Automatic Pallet Changer Operator's Addendum - Haas Automation ...

Automatic Pallet Changer Operator's Addendum - Haas Automation ...

Automatic Pallet Changer Operator's Addendum - Haas Automation ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

*<br />

20<br />

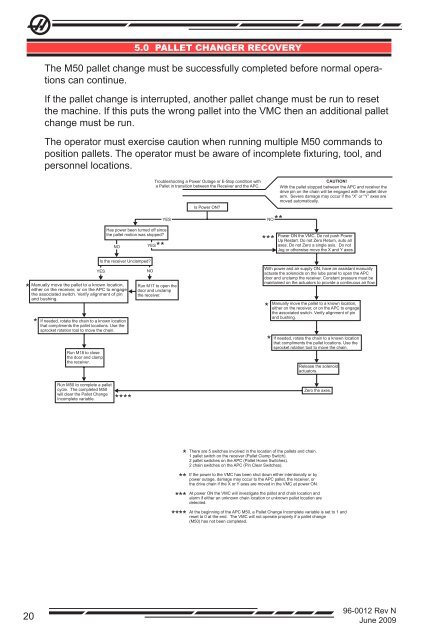

5.0 PAllet chAnger recovery<br />

The M50 pallet change must be successfully completed before normal operations<br />

can continue.<br />

If the pallet change is interrupted, another pallet change must be run to reset<br />

the machine. If this puts the wrong pallet into the VMC then an additional pallet<br />

change must be run.<br />

The operator must exercise caution when running multiple M50 commands to<br />

position pallets. The operator must be aware of incomplete fixturing, tool, and<br />

personnel locations.<br />

Has power been turned off since<br />

the pallet motion was stopped?<br />

Is the receiver Unclamped?<br />

YES<br />

NO<br />

Manually move the pallet to aknown location,<br />

either on the receiver, oronthe APC to engage<br />

the associated switch. Verify alignment of pin<br />

and bushing.<br />

*<br />

If needed, rotate the chain toaknown location<br />

that compliments the pallet locations. Use the<br />

sprocket rotation tool to move the chain.<br />

Run M18 to close<br />

the door and clamp<br />

the receiver.<br />

Run M50 to complete apallet<br />

cycle. The completed M50<br />

will clear the <strong>Pallet</strong> Change<br />

Incomplete variable.<br />

* * * *<br />

YES<br />

NO<br />

Troubleshooting aPower Outage or E-Stop condition with<br />

a <strong>Pallet</strong> intransition between the Receiver and the APC.<br />

* *<br />

Run M17 to open the<br />

door and unclamp<br />

the receiver.<br />

Is Power ON?<br />

YES NO*<br />

*<br />

* There are 5switches involved in the location ofthe pallets and chain.<br />

**<br />

* **<br />

** **<br />

* * *<br />

CAUTION!<br />

With the pallet stopped between the APC and receiver the<br />

drive pin onthe chain will be engaged with the pallet drive<br />

arm. Severe damage may occur if the “X” or “Y” axes are<br />

moved automatically.<br />

Power ON the VMC. Do not push Power<br />

Up Restart. Do not Zero Return, auto all<br />

axes. Do not Zero asingle axis. Do not<br />

Jog or otherwise move the Xand Y axes.<br />

1pallet switch onthe receiver (<strong>Pallet</strong> Clamp Switch).<br />

2pallet switches on the APC (<strong>Pallet</strong> Home Switches).<br />

2 chain switches on the APC (Pin Clear Switches).<br />

With power and air supply ON, have an assistant manually<br />

actuate the solenoids on the lube panel to open the APC<br />

door and unclamp the receiver. Constant pressure must be<br />

maintained on the actuators to provide acontinuous air flow.<br />

*<br />

*<br />

Manually move the pallet toaknown location,<br />

either on the receiver, oronthe APC to engage<br />

the associated switch. Verify alignment of pin<br />

and bushing.<br />

If needed, rotate the chain toaknown location<br />

that compliments the pallet locations. Use the<br />

sprocket rotation tool to move the chain.<br />

Release the solenoid<br />

actuators.<br />

Zero the axes.<br />

If the power to the VMC has been shut down either intentionally or by<br />

power outage, damage may occur to the APC pallet, the receiver, or<br />

the drive chain ifthe XorYaxes are moved in the VMC at power ON.<br />

At power ON the VMC will investigate the pallet and chain location and<br />

alarm if either an unknown chain location or unknown pallet location are<br />

detected.<br />

At the beginning of the APC M50, a<strong>Pallet</strong> Change Incomplete variable is set to 1and<br />

reset to 0atthe end. The VMC will not operate properly ifapallet change<br />

(M50) has not been completed.<br />

96-0012 Rev N<br />

June 2009