DMO Bulletin For Industry - Department of Defence

DMO Bulletin For Industry - Department of Defence

DMO Bulletin For Industry - Department of Defence

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

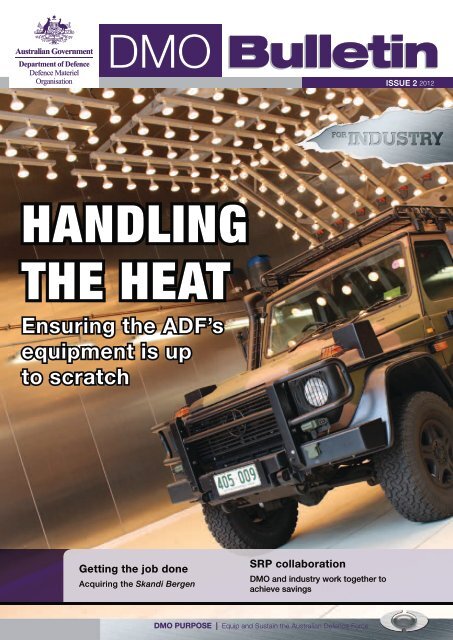

Handling<br />

tHe Heat<br />

Ensuring the ADF’s<br />

equipment is up<br />

to scratch<br />

Getting the job done<br />

Acquiring the Skandi Bergen<br />

<strong>Bulletin</strong><br />

SRP collaboration<br />

<strong>DMO</strong> and industry work together to<br />

achieve savings<br />

<strong>DMO</strong> PURPOSE | Equip and Sustain the Australian <strong>Defence</strong> <strong>For</strong>ce<br />

ISSUE 2 2012

Thanks to everyone who<br />

provided background<br />

information for the articles in<br />

this edition <strong>of</strong> the<br />

<strong>DMO</strong> <strong>Bulletin</strong>.<br />

Special thanks to the<br />

following:<br />

Writing/Editing/Pro<strong>of</strong>ing<br />

Harry Baxter<br />

Luke Brown<br />

Wendy Messer<br />

Michelle Perks<br />

Richard Stevenson<br />

Graphic Design<br />

Mic Bowbrick<br />

Zuzana Milne<br />

Artwork styled and produced<br />

by <strong>DMO</strong> Communications.<br />

Please contact the <strong>DMO</strong><br />

<strong>Bulletin</strong> Editor if you would<br />

like to re-use any part <strong>of</strong> this<br />

publication.<br />

All republished articles<br />

must be attributed to<br />

the <strong>DMO</strong> <strong>Bulletin</strong>.<br />

Contact the<br />

<strong>DMO</strong> <strong>Bulletin</strong> Editor,<br />

Michelle Perks, with your<br />

story ideas:<br />

e: dmo.bulletin@<br />

defence.gov.au<br />

p: 02 6265 1636<br />

<strong>For</strong> general enquiries or<br />

support please email the<br />

<strong>DMO</strong> Communications team:<br />

e: dmo.communication@<br />

defence.gov.au<br />

The editorial team reserves<br />

the right to edit and rearrange<br />

all items in the <strong>DMO</strong> <strong>Bulletin</strong><br />

for the reasons <strong>of</strong> clarity and<br />

space. While the editorial<br />

team isn’t responsible for the<br />

accuracy <strong>of</strong> the information<br />

submitted, every reasonable<br />

effort will be made to verify<br />

content.<br />

MARCH:<br />

APRIL:<br />

MAY:<br />

IN THE NEWS<br />

The Australian <strong>Defence</strong> <strong>For</strong>ce (ADF) will have access to an additional C-17<br />

following Government approval to purchase a sixth aircraft through the United<br />

States (US) <strong>For</strong>eign Military Sales (FMS) program. The sixth C-17 has been<br />

acquired for $280 million and is expected to arrive in Australia early<br />

next year.<br />

A second Shadow 200 Tactical Unmanned Aerial System (TUAS) will be<br />

delivered for use to Australian troops preparing to deploy to Afghanistan,<br />

almost one year ahead <strong>of</strong> schedule. While this TUAS was originally scheduled<br />

to be delivered in the first half <strong>of</strong> 2013, the US has agreed to deliver it in the<br />

first half <strong>of</strong> 2012.<br />

The Air Warfare Destroyer program has reached an important milestone<br />

following the arrival in Adelaide <strong>of</strong> the first <strong>of</strong> three state <strong>of</strong> the art horizonsearch<br />

radars.The radars were purchased for around $10 million each and will<br />

be used to search and track targets immediately above the sea surface.<br />

The Minister for <strong>Defence</strong> Materiel, Jason Clare, held a two-day summit with<br />

senior <strong>Defence</strong> Officials and the CEOs <strong>of</strong> companies involved with Projects <strong>of</strong><br />

Concern, to ensure that the “people responsible for these projects are doing<br />

everything necessary to remediate them.” According to Minister Clare, these<br />

meetings “bring the right people together and focus them on getting these<br />

projects back on track and <strong>of</strong>f the list.” There are currently six projects on the<br />

Projects <strong>of</strong> Concern list.<br />

Nine Australian companies are being <strong>of</strong>fered more than $12 million in matched<br />

funding to commercialise new defence technologies that will contribute to<br />

Australia’s Priority <strong>Industry</strong> Capabilities (PICs) in the defence sector. Over the<br />

next seven years $45 million will be invested in PICs through this program. The<br />

Minister for <strong>Defence</strong> Materiel, Jason Clare, said the funding “is about making<br />

sure our troops have the equipment they need to do their job.”<br />

The Government has appointed a General Manager <strong>of</strong> Submarines to take<br />

responsibility for all materiel related aspects <strong>of</strong> submarine support across<br />

<strong>Defence</strong>. David Gould has been appointed to the position and will answer to<br />

the CEO <strong>DMO</strong>. The Government also announced that it would provide $214<br />

million for the next stage <strong>of</strong> the Future Submarines Project. This funding will<br />

go towards further detailed studies and analysis to inform the Government’s<br />

decision on the design <strong>of</strong> Australia’s next submarine.<br />

The Prime Minister and the Minister for <strong>Defence</strong> have released the final report<br />

<strong>of</strong> the Australian <strong>Defence</strong> <strong>For</strong>ce Posture Review. This review addresses a<br />

range <strong>of</strong> present and emerging global, regional and national strategic and<br />

security factors that require careful consideration for the future. The <strong>For</strong>ce<br />

Posture Review will feed into the 2013 <strong>Defence</strong> White Paper.<br />

Access the <strong>DMO</strong>’s latest news on the <strong>DMO</strong> website.<br />

The <strong>DMO</strong>: www.defence.gov.au/dmo<br />

Skilling Australia's <strong>Defence</strong> <strong>Industry</strong>: www.defence.gov.au/dmo/id/sadi<br />

The <strong>Defence</strong> and <strong>Industry</strong> ePortal: www.dplusi.defence.gov.au<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 2

Deming’s words are a good warning<br />

against over-optimism and blind faith.<br />

Clearly one <strong>of</strong> the <strong>DMO</strong>’s most important<br />

tasks is delivering what the ADF needs, when<br />

they need it and within the affordability and<br />

scope requirements approved by Government.<br />

We cannot fulfil this task effectively without<br />

thorough and accurate analysis <strong>of</strong> the<br />

requirements, cost, schedule and risks<br />

associated with every project.<br />

Simply parroting the project ambitions for<br />

capability, cost and schedule that were<br />

envisaged early in the acquisition development<br />

cycle is not acceptable.<br />

The implementation <strong>of</strong> the two-pass approval<br />

process provides us the time and resources<br />

necessary to undertake this work thoroughly.<br />

To date this has been broadly successful<br />

with a measurable improvement in schedule<br />

performance.<br />

We must continue to use this process wisely and<br />

for the best outcomes.<br />

I am concerned that just occasionally our<br />

project managers have become more<br />

“project advocates” than pr<strong>of</strong>essional project<br />

implementers. Our role is to advise on project<br />

issues, plan an effective project strategy<br />

including risk reduction and, once approved,<br />

implement those plans to get the job done. Let’s<br />

leave project advocacy to the capability manager<br />

who is best placed to do this in<br />

any case.<br />

Of course this is not an excuse to simply<br />

make our targets so s<strong>of</strong>t that we will always<br />

reach them. Against the background <strong>of</strong> proper<br />

care and caution we also need to proceed<br />

with ‘managed urgency’ and set ourselves<br />

responsible but nevertheless challenging project<br />

outcomes.<br />

Sometimes the outcome apparent to us as<br />

the best or most obvious choice isn’t backed<br />

Warren King<br />

CEO <strong>DMO</strong><br />

CEO <strong>DMO</strong><br />

UnDERStAnDInG<br />

OUR ROLE<br />

a message from<br />

the ceo<br />

Warren King<br />

“In God we trust; all others must bring data.” Management guru, W. Edwards Deming<br />

3 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

by analysis <strong>of</strong> the data. Our advice and<br />

recommendations must be supported by<br />

detailed analysis and evidence.<br />

Out and about<br />

In the lead-up to the Melbourne BPR I was<br />

able to visit a few <strong>DMO</strong> teams in and around<br />

Melbourne. I was impressed with their level <strong>of</strong><br />

commitment and energy, and it was good to<br />

come face-to-face with some <strong>of</strong> the people<br />

involved behind-the-scenes in delivering<br />

successful projects. I met with individuals who<br />

are providing direct support to operational<br />

deployments and actively supporting the efficient<br />

processing <strong>of</strong> international financial transactions.<br />

I also met with teams supporting the introduction<br />

<strong>of</strong> new force protection measures and testing<br />

enhancements to soldier safety.<br />

Speaking <strong>of</strong> the BPR, we were fortunate to hear<br />

from Major General Angus Campbell, the new<br />

Deputy Chief <strong>of</strong> Army. In his typically insightful<br />

way, the General reminded us <strong>of</strong> Army’s priorities<br />

and challenges and reinforced the importance <strong>of</strong><br />

fielding solutions, rather than just admiring the<br />

problems.<br />

As the recent Commander <strong>of</strong> the Australian<br />

forces in the Middle East, he spoke with<br />

authority about the positive contribution our<br />

efforts are making in support <strong>of</strong> ADF operations.<br />

His words were very appropriate and a timely<br />

reminder <strong>of</strong> the reason for our existence – to<br />

equip and support the men and women <strong>of</strong> the<br />

ADF – with a particular and urgent focus on the<br />

requirements <strong>of</strong> deployed units and those in the<br />

critical training and readying phases.<br />

Putting it to<br />

the test<br />

04<br />

Getting on with<br />

the job<br />

09<br />

Cooperation is<br />

the key<br />

11<br />

SRP collaboration<br />

13<br />

Going digital<br />

15<br />

INSIDE THIS ISSUE

<strong>DMO</strong> ENGINEERING<br />

Looking into PTS’ hot chamber.<br />

Ever wondered what happens<br />

to an ADF vehicle when it’s<br />

left outside on a cold winter’s<br />

night in Afghanistan? Does the<br />

demister work and the engine start<br />

in minus 17 degrees Celsius? What<br />

happens if you leave one <strong>of</strong> these<br />

vehicles sitting on the tarmac in<br />

Darwin in the middle <strong>of</strong> summer?<br />

Nestled in the Victorian bushland is a<br />

<strong>DMO</strong> facility that can simulate these<br />

exact climatic conditions. Step into<br />

the giant metal fridge and it feels like<br />

you’re at the snow, then walk through<br />

the corridor and into the room filled<br />

with countless rows <strong>of</strong> heat lamps and<br />

it’s like you’re in the tropics.<br />

Equipment that goes to the ADF is<br />

rigorously tested—but how does this<br />

actually happen? The <strong>DMO</strong> <strong>Bulletin</strong><br />

recently visited the Land Engineering<br />

Agency’s (LEA) proving ground at<br />

Monegeetta, Victoria, to get a better<br />

idea <strong>of</strong> how we ensure the ADF’s land<br />

equipment is up to scratch.<br />

Our tour <strong>of</strong> the facility concentrated on<br />

the work conducted by the Prototype<br />

and Test Services (PTS) group. This<br />

team helps to ensure that technical<br />

integrity <strong>of</strong> land materiel is attained<br />

and maintained over its entire lifecycle<br />

at an affordable cost. The team does<br />

this by conducting a range <strong>of</strong> trials,<br />

capturing and analysing the data and<br />

then providing independent technical<br />

PUttInG It tO tHE tESt<br />

advice to project teams. It’s essential<br />

that LEA’s advice and test data are<br />

accurate and comprehensive, because<br />

the information it provides helps<br />

capability managers and Government<br />

to make informed acquisition and<br />

sustainment decisions.<br />

While this is serious and precise work,<br />

the Director <strong>of</strong> PTS, Gary Lampard,<br />

said his team has a lot <strong>of</strong> fun in the<br />

process.<br />

“Unlike many other jobs, our staff get<br />

their hands dirty actually using and<br />

testing military equipment,” he said.<br />

“That’s the only way we can check<br />

whether the equipment will meet the<br />

soldier’s needs.”<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 4

FAST FACT<br />

The LEA proving ground<br />

has been used to test Army<br />

equipment for approximately<br />

70 years. A new facility was<br />

<strong>of</strong>ficially opened by the<br />

Minister for <strong>Defence</strong> Materiel,<br />

Jason Clare, in November<br />

2010. As <strong>of</strong> this year, all test<br />

facilities are now located at the<br />

Monegeetta site, providing the<br />

Army with a one stop shop for<br />

all its testing requirements.<br />

The Manager <strong>of</strong> the Automotive<br />

Performance Lab, Les Caddaye,<br />

showed us how the Army’s vehicles<br />

are put through their paces. Setting <strong>of</strong>f<br />

in a G-Wagon, Les took us on a tour<br />

<strong>of</strong> the vehicle proving ground. While<br />

we started <strong>of</strong>f on a few kilometres <strong>of</strong><br />

normal bitumen road, we got more<br />

adventurous as the drive continued.<br />

“Michelle, do you reckon this vehicle<br />

can get up a set <strong>of</strong> stairs?” asked Les.<br />

“How about drive over some concrete<br />

obstacles?”<br />

By the end <strong>of</strong> our tour I realised<br />

that this utility could handle pretty<br />

much anything. Mud, grass, gravel,<br />

boulders, stairs – you name it, we<br />

went through it or over it. (<strong>For</strong> the<br />

record, the vehicle we were travelling<br />

in can drive up, down and complete<br />

Inside PTS’ mechanical testing lab.<br />

5 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

a reverse hill start on a 60 per cent<br />

/ 31 degree incline. I have a new<br />

appreciation for seatbelts.)<br />

Les explained that these kinds <strong>of</strong> tests<br />

help the Army understand the limits <strong>of</strong><br />

its vehicles.<br />

“Our serving men and women need to<br />

know what their vehicles can handle<br />

before they get into the field,” he said.<br />

“When they’re in the middle <strong>of</strong> an<br />

operation they need to know exactly<br />

where they can drive and for how long<br />

in order to plan their missions properly.<br />

This is why our test and evaluation<br />

processes are so important.”<br />

Brett Oldfield, the Manager <strong>of</strong> the<br />

Mechanical and Environmental Lab<br />

also manages testing, but unlike Les,<br />

his job is to assess the mechanical<br />

integrity <strong>of</strong> ADF equipment and the<br />

impact that different environmental<br />

conditions can have on its<br />

performance.<br />

In the large climatic chambers, Brett<br />

and his team can simulate a range<br />

<strong>of</strong> conditions that Australian Army<br />

equipment could endure. They can<br />

create hot environments <strong>of</strong> up to 73<br />

degrees Celsius, cool environments<br />

down to minus 33 degrees Celsius and<br />

muggy conditions with up to 98 per<br />

cent humidity. They can also see how<br />

equipment copes when bombarded<br />

with different elements like dust, salt<br />

and heavy rain.<br />

continued page 6<br />

<strong>DMO</strong> ENGINEERING<br />

Testing vehicles on LEA’s proving ground.

<strong>DMO</strong> ENGINEERING<br />

Inside PTS’ hot chamber.<br />

Brett said some <strong>of</strong> this testing is about<br />

asking common sense questions.<br />

“A vehicle can have all the mod-cons<br />

in the world, but if it doesn’t do what<br />

you need it to, it’s <strong>of</strong> little value,”<br />

he said.<br />

“ADF vehicles in Afghanistan face<br />

some extraordinary conditions in<br />

winter. So we need to check some<br />

simple things; in extreme temperatures<br />

can the vehicle be started and does<br />

the demister work so that troops can<br />

actually see out <strong>of</strong> the windows.”<br />

Over in the mechanical labs, Brett and<br />

his team pull, stretch, drop, beat and<br />

shake different pieces <strong>of</strong> equipment to<br />

better understand capability limits.<br />

Standing in a room full <strong>of</strong> technical<br />

contraptions, Brett explained how<br />

some <strong>of</strong> the testing takes place.<br />

“Sometimes there’ll be reports <strong>of</strong> certain<br />

pieces <strong>of</strong> equipment all experiencing the<br />

same problems,” he said.<br />

“Say for example when a particular<br />

kind <strong>of</strong> radio is dropped, the battery<br />

pack falls out.”<br />

The hot and cold chambers at LEA’s<br />

Monegeetta facility.<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 6

“We’ll then get a sample <strong>of</strong> these radios<br />

and drop them from exactly the same<br />

height and record what happens. This’ll<br />

let us know whether it’s a problem with<br />

the actual capability or just a bad batch<br />

<strong>of</strong>f the production line.”<br />

“Even this kind <strong>of</strong> basic testing<br />

makes a real difference to our<br />

troops on the ground.”<br />

Aside from environmental, mechanical<br />

and automotive testing, PTS is also<br />

equipped to test communications and<br />

electro-optics equipment, and measure<br />

electromagnetic compatibility, noise<br />

7 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

and vibration, blast, ballistics and<br />

various electrical parameters.<br />

According to Gary Lampard, this<br />

diverse range <strong>of</strong> testing makes PTS<br />

a fascinating place to work.<br />

“The people that we’ve got here,<br />

particularly the young engineers and<br />

technical <strong>of</strong>ficers, really enjoy what<br />

we do,” he said.<br />

“We take work experience kids from<br />

secondary schools and people from<br />

the different <strong>DMO</strong> graduate programs<br />

and try to show them the opportunities<br />

that exist in this line <strong>of</strong> work.”<br />

<strong>DMO</strong> ENGINEERING<br />

Attracting young technical people<br />

to <strong>Defence</strong> business has arguably<br />

never been so important. With the<br />

recent record numbers <strong>of</strong> project<br />

approvals and the threat facing our<br />

land forces continuously changing,<br />

Australia needs a solid base <strong>of</strong><br />

technical staff to ensure our troops<br />

are provided with the best possible<br />

equipment. LEA’s continued efforts<br />

to train and retain these technically<br />

skilled workers will no doubt assist<br />

the <strong>DMO</strong> in responding to the<br />

ADF’s needs.

<strong>DMO</strong> + INDuSTRy<br />

<strong>For</strong>gacs worker stripping the forecastle deck.<br />

A<br />

successful <strong>Defence</strong> industry<br />

program has been adjusted<br />

to make it easier for<br />

companies to get involved in the<br />

scheme and enhance the training<br />

provided to workers in Australia’s<br />

defence industry.<br />

The Minister for <strong>Defence</strong> Materiel,<br />

Jason Clare, announced reforms<br />

to the Skilling Australia’s <strong>Defence</strong><br />

<strong>Industry</strong> (SADI) program in late April.<br />

The changes are being introduced<br />

after extensive consultation with<br />

industry during 2011 and include:<br />

• Providing up to $400,000 per<br />

company per year for on-the-job<br />

technical training<br />

• Shortening the forecasting outlook<br />

for companies by holding two<br />

guaranteed funding rounds each<br />

year, aligned with educational<br />

semesters<br />

• Introducing quarterly reporting on<br />

funded activities, to allow unused<br />

funds to be reallocated in the<br />

second round<br />

• Introducing an online application<br />

and grants management system to<br />

minimise paperwork for businesses<br />

applying for SADI funding.<br />

Priority may be given to applications<br />

for funding in areas identified<br />

as Priority or Strategic <strong>Industry</strong><br />

Capabilities.<br />

SADI CHAnGES<br />

More information on the SADI program<br />

including Program guidelines and stepby-step<br />

guidance on completing the<br />

application form is available on the<br />

<strong>DMO</strong> website.<br />

FAST FACT<br />

Applications for the next round<br />

<strong>of</strong> grants for up to $8 million <strong>of</strong><br />

funding can be submitted until<br />

midnight 29 May 2012.<br />

Successful grant recipients<br />

will be notified before the end<br />

<strong>of</strong> June.<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 8

ADF providing humanitarian and disaster relief assistance following the Aceh tsunami.<br />

2011 was a challenging time<br />

for <strong>Defence</strong>’s amphibious<br />

capability. But rather than<br />

wallowing in the downfalls<br />

identified, maritime stakeholders<br />

across the department and abroad<br />

are collaborating to ensure the<br />

problems are remedied. From<br />

investigations like the Rizzo Review,<br />

to the purchase and leasing <strong>of</strong><br />

additional vessels, significant effort<br />

is being invested into the maritime<br />

space to ensure the ADF has the<br />

amphibious support it requires both<br />

now and in the future.<br />

“You want it when?”<br />

This is probably how most people<br />

9 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

would respond if they were asked<br />

to acquire a new support ship for<br />

the Australian Navy within a matter<br />

<strong>of</strong> months. But when Commander<br />

(CMDR) Matt McCormack was asked<br />

to lead Joint Project (JP) 3033 in<br />

October 2011, and acquire an Interim<br />

Maritime Humanitarian Assistance<br />

and Disaster Relief Capability by early<br />

2012, he rose to the occasion.<br />

CMDR McCormack and his team<br />

met these steep requirements and on<br />

March 17 2012, the contract for the<br />

acquisition <strong>of</strong> the MV Skandi Bergen<br />

was signed.<br />

So how did this swift acquisition<br />

actually eventuate?<br />

<strong>DMO</strong> CAPABILITy<br />

GEttInG On WItH tHE jOb<br />

CMDR McCormack said it was<br />

largely to do with pr<strong>of</strong>essionalism and<br />

teamwork.<br />

“We had people all over <strong>Defence</strong>,<br />

central agencies and industry working<br />

to acquire this ship; specialists from<br />

the <strong>DMO</strong>, the Capability Development<br />

Group, the Australian Government<br />

Solicitor, and contractors,” he said.<br />

“Everybody had to be on board with<br />

the approach and the high pressure<br />

timeline, and focussed on what could<br />

be done rather than why we couldn’t<br />

do it.”<br />

After the project was approved in<br />

December, the project team worked<br />

with <strong>DMO</strong> contracting and legal experts<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 9

<strong>DMO</strong> CAPABILITy<br />

to develop an acquisition strategy.<br />

It was decided that the contract<br />

would be built around an international<br />

maritime industry standard contract,<br />

and while this required significant<br />

legal effort, it resulted in a quicker<br />

contracting process.<br />

The project team then released two<br />

direct source tenders in January to<br />

find (i) a maritime broker who could<br />

locate and purchase a ship, and<br />

(ii) a contractor who could conduct<br />

due diligence inspections <strong>of</strong> the<br />

candidate ships as well as initial ship<br />

management, crewing and sustainment.<br />

With both <strong>of</strong> these contracts fulfilled<br />

by February 2012, the contractors<br />

could get on with rapidly acquiring our<br />

next ship.<br />

By February 2012, the selected<br />

maritime broker, Strategic Marine<br />

Group, had located over 8000<br />

candidate ships. A team <strong>of</strong> experts<br />

then inspected the selected contenders<br />

10 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

and narrowed down this list to those<br />

that could do the job.<br />

The ships were judged against various<br />

<strong>Defence</strong> requirements including cargo<br />

capacity, accommodation, endurance,<br />

speed, age and condition.<br />

As with most projects, a number <strong>of</strong><br />

vessels were identified as largely<br />

suitable and these options were<br />

presented to senior management for<br />

final selection. The CEO <strong>DMO</strong>, General<br />

Manager Systems, General Manager<br />

Commercial and Head Maritime<br />

Systems all reviewed the candidates<br />

and liaised with the Government<br />

throughout the process to make a<br />

final decision.<br />

This new ship will primarily be used<br />

to transport troops and supplies in<br />

support <strong>of</strong> humanitarian and disaster<br />

relief. It will be operated under a<br />

civilian crew arrangement and after<br />

<strong>Defence</strong> introduces the Landing<br />

Helicopter Dock (LHD) ships the ship<br />

the <strong>DMO</strong> <strong>Bulletin</strong> answers more question about this purchase on page 18.<br />

Australian soldiers practice delivering humanitarian assistance during amphibious Exercise SEA LION 2012.<br />

FAST FACT<br />

The vessel will be delivered to<br />

<strong>Defence</strong> in May in Norway and<br />

<strong>Defence</strong> contractor Teekay will<br />

operate the vessel for the first<br />

three months. The long term<br />

ship management, crewing<br />

and sustainment contract for<br />

the ship is currently being<br />

tendered.<br />

will be transferred to Customs and<br />

Border Protection.<br />

Skandi Bergen represented the best<br />

value-for-money whole <strong>of</strong> government<br />

solution due to its ability to meet the<br />

needs <strong>of</strong> multiple customers and the<br />

longevity <strong>of</strong> its remaining service life.<br />

It met both <strong>Defence</strong>’s humanitarian<br />

assistance and disaster relief<br />

requirements, as well as Customs’<br />

Southern Ocean patrol needs, and will<br />

be in service for the next 20 years.<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 10

A US Army CH-47 Chinook during a resupply mission in Afghanistan.<br />

The needs <strong>of</strong> our deployed<br />

forces are constantly<br />

changing depending<br />

on the threats and situations<br />

they face. With the <strong>DMO</strong><br />

responsible for equipping and<br />

sustaining the ADF, one <strong>of</strong> our<br />

biggest challenges is ensuring<br />

that we can rapidly deliver<br />

materiel solutions to our<br />

troops’ ever-changing needs.<br />

In May 2011, the ADF lost one<br />

if its highly capable workhorses<br />

when a Chinook helicopter<br />

crashed in Afghanistan and was<br />

destroyed.<br />

11 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

Australian Chinooks play a pivotal<br />

role in both national and international<br />

military operations. They transport<br />

troops and battlefield equipment,<br />

assist during search, rescue and<br />

disaster relief operations, and are in<br />

high demand due to their superior<br />

performance in hot and high-altitude<br />

conditions in the Middle East Area<br />

<strong>of</strong> Operations.<br />

Understanding this aircraft’s crucial<br />

role, the Government approved the<br />

purchase <strong>of</strong> two additional Chinooks<br />

just six months after the May<br />

Chinook crash. In November 2011,<br />

the Government announced that the<br />

<strong>DMO</strong> CAPABILITy<br />

COOPERAtIOn IS tHE KEY<br />

helicopters would be purchased via<br />

FMS from surplus US Army stock.<br />

The <strong>DMO</strong> project team responsible<br />

for this acquisition has since been<br />

working tirelessly with the US Army<br />

and industry, to allow the aircraft to<br />

be delivered as quickly as possible<br />

to the Australian Army.<br />

Speaking to the <strong>DMO</strong> <strong>Bulletin</strong>, the<br />

AIR 9000 Phase 5D Project Manager,<br />

Lieutenant Colonel (LTCOL) Tyron de<br />

Boer, said cooperation and planning<br />

were key to this project’s success.<br />

“We have had a highly aggressive<br />

continued page 12<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 11

<strong>DMO</strong> CAPABILITy<br />

An Australian CH-47 D Chinook hovers and waits for clearance to take <strong>of</strong>f at Kandahar Airfield, Afghanistan.<br />

project schedule, from initial<br />

planning and project approvals<br />

right through to delivery <strong>of</strong><br />

capability,” he said.<br />

“We continuously engaged<br />

with the many players involved<br />

in the process to ensure they<br />

were aware <strong>of</strong> our schedule<br />

requirements and worked with us<br />

to meet our deadlines.”<br />

Working through the Christmas<br />

stand down period, the project<br />

team successfully accepted<br />

the aircraft from the US Army in<br />

Germany in January 2012. The<br />

project team then collaborated<br />

with ADF contractors, US<br />

Government <strong>of</strong>ficials and local<br />

German authorities to transport<br />

the Chinooks (by road) to a US<br />

Air <strong>For</strong>ce base in Germany. From<br />

there, they were relocated to<br />

Australia via two separate C-17<br />

strategic airlift operations.<br />

On arrival in Townsville, the<br />

aircraft underwent deeper<br />

maintenance and modification to<br />

match the configuration <strong>of</strong> the<br />

rest <strong>of</strong> the ADF’s Chinook fleet.<br />

This maintenance, rectification and<br />

modification program was extensive<br />

and required significant effort and<br />

coordination between engineering<br />

and logistics staff and our industry<br />

partners, BAE Systems and<br />

Columbia Helicopters Inc.<br />

Initial ground flight tests <strong>of</strong> the<br />

Chinooks are now underway and the<br />

project is on track to deliver Initial<br />

Operational Capability by mid-2012.<br />

The aircraft will undergo a second<br />

modification program in early 2013 to<br />

become fully deployable, paving the<br />

way for Final Operational Capability<br />

to be achieved by mid 2013.<br />

LTCOL de Boer said lessons learnt<br />

during this acquisition process will be<br />

very useful for later AIR 9000 phases.<br />

“The planning, cooperation, flexibility<br />

and coordination within the project<br />

team and across <strong>Defence</strong> were<br />

critical factors in this success,<br />

combined with the effective use<br />

<strong>of</strong> contracted support throughout<br />

the project.”<br />

“In essence this project has been a<br />

dress rehearsal for when we replace<br />

the existing ADF fleet with the<br />

modernised variant <strong>of</strong> the Chinook<br />

(CH-47F) in 2014-16 under AIR 9000<br />

Phase 5C.”<br />

Air 9000 Phase 5D has reinforced the<br />

need for the <strong>DMO</strong> to play a greater<br />

role in the FMS process. It’s also<br />

shown the value <strong>of</strong> having ‘boots on<br />

the ground’ representing the ADF’s<br />

interests.<br />

This acquisition success story is the<br />

result <strong>of</strong> thorough cooperation and<br />

holds great lessons for all <strong>of</strong> us as<br />

we strive to rapidly respond to the<br />

ADF’s changing needs.<br />

About AIR9000 Phase 5D<br />

The additional Chinooks<br />

acquired under Air 9000 5D<br />

take the ADF’s fleet to seven.<br />

This will reduce the pressure<br />

on the Chinook’s training<br />

and maintenance schedule,<br />

resulting in enhanced support<br />

<strong>of</strong> the Chinooks currently<br />

deployed in Afghanistan on<br />

Operation SLIPPER.<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 12

RAAF Air Traffic Control Officers maintain the control <strong>of</strong> all aircraft movements, both military and civilian, at RAAF Base Darwin during<br />

Exercise Pitch Black 2008.<br />

A<br />

revised support contract<br />

for the Australian<br />

Military Airspace Control<br />

Communication System (AMACCS)<br />

is set to deliver significant Strategic<br />

Reform Program (SRP) savings for<br />

the Commonwealth.<br />

BAE Systems was awarded a five year<br />

extension <strong>of</strong> the AMACCS contract<br />

in April. The <strong>DMO</strong> and BAE Systems<br />

renegotiated this contract<br />

to ensure that it was more costeffective<br />

and continued to deliver<br />

required levels <strong>of</strong> service to the Air<br />

<strong>For</strong>ce as the lead customer.<br />

The <strong>DMO</strong>’s Ground<br />

Telecommunications Equipment<br />

(GTE) SPO worked closely with BAE<br />

Systems to rebuild the contract. The<br />

savings were achieved by analysing<br />

the project practices, streamlining<br />

13 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

processes using LEAN principles,<br />

and drawing on past experience with<br />

AMACCS.<br />

The Director <strong>of</strong> GTESPO, Group<br />

Captain Peter Pollock, said the revised<br />

contract is a win for <strong>Defence</strong> and<br />

industry.<br />

“The <strong>DMO</strong> and BAE Systems have<br />

collaborated to develop a contract that<br />

will deliver improved levels <strong>of</strong> support<br />

for the AMACCS fleet and provide<br />

ongoing savings to <strong>Defence</strong>,” he said.<br />

BAE Systems’ Director Land &<br />

Integrated Systems, Kim Scott,<br />

echoed with similar comments.<br />

“Ensuring we continue to find<br />

innovative ways to deliver value to<br />

the Commonwealth through the SRP<br />

program remains a key objective for<br />

us,” Kim said.<br />

<strong>DMO</strong> REFORM<br />

SRP COLLAbORAtIOn<br />

“This AMACCS extension is another<br />

testimony <strong>of</strong> how working together we<br />

can achieve significant long<br />

term cost savings on our projects<br />

without compromising the quality<br />

<strong>of</strong> service.”<br />

FAST FACT<br />

AMACCS provides in<br />

service support to the Air<br />

<strong>For</strong>ce’s ground to air radio<br />

assets across a range <strong>of</strong><br />

segments; air traffic control,<br />

air weapons ranges, pilot<br />

monitoring facilities, air<br />

defence ground environment<br />

and some remote Airservices<br />

Australia sites.

<strong>DMO</strong> + INDuSTRy<br />

The JSF at the Australian International Airshow 2009.<br />

An Australian company<br />

involved in the development<br />

<strong>of</strong> the Joint Strike Fighter<br />

(JSF) has reached an important<br />

milestone, completing first<br />

production <strong>of</strong> its parts two months<br />

ahead <strong>of</strong> schedule.<br />

Quickstep Holdings specialises in the<br />

production <strong>of</strong> advanced composites<br />

manufacturing and technology<br />

development and has been contracted<br />

to produce assembled access doors<br />

and panels for the centre section <strong>of</strong> the<br />

F-35 JSF aircraft.<br />

The parts have been presented to<br />

Northrop Grumman for acceptance.<br />

Quickstep expects to manufacture<br />

approximately one completed part<br />

per week, and will gradually ramp up<br />

that quantity as the JSF production<br />

rate increases.<br />

Quickstep’s Managing Director, Philippe<br />

Odouard, said the commencement<br />

<strong>of</strong> commercial JSF production was a<br />

significant event for the company.<br />

“This represents the start <strong>of</strong><br />

Quickstep’s first major production<br />

contract for the international defence<br />

industry,” he said.<br />

“To date, Quickstep has met, and in<br />

many cases outperformed, all JSF<br />

delivery deadlines agreed with Northrop<br />

Grumman – a record <strong>of</strong> which we can<br />

be justifiably proud.”<br />

The <strong>DMO</strong>’s Director <strong>of</strong> the JSF <strong>Industry</strong><br />

Team, part <strong>of</strong> the New Air Combat<br />

Capability project, John Wilshire,<br />

echoed with similar comments.<br />

“This successful delivery marks the<br />

beginning <strong>of</strong> many years <strong>of</strong> production<br />

<strong>of</strong> composite parts for the F-35, and<br />

will no doubt lead to other defence and<br />

aerospace composite manufacturing<br />

opportunities for the company,”<br />

he said.<br />

More information on the progress <strong>of</strong> the JSF is available on the <strong>DMO</strong> Website<br />

jSF PROGRESS<br />

“This opportunity demonstrates the<br />

value <strong>of</strong> Australian industry participation<br />

in the JSF production program.”<br />

FAST FACT<br />

Vipac Engineers and Scientists<br />

Ltd has become the fifth<br />

Australian-based industry<br />

supplier to receive a grant<br />

under the NACC industry<br />

support program.<br />

Vipac is developing an<br />

Aircraft Bearing Acoustic<br />

Monitor (AirBAM) system,<br />

which uses remote<br />

microphones to monitor<br />

the health <strong>of</strong> aircraft jet<br />

engines. AirBAM will monitor<br />

bearings, pumps and gears and<br />

detect internal foreign object<br />

damage as well as engine<br />

combustion irregularities.<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 14

The pallets <strong>of</strong> F-111 records at RAAF Base Amberley.<br />

Nobody likes filing, but<br />

when it comes to decades<br />

<strong>of</strong> <strong>Defence</strong> documents,<br />

we have to make sure this<br />

history is preserved. With all<br />

<strong>of</strong> the demands for access to<br />

information about our business,<br />

and the changes to the Freedom<br />

<strong>of</strong> Information Act, it’s now more<br />

important than ever that <strong>DMO</strong><br />

records are properly managed.<br />

Tucked away in a hangar at RAAF<br />

Base Amberley are over 130<br />

pallets <strong>of</strong> F-111 records. That’s<br />

approximately six million sheets<br />

15 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

<strong>of</strong> paper that encapsulate the<br />

history <strong>of</strong> this hard working and<br />

dearly loved aircraft. Understanding<br />

the significance <strong>of</strong> these records,<br />

the Disposal and Aerial Targets<br />

Office (DATO) (formerly known as<br />

the Strike and Reconnaissance SPO)<br />

is looking to improve how they are<br />

managed. Physical storage over<br />

many decades is a costly activity.<br />

The DATO has identified what<br />

documents need to be archived and<br />

how long each document needs<br />

to be kept (known as a retention<br />

period) and has recently established<br />

continued page 16<br />

<strong>DMO</strong> RECORDS<br />

GOInG DIGItAL<br />

FAST FACT<br />

Careful and accurate<br />

records management<br />

throughout a platform’s life<br />

reduces the work required<br />

when the platform is retired.<br />

The introduction <strong>of</strong><br />

Objective will assist areas<br />

in maintaining records and<br />

prevent the build up <strong>of</strong> hard<br />

copy documents, which<br />

will ultimately save space<br />

and money.

<strong>DMO</strong> RECORDS<br />

a $1.2 million contract with<br />

Salmat Business Process<br />

Outsourcing to create a suitable<br />

archive format for these physical<br />

records.<br />

Over the next six months,<br />

Salmat will bring these records<br />

into the digital age. Employing<br />

local residents from the Ipswich<br />

area, Salmat will scan each<br />

piece <strong>of</strong> paper and create an<br />

electronic version <strong>of</strong> these<br />

records. Individual records will<br />

be accompanied by relevant<br />

background information (known<br />

as metadata) and appropriate<br />

search and index tools will<br />

be built into the electronic<br />

database.<br />

DATO Director, Teresa Harding,<br />

said there are many benefits <strong>of</strong><br />

digitising these documents.<br />

“Bringing these records into a<br />

digital format will not only make<br />

them more cost effective and<br />

easier to manage and access,<br />

but it will also prevent them<br />

from being lost or damaged,”<br />

she said.<br />

“After the work is completed, the<br />

paper records will be destroyed,<br />

which will free up a lot <strong>of</strong> space<br />

at RAAF Base Amberley. We’ll<br />

also transfer this electronic<br />

database to <strong>Defence</strong>’s mandated<br />

records management tool –<br />

Objective.”<br />

Record digitisation saves time,<br />

space and ultimately money.<br />

While it requires financial<br />

investment and careful planning<br />

to initiate, the long term benefits<br />

make it worthwhile.<br />

Record digitisation is happening<br />

right across <strong>Defence</strong> and<br />

it’s important that <strong>DMO</strong> staff<br />

understand these activities.<br />

Left and Above: F-111 aircraft.<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 16

The <strong>DMO</strong> manages a significant<br />

amount <strong>of</strong> Commonwealth<br />

money as it works to deliver<br />

vital equipment and services to the<br />

ADF. Our serving men and women<br />

and all Australian taxpayers rely on<br />

us to do our job effectively.<br />

A useful way to assess our<br />

performance is to compare our<br />

organisation with our counterparts<br />

abroad. While the differences between<br />

some <strong>of</strong> our key processes prevent<br />

direct comparisons, budget and<br />

staffing are two points that can be<br />

assessed.<br />

The <strong>DMO</strong> delivers its services with a<br />

level <strong>of</strong> workforce consistent with the<br />

UK and Canada.<br />

With about 85 per cent <strong>of</strong><br />

our <strong>Defence</strong> equipment<br />

set to be replaced over the<br />

next 15 years, Australia needs a<br />

solid base <strong>of</strong> local engineers to help<br />

meet the ADF’s materiel needs.<br />

With this in mind, the Minister<br />

for <strong>Defence</strong> Materiel, Jason Clare,<br />

recently announced that the <strong>DMO</strong><br />

would extend its sponsorship <strong>of</strong> the<br />

F1 in Schools Technology Challenge<br />

– a program that encourages school<br />

students to take up careers in<br />

engineering.<br />

The news follows the announcement<br />

<strong>of</strong> the 2012 F1 in Schools Australian<br />

winner – Brighton Secondary School,<br />

Adelaide, which will be attending<br />

17 | <strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012<br />

Budget ($AuD<br />

million )<br />

<strong>DMO</strong> COntInUES tO SUPPORt<br />

YOUnG EnGInEERS<br />

the World Final in England later<br />

in the year.<br />

The F1 in Schools program gives<br />

primary and secondary students<br />

the opportunity to design, test,<br />

manufacture and race miniature<br />

<strong>For</strong>mula 1 cars.<br />

The students collaborate with industry<br />

partners to develop engineering,<br />

leadership, teamwork, media and<br />

project management skills.<br />

Speaking about the competition,<br />

Mr Clare confirmed that the Federal<br />

Government, through the <strong>DMO</strong>, would<br />

provide an additional $1.1 million<br />

over three years to continue the<br />

successful program.<br />

<strong>DMO</strong> <strong>Bulletin</strong> Issue 2 2012 | 17<br />

<strong>DMO</strong><br />

AuStRAliA<br />

DEFENCE<br />

EquIPMENT<br />

AND<br />

SuPPORT<br />

uniteD<br />

KingDom<br />

<strong>DMO</strong> uPDATE<br />

“Australia needs more engineers and<br />

the <strong>Defence</strong> industry is no exception,”<br />

Mr Clare said.<br />

“This program puts Australian students<br />

in the fast lane towards a career in<br />

engineering.”<br />

Research shows that over 60 per<br />

cent <strong>of</strong> boys and 35 per cent <strong>of</strong> girls<br />

who participated in the F1 in Schools<br />

challenge changed their school<br />

subjects to science, technology,<br />

engineering and maths.<br />

<strong>For</strong> more information<br />

head to:<br />

f1inschools.org.au<br />

MATERIEL<br />

GROuP,<br />

DEPARTMENT<br />

OF NATIONAL<br />

DEFENCE<br />

CAnADA<br />

10,100 21,400 4500<br />

Staffing 7400 20,000 4100<br />

Budget/Staffing<br />

Ratio($AuD<br />

million / head)<br />

HOW DO WE COMPARE?<br />

1.36 1.05 1.10<br />

Values are in 2011-12 Additional Estimates prices and at constant Exchange Rates<br />

Figures for each country are drawn from open source (public) material

Page title<br />

StREnGtHEnInG OUR AMPHIbIOUS CAPAbILItY<br />

The ADF’s pr<strong>of</strong>essional warfighting efforts receive<br />

worldwide recognition, but it also undertakes many<br />

activities outside <strong>of</strong> combat zones.<br />

From the Queensland floods, to the Indonesian earthquakes and<br />

tsunamis, the ADF has, and must continue, to provide specialist<br />

equipment and support to humanitarian assistance and disaster<br />

relief operations.<br />

In December 2011, the Minister for <strong>Defence</strong>, Stephen Smith, and<br />

the Minister for <strong>Defence</strong> Materiel, Jason Clare, announced plans<br />

to purchase an additional humanitarian and disaster relief ship<br />

to ensure the ADF is equipped to respond to these missions.<br />

Three months later, in March 2012, the Ministers announced the<br />

Government had agreed to purchase the <strong>of</strong>fshore support vessel<br />

Skandi Bergen.<br />

Some have questioned the purchase <strong>of</strong> this additional ship.<br />

According to the Canberra Times, critics believe “the Skandi<br />

Bergen is <strong>of</strong> no use to the Navy and the purchase is a public<br />

relations stunt”.<br />

Strengthening our amphibious capability has been a major focus<br />

for <strong>Defence</strong> (<strong>DMO</strong> and Navy included) and the Government over<br />

the last 12 months. Developments in this area have included the<br />

purchase <strong>of</strong> HMAS Choules, the Rizzo Review and the leasing<br />

<strong>of</strong> vessels 18 | <strong>DMO</strong> to provide <strong>Bulletin</strong> an Issue interim 2 2012capability.<br />

The Skandi Bergen is<br />

one part <strong>of</strong> this overall package; a swift but carefully-scrutinised<br />

purchase to assist the ADF to complete its humanitarian and<br />

disaster response operations. Claims that it is <strong>of</strong> no use to the<br />

Navy have been labelled by the Chief <strong>of</strong> Navy (CN) as incorrect.<br />

Instead, CN says, the purchase “significantly enhances” <strong>Defence</strong>’s<br />

ability to manage the transition period prior to the introduction <strong>of</strong><br />

the LHD.<br />

The ADF will use this additional humanitarian and disaster relief<br />

ship until the arrival <strong>of</strong> the LHD ships in the middle <strong>of</strong> the decade.<br />

The Government has agreed that the ship will then be transferred<br />

to the Australian Customs and Border Protection Service. This, to<br />

quote Minister Smith, “is a capability advantage and an effective<br />

and efficient use <strong>of</strong> taxpayer funding.”<br />

Both Minister Smith and CN have publicly responded to the<br />

criticism surrounding the purchase <strong>of</strong> the Skandi Bergen. Their<br />

comments, as well as the responses <strong>Defence</strong> provided to the<br />

Canberra Times, are available on the <strong>Defence</strong> website.<br />

See page 9 <strong>of</strong> this edition <strong>of</strong> the Dmo <strong>Bulletin</strong> for more<br />

details on the acquisition <strong>of</strong> the Skandi Bergen.