SILRES® resins - Brenntag Specialties, Inc.

SILRES® resins - Brenntag Specialties, Inc.

SILRES® resins - Brenntag Specialties, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

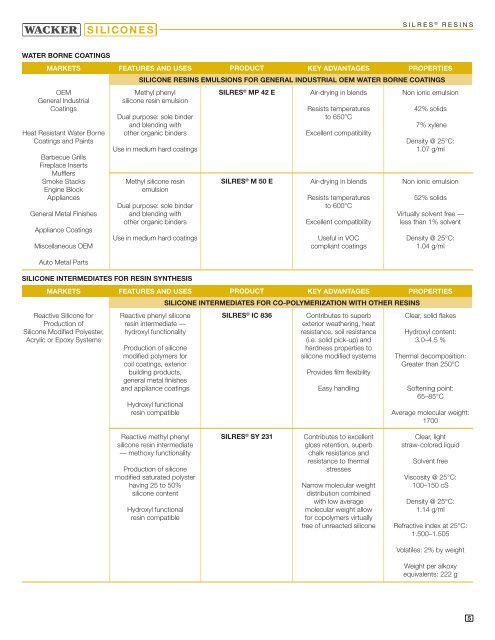

WATER BORNE COATINGS<br />

MARKETS<br />

OEM<br />

General Industrial<br />

Coatings<br />

Heat Resistant Water Borne<br />

Coatings and Paints<br />

Barbecue Grills<br />

Fireplace Inserts<br />

Mufflers<br />

Smoke Stacks<br />

Engine Block<br />

Appliances<br />

General Metal Finishes<br />

Appliance Coatings<br />

Miscellaneous OEM<br />

Auto Metal Parts<br />

MARKETS<br />

Reactive Silicone for<br />

Production of<br />

Silicone Modified Polyester,<br />

Acrylic or Epoxy Systems<br />

FEATURES AND USES<br />

Methyl phenyl<br />

silicone resin emulsion<br />

Dual purpose: sole binder<br />

and blending with<br />

other organic binders<br />

Use in medium hard coatings<br />

Methyl silicone resin<br />

emulsion<br />

Dual purpose: sole binder<br />

and blending with<br />

other organic binders<br />

Use in medium hard coatings<br />

SILICONE INTERMEDIATES FOR RESIN SYNTHESIS<br />

FEATURES AND USES<br />

Reactive phenyl silicone<br />

resin intermediate —<br />

hydroxyl functionality<br />

Production of silicone<br />

modified polymers for<br />

coil coatings, exterior<br />

building products,<br />

general metal finishes<br />

and appliance coatings<br />

Hydroxyl functional<br />

resin compatible<br />

Reactive methyl phenyl<br />

silicone resin intermediate<br />

— methoxy functionality<br />

Production of silicone<br />

modified saturated polyster<br />

having 25 to 50%<br />

silicone content<br />

Hydroxyl functional<br />

resin compatible<br />

PRODUCT<br />

PRODUCT<br />

KEY ADVANTAGES<br />

SILICONE INTERMEDIATES FOR CO-POLYMERIZATION WITH OTHER RESINS<br />

SILRES ® IC 836<br />

SILRES ® SY 231<br />

Contributes to superb<br />

exterior weathering, heat<br />

resistance, soil resistance<br />

(i.e. solid pick-up) and<br />

hardness properties to<br />

silicone modified systems<br />

Provides film flexibility<br />

Easy handling<br />

Contributes to excellent<br />

gloss retention, superb<br />

chalk resistance and<br />

resistance to thermal<br />

stresses<br />

Narrow molecular weight<br />

distribution combined<br />

with low average<br />

molecular weight allow<br />

for copolymers virtually<br />

free of unreacted silicone<br />

S I L R E S ® R E S I N S<br />

SILICONE RESINS EMULSIONS FOR GENERAL INDUSTRIAL OEM WATER BORNE COATINGS<br />

SILRES ® MP 42 E<br />

SILRES ® M 50 E<br />

KEY ADVANTAGES<br />

Air-drying in blends<br />

Resists temperatures<br />

to 650°C<br />

Excellent compatibility<br />

Air-drying in blends<br />

Resists temperatures<br />

to 600°C<br />

Excellent compatibility<br />

Useful in VOC<br />

compliant coatings<br />

PROPERTIES<br />

Non ionic emulsion<br />

42% solids<br />

7% xylene<br />

Density @ 25°C:<br />

1.07 g/ml<br />

Non ionic emulsion<br />

52% solids<br />

Virtually solvent free —<br />

less than 1% solvent<br />

Density @ 25°C:<br />

1.04 g/ml<br />

PROPERTIES<br />

Clear, solid flakes<br />

Hydroxyl content:<br />

3.0–4.5 %<br />

Thermal decomposition:<br />

Greater than 250°C<br />

Softening point:<br />

65–85°C<br />

Average molecular weight:<br />

1700<br />

Clear, light<br />

straw-colored liquid<br />

Solvent free<br />

Viscosity @ 25°C:<br />

100–150 cS<br />

Density @ 25°C:<br />

1.14 g/ml<br />

Refractive index at 25°C:<br />

1.500–1.505<br />

Volatiles: 2% by weight<br />

Weight per alkoxy<br />

equivalents: 222 g<br />

5