transmitter in Zone 2 explosion-hazard areas or in areas not exposed to explosion hazard:<br />

— Nur Speisegeräte der Gerätekategorie 3 verwenden.<br />

— Darauf achten, dass die maximal an das Speisegerät anschließbare Kapazität und Induktivität nicht überschritten wird (Leitung berücksichtigen).<br />

Die sicherheitstechnischen Eingangsparameter des Transmitters betragen: C i = 5 nF, Li = 50 µH.<br />

Caution:<br />

Kategorie 1-Kennzeichnung an vorgesehener Stelle aus dem Typenschild-Anhänger herausschneiden. Das Gerät darf nach dem<br />

erstmaligen Betrieb gemäß dieser <strong>Installation</strong> nicht mehr in explosionsgefährdeten Bereichen der Zone 0 und Zone 1<br />

(Gerätekategorie 1 oder 2) installiert werden.<br />

If installing the transmitter in areas not exposed to explosion hazard:<br />

Non-Ex-hazard area<br />

Safety barrier<br />

Caution:<br />

Ex-Schutz Kennzeichnung vom Transmitter entfernen. Der Transmitter darf nach dem erstmaligen Betrieb gemäß dieser <strong>Installation</strong><br />

nicht mehr in explosionsgefährdeten Bereichen installiert werden.<br />

+24 V<br />

4 to 20 mA<br />

Ex-hazard area zone 0 or zone 1<br />

Non-Ex-hazard area<br />

Connection to central unit<br />

● Connect the shield to the earth of the central unit (e.g. housing, earthing rail etc.)<br />

If installing more than one transmitter and HART multidrop-capable central unit<br />

● Observe the installation instructions in the <strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong>.<br />

3-core connection<br />

Install the 4 to 20 mA current loop<br />

● Insert the 3-wire connecting cable in the cable gland, cut it to length and strip the insulation<br />

(approx. 80 mm).<br />

● Shorten the shield, if fitted, so that no short-circuits can occur.<br />

● Connect the cable:<br />

1 Fasten in the terminals of the 4-pin terminal block for <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong><br />

Check correct polarity. Slide the terminal block back into the holder.<br />

● Fasten the cable in the holder.<br />

● Fold up these <strong>Installation</strong> <strong>Instructions</strong> and place them inside the <strong>Dräger</strong> Docking Station<br />

ready for commissioning/start-up.<br />

● Refit the raincover (protection against dust and splash-water).<br />

Ex i<br />

PA<br />

Non-Ex-hazard area<br />

Ex i<br />

Safety barrier<br />

PA<br />

Equipotential bond<br />

Equipotential bond<br />

+<br />

4 ... 20 mA<br />

0 V<br />

+<br />

–<br />

Central controller<br />

+<br />

4 ... 20 mA<br />

0 V<br />

+<br />

–<br />

Central controller<br />

+<br />

4 ... 20 mA<br />

0 V<br />

+<br />

–<br />

Central controller<br />

+24 V<br />

0 V<br />

0 V<br />

Signal<br />

1<br />

00823760_1_en.eps<br />

00923760_1_en.eps<br />

00723760_1_en.eps<br />

01423760_1.eps

If installing the transmitter in areas not exposed to explosion hazard:<br />

Caution:<br />

Ex-Schutz Kennzeichnung vom Transmitter entfernen. Der Transmitter darf nach dem erstmaligen Betrieb gemäß dieser <strong>Installation</strong><br />

nicht mehr in explosionsgefährdeten Bereichen installiert werden.<br />

Technical data<br />

Cable type Min. 2-core cable<br />

Wire cross-section 0.5 mm 2 (AWG 20) to 2.5 mm 2 (AWG 14)<br />

Cable grommet M20x1.5 for cable diameter 6 mm to 12 mm<br />

Drilling template<br />

90 23 760 - MA 4683.102 en<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

1 st edition - September 2003<br />

Subject to alteration<br />

Non-ex-hazard area<br />

+<br />

4 ... 20 mA<br />

Central controller<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.de<br />

ARUA-F001<br />

0 V<br />

+<br />

–<br />

66 ±4 mm<br />

01123760_1_en.eps<br />

01523760_1.eps

Duct Mounting Kit – 83 17 150,<br />

<strong>Installation</strong> <strong>Instructions</strong><br />

Any use of the Duct Mounting Kit requires full understanding and strict observation of the<br />

<strong>Polytron</strong> 3000 "<strong>Instructions</strong> for Use" (part number 90 23 785) / <strong>Polytron</strong> <strong>7000</strong> "<strong>Instructions</strong><br />

for Use" (part number 90 23 758)!<br />

● Bore a hole 35 +1 mm in diameter into the duct at the desired measuring point.<br />

1 Attach the sealing sleeve into the duct.<br />

2 Align angle support centrally around the bored hole and secure the angle support with<br />

clamp straps around the duct and/or with screws to the duct depending on curvature and<br />

thickness of the duct.<br />

3 When the duct is curved the four stoppers must be screwed in along the diagonal slots of<br />

the angle support and adjusted.<br />

4 Loosley screw the upper screw of the <strong>Polytron</strong> Docking Station (part number 83 16 990)<br />

to the angle support with the help of a threaded bar. Secure the lower screw and then<br />

retighten the upper screw.<br />

● The electrical connection is made in accordance with the installation instructions of the<br />

<strong>Polytron</strong> Docking Station.<br />

● Connect the measuring unit in accordance with the <strong>Polytron</strong> 3000 / <strong>Polytron</strong> <strong>7000</strong><br />

<strong>Measuring</strong> <strong>Unit</strong> installation instructions.<br />

For the sensor assembly:<br />

1 Slightly loosen the screws at the back of the angle support.<br />

2 Raise the Docking Station with <strong>Measuring</strong> <strong>Unit</strong> so that the upper screw is free of the angle<br />

support and then swivel.<br />

To insert the sensor into the extension:<br />

3 Unscrew the bayonet ring on the end of the sensor extension.<br />

● Remove the dummy disk.<br />

● Check the sensor part number –<br />

see <strong>Polytron</strong> 3000 / <strong>Polytron</strong> <strong>7000</strong> <strong>Measuring</strong> <strong>Unit</strong> installation instructions.<br />

● Slide sensor into the sensor extension (the <strong>Dräger</strong> signature at the sensor and at the<br />

sensor extension must align together and point in the same direction). Then with light<br />

presure push upwards until the plug engages.<br />

● Secure sensor with bayonet ring.<br />

To insert the sensor extension into the Docking Station:<br />

4 Unscrew bayonet from the Docking Station.<br />

● Remove the dummy disk.<br />

5 Push sensor extension with the <strong>Dräger</strong> signature facing foward into the opening of the<br />

Docking Station until the connection engages.<br />

4 Secure extension with bayonet ring.<br />

● Turn the transmitter back to a vertical position and then lower the sensor into the sensor<br />

sleeve.<br />

● Tighten the screws on the angle support to secure the <strong>Measuring</strong> <strong>Unit</strong> with Docking<br />

Station.<br />

90 23 721 - MA 4684.103 en/de/fr/es<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

2nd edition - January 2004<br />

Subject to alteration<br />

ARUB-F001<br />

2<br />

1<br />

3<br />

3<br />

D<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.com<br />

www.draeger-safety.de<br />

2<br />

4<br />

5<br />

4<br />

3<br />

1<br />

00123721_1.eps<br />

00223721_1.eps<br />

00323721_1.eps

Remote Sensor, <strong>Installation</strong> <strong>Instructions</strong><br />

Operation of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> with the remote sensor requires full understanding and<br />

strict observance of the <strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> (Part No. 90 23 758)!<br />

Intended use<br />

Remote Sensor – 83 17 275:<br />

— For the external installation of a sensor at a measuring point located at a distance of up<br />

to 30 m from the installation site of the <strong>Polytron</strong> <strong>7000</strong> Transmitter.<br />

With:<br />

— Remote Adapter, type P3U Remote Adapter, 5 m – 83 17 270,<br />

— Remote Adapter, type P3U Remote Adapter, 15 m – 83 17 591,<br />

— Remote Adapter, type P3U Remote Adapter, 30 m – 83 17 592:<br />

Attention:<br />

The cable lenght of the remote adapter may be shortened on the connector side. An<br />

extension of the cable or replacement by a different cable is not permitted.<br />

Bei Verwendung des Remote-Adapters + -Sensors an einem gemäß Gerätekategorie 3 installierten<br />

Transmitter:<br />

Vorsicht:<br />

Kategorie 1-Kennzeichnung an vorgesehener Stelle vom Transmitter entfernen. Das<br />

Zubehör darf nach dem erstmaligen Betrieb gemäß dieser <strong>Installation</strong> nicht mehr in<br />

explosionsgefährdeten Bereichen der Zone 0 und Zone 1 (Gerätekategorie 1 oder 2)<br />

verwendet werden!<br />

Bei Verwendung des Remote-Adapters + -Sensors an einem nicht explosionsgeschützt installierten<br />

Transmitter:<br />

Vorsicht:<br />

Ex-Schutz Kennzeichnung vom Typenschild entfernen. Das Zubehör darf nach dem<br />

erstmaligen Betrieb gemäß dieser <strong>Installation</strong> nicht mehr in explosionsgefährdeten<br />

Bereichen installiert werden!<br />

Wall mounting<br />

1 Drill the fixing holes for the mounting plate (drilling template: see the pale grey illustration<br />

on page 2). Spacing between holes: 50 ±4 mm.<br />

● Screw the mounting plate for the remote sensor in the desired position.<br />

2 Fit the housing of the remote sensor onto the mounting plate so that it clicks into place.<br />

Installing the sensor<br />

3 Unscrew the bayonet ring from the transmitter and remove the dummy plate.<br />

● Remove the sensor from the pack.<br />

● Place the sensor in the opening, with the <strong>Dräger</strong> logo facing the front.<br />

● Secure the sensor with the bayonet ring.<br />

1<br />

1<br />

D<br />

3<br />

2<br />

00123761_1.eps<br />

00223761_1.eps

Connection to the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong><br />

4 Connect the plug of the external sensor (cable length 5, 15 or 30 m) to the housing and<br />

secure by turning the ring clockwise.<br />

5 Insert the sensor adapter into the opening of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> Transmitter, with<br />

the <strong>Dräger</strong> logo on the sensor facing the front.<br />

6 Secure the sensor adapter with the bayonet ring.<br />

Note:<br />

The remote sensor is recognised automatically by the transmitter. No more installation<br />

steps are required.<br />

Drilling template<br />

90 23 761 - MA 4683.105 en<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

1 st edition - September 2003<br />

Subject to alteration<br />

4<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.de<br />

ARUA-F001<br />

6<br />

50 ±4 mm<br />

5<br />

00323761_1.eps<br />

00423761_1.eps

Duct Adapter for Remote Sensor, <strong>Installation</strong> <strong>Instructions</strong><br />

Operation of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> with the duct adapter requires full understanding and strict<br />

observance of the <strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> (Part No. 90 23 758)!<br />

Intended use<br />

Duct adapter for remote sensor – 83 17 617:<br />

— For mounting a remote sensor on a pipe or duct,<br />

— for gas measurement in the pipe or duct.<br />

<strong>Installation</strong><br />

● Drill hole (Ø 35 + 1 mm) at the desired measuring point of the duct.<br />

● Fit the sealing sleeve into the hole.<br />

● Position the retaining clamp centrally over the hole.<br />

1 Drill the holes for the fixing screws. Drilling template: see below.<br />

2 Remove the bayonet ring of the remote sensor.<br />

3 Place the retaining clamp on the housing support and refit the bayonet ring.<br />

● Fit the sensor supports in the sealing sleeve.<br />

● Turn the retaining clamp to the appropriate position and screw securely.<br />

Caution:<br />

To avoid faulty measurements pay close attention to the fitting of the sensor in the<br />

sealing sleeve!<br />

Dismantling/Sensor replacement<br />

● Loosen the retaining screws.<br />

● Swivel the retaining clamp to release it.<br />

● Pull the remote sensor out of the sealing sleeve.<br />

● Replace the sensor.<br />

● Refit the remote sensor.<br />

Drilling template<br />

90 23 762 - MA 4683.106 en<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

1 st edition - September 2003<br />

Subject to alteration<br />

94 ±1 mm<br />

ARUA-F001<br />

Ø 35 ±1 mm<br />

3<br />

D<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.de<br />

1<br />

2<br />

1<br />

00123762_1.eps<br />

00223762_1.eps<br />

00323762_1.eps

Relay Module, <strong>Installation</strong> <strong>Instructions</strong><br />

Operation of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> with the relay module requires full understanding and strict<br />

observance of the <strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> (Part No. 90 23 758).<br />

We recommend that the relay module should be installed by specially trained technical<br />

personnel.<br />

— Das Gerät muss vom Netz getrennt sein!<br />

Intended use<br />

Relay module – 83 17 360:<br />

— For locally switching actuators, alarm emitters etc. as a function of the measured gas concentration.<br />

Caution:<br />

By retrofitting the relay module and/or pump module to the <strong>Polytron</strong> <strong>7000</strong>, the overall<br />

device loses its “Ex” explosion-proof approval. The operator must ensure that there is<br />

no approved explosion-proof approval displayed when pump and/or relay module are<br />

installed. Remove approval label from transmitter.<br />

The <strong>Polytron</strong> <strong>7000</strong> with installed pump module and/or relay module must not be used<br />

in explosion hazard areas.<br />

Note:<br />

Für den Betrieb des Pumpenmoduls muss der elektrische Anschluss in 3-Leitertechnik<br />

erfolgen.<br />

Preparing the Docking Station<br />

● If there is a label sticker on the Docking Station it must be removed.<br />

1 Release the measuring unit with an Allen key by turning the eccentric catches<br />

counter-clockwise ( ⇒ = approx. 180 o ).<br />

Caution: use only an Allen key (5 mm) without golfball.<br />

2 Push the measuring unit up to about half height (approx. 60 mm) and then pull it forwards<br />

out of the docking station.<br />

Install the Relay Module in measuring unit<br />

3 Bend the snap-hooks on the sides of the measuring unit cover gently outwards to release<br />

the cover.<br />

● Remove the cover.<br />

4 Plug the connecting cable for the relay module to the terminal strip behind the display,<br />

making sure that the cable is not twisted.<br />

● Place the relay module on the measuring unit and snap into place on both sides.<br />

The relay cap can be removed for easier handling.<br />

Attention:<br />

Darauf achten, dass nur Druck auf die Hülse der Messeinheit ausgeübt wird. Druck<br />

auf das innere Gerüst kann zu Beschädigungen führen.<br />

2<br />

D<br />

1<br />

<strong>Polytron</strong><br />

3 3<br />

4<br />

OK<br />

00123763_1.eps<br />

00223763_1.eps<br />

00323763_1.eps

After connecting the relay module to the measuring unit:<br />

5 refit the cap.<br />

Inserting the measuring unit with relay module<br />

6 Push the measuring unit with relay module into the docking station and lower it as<br />

described in <strong>Installation</strong> <strong>Instructions</strong> 90 23 759.<br />

7 Lock the measuring unit with the Allen key by turning the eccentric catches<br />

clockwise ( ⇒ = approx. 180 o ).<br />

Connecting the devices to be switched<br />

3 voltageless relay outputs with 250 V / 5 A (AC) switching capacity are available:<br />

— A1 relay (switches in response to A1 gas alarm)<br />

— A2 relay (switches in response to A2 gas alarm)<br />

— Fault relay (switches in response to a device fault).<br />

Setting the alarm limits: see <strong>Instructions</strong> for Use of the <strong>Polytron</strong> <strong>7000</strong>, Part No. 90 23 758.<br />

● Connect the devices you wish to switch to the cable sockets.<br />

The following cable sockets can be used:<br />

—<br />

—<br />

—<br />

—<br />

Binder<br />

Amphenol<br />

Hirschmann<br />

<strong>Dräger</strong> Safety<br />

Type 692<br />

Type C16-1<br />

Type CA3<br />

Order No. 99–0210–00–04<br />

Order No. T 3109–001<br />

Order No. 932–322–100<br />

Order No. 18 90 086<br />

Connector Relay Module terminal layout:<br />

(see also inside the relay cap)<br />

1 normally closed<br />

2 common<br />

3 normally open<br />

4 not connected<br />

● Note down the connections of the relay outputs on the sticker in the relay cap.<br />

● Plug in the connector and lock into place.<br />

● Close the relay cap.<br />

90 23 763 - MA 4683.107 en<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

1 st edition - September 2003<br />

Subject to alteration<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.de<br />

ARAU-F001<br />

5<br />

6<br />

1<br />

2<br />

4<br />

7<br />

<strong>Polytron</strong><br />

OK<br />

3<br />

00423763_1.eps<br />

00523763_1.eps<br />

00623763_1.eps

Pump Module, <strong>Installation</strong> <strong>Instructions</strong><br />

Operation of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> with the pump module requires full understanding and strict<br />

observance of the <strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> (Part No. 90 23 758).<br />

We recommend that the pump module should be installed by specially trained technical<br />

personnel.<br />

Intended use<br />

Pump module – 83 17 350:<br />

— For drawing measuring gas from a remote site into the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> transmitter.<br />

Caution:<br />

By retrofitting the relay module and/or pump module to the <strong>Polytron</strong> <strong>7000</strong>, the overall<br />

device loses its “Ex” explosion-proof approval. The operator must ensure that there is<br />

no approved explosion-proof approval displayed when pump and/or relay module are<br />

installed. Remove approval label from transmitter.<br />

The <strong>Polytron</strong> <strong>7000</strong> with installed pump module and/or relay module must not be used<br />

in explosion hazard areas.<br />

Note:<br />

Für den Betrieb des Pumpenmoduls muss der elektrische Anschluss in 3-Leitertechnik<br />

erfolgen.<br />

Caution:<br />

Bei dem Einbau des Pumpenmoduls muss das <strong>Polytron</strong> <strong>7000</strong> von der Spannungsversorgung<br />

getrennt sein.<br />

Preparing the Docking Station<br />

● If there is a label sticker on the Docking Station it must be removed.<br />

1 Release the measuring unit with an Allen key by turning the eccentric catches<br />

counter-clockwise ( ⇒ = approx. 180o ).<br />

Caution: use only an Allen key (5 mm) without golfball.<br />

Push the measuring unit up to about half height (approx. 60 mm) and then pull it forwards<br />

out of the docking station.<br />

2 Special gush holes are provided on the left and right-hand sides of the sensor recess.<br />

The glass tubes of the pump can be inserted in these holes.<br />

Punch or drill the holes all the way through the docking station from inside. Each hole<br />

should have a 6 mm channel.<br />

Then deburr the holes from the outside.<br />

3 From the underside of the docking station, check the hole channels again.<br />

● Check that the docking station has no loose parts, and clean it if necessary.<br />

3 Remove the O-rings from the glass tubes and insert them in the grooves on the base of the<br />

docking station.<br />

Installing the Pump in the <strong>Measuring</strong> <strong>Unit</strong><br />

4 Bend the snap-hooks on the sides of the measuring unit cover gently outwards to release<br />

the cover.<br />

● Remove the cover.<br />

2<br />

3<br />

D<br />

1<br />

3<br />

4 4<br />

<strong>Polytron</strong><br />

5 5<br />

OK<br />

00123764_1.eps<br />

00223764_1.eps<br />

00323764_1.eps<br />

00423764_1.eps

1 Plug the pump connecting cable to the terminal strip.<br />

2 Insert the glass tubes into the side holes of the housing, and fit the pump module into the<br />

holder. Position the hoses inside the housing.<br />

Attention:<br />

Darauf achten, dass nur Druck auf die Hülse der Messeinheit ausgeübt wird. Druck<br />

auf das innere Gerüst kann zu Beschädigungen führen.<br />

● Replace the measuring unit cover until the side snap-hooks clip into place.<br />

3 Push the measuring unit with pump module into the docking station and lower it as<br />

described in <strong>Installation</strong> <strong>Instructions</strong> 90 23 759.<br />

4 Lock the measuring unit with the Allen key by turning the eccentric catches<br />

clockwise ( ⇒ = approx. 180 o )<br />

Installing the sensor and pump adapter<br />

● Unscrew the bayonet ring from the transmitter and remove the blanking disc.<br />

● Place the sensor in the opening with the <strong>Dräger</strong> loger facing the front, and push upwards<br />

gently until the connector engages.<br />

1 Place the fastening ring over the sensor opening.<br />

2 Secure the sensor with the bayonet ring.<br />

The orientation of the pump adapter determines the direction of the gas flow between the<br />

pump and sensor:<br />

— If the supply and exhaust air ports are facing left, with the +<br />

the pump is in the gas flow upstream of the sensor.<br />

symbol visible from the front,<br />

— If the supply and exhaust air ports are facing right, with the –<br />

the pump is in the gas flow downstream of the sensor.<br />

symbol visible from the front,<br />

● Insert the pump adapter sleeves into the holes on the underside of the docking station. The<br />

seal slides over the sensor.<br />

1 Turn the fastening ring clockwise until the pump adapter is secured.<br />

Hint for use of connecting tubing<br />

Die Wahl des Materials des Ansaugschlauches/Ansaugrohres und die Länge der<br />

Ansaugstrecke beeinflusst die Ansprechzeit des Messsignals. Durch eine Reaktion bzw.<br />

Adsorbtion mit dem verwendeten Material, erreicht im ungünstigsten Fall keine messbare<br />

Gaskonzentration mehr den Sensor.<br />

— Informationen zur Auswahl des geeigneten Schlauch-/Rohrmaterials erhalten Sie unter<br />

<strong>Dräger</strong> Safety Gas Detection Systems – Tel. +49 (0)451 882 2794.<br />

● Zur Prüfung auf Leckagen im Ansaugweg empfehlen wir vor der Inbetriebnahme, und danach<br />

alle 6 Monate, eine Flowkontrolle an der Ansaugstelle und hinter dem Transmitter vorzunehmen.<br />

90 23 764 - MA 4683.108 en<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

1 st edition - September 2003<br />

Subject to alteration<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.de<br />

ARAU-F001<br />

1<br />

2 2<br />

3<br />

2<br />

+<br />

4<br />

<strong>Polytron</strong><br />

OK<br />

1<br />

00523764_1.eps<br />

00623764_1.eps<br />

00723764_1.eps<br />

00823764_1.eps

<strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> Software Dongles, <strong>Installation</strong> <strong>Instructions</strong><br />

Operation of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> software dongles requires full understanding and strict<br />

observance of the <strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> (Part No. 90 23 758)!<br />

We recommend that the software dongles should be installed by specially trained technical<br />

personnel.<br />

Intended use<br />

<strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> Software Dongle – 83 17 618, 83 17 619 or 83 17 860:<br />

— For activating additional functions of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong>:<br />

Data Dongle<br />

83 17 618<br />

Colour code: blue<br />

Sensor Dongle<br />

83 17 619<br />

Colour code: silver<br />

Sensor Diagnostic Dongle<br />

83 17 860<br />

Colour code: green<br />

Installing the Software Dongles<br />

— Activates the event logger, data logger and graphical<br />

concentration display.<br />

— Activates the sensor self-test.<br />

— Activates the sensor self-test, the display for the<br />

remaining sensor activity and the predictive<br />

maintenance function.<br />

— Das Gerät muss vom Netz getrennt sein!<br />

1 Release the measuring unit with an Allen key by turning the eccentric catches counterclockwise<br />

( ⇒ = approx. 180o ).<br />

Attention:<br />

Use only an Allen key (5 mm) without golfball.<br />

Push the measuring unit up to about half height (approx. 60 mm) and then pull it forwards<br />

out of the docking station.<br />

2 Bend the snap-hooks on the sides of the measuring unit cover gently outwards to release<br />

the cover.<br />

3 Remove the cover.<br />

4 The <strong>Dräger</strong> logo on the dongle must be facing the front of the measuring unit. Then insert<br />

the dongle in any of the three slots provided.<br />

● Replace the measuring unit cover until the side snap-hooks clip into place.<br />

Attention:<br />

Darauf achten, dass nur Druck auf die Hülse der Messeinheit ausgeübt wird. Druck<br />

auf das innere Gerüst kann zu Beschädigungen führen.<br />

5 Push the measuring unit with dongle into the docking station and lower it as described in<br />

<strong>Installation</strong> <strong>Instructions</strong> 90 23 759.<br />

6 Lock the measuring unit with the Allen key by turning the eccentric catches clockwise<br />

( ⇒ = approx. 180 o ).<br />

Note:<br />

To check the correct function of the Software Dongles after start-up go to<br />

» Information «, »Instrument «, » Module «.<br />

90 23 765 - MA 4683.109 de<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

1 st edition - September 2003<br />

Subject to alteration<br />

ARUA-F001<br />

D<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.de<br />

2<br />

1<br />

<strong>Polytron</strong><br />

3 3<br />

6<br />

OK<br />

5 5 5<br />

7<br />

00123765_1.eps<br />

00223765_1.eps<br />

00323765_1.eps<br />

00523763_1.eps

Daisy Chain Kit, <strong>Installation</strong> <strong>Instructions</strong><br />

Operation of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> with the Daisy Chain kit requires full understanding and<br />

strict observance of the <strong>Instructions</strong> for Use of the <strong>Dräger</strong> <strong>Polytron</strong> <strong>7000</strong> (Part No. 90 23 758)!<br />

Intended use<br />

Daisy Chain Kit – 83 17 282:<br />

— For connecting a number of transmitters to a bus (daisy chaining / multi-drop)<br />

Contents of the cable set<br />

— Cable grommet<br />

— Nut for cable grommet<br />

— 4-pin connector terminal, orange<br />

Preparing the docking station<br />

● Install the docking station as described in the <strong>Installation</strong> <strong>Instructions</strong> 90 23 760.<br />

1 Punch or drill the hole for the second cable grommet from inside the docking station.<br />

The hole should have a clear diameter of Ø 20.5 mm.<br />

● Check the docking stations for any loose parts, and clean if necessary.<br />

● Insert the nut for the cable grommet inside the docking station.<br />

● Screw the cable grommet from the outside of the docking station and tighten into place.<br />

Installing the electrical connections<br />

● Connect the electrical installation as described in the <strong>Installation</strong> <strong>Instructions</strong> of the<br />

docking station 90 23 760.<br />

2 Fit the 4-pin connector terminal in the holder on the mounting plate.<br />

If necessary:<br />

● Refit the raincover (for protection against dust and splashwater).<br />

Note:<br />

The 4pin input terminal (3) and output terminal (2) are electrically connected 1:1.<br />

Installing the measuring unit<br />

● Install the measuring unit as described in the <strong>Installation</strong>s for Use 90 23 759.<br />

— Due to the additional cable inlet, the resistance when fitting the measuring unit is<br />

slightly increased.<br />

Make sure that the measuring unit is lowered all the way to the stop.<br />

90 23 766 - MA 4683.110 en<br />

© <strong>Dräger</strong> Safety AG & Co. KGaA<br />

1 st edition - September 2003<br />

Subject to alteration<br />

ARUA-F001<br />

D<br />

<strong>Dräger</strong> Safety AG & Co. KGaA – Revalstraße 1, D-23560 Lübeck, Germany<br />

Tel. +49 451 8 82 - 27 94 – Fax +49 451 8 82 - 49 91<br />

www.draeger-safety.de<br />

1<br />

+24 V<br />

0 V<br />

0 V<br />

4...20 mA<br />

+24 V<br />

0 V<br />

0 V<br />

4...20 mA<br />

2 3<br />

00123766_1.eps<br />

00223766_1.eps