Operating Manual for Hot runner Nozzles Thermoject® - psg-online.de

Operating Manual for Hot runner Nozzles Thermoject® - psg-online.de

Operating Manual for Hot runner Nozzles Thermoject® - psg-online.de

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Operating</strong> <strong>Manual</strong> <strong>for</strong> <strong>Hot</strong> <strong>runner</strong> <strong>Nozzles</strong> <strong>Thermoject®</strong><br />

Mini-Series 2022-Version-B<br />

Uni-Series 2026/2040-Version-B<br />

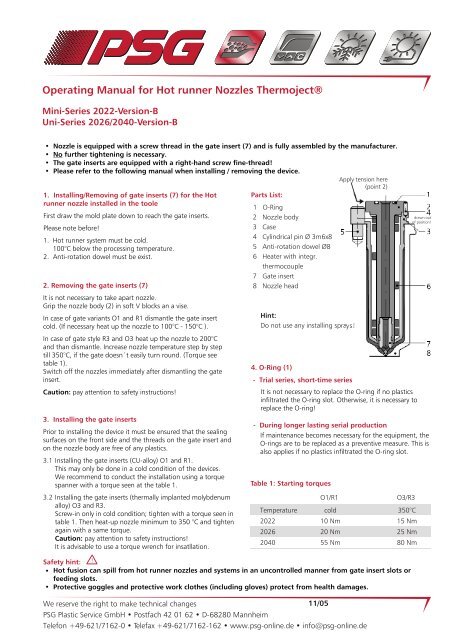

• Nozzle is equipped with a screw thread in the gate insert (7) and is fully assembled by the manufacturer.<br />

• No further tightening is necessary.<br />

• The gate inserts are equipped with a right-hand screw fine-thread!<br />

• Please refer to the following manual when installing / removing the <strong>de</strong>vice.<br />

Apply tension here<br />

(point 2)<br />

1. Installing/Removing of gate inserts (7) <strong>for</strong> the <strong>Hot</strong><br />

<strong>runner</strong> nozzle installed in the toole<br />

First draw the mold plate down to reach the gate inserts.<br />

Please note be<strong>for</strong>e!<br />

1. <strong>Hot</strong> <strong>runner</strong> system must be cold.<br />

100°C below the processing temperature.<br />

2. Anti-rotation dowel must be exist.<br />

2. Removing the gate inserts (7)<br />

It is not necessary to take apart nozzle.<br />

Grip the nozzle body (2) in soft V blocks an a vise.<br />

In case of gate variants O1 and R1 dismantle the gate insert<br />

cold. (If necessary heat up the nozzle to 100°C - 150°C ).<br />

In case of gate style R3 and O3 heat up the nozzle to 200°C<br />

and than dismantle. Increase nozzle temperature step by step<br />

till 350°C, if the gate doesn´t easily turn round. (Torque see<br />

table 1).<br />

Switch off the nozzles immediately after dismantling the gate<br />

insert.<br />

Caution: pay attention to safety instructions!<br />

3. Installing the gate inserts<br />

Prior to installing the <strong>de</strong>vice it must be ensured that the sealing<br />

surfaces on the front si<strong>de</strong> and the threads on the gate insert and<br />

on the nozzle body are free of any plastics.<br />

3.1<br />

3.2<br />

Installing the gate inserts (CU-alloy) O1 and R1.<br />

This may only be done in a cold condition of the <strong>de</strong>vices.<br />

We recommend to conduct the installation using a torque<br />

spanner with a torque seen at the table 1.<br />

Installing the gate inserts (thermally implanted molyb<strong>de</strong>num<br />

alloy) O3 and R3.<br />

Screw-in only in cold condition; tighten with a torque seen in<br />

table 1. Then heat-up nozzle minimum to 350 °C and tighten<br />

again with a same torque.<br />

Caution: pay attention to safety instructions!<br />

It is advisable to use a torque wrench <strong>for</strong> insatllation.<br />

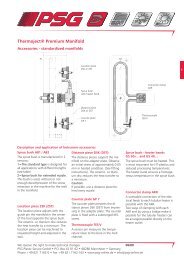

Parts List:<br />

1 O-Ring<br />

2 Nozzle body<br />

3 Case<br />

4 Cylindrical pin Ø 3m6x8<br />

5 Anti-rotation dowel Ø8<br />

6 Heater with integr.<br />

thermocouple<br />

7 Gate insert<br />

8 Nozzle head<br />

Hint:<br />

Do not use any installing sprays!<br />

4. O-Ring (1)<br />

- Trial series, short-time series<br />

It is not necessary to replace the O-ring if no plastics<br />

infiltrated the O-ring slot. Otherwise, it is necessary to<br />

replace the O-ring!<br />

- During longer lasting serial production<br />

If maintenance becomes necessary <strong>for</strong> the equipment, the<br />

O-rings are to be replaced as a preventive measure. This is<br />

also applies if no plastics infiltrated the O-ring slot.<br />

Table 1: Starting torques<br />

Temperature<br />

Safety hint: !<br />

• <strong>Hot</strong> fusion can spill from hot <strong>runner</strong> nozzles and systems in an uncontrolled manner from gate insert slots or<br />

feeding slots.<br />

• Protective goggles and protective work clothes (including gloves) protect from health damages.<br />

O1/R1<br />

We reserve the right to make technical changes<br />

11/05<br />

PSG Plastic Service GmbH • Postfach 42 01 62 • D-68280 Mannheim<br />

Telefon +49-621/7162-0 • Telefax +49-621/7162-162 • www.<strong>psg</strong>-<strong>online</strong>.<strong>de</strong> • info@<strong>psg</strong>-<strong>online</strong>.<strong>de</strong><br />

2022<br />

2026<br />

2040<br />

cold<br />

10 Nm<br />

20 Nm<br />

55 Nm<br />

O3/R3<br />

350°C<br />

15 Nm<br />

25 Nm<br />

80 Nm<br />

drawn out<br />

of position!

5. Installing/removing the nozzle during replacement<br />

oh heater<br />

The fundamental handling - (see fig.1-3).<br />

Only with the Uni-series the cable attachment is to be<br />

removed. Besi<strong>de</strong> the basic <strong>de</strong>vice one needs the<br />

assembly/disassembly set. Thus the housing (3) is pushed<br />

by the nozzle body (2) - (see fig.1+2).<br />

The ingate employment (7) remains thereby in the nozzle.<br />

The disassembly of the heater is facilitated through <strong>for</strong><br />

tricks against the turn direction, when simultaneous<br />

pushing.<br />

Picture 1:<br />

Picture 2:<br />

Picture 3:<br />

6. Further hints<br />

Main <strong>de</strong>vice<br />

Removal tools<br />

Installing tools<br />

In the case of use of normal ring spanners it can come<br />

<strong>de</strong>pending up on energy expenditure to the <strong>de</strong><strong>for</strong>mation of<br />

the gate insert!<br />

We recommend to work generally with a torque wrench.<br />

7. Special tools <strong>for</strong> easier service<br />

7.2 Installing-/Removal tools<br />

Main <strong>de</strong>vice - <strong>de</strong>vice no. 265760<br />

Installing-/Removal tools<br />

For Thj 2022<br />

For Thj 2026<br />

For Thj 2040<br />

7.3 Drawout <strong>de</strong>vice<br />

Drawout <strong>de</strong>vice<br />

For Thj 2022<br />

For Thj 2026<br />

For Thj 2040<br />

Art.-No.<br />

290 472<br />

291 571<br />

291 572<br />

Art.-No.<br />

290 477<br />

291 581<br />

291 582<br />

The drawout <strong>de</strong>vice facilitates the <strong>de</strong>velopment of the hot<br />

<strong>runner</strong> nozzle from the tool. See fig. 4-7.<br />

Picture 4:<br />

Picture 5: Picture 6: Picture 7: