The 4T50ME-GI Test Engine at MAN Diesel & Turbo's ... - Sae.org

The 4T50ME-GI Test Engine at MAN Diesel & Turbo's ... - Sae.org

The 4T50ME-GI Test Engine at MAN Diesel & Turbo's ... - Sae.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

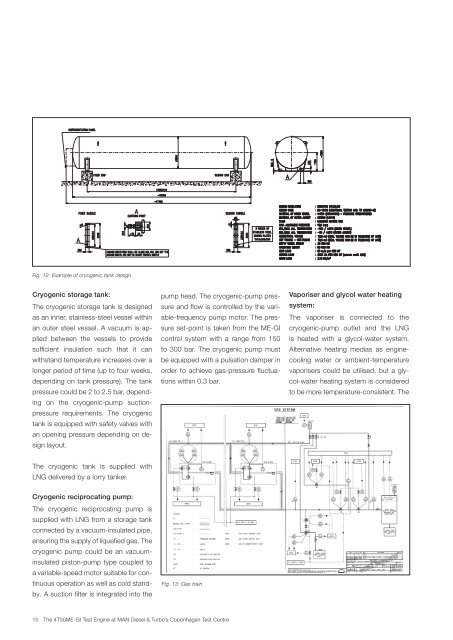

Fig. 12: Example of cryogenic tank design<br />

Cryogenic storage tank:<br />

<strong>The</strong> cryogenic storage tank is designed<br />

as an inner, stainless-steel vessel within<br />

an outer steel vessel. A vacuum is ap-<br />

plied between the vessels to provide<br />

sufficient insul<strong>at</strong>ion such th<strong>at</strong> it can<br />

withstand temper<strong>at</strong>ure increases over a<br />

longer period of time (up to four weeks,<br />

depending on tank pressure). <strong>The</strong> tank<br />

pressure could be 2 to 2.5 bar, depend-<br />

ing on the cryogenic-pump suction-<br />

pressure requirements. <strong>The</strong> cryogenic<br />

tank is equipped with safety valves with<br />

an opening pressure depending on de-<br />

sign layout.<br />

<strong>The</strong> cryogenic tank is supplied with<br />

LNG delivered by a lorry tanker.<br />

Cryogenic reciproc<strong>at</strong>ing pump:<br />

<strong>The</strong> cryogenic reciproc<strong>at</strong>ing pump is<br />

supplied with LNG from a storage tank<br />

connected by a vacuum-insul<strong>at</strong>ed pipe,<br />

ensuring the supply of liquefied gas. <strong>The</strong><br />

cryogenic pump could be an vacuum-<br />

insul<strong>at</strong>ed piston-pump type coupled to<br />

a variable-speed motor suitable for con-<br />

tinuous oper<strong>at</strong>ion as well as cold stand-<br />

by. A suction filter is integr<strong>at</strong>ed into the<br />

pump head. <strong>The</strong> cryogenic-pump pres-<br />

sure and flow is controlled by the vari-<br />

able-frequency pump motor. <strong>The</strong> pres-<br />

sure set-point is taken from the ME-<strong>GI</strong><br />

control system with a range from 150<br />

to 300 bar. <strong>The</strong> cryogenic pump must<br />

be equipped with a puls<strong>at</strong>ion damper in<br />

order to achieve gas-pressure fluctua-<br />

tions within 0.3 bar.<br />

Fig. 13: Gas train<br />

15 <strong>The</strong> <strong>4T50ME</strong>-<strong>GI</strong> <strong>Test</strong> <strong>Engine</strong> <strong>at</strong> <strong>MAN</strong> <strong>Diesel</strong> & Turbo’s Copenhagen <strong>Test</strong> Centre<br />

Vaporiser and glycol w<strong>at</strong>er he<strong>at</strong>ing<br />

system:<br />

<strong>The</strong> vaporiser is connected to the<br />

cryogenic-pump outlet and the LNG<br />

is he<strong>at</strong>ed with a glycol-w<strong>at</strong>er system.<br />

Altern<strong>at</strong>ive he<strong>at</strong>ing medias as engine-<br />

cooling w<strong>at</strong>er or ambient-temper<strong>at</strong>ure<br />

vaporisers could be utilised, but a gly-<br />

col-w<strong>at</strong>er he<strong>at</strong>ing system is considered<br />

to be more temper<strong>at</strong>ure-consistent. <strong>The</strong>