Silres® MK Powder - Brenntag Specialties, Inc.

Silres® MK Powder - Brenntag Specialties, Inc.

Silres® MK Powder - Brenntag Specialties, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SILRES® <strong>MK</strong><br />

METHYL SILICONE RESIN<br />

Product description<br />

SILRES® <strong>MK</strong> is a solvent-free, solid methyl silicone<br />

resin whose high reactivity and heat resistance make it<br />

ideal as a binder for all kinds of laminates and<br />

moldings. SILRES® <strong>MK</strong> has the highest SiO ² content<br />

of all WACKER silicone resins (after complete<br />

oxidation: approx. 82 % SiO ² , expressed in terms of<br />

solid resin [DSC]) and is soluble in aromatics, esters,<br />

ketones and selected paraffins and chlorinated<br />

hydrocarbons.<br />

Special features<br />

- highest SiO ² content of all WACKER silicone resins<br />

- very high binding strength<br />

- little smoke evolution on pyrolysis<br />

- excellent thermal stability<br />

- ideal for producing non-stick prepregs with<br />

excellent storage stabilitys<br />

Application<br />

The primary application for SILRES® <strong>MK</strong> is the<br />

production of laminates and moldings based on<br />

inorganic raw materials, such as mica, alumina,<br />

magnesium oxide, glassfibers and silica. A particular<br />

advantage of SILRES® <strong>MK</strong> is that it can be<br />

incorporated from aqueous suspension.<br />

In molding compounds, SILRES® <strong>MK</strong> is permanently<br />

stable up to 300 °C, and can withstand brief exposure<br />

to 350 °C. Above 350 °C and as the temperature rises,<br />

the methyl silicone resin undergoes oxidative<br />

degradation to silica, carbon dioxide and water. Very<br />

little smoke is evolved during this thermal degradation<br />

and soot-like decomposition products are not formed.<br />

The SiO ² backbone left behind after decomposition<br />

joins the fillers into molded shapes of high mechanical<br />

strength. The heat resistance of products ceramified in<br />

this way is limited by the fillers and support materials<br />

employed.<br />

Processing<br />

The quality of the end product is determined mainly by<br />

the concentration of curing agent, the drying and<br />

compression temperatures and the pressure<br />

employed. The best processing conditions must be<br />

determined by preliminary trials.<br />

SILRES® <strong>MK</strong> may be processed in powder form, as an<br />

aqueous suspension and in solution. When it is applied<br />

from solution, be aware that the higher the solids<br />

content, the lower is the storage stability of the<br />

solution. For this reason, we recommend adding at<br />

least 5 wt. % of an alcohol, such as ethanol or butanol,<br />

to concentrated SILRES® <strong>MK</strong> solutions.<br />

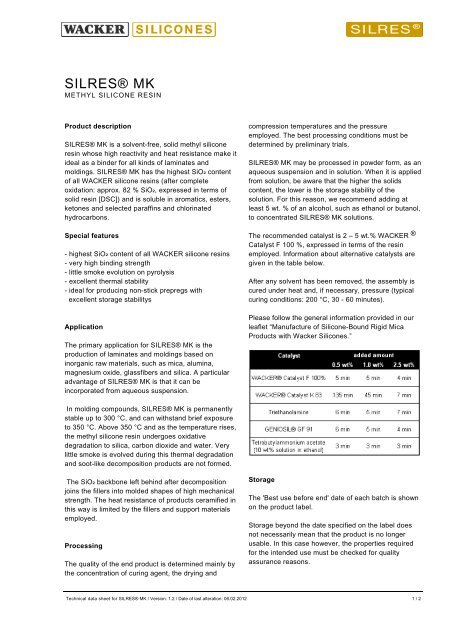

The recommended catalyst is 2 – 5 wt.% WACKER ®<br />

Catalyst F 100 %, expressed in terms of the resin<br />

employed. Information about alternative catalysts are<br />

given in the table below.<br />

After any solvent has been removed, the assembly is<br />

cured under heat and, if necessary, pressure (typical<br />

curing conditions: 200 °C, 30 - 60 minutes).<br />

Please follow the general information provided in our<br />

leaflet “Manufacture of Silicone-Bound Rigid Mica<br />

Products with Wacker Silicones.”<br />

Storage<br />

The 'Best use before end' date of each batch is shown<br />

on the product label.<br />

Storage beyond the date specified on the label does<br />

not necessarily mean that the product is no longer<br />

usable. In this case however, the properties required<br />

for the intended use must be checked for quality<br />

assurance reasons.<br />

Technical data sheet for SILRES® <strong>MK</strong> / Version: 1.2 / Date of last alteration: 06.02.2012 1 / 2

Safety notes<br />

Comprehensive instructions are given in the<br />

corresponding Material Safety Data Sheets. They are<br />

Product data<br />

available on request from WACKER subsidiaries or<br />

may be printed via WACKER web site<br />

http://www.wacker.com.<br />

Typical general characteristics Inspection Method Value<br />

Supply form white powder<br />

Melting point / Melting range 35 - 55 °C<br />

Bulk density 500 kg/m³<br />

Thermal decomposition min. 350 °C<br />

These figures are only intended as a guide and should not be used in preparing specifications.<br />

The data presented in this leaflet are in accordance with the present state of<br />

our knowledge, but do not absolve the user from carefully checking all<br />

supplies immediately on receipt. We reserve the right to alter product<br />

constants within the scope of technical progress or new developments. The<br />

recommendations made in this leaflet should be checked by preliminary<br />

trials because of conditions during processing over which we have no<br />

control, especially where other companies' raw materials are also being<br />

used. The recommendations do not absolve the user from the obligation of<br />

investigating the possibility of infringement of third parties' rights and, if<br />

necessary, clarifying the position. Recommendations for use do not<br />

constitute a warranty, either express or implied, of the fitness or suitability of<br />

the products for a particular purpose.<br />

The management system has been<br />

certified according to DIN EN ISO<br />

9001 and DIN EN ISO 14001<br />

WACKER is a trademark of Wacker<br />

Chemie AG.<br />

SILRES® is a trademark of Wacker<br />

Chemie AG.<br />

For technical, quality, or product<br />

safety questions, please contact:<br />

Wacker Chemie AG<br />

Hanns-Seidel-Platz 4<br />

81737 München, Germany<br />

info.silicones@wacker.com<br />

www.wacker.com<br />

Technical data sheet for SILRES® <strong>MK</strong> / Version: 1.2 / Date of last alteration: 06.02.2012 2 / 2