3D TRASAR® Technology for Boilers Improves Reliability at - Nalco

3D TRASAR® Technology for Boilers Improves Reliability at - Nalco

3D TRASAR® Technology for Boilers Improves Reliability at - Nalco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The key business drivers <strong>for</strong> the customer included:<br />

• Improve the reliability and availability of the boiler<br />

plant<br />

• Maintain clean w<strong>at</strong>er-side surfaces in the boiler<br />

• Reduce the volume of chemicals required <strong>for</strong><br />

tre<strong>at</strong>ment due to upset conditions<br />

New Programme<br />

Under traditional w<strong>at</strong>er tre<strong>at</strong>ment regimes, where<br />

wet chemistry analyses are only conducted intermittently,<br />

upset conditions can go undetected <strong>for</strong><br />

long periods, during which significant problems can<br />

arise. This is a challenge which can be immedi<strong>at</strong>ely<br />

addressed with <strong>3D</strong> TRASAR Boiler <strong>Technology</strong>,<br />

with the p<strong>at</strong>ented <strong>Nalco</strong> Corrosion Stress Monitor<br />

(NCSM). This can be extremely valuable in protecting<br />

steam gener<strong>at</strong>ion assets, providing real-time<br />

on-line monitoring of system conditions, and an<br />

immedi<strong>at</strong>e alarm and corrective action as soon as<br />

upset conditions start to occur.<br />

At the mill, <strong>Nalco</strong> and the customer worked together<br />

to implement a joint str<strong>at</strong>egy to deliver improved<br />

boiler reliability. <strong>3D</strong> TRASAR Boiler <strong>Technology</strong><br />

was installed, and from start to finish was in full<br />

oper<strong>at</strong>ion after just three hours of install<strong>at</strong>ion and<br />

commissioning.<br />

In keeping with standard practice, the following Key<br />

Per<strong>for</strong>mance Indic<strong>at</strong>ors (KPIs) were established <strong>for</strong><br />

the use of <strong>3D</strong> TRASAR Boiler <strong>Technology</strong> on the<br />

boiler system:<br />

• Ability to determine vari<strong>at</strong>ions in corrosivity of the<br />

feedw<strong>at</strong>er and make a link to specific oper<strong>at</strong>ional<br />

and chemical parameters.<br />

• Ability to control the system variability and provide<br />

maximum asset protection and maximum<br />

availability to gener<strong>at</strong>e steam <strong>for</strong> the production<br />

process.<br />

• Improvement in the service level by <strong>Nalco</strong>, by<br />

providing real-time alarms and communic<strong>at</strong>ion of<br />

upset conditions th<strong>at</strong> require immedi<strong>at</strong>e <strong>at</strong>tention,<br />

allowing plant oper<strong>at</strong>ors to focus on the main<br />

production process.<br />

Since the unit was commissioned, it has oper<strong>at</strong>ed<br />

without major problems, and has required minimal<br />

service and maintenance <strong>at</strong>tention, with just one<br />

regular service and calibr<strong>at</strong>ion after nine months.<br />

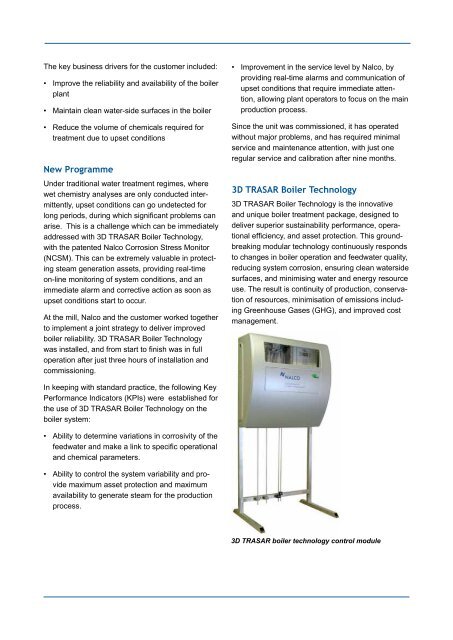

<strong>3D</strong> TRASAR Boiler <strong>Technology</strong><br />

<strong>3D</strong> TRASAR Boiler <strong>Technology</strong> is the innov<strong>at</strong>ive<br />

and unique boiler tre<strong>at</strong>ment package, designed to<br />

deliver superior sustainability per<strong>for</strong>mance, oper<strong>at</strong>ional<br />

efficiency, and asset protection. This groundbreaking<br />

modular technology continuously responds<br />

to changes in boiler oper<strong>at</strong>ion and feedw<strong>at</strong>er quality,<br />

reducing system corrosion, ensuring clean w<strong>at</strong>erside<br />

surfaces, and minimising w<strong>at</strong>er and energy resource<br />

use. The result is continuity of production, conserv<strong>at</strong>ion<br />

of resources, minimis<strong>at</strong>ion of emissions including<br />

Greenhouse Gases (GHG), and improved cost<br />

management.<br />

<strong>3D</strong> TRASAR boiler technology control module