I R 1 2 3 4 5 6 7 8 9 10 11 12 13 T 14 15 A

I R 1 2 3 4 5 6 7 8 9 10 11 12 13 T 14 15 A

I R 1 2 3 4 5 6 7 8 9 10 11 12 13 T 14 15 A

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

I<br />

R<br />

T<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

<strong>10</strong><br />

<strong>11</strong><br />

<strong>12</strong><br />

<strong>13</strong><br />

<strong>14</strong><br />

<strong>15</strong><br />

A<br />

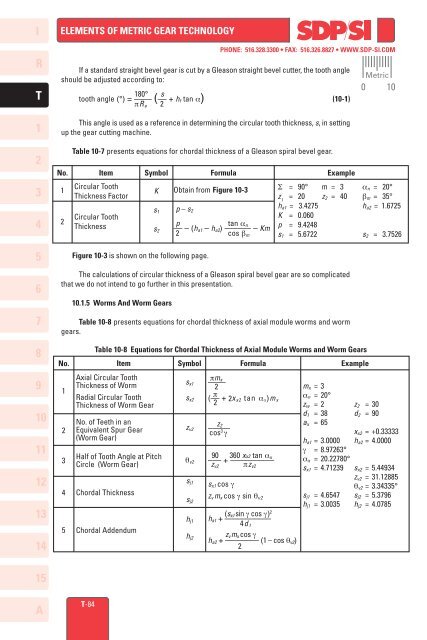

ELEMENTS OF METRIC GEAR TECHNOLOGY<br />

T-84<br />

PHONE: 516.328.3300 • FAX: 516.326.8827 • WWW.SDP-SI.COM<br />

If a standard straight bevel gear is cut by a Gleason straight bevel cutter, the tooth angle<br />

should be adjusted according to:<br />

180° s<br />

tooth angle (°) = –––– (–– + hf tan a) (<strong>10</strong>-1)<br />

pRe 2<br />

This angle is used as a reference in determining the circular tooth thickness, s, in setting<br />

up the gear cutting machine.<br />

Table <strong>10</strong>-7 presents equations for chordal thickness of a Gleason spiral bevel gear.<br />

No. Item Symbol<br />

Formula<br />

Example<br />

1<br />

2<br />

Circular Tooth<br />

Thickness Factor<br />

Circular Tooth<br />

Thickness<br />

Figure <strong>10</strong>-3 is shown on the following page.<br />

The calculations of circular thickness of a Gleason spiral bevel gear are so complicated<br />

that we do not intend to go further in this presentation.<br />

<strong>10</strong>.1.5 Worms And Worm Gears<br />

K<br />

s1<br />

s2<br />

Obtain from Figure <strong>10</strong>-3<br />

p – s2<br />

p tan an<br />

–– – (ha1 – ha2) –––––– – Km<br />

2 cos bm<br />

S = 90° m = 3 an = 20°<br />

z 1 = 20 z2 = 40 bm = 35°<br />

ha1 = 3.4275 ha2 = 1.6725<br />

K = 0.060<br />

p = 9.4248<br />

s1 = 5.6722 s2 = 3.7526<br />

Table <strong>10</strong>-8 presents equations for chordal thickness of axial module worms and worm<br />

gears.<br />

Table <strong>10</strong>-8 Equations for Chordal Thickness of Axial Module Worms and Worm Gears<br />

No. Item Symbol Formula<br />

Example<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Axial Circular Tooth<br />

Thickness of Worm<br />

Radial Circular Tooth<br />

Thickness of Worm Gear<br />

No. of Teeth in an<br />

Equivalent Spur Gear<br />

(Worm Gear)<br />

Half of Tooth Angle at Pitch<br />

Circle (Worm Gear)<br />

Chordal Thickness<br />

Chordal Addendum<br />

sx1<br />

sx2<br />

zv2<br />

qv2<br />

sj1<br />

sj2<br />

hj1<br />

hj2<br />

pmx<br />

––––<br />

2<br />

(––<br />

p<br />

+ 2x x2 tan ax)mx<br />

2<br />

z2<br />

–––––<br />

cos 3 g<br />

90 360 xx2 tan ax<br />

––– + ––––––––––<br />

zv2 pzv2<br />

sx1 cos g<br />

zv mx cos g sin qv2<br />

(sx1 sin g cos g) 2<br />

ha1 + –––––––––––<br />

4d1<br />

zv mx cos g<br />

ha2 + –––––––– (1 – cos qv2)<br />

2<br />

Metric<br />

0 <strong>10</strong><br />

mx = 3<br />

an = 20°<br />

zw = 2 z2 = 30<br />

d1 = 38 d2 = 90<br />

ax = 65<br />

xx2 = +0.33333<br />

ha1 = 3.0000 ha2 = 4.0000<br />

g = 8.97263°<br />

ax = 20.22780°<br />

sx1 = 4.7<strong>12</strong>39 sx2 = 5.44934<br />

zv2 = 31.<strong>12</strong>885<br />

qv2 = 3.34335°<br />

sj1 = 4.6547 sj2 = 5.3796<br />

hj1 = 3.0035 hj2 = 4.0785