Expanded Aluminium Foil Aluminium Filtafoil Test Results

Expanded Aluminium Foil Aluminium Filtafoil Test Results

Expanded Aluminium Foil Aluminium Filtafoil Test Results

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Filtration Product<br />

Specifications<br />

We understand that filtration<br />

product applications, performance<br />

environments and critical factors<br />

dictate construction materials and<br />

methods required by our customers.<br />

Given our experience of prototyping<br />

and new product development<br />

with customers to create filtration<br />

solutions, we would urge you to<br />

consider the following factors in<br />

specifying your bespoke filtration<br />

components:<br />

1. Material Type<br />

2. Critical performance factors<br />

3. Mesh opening dimensions<br />

required<br />

4. Material thickness<br />

5. Flattened or raised mesh<br />

6. Quantity of sheets or coils<br />

7. Additional processes and special<br />

finishes required (e.g. cut to size,<br />

pressed, welded, shaped, powder<br />

coated, fabricated)<br />

All sheet sizes are nominal, normally oversize. If exact sheared<br />

sizes are required, this must be stated on the order. All dimensions<br />

are in millimetres.<br />

<strong>Aluminium</strong> <strong>Filtafoil</strong> <strong>Test</strong> <strong>Results</strong><br />

<strong>Test</strong> <strong>Results</strong> relating to Expamet’s <strong>Filtafoil</strong> Range of Panels<br />

Grease Filtration<br />

Expamet filters are widely used to extract grease in domestic and commercial kitchens.<br />

<strong>Test</strong>s carried out confirm <strong>Filtafoil</strong>’s ability to remove up to 96% of grease from the<br />

airstream. This is based on a 50mm Super Panel at 2m/s air velocity. A 25mm panel<br />

will remove 94% contamination from the airstream. The test involved simulating typical<br />

conditions above an active grill/fryer utilising 50g of cooking oil. The removal efficiency<br />

was then calculated by weighing the quantity of oil used versus the percentage which<br />

had passed beyond the filter to the thick cotton pad.<br />

Mist Filtration<br />

<strong>Test</strong>s at the University of Birmingham have shown that a water mist droplet removal<br />

efficiency of 98-99% at air velocities of 2m/s through a 50mm corrugated <strong>Filtafoil</strong> pack<br />

can be achieved. Super Panel and Stainless Steel are advised for the removal of mist.<br />

Dust Filtration<br />

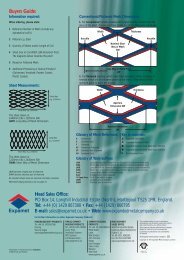

Chart 1: <strong>Test</strong> Data: BS 6540 Part 1: Sec 3: Eurovent 4/5 Para 6<br />

Pa Bar p (Resistance to Air Flow)<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Dust Load g/m<br />

Graph 2: Average Resistance to Airflow<br />

2 600 1200<br />

Pa Resistance p (Pressure Drop)<br />

100<br />

75<br />

50<br />

Filter Type Economy (E) Super (SP)<br />

Thickness mm 25 50 25 50<br />

Air Velocity m/s 2 2 2 2 2<br />

Initial Resistance (Clean) Pa 37 39 54 78<br />

Final Resistance Pa 287 289 304 328<br />

Average Synthetic Dust (weight) Arrestance % 72 74 78 85<br />

Fire Resistance Standards<br />

<strong>Test</strong>s by the Department of the Environment Building Research Establishment Fire<br />

Research Station show that <strong>Filtafoil</strong> would achieve Class 1 when tested to BS 476<br />

Part 7: 1971.<br />

Graph 1: Efficiency, Resistance and Dust Load using ASHRAE test dust at an<br />

air velocity of 2m per second. Pressure drop across Expamet <strong>Filtafoil</strong> panels<br />

50mm Panel 25mm Panel 12.5mm Panel<br />

Thickness Thickness Thickness<br />

Lighter Curves: Efficiency/Dust<br />

Darker Curves: Pressure Drop/Dust<br />

Efficiency 80%<br />

50mm Panel 25mm Panel 12.5mm Panel<br />

Thickness Thickness Thickness<br />

25<br />

Air Velocity m/s 1.00 2.00 3.00<br />

Tel: +44 (0)1429 867388 · Fax: +44 (0)1429 866795 · Website: www.expandedmetalcompany.co.uk<br />

70%<br />

60%<br />

50%<br />

<strong>Expanded</strong> <strong>Aluminium</strong> <strong>Foil</strong><br />

This highly efficient aluminium mesh has been proven to perform in a diverse range of applications.<br />

The material is available as coils, cut to size sheets and even as bespoke manufactured components.<br />

Amongst its uses, aluminium foil is layered into filter panels to capture dust and grease for both internal<br />

and external air filtration.<br />

The product is also transformed into explosion suppression safety foil, commonly used in fuel storage tanks for<br />

petrol and even for aviation fuel at airports and helicopter landing pads. Extensive testing by the MOD has<br />

revealed that storage tanks, filled with both fuel and aluminium foil, are able to withstand bullet and shrapnel<br />

penetration, as well as direct combustion without actually exploding. A further advantage is minimum<br />

displacement of only 0.95% of volume filled.<br />

<strong>Aluminium</strong> expanded foil can be compressed into various bespoke shapes, developed by our customers to be<br />

used as effective oil filters and automotive air filters. It is also used as an integral part of heatshields in automotive<br />

vehicle power trains.<br />

www.rhpcreative.com<br />

–<br />

THE EXPANDED METAL COMPANY<br />

Poker Hot<br />

PO Box 14, Longhill Industrial Estate (North),<br />

Red by<br />

Hartlepool, TS25 1PR, United Kingdom<br />

Tel: +44 (0)1429 867388 · Fax: +44 (0)1429 866795<br />

produced<br />

E-mail: sales@expamet.co.uk<br />

and<br />

The company policy is one of continuous development. We reserve the right to alter specifications, etc. without notice. Customers<br />

are advised to check availability of material. An Expamet International Company ©The <strong>Expanded</strong> Metal Company Limited Designed<br />

Tel: +44 (0)1429 867388 · Fax: +44 (0)1429 866795 · Website: www.expandedmetalcompany.co.uk

<strong>Expanded</strong> Metal for Filtration<br />

As a valued supplier to major industry filter manufacturers and distributors with over 110 years<br />

of experience, The <strong>Expanded</strong> Metal Company has earned a reputation for quality products<br />

and expert advice, built on total customer focus.<br />

Our highly skilled staff are able to offer a wide range of flexible service options coupled with<br />

unrivalled lead times. We specialise in made to order solutions, having the production capability<br />

to manufacture a wide range of filters in varied sizes and materials, utilising a number of different<br />

construction methods.<br />

Made to Order Expertise<br />

As the UK Market Leader in <strong>Expanded</strong> Metal production, we offer an<br />

unrivalled range of meshes combined with cost effective manufacturing<br />

expertise.<br />

Customer satisfaction is the key to our success. A major part of our business is our<br />

made to order service. Our production capability and experience allow us to offer<br />

bespoke solutions to your filtration problems.<br />

We can always use our experience to interpret your filtration problems and offer<br />

a bespoke product as a solution.<br />

Fine Mesh for Filtration<br />

Our unrivalled range of fine expanded meshes are ideal for multi-purpose<br />

filtration. Cost savings can be achieved when switching from perforated<br />

or woven materials to expanded metal guazes. Finer meshes are available<br />

as coil form, sheet or cut to size pieces.<br />

Versatile and adaptable, expanded meshes can also be pressed, formed,<br />

shaped and welded in-house into components for straining, retention and<br />

filtration, utilised across a wide range of industries.<br />

Below are examples of some of the meshes available. For more<br />

comprehensive details and more products, please call us to discuss your<br />

requirements, request a brochure or view our products online at<br />

www.expandedmetalcompany.co.uk<br />

Stainless Steel Meshes<br />

Strand % Open Standard<br />

Ref No. LWD SWD Width Thickness Kgm2 Area Stock Size Manufactured Size<br />

941MM 1.00 0.67 0.20 0.15 0.8 38 212 x coil<br />

942MM 1.50 0.92 0.31 0.15 0.87 33 313 x coil<br />

957MM 1.50 0.92 0.22 0.15 0.62 52 313 x coil<br />

926S 3.18 1.95 0.79 0.46 2.95 19 610 x 1070<br />

Copper and Brass Meshes<br />

Copper Brass Strand Copper Brass % Open Standard<br />

Ref No. Ref No. LWD SWD Width Thickness Kgm2 Kgm2 Area Manufactured Size<br />

949MM 945mm 1.00 0.67 0.20 0.15 0.83 0.79 40 200 x coil<br />

950MM 946mm 1.50 0.92 0.31 0.15 0.90 33 33 200 x coil<br />

Tel: +44 (0)1429 867388 · Fax: +44 (0)1429 866795 · Website: www.expandedmetalcompany.co.uk<br />

Formed Filtration Components<br />

A clear focus on meeting customer needs has led to extensive<br />

experience of prototyping and new product development for<br />

formed expanded metal filtration components. We thrive on<br />

assisting our customers to utilise expanded meshes to solve<br />

filtration problems, helping to reduce costs and increase<br />

efficiency.<br />

In-house tooling capabilities give us a leading edge in assisting<br />

customers to develop new filtration products. We manufacture<br />

a range of formed filtration components, from vent ridge tiles for<br />

roof ventilation to small bullet filters for domestic heating systems.<br />

We specialise in high volume pressings for filter retention panels<br />

and casings and can also accommodate specialist batch work.<br />

Given the competitive advantages of cost savings,<br />

technical expertise and strength, meshes can be<br />

shaped into filtration products that meet exacting<br />

customer specifications and performance criteria.<br />

The most common filtration products<br />

that we produce are cylindrical tubes,<br />

conicals, casings, filter housings,<br />

strainers and pressed panels.<br />

<strong>Expanded</strong> Metal Support Mesh<br />

<strong>Expanded</strong> metal support mesh (pictured<br />

below left) can be manufactured to<br />

bespoke specifications to provide filter<br />

manufacturers with the perfect solution<br />

for adding cost effective reinforcement<br />

to a multitude of filtration applications,<br />

providing strength and flexibility.<br />

Tel: +44 (0)1429 867388 · Fax: +44 (0)1429 866795 · Website: www.expandedmetalcompany.co.uk<br />

Filter Panels<br />

As standard, we currently offer made to order products<br />

with frames and backing meshes constructed in<br />

stainless steel, aluminium, galvanised steel and tinplate,<br />

in thicknesses ranging from 7mm to 50mm.<br />

Expamet filtafoil, bondina, galvanised and stainless steel<br />

mesh are widely used as infill options. We can also<br />

utilise any infill material you may require.<br />

Construction<br />

Expamet filtafoil panels<br />

are constructed from multiple<br />

layers of expanded aluminium<br />

foil mesh, arranged alternately at<br />

right angles to each other. This structure<br />

ensures a robust, high performance filter<br />

with low resistance to airflow.<br />

Each layer of foil has jointless continuity, which<br />

prevents the hazard of loose fibres and ensures strength<br />

and efficiency.<br />

Features and Benefits<br />

Bespoke Solutions Available<br />

Low Initial and Lifetime Cost<br />

Washable and Reuseable<br />

Proven Performance<br />

Low Resistance to Airflow<br />

High Efficiency<br />

Robust Construction<br />

<strong>Filtafoil</strong> Adhesive<br />

can greatly enhance the performance of your filter.<br />

<strong>Test</strong>s show that the dust arresting capacity and<br />

efficiency of your filter are increased, prolonging<br />

its lifespan and further protecting your environment.<br />

Caring for your Filter<br />

Cleaning in accordance with our recommendations<br />

will reduce the total lifetime cost of your filter. Using<br />

mild detergent, the Super Panel will remain robust and<br />

effective after many washes and Economy Panels after<br />

several washes. Stainless steel and galvanised panels<br />

must be steam cleaned.<br />

Tel: +44 (0)1429 867388 · Fax: +44 (0)1429 866795 · Website: www.expandedmetalcompany.co.uk<br />

Filter Panel<br />

Specifications<br />

Made to Order<br />

Your filter panels can be made from any<br />

combination of the following materials:<br />

Support Mesh – Stainless Steel,<br />

Galvanised Steel, <strong>Aluminium</strong>, Tinplate<br />

Frames – Stainless Steel,<br />

Galvanised Steel, <strong>Aluminium</strong>, Tinplate<br />

Infill – <strong>Aluminium</strong> <strong>Filtafoil</strong>, Bondina<br />

(plus any other material you require)<br />

Thicknesses – 7mm, 9.5mm, 12.5mm,<br />

25mm, 50mm (nominal sizes)<br />

Handles and drainage holes optional.<br />

Please provide actual sizes when ordering.<br />

Expamet <strong>Aluminium</strong> Super Panels<br />

Nominal Sizes (in mm)<br />

Thickness Size<br />

50 SP 610 x 610<br />

50 SP 508 x 508<br />

50 SP 457 x 457<br />

25 SP 508 x 508<br />

25 SP 457 x 457<br />

Actual Sizes (in mm)<br />

Thickness Size<br />

47.6 SP 603 x 603<br />

47.6 SP 502 x 502<br />

47.6 SP 451 x 451<br />

22.2 SP 502 x 502<br />

22.2 SP 451 x 451<br />

Expamet Tinplate Economy Panels<br />

Nominal Sizes (in mm)<br />

Thickness Size<br />

50 E 610 x 610<br />

50 E 508 x 508<br />

50 E 457 x 457<br />

25 E 508 x 508<br />

25 E 457 x 457<br />

Actual Sizes (in mm)<br />

Thickness Size<br />

47.6 E 603 x 603<br />

47.6 E 502 x 502<br />

47.6 E 451 x 451<br />

22.2 E 502 x 502<br />

22.2 E 451 x 451<br />

Standard Specifications<br />

Handles optional on all filters<br />

Expamet <strong>Aluminium</strong> Super Panels<br />

25 SP Thick – Infill: 2 layers 451A<br />

and 4 layers 450A (<strong>Filtafoil</strong>),<br />

2 aluminium support meshes.<br />

50 SP Thick – Infill: 7 layers 451A<br />

and 4 layers 450A (<strong>Filtafoil</strong>),<br />

2 aluminium support meshes.<br />

Expamet <strong>Aluminium</strong> Economy Panels<br />

25 E Thick – Infill: 2 layers 451A<br />

and 3 layers 450A (<strong>Filtafoil</strong>),<br />

2 aluminium support meshes.<br />

50 E Thick – Infill: 7 layers 451A,<br />

2 aluminium support meshes.<br />

Other Standard Filters<br />

12.5 Thick – Infill: 5 layers 450A (<strong>Filtafoil</strong>),<br />

2 aluminium support meshes.<br />

12.5 Thick <strong>Aluminium</strong> Bondina Filter<br />

– Infill: 1 layer Bondina Ref P15/150,<br />

2 aluminium support meshes.<br />

9.5 SP Thick <strong>Aluminium</strong> Panels – Infill: 4 layers<br />

Ref 450A (<strong>Filtafoil</strong>), 2 aluminium support meshes.<br />

7 SP Thick – Infill: 3 layers Ref 450A (<strong>Filtafoil</strong>)<br />

or 1 layer Bondina Ref P15/150, 2 aluminium<br />

support meshes.